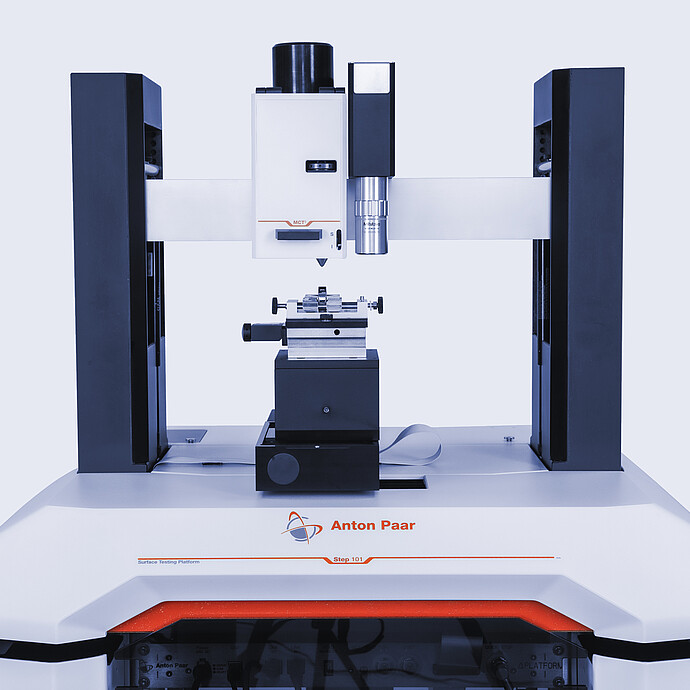

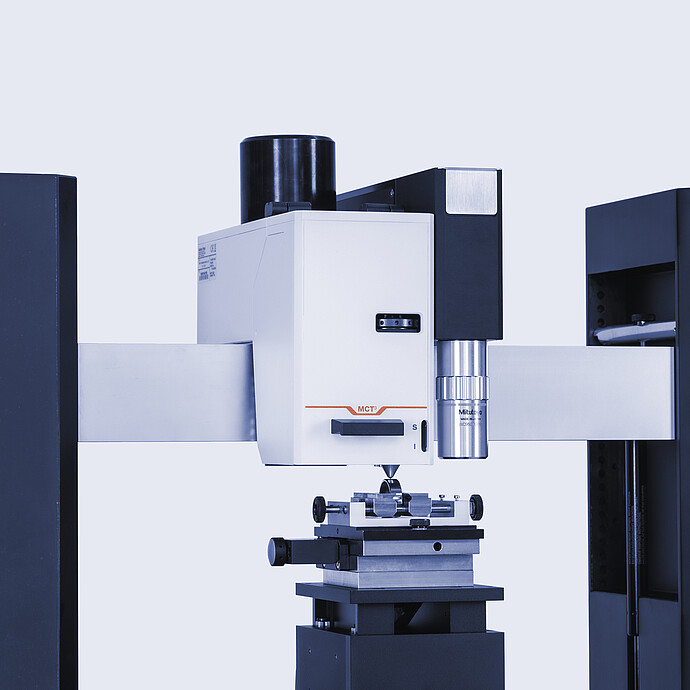

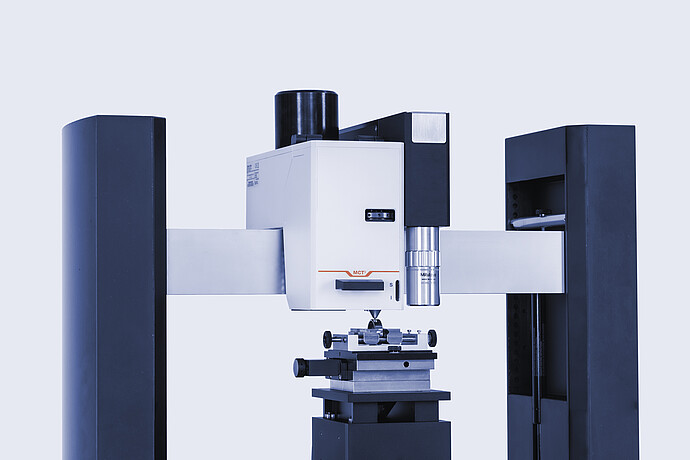

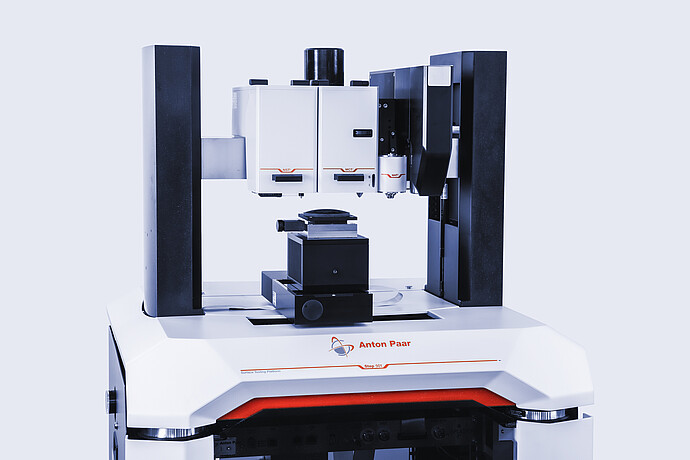

マイクロコンビテスタ:

MCT³

- インデンテーション試験、ビッカース硬さ、スクラッチ試験、基本トライボロジー試験に適した4-in-1セットアップ

- 硬さ、弾性率、コーティング密着性、耐スクラッチ性、摩耗性などの表面機械特性の測定

- ハードコーティング、溶射/プラズマ溶射コーティング、セメント質材料、金属、ポリマーの特性評価向け

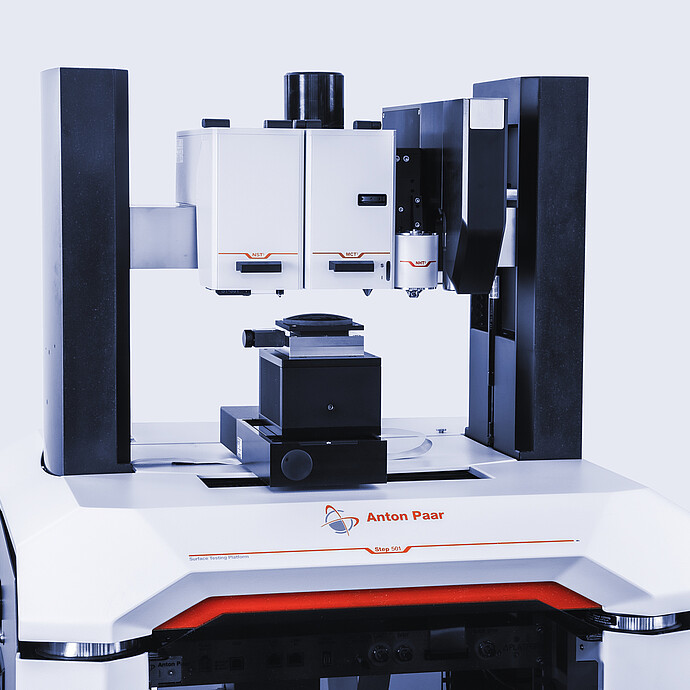

マイクロコンビテスタ (MCT³) は、コーティングやバルクサンプルの完全な機械特性評価に適した万能測定ヘッドです。

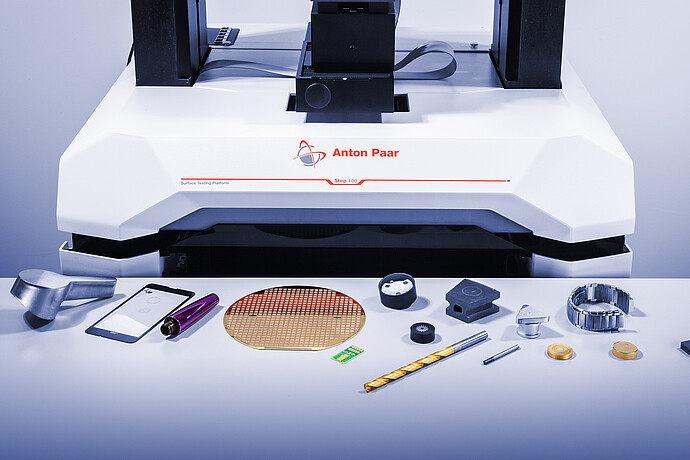

この装置は独自の広い荷重範囲により、さまざまなサンプルの密着性、耐スクラッチ性、硬さ、弾性率、摩擦、摩耗を測定することができます。有機/無機、軟質/硬質のコーティング (1~20 µm) やバルク材料に対応しています。

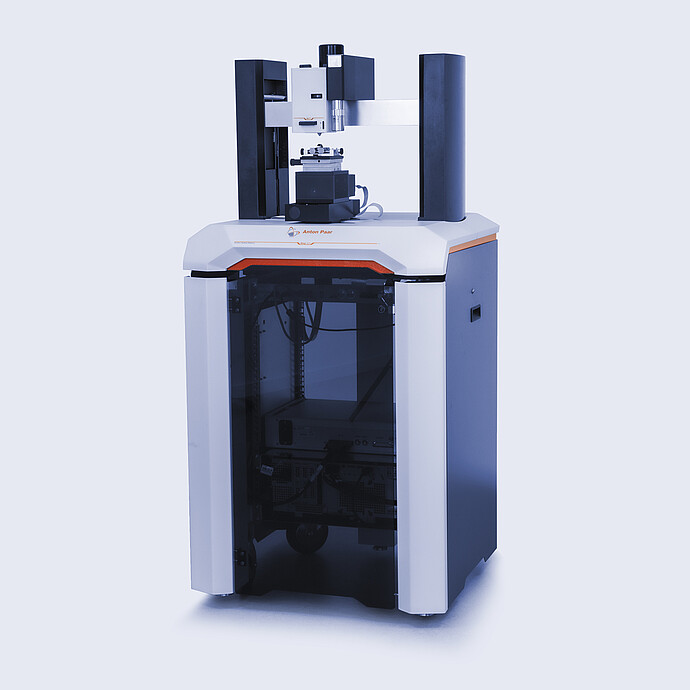

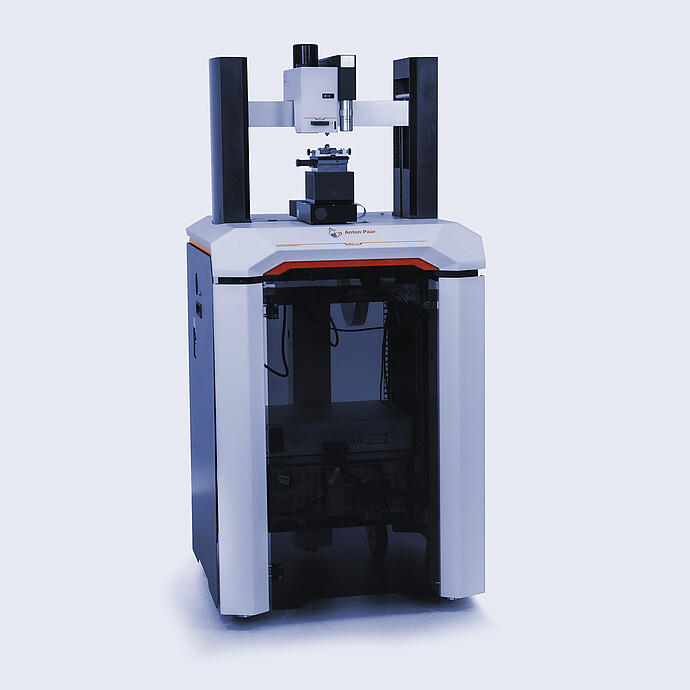

また、統一のStep表面試験プラットフォーム上で、他の計装化押し込み試験用ヘッドやスクラッチ試験用ヘッド、あるいは原子間力顕微鏡と組み合わせることにより、特性評価の荷重範囲をさらに拡大することができます。

主な機能

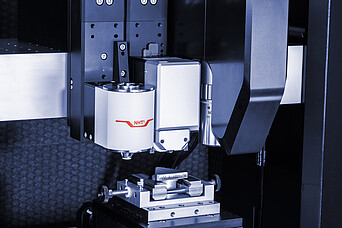

4-in-1の機械特性評価

マイクロコンビテスタMCT³は、その独自の機械設計において、測定品質に妥協することなく、4つの機械特性評価法をたった1つの測定ヘッドに組み込んでいます。この1つのヘッドで、コーティングの密着性と耐スクラッチ性 (スクラッチ試験)、硬さと弾性率 (計装化押し込み試験)、ビッカース硬さ 、摩擦と摩耗 (マルチパストライボロジー試験) の測定が可能です。

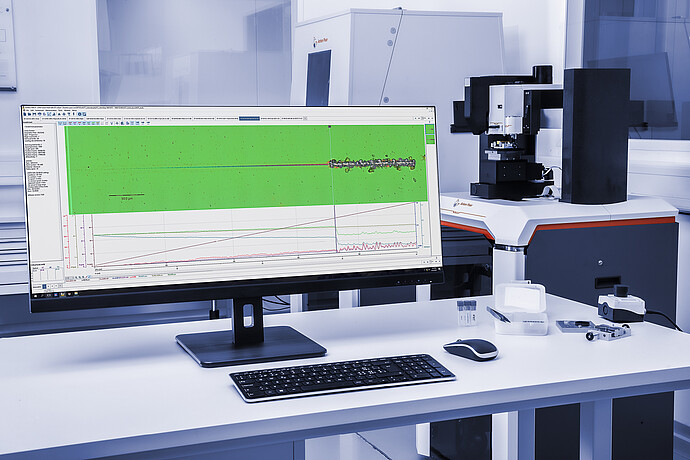

完全自動の機械特性評価試験機

アントンパールのあらゆるスクラッチ試験機と同様に、MCT³は臨界荷重を自動で検出します。摩擦力、押し込み深さ、またはアコースティックエミッションの信号を用いて、アルゴリズムにより分析し、オペレーターによる影響を受けることなく臨界荷重を自動判定します。このソフトウェアパッケージにより、ビッカース硬さ試験が可能になり、インプリントが自動的に検出・測定されます。硬さと弾性率は、計装化押し込み試験による1回の測定で、さまざまな位置で判定することができます。

幅広い用途に対応する理想的な荷重範囲

MCT³は、浅め (表面検出向けに数nm) から深め (最大1 mm) までのスクラッチ試験や計装化押し込み試験 (IIT) を実施します。その幅広い印加・測定荷重範囲 (10 mN~30 N) は、ほぼすべてのサンプル特性に適合します。この荷重と深さの範囲は、ハードコーディング (PVD、CVD、1~20 µm)、溶射/プラズマ溶射コーティング、セメント質材料、金属、ポリマーの機械特性評価に最適です。お客様の規格がバルク材料のビッカース硬さを必要とする場合、MCT³は同じ荷重範囲内でビッカース硬さ試験を実施します。

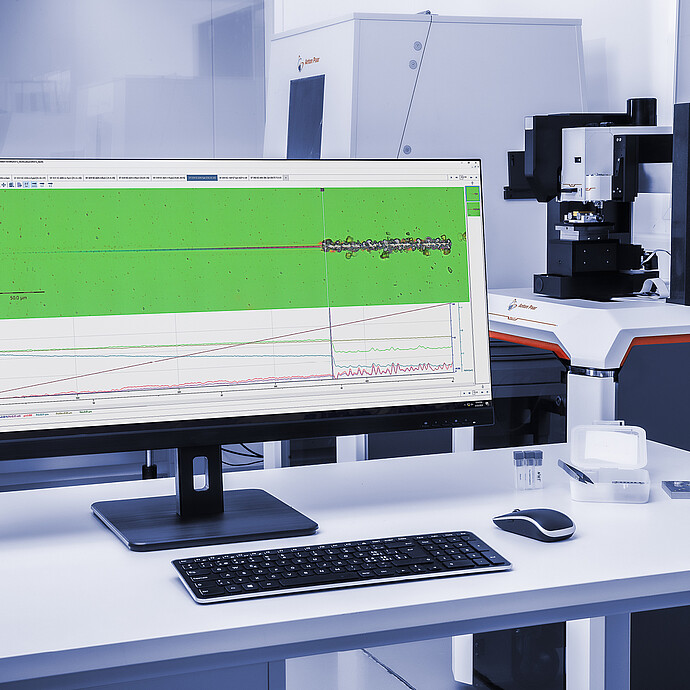

特許取得済みの同期パノラマモード

この独自機能では、完璧に焦点のあったスクラッチ画像全体に、すべてのセンサ信号の記録が自動的に同期されます。臨界荷重は、この同期された光学記録と信号記録を観察することで簡単に特定できます。この機能に関して、アントンパールは米国特許8261600、欧州特許EP 2065695を取得しています。

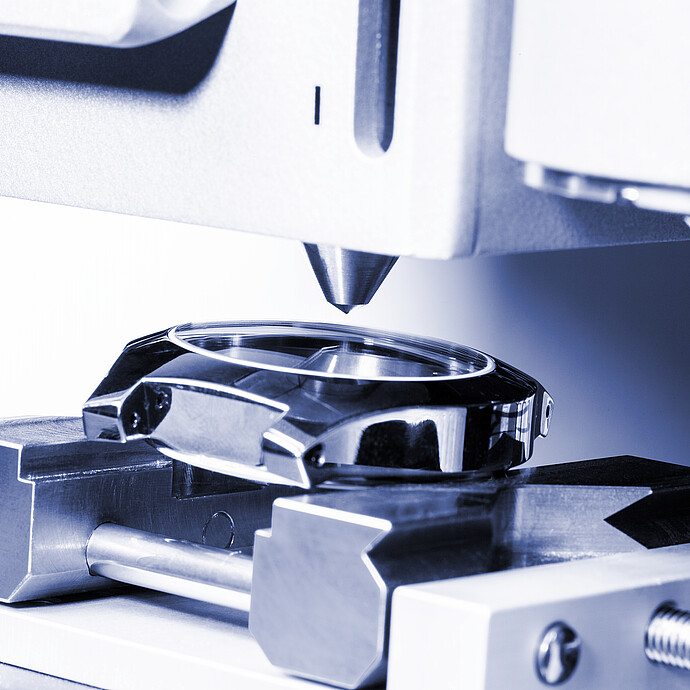

曲面や凹凸のある面上でも正確な測定結果

独自の荷重センサ制御により、MCT³はあらゆる表面偏差を検出し、アクティブフォースフィードバック機能で偏差を補正します。

MCT³は、サンプルの形状に関係なく、所望の荷重を完全に制御しながら形状に追従していくため、凸凹のある面や曲面 (レンズなど) でも確実な測定が可能です。

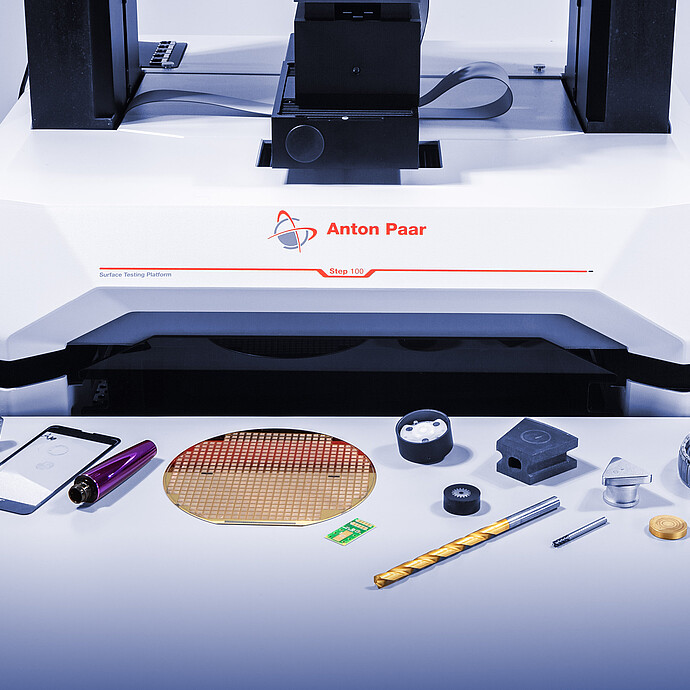

Stepプラットフォームによるマイクロコンビテスタの汎用性の最大化

Stepプラットフォームにより、マイクロコンビテスタMCT³の汎用性を最大化することができます。MCT³ヘッドに他の圧子またはスクラッチ試験機を追加して、ナノ/マイクロ/マクロ領域を完全にカバーしたり、AFMを追加して表面トポグラフィーを取得し、単一プラットフォームによる完全な表面機械特性評価を行うことができます。

技術仕様

| 最大荷重[N] | 30 |

| 荷重分解能[μN] | 6 |

| 荷重ノイズフロア[rms] [μN] | 100 |

| 荷重速度[N/min] | 最大300 |

| 深さレンジ[μm] | 1000 |

| 深さ分解能[nm] | 0.03 |

| 深さノイズフロア[rms] [nm] | 1.5 |

| サンプリングレート[kHz] | 192 |

| スクラッチ速度[mm/min] | 0.1〜600 |

| オプション | |

| ペルチェ加熱 (最高120 °C) | ✓ |

| 加熱ステージ (最高200 °C) | ✓ |

| 冷却 (最低-120 °C) | ✓ |

| 液体試験 | ✓ |

標準規格

ASTM

ISO

アントンパール認定サービス

- 世界各地に350名以上のメーカー認定の技術者がいます。

- お客様の言語でサポート

- ライフサイクル全体にわたる資産の保護

- 3年保証

書類

-

Applications of indentation in polymer industry アプリケーションレポート

-

Applications of scratch testing in polymer industry アプリケーションレポート

-

Automatic Vickers hardness test by scratch tester アプリケーションレポート

-

Biofouling – when Adhesion is a Double-edged Sword アプリケーションレポート

関連製品

消耗品 & アクセサリー

消耗品 & アクセサリー

アクセサリー

アクセサリー

お探しの商品が見つからない場合は、アントンパール社の営業担当にお問い合わせください。

お住まいの国からオンラインで購入できるかは、以下のオンライン販売状況をご確認ください。

ステッププラットフォーム用アクセサリ原子間力顕微鏡(AFM)

- 幅広い科学・産業用途に対応する汎用AFMソリューション

- ナノスケールの表面情報を提供するイメージング・分析機能

- サンプルの非破壊分析

スクラッチ試験機用アクセサリー:

摩擦モジュール

- 材料の摩擦挙動評価

- 接着不良の評価における補完的ツール

- スクラッチ試験と摩擦力試験の融合