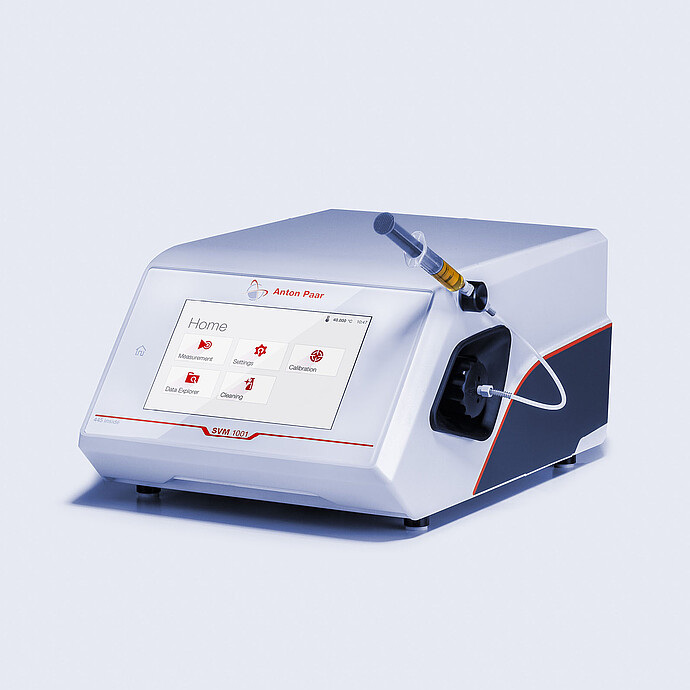

Automatic Kinematic Viscometer:

SVM

- Enjoy an automatic kinematic viscometer at a market-leading price

- Benefit from an intuitive user interface and compact design (battery option available)

- Select your temperature between 15 °C and 100 °C

- Get results digitally in less than five minutes with just 1.5 mL of sample: no more stopwatch or manual calculations

- Use one unbreakable cell instead of 12 Ubbelohde viscometers

This product is part of our current starter kits. Find out more about our exclusive offer here: Tank Terminal Kit

Our automatic kinematic viscometers determine kinematic and dynamic viscosity, density, viscosity index (VI), cloud point, freeze point, and many other parameters in one run. Exchange all your capillaries for a single unit. The SVM series covers the entire range with one cell for maximum flexibility. Enjoy all the benefits of ASTM D7042 and report in both D7042 as well as D445 with the integrated ASTM-defined bias corrections. No matter the sample, there’s an SVM that fits your needs.

Key features

Save time with our automatic kinematic viscometers

- 150 % higher throughput compared to manual methods

- Faster results help avoid out-of-spec production

- Temperature equilibration in one minute or less

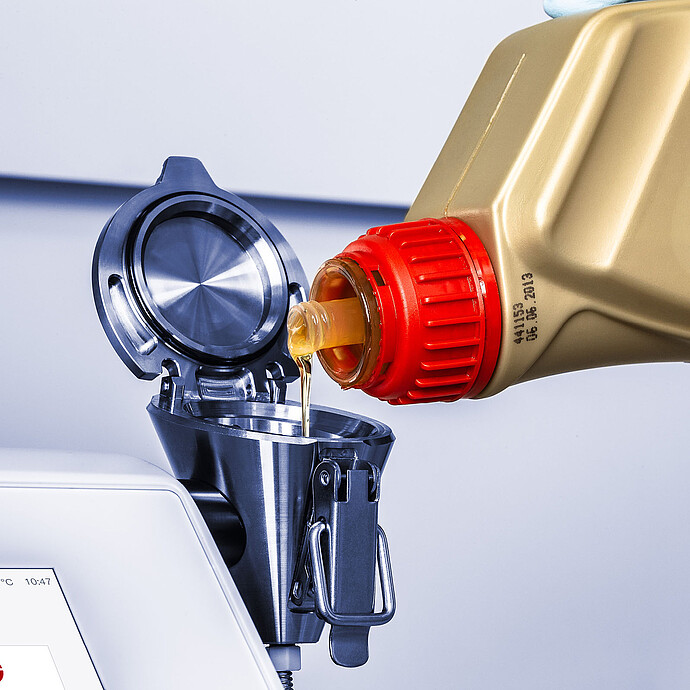

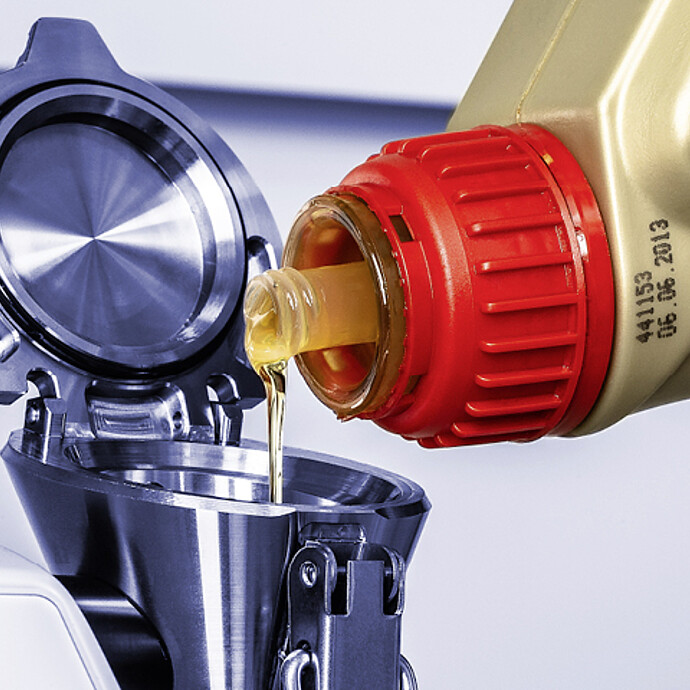

- Fill sample or solvent directly from the container with Simple Fill funnel: No pipette or syringe required with SVM 1001 Simple Fill and SVM 1101 Simple Fill

Experience error-free digital data handling

- Automatic calculations and digital data recording and storage for error-free measurements and traceability

- Data export from device to a PC or USB drive

- One-click data access from your automatic kinematic viscometer

- Compatible with AP Connect for digital data management

Improve safety for lab and operator

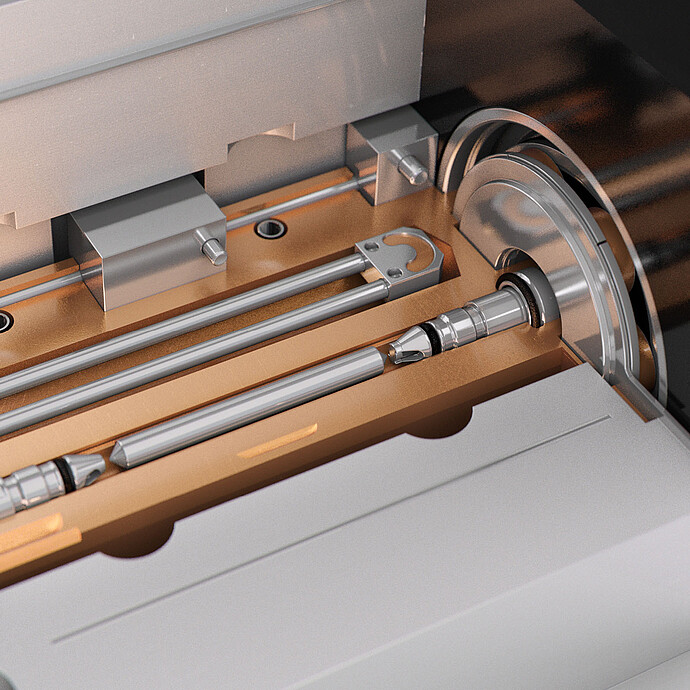

- A metal measuring cell makes glass breakage a thing of the past

- Built-in Peltier thermostatting for fast temperature control

- Reduced exposure to hazardous solvents or flammable bath liquids

Minimal sample, solvent, and energy consumption

- Analysis with just 5 mL of sample and 6 mL of solvent

- Low energy consumption – 50 W to get started

- Minimal downtime: 2-minute cleaning, 30-minute downtime during maintenance

- Quality control documentation efforts reduced by 50 %

- No external PC or software needed

Stay compliant and benefit from bias correction

- ASTM D7042 is referenced in ASTM, SAE, ISO, IP, EN, DIN, DEFSTAN, MIL, GB, GOST, and other standards as an accepted alternative to D445

- With the ASTM bias correction, you can report results in both D7042 and D445

- Complies with ASTM D396, D975, D1655, D3699, D6158, D6823, D7467, and other standards

- ASTM D4052 density measurement included (SVM 1101 Simple Fill/SVM 3001/SVM 3001 Cold Properties/SVM 4001)

Enjoy 24/7 automatic kinematic viscometer measurements

- Robotic solution options for labs analyzes hundreds of samples per day

- Compatible with heated and non-heated sample changers for all-day measurements

- Reproducible and unattended filling and cleaning process, even over night

Specifications

| SVM 1001 | SVM 1001 Simple Fill | SVM 1101 Simple Fill | SVM 2001 | SVM 3001 | SVM 3001 Cold Properties | SVM 4001 | |

| Patents | AT516058 (B1), US10036695 (B2), CN105424556, EP2995928 (B1) | AT516058 (B1), US10036695 (B2), CN105424556, EP2995928 (B1), AT 516302 (B1), CN105628550 | AT516058 (B1), US10036695 (B2), CN105424556, EP2995928 (B1) | AT516058 (B1), US10036695 (B2), CN105424556, EP2995928 (B1) AT516302 (B1), CN105628550 | |||

| Test methods | ASTM D7042, D445 bias corrected, ISO 23581, EN 16896 | ASTM D4052, ISO 12185 | ASTM D7042, D445 bias-corrected, ISO 23581, EN 16896 ASTM D4052 (optional) | ASTM D7042, D445 bias-corrected, ISO 23581, EN 16896 ASTM D4052, ISO 12185 | ASTM D7042, D445 bias -corrected, ISO 23581, EN 16896 ASTM D4052, ISO 12185 ASTM D2386 equiv. or better ASTM D2500 equiv. or better | ASTM D7042, D445 bias-corrected, ISO 23581, EN 16896, ASTM D4052, ISO 12185 | |

| Measuring Range | |||||||

| Viscosity | 0.3 mm²/s to 5,000 mm²/s | 0.3 mm²/s to 1,000 mm²/s | 0.2 mm²/s to 30,000 mm²/s* | ||||

| Density | - | - | 0 g/cm³ to 3 g/cm³ | 0 g/cm³ to 3 g/cm³ | |||

| Temperature | +15 °C to +100 °C (one temperature, second temperature optional) | +15 °C to +100 °C | +15 °C to +100 °C | -60 °C to +135 °C | -60 °C to +100 °C | +15 °C to +100°C | |

| Precision | |||||||

| Viscosity repeatability** and reproducibility** | 0.1 % and 0.35 % | 0.2 % and 0.7 % | 0.1 % and 0.35 % | ||||

| Density repeatability** and reproducibility** | - | - | 0.00005 g/cm³ and 0.0001 g/cm³ | 0.0002 g/cm³ (0.00005 g/cm² with ASTM D4052 option) and 0.0005 g/cm³ (0.0001 g/cm² with ASTM D4052 option) | 0.00005 g/cm³ and 0.0001 g/cm³ | ||

| Cloud/freeze point repeatability** and reproducibility** | - | - | - | - | - | <0.5 °C / <0.5 °C and <2.5 °C / <1.3 °C | - |

| Temperature repeatability | 0.005 °C | 0.005 °C | |||||

| Temperature reproducibility | 0.03 °C from +15 °C to +100 °C | 0.03 °C from +15 °C to +100 °C | 0.03 °C from +15 °C to +100 °C | 0.03 °C from +15 °C to +100 °C | |||

| Performance | |||||||

| Sample volume min. / typical | 1.5 mL / 5 mL | 3.5 mL / 8 mL | 1.5 mL / 5 mL | 2.5 mL / 6 mL | |||

| Solvent volume min. / typical | 1.5 mL / 6 mL | 5 mL / 10 mL | 1.5 mL / 6 mL | 2.5 mL / 10 mL | |||

| Max. sample throughput | 37 samples per hour | 21 samples per hour | 33 samples per hour | 30 samples per hour | 24 samples per hour | ||

| Features | |||||||

| Optional upgrades | Second temperature | - | Automatic VI determination ASTM D4052-compliant density measurement | Chemical upgrade kit | - | - | |

| Modularity with Abbemat refractometers 300/500, 350/550, 450/650 | |||||||

| Accessories | Magnetic particle trap (MPT) | - | - | Magnetic particle trap (MPT), hot filling attachment (HFA) | Magnetic particle trap (MPT) | ||

| Automation | - | Integrated Simple Fill Filling Device | Optional sample changer + High-Throughput Platform HTV | Optional sample changer + High-Throughput Platform HTV | Optional sample changer + High-Throughput Platform HTV | ||

| Technical Data | |||||||

| Data memory | 1,000 measurement results | ||||||

| HID (Human Interface Device) | 7" touchscreen | 10.4" touchscreen, optional keyboard, mouse, and 2D bar code reader | |||||

| Interfaces | 4 x USB (3 x A, 1 xB) | 4 x USB (2.0 full speed), 1 x Ethernet (100 Mbit), 1 X CAN bus, 1 x RS-232, 1 x VGA | |||||

| Power supply | At instrument: DC, 24 V /3A, AC adapter 90 VAC to 264 VAC, 47 Hat to 63 Hz, < 75W | AC 100 V to 240 V, 50 Hz to 60 Hz, 250 VA max. | |||||

| Ambient conditions | 15 °C to 35 °C, max. 80 % r.h. non-condensing | ||||||

| Net weight in kg | 5.6 kg | 6.6 kg | 15.9 kg | 17.6 kg | 18.0 kg | 17.8 kg | |

| Dimensions (W x D x H) | 26.5 cm x 36.5 cm x 18 cm | 33 cm x 36.5 cm x 20.5 cm | 33 cm x 51 cm x 23.1 cm | ||||

| Trademarks | SVM (13411996), FillingCheck (6834725), Abbemat (1084545) | ||||||

*Viscosity range with chemical upgrade kit from 1 mPa·s to 10,000 mPa·s.

**Attested at the points of the works adjustment or at calibration correction points, not including the uncertainty of the standard

Standards

DIN

EN

GJB

GOST

IP

IS

OENORM

RANP

SAE

SH

SN

ABNT

ASTM

ISO

CAN/CGSB

Standards

DIN

EN

GJB

GOST

IP

IS

OENORM

RANP

SAE

SH

SN

ABNT

ASTM

ISO

CAN/CGSB

Standards

ASTM

ISO

Standards

ASTM

DIN

EN

GB

GJB

IS

SH

SN

IP

OENORM

GOST

SAE

RANP

ABNT

ISO

CAN/CGSB

Standards

API

ASTM

DIN

DEFSTAN

EN

GB

GJB

IP

ISO

IS

JIG

SH

SN

MIL

OENORM

GOST

SAE

ABNT

RANP

CAN/CGSB

Standards

ASTM

GOST

SAE

ABNT

API

DEFSTAN

DIN

EN

GB

GJB

IP

IS

ISO

JIG

MIL

OENORM

RANP

SH

SN

CAN/CGSB

Standards

API

ASTM

DIN

EN

GB

GJB

IP

ISO

IS

SH

SN

OENORM

GOST

SAE

ABNT

RANP

CAN/CGSB

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Automated Viscosity Measurement of In-Service Oils Application Reports

-

Automated Viscosity Measurement of Raw Materials for Cosmetic Products Application Reports

-

Automotive | SVM 3001: Automotive Brake Fluids Application Reports

-

Aviation | Aviation industry – What SVM can do for you Application Reports

-

Aviation | Cold Flow Properties of Jet Fuel (Freezing Point) Application Reports

-

Aviation | Jet Fuel Viscosity - SVM 3001 Application Report Application Reports

-

Aviation | Viscosity of Aviation Lube Oils and Hydraulic Fluids Application Reports

-

Base Oils, Lubricants | SVM 1001 for Quality Control of Base Oils Application Reports

-

Base Oils, Pharma, Lubricants | Viscosity of White Oils Application Reports

-

Base and Lube Oils | Viscosity Index of Base and Lube Oils with SVM 4001 Application Reports

-

Chemicals | Multiparameter Analysis of AdBlue® Application Reports

-

E-Book - Analytical Methods for the Evaluation of Lubricants Application Reports

-

E-Book - The Field Guide to Data Integrity in Regulated Industries Application Reports

-

E-Book - The Future of Plant-Based Foods Application Reports

-

Efficiency Meets Sustainability – Biodiesel Measurements Made Easy Application Reports

-

Flavor, Fragrance | Quality Control of E-Liquids Application Reports

-

Food | Liquid Food Flavors with SVM 3001 and Abbemat Refractometer Application Reports

Similar products

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

Lab Execution System:

AP Connect Standard one-time license

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

- One-time fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Pharma one-time license

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

- One-time fee per instrument

- Time-saving processes: automatic, digital data transfer

- Assurance of lab data integrity

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Standard subscription license

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

- Annual fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Pharma subscription license

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

- Annual fee per instrument

- Time-saving processes: automatic, digital data transfer

- Assurance of lab data integrity

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Start

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

- Kickstart your paperless lab

- Featuring key benefits of the Standard edition

- Restricted to one instrument, single user access, one export rule

O-RING 2.5x1 FEPM 75 VITON EXTREME

SVM 1001 | 2001 | 3001 | 3001 Cold Properties | 4001

LABELS 90 x 29 mm, 1 x 400 pcs. FOR BROTHER Label Printer

SVM 1001

ADAPTER LUER LOCK 1/4""-28 UNF PEEK

SVM 1001

CABLE TIE HEAT-RESISTANT 100 pcs

SVM 1001

VISCOSITY STANDARD ANTON PAAR N4000 500 ml - 16000 / 2900 / 100 mPa.s

SVM 1001 | 2001 | 3001 | 3001 Cold Properties | 4001

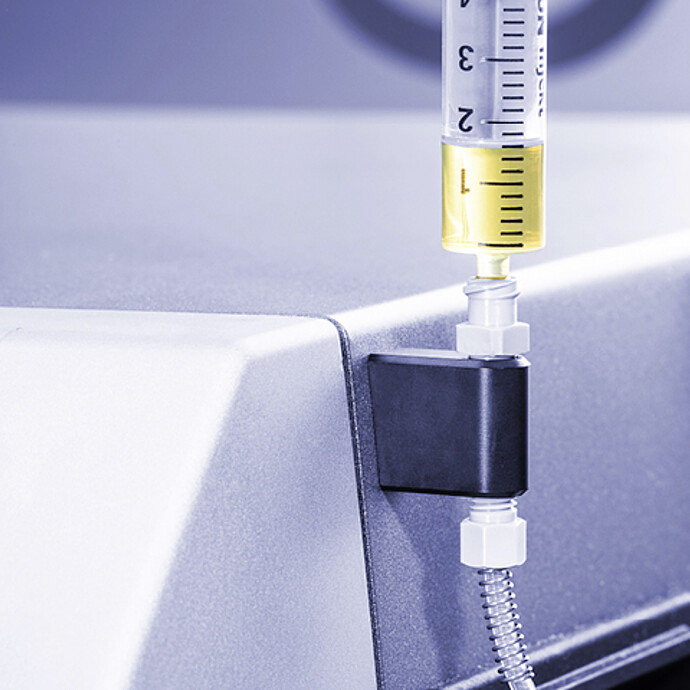

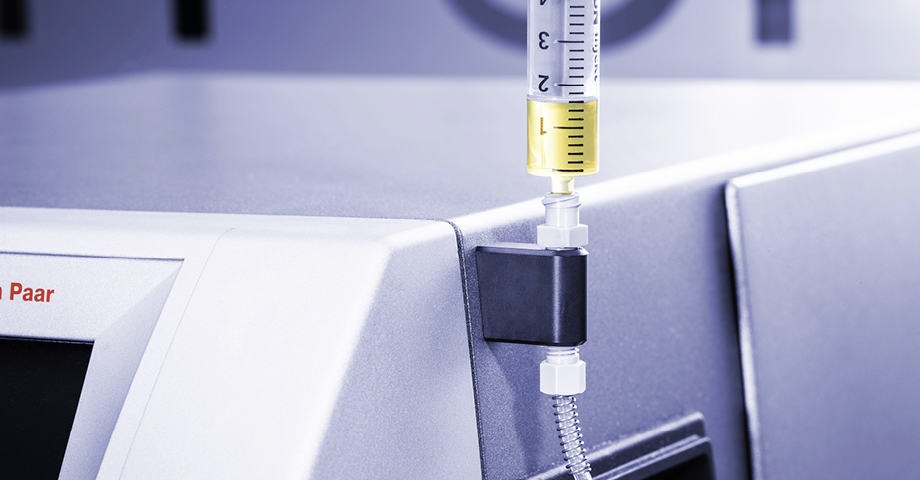

SYRINGES 2 ml LUER (100 pcs.)

SVM 1001 | 1001 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

VISCOSITY STANDARD SET FOR SVM 1001 4x100 ml AP S3, N7.5, N26, N415

SVM 1001 | 1001 Simple Fill

ADAPTER LUER CONE

SVM 1001 | 1001 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

MALE LUER PLUG

SVM 1001 | 1001 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

ACCESSORY KIT SVM 1001

SVM 1001 | 1001 Simple Fill

CARRYING CASE SVM 1001

SVM 1001 | 1001 Simple Fill

MAGNETIC PARTICLE TRAP SVM 1001 ONLY FOR SVM 1001 – NOT FOR Simple Fill

SVM 1001

SET BATTERY HOLDER SVM 1001

SVM 1001 | 1001 Simple Fill

1 pc. battery holder and 1 pc. cable for battery

SVM 1001 Dual Temperature Option

SVM 1001 | 1001 Simple Fill

SYRINGE HOLDER

SVM 1001 | 1001 Simple Fill

ANGULAR SCREWDRIVER TORX T10

SVM 1001 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

HOSE 250x3x2 FEP 2x1/4"-28 UNF "BB"

SVM 1001 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

HOSE 5x8 VITON-BK ISO VERSINIC

SVM 1001 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

CLEANING BRUSH D = 5 mm

SVM 2001 | 3001 | 3001 Cold Properties | 4001

CLEANING BRUSH D = 7 mm

SVM 2001 | 3001 | 3001 Cold Properties | 4001

PULLER FOR ROTOR BEARING RINGS SVM

SVM 2001 | 3001 | 3001 Cold Properties | 4001

SYRINGES 10 mL LUER LOCK (100 pcs.)

SVM 2001 | 3001 | 3001 Cold Properties | 4001

ADAPTER LUER HOSE ID4

SVM 2001 | 3001 | 3001 Cold Properties | 4001

ACCESSORY BOX SVM X001

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 10x3 KALREZ 4079

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 2x1 FPM 75 VITON EXTREME

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 5x1.1 FPM 75 VITON EXTREME

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 6x1.1 FPM 75 VITON EXTREME

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 4x1 FPM 75 VITON EXTREME

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 5x1 FPM 75 VITON EXTREME

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 4x1 FPM 75 VITON

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 10x2.5 FPM 80 VITON

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 3x1 FPM 75 VITON EXTREME

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 9x1.5 FPM 75 VITON EXTREME

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 28x1.5 FPM 75 VITON EXTREME

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 2x1.5 FPM 75 VITON EXTREME

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 2x1 KALREZ 6375 SPECTRUM

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 5x1 KALREZ 6375 SPECTRUM

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 6x1 KALREZ 6375 SPECTRUM

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 4.5x1 KALREZ 6375 SPECTRUM

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 28x1.5 KALREZ 0040 SPECTRUM

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 6x1 KALREZ 0040 SPECTRUM

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 2x1 KALREZ 0040 SPECTRUM

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 2x1.5 KALREZ 0040 SPECTRUM

SVM 2001 | 3001 | 3001 Cold Properties | 4001

O-RING 3x1 KALREZ 0040 SPECTRUM

SVM 2001 | 3001 | 3001 Cold Properties | 4001

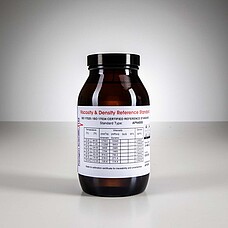

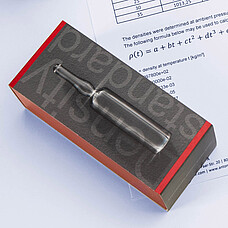

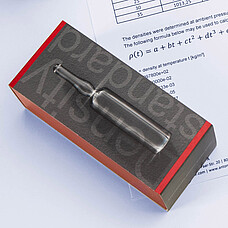

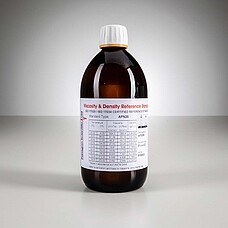

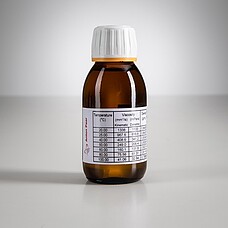

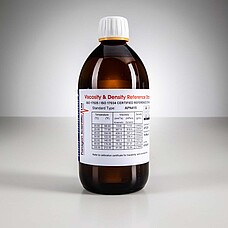

ISO 17034-Certified Reference Material:

Density Standards

SVM 2001 | 3001 | 4001

- Market-leading uncertainty of 0.015 kg/m³ (ISO 17034)

- Application-specific density standards, available via webshop

- Online certificate with lifetime reference values guarantee

- Conformity with ISO requirements ISO 17025 and even ISO 17034

- Safety glass ampoule for zero contamination

AP DENSITY STANDARD DODECANE 1x10 mL WITH ISO 17034 CERTIFICATE

SVM 2001 | 3001 | 4001

- Density standard with low density (750 kg/m³)

- Organic liquid

- Measuring uncertainty: 0.015 kg/m³

- Specified temperature range: 15 °C – 50 °C

- Durability: 18 months

- Volume: 10 mL

- ISO 17034-certified reference material

- Complies with ISO 17025 and ISO 17034 requirements

AP DENSITY STANDARD OIL 30 cSt @ 40 °C 1x10 mL, WITH ISO 17034 CERTIFICATE

SVM 2001 | 3001 | 4001

- Density standard with low density (830 kg/m3)

- Organic liquid

- Viscous liquid

- Measuring uncertainty: 0.015 kg/m³

- Specified temperature range: 15 °C – 50 °C

- Durability: 18 months

- Volume: 10 mL

- ISO 17034-certified reference material

- Complies with ISO 17025 and ISO 17034 requirements

Heated Sample Changer:

Xsample 610

SVM 2001 | 3001 | 4001

- The single sample changer for heavy duty applications

- Heats up samples up to 95 °C (200 °F) for easy filling

- Ideal for crude oil, waxes, and gels

- Automated cleaning and drying enables minimal operator handling

- Compatible with most commercially available syringes

Accessory for Used-Oil Analysis:

Magnetic Particle Trap (MPT)

SVM 2001 | 3001 | 3001 Cold Properties | 4001

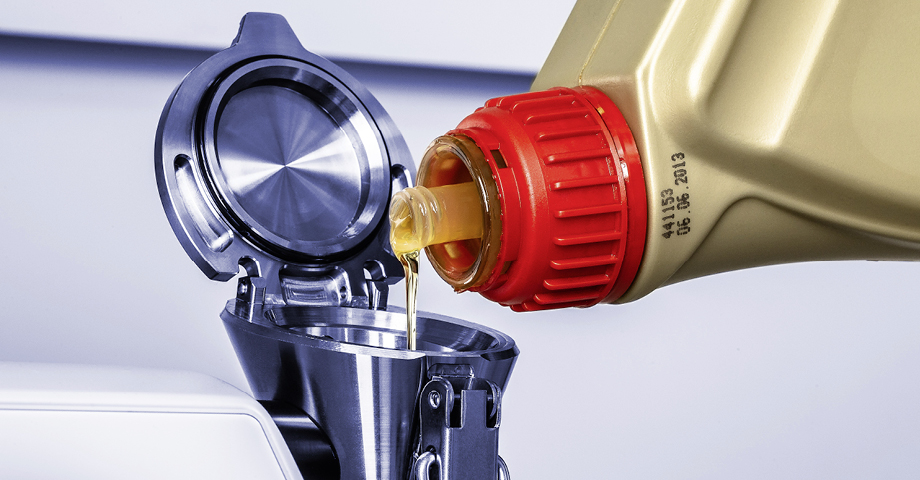

Accessory for SVM 2001/3001:

Hot Filling Attachment

SVM 2001 | 3001

- Keeps samples with high melting point in liquid state during tests

- Suitable for waxes, residual fuel oil, vacuum residue, heavy crude oil and more

- Heated by the Peltier system of SVM, thermal insulation ensures absolute safety

- Minimal space required

Sample Changer:

Xsample 340

SVM 2001 | 3001 | 3001 Cold Properties | 4001

- The single sample changer for different syringe sizes

- The robust solution for reliable and repeatable results

- Prevents sample carry-over with automatic rinsing and drying after each sample

- Highly resistant wetted parts for handling aggressive samples

Sample Changer:

Xsample 530

SVM 2001 | 3001 | 3001 Cold Properties | 4001

- The multi-sample changer with the highest cleaning performance

- Handles up to 71 samples with optional sample recovery

- Automated cleaning and drying with up to three solvents

- Customized magazines available for your own vials

- Measurement of volatile samples

HOSE 3.2x6.4 mm TYGON A-60-G, BLACK (FORMERLY:

NORPRENE A-60-G)

SVM 2001 | 3001 | 3001 Cold Properties | 4001

ANGULAR SCREWDRIVER TORX T20

SVM 2001 | 3001 | 3001 Cold Properties | 4001

HOSE CLAMP DMIN 8.8 DMAX 9.3

SVM 2001 | 3001 | 3001 Cold Properties | 4001

VISCOSITY STANDARD APCL68 CCS (500 mL)

SVM 2001 | 3001 | 3001 Cold Properties | 4001

- Low-temperature viscosity standard.

- Viscosity values from 19,584 mPa.s (-15 °C) up to 11,417 mPa.s (-10 °C)

VISCOSITY STANDARD APCL60 CCS (500 mL)

SVM 2001 | 3001 | 3001 Cold Properties | 4001

- Low-temperature viscosity standard.

- Viscosity values from 21,961 mPa.s (-18 °C) up to 5,731 mPa.s (-5 °C)

HOSE 4X6 SILICONE

SVM 2001 | 3001 | 3001 Cold Properties | 4001

PRINTER PAPER 57x30 STANDARD

SVM 2001 | 3001 | 3001 Cold Properties | 4001

PRINTER CONNECTION CABLE

SVM 2001 | 3001 | 3001 Cold Properties | 4001

ADAPTER LUER 1/4" UNF

SVM 2001 | 3001 | 3001 Cold Properties | 4001

DRYING CARTRIDGE

SVM 2001 | 3001 | 3001 Cold Properties | 4001

KEYBOARD USA USB

SVM 2001 | 3001 | 3001 Cold Properties | 4001

KEYBOARD GERMAN USB

SVM 2001 | 3001 | 3001 Cold Properties | 4001

STAND FOR Xsample

SVM 2001 | 3001 | 3001 Cold Properties | 4001

SAFETY WASTE CONTAINER

SVM 2001 | 3001 | 3001 Cold Properties | 4001

PRINTER PAPER FOR EPSON TM-U220

SVM 2001 | 3001 | 3001 Cold Properties | 4001

RIBBON CARTRIDGE FOR EPSON PRINTER TM-U220

SVM 2001 | 3001 | 3001 Cold Properties | 4001

PRINTER EPSON TM-U220

SVM 2001 | 3001 | 3001 Cold Properties | 4001

DENSITY STANDARD LUBE OIL LARGO 8cSt@40°C

SVM 2001 | 3001 | 3001 Cold Properties | 4001

RS 232 CONNECTION CABLE 9PIN 3 M

SVM 2001

SELF-LOCKING COUPLING 9 mm

SVM 2001 | 3001 | 3001 Cold Properties | 4001

CABLE CLIP SELF-ADHESIVE L20B15H4 GRAY

SVM 2001 | 3001 | 3001 Cold Properties

BRUSH 175x25x2.7 NYLON 0.06 (5 pcs.)

SVM 2001 | 3001 | 3001 Cold Properties | 4001

ETHERNET CABLE FOR PC CONNECTION CAT5E, RJ45G-RJ45G, SFTP, 2 m, CROSSED

SVM 2001 | 3001 | 3001 Cold Properties | 4001

Only for ViscoQC 300. Cable for LIMS Bridge connection to PC for transferring measurement data.

BARCODE SCANNER 2D WITH USB CABLE

SVM 2001 | 3001 | 3001 Cold Properties | 4001

Only for ViscoQC 300

VISCOSITY STANDARD APCL38 CCS (500 mL)

SVM 2001 | 3001 | 3001 Cold Properties | 4001

- Low-temperature viscosity standard.

- Viscosity values from 20,950 mPa.s (-25 °C) up to 2,670 mPa.s (-5 °C)

PROTECTING COVER FOR KEYBOARD

SVM 2001 | 3001 | 3001 Cold Properties | 4001

In combination with keyboard (80809 or 80807)

POWER SUPPLY PoE INCL. POWER CABLE

SVM 2001 | 3001 | 3001 Cold Properties | 4001

HOSE CLAMP DMIN 5.8 DMAX 6.5

SVM 2001 | 3001 | 3001 Cold Properties | 4001

HOSE 3.2x6.4 mm TYGON CHEMICAL (FORMERLY:

NORPRENE CHEMICAL)

SVM 2001 | 3001 | 3001 Cold Properties | 4001

For use with Xsample modules from Serial Nr. 80977476 - 81464920 please contact Anton Paar GmbH.

RIBBON CARTRIDGE FOR CITIZEN PRINTER CBM910 / IDP3110

SVM 2001 | 3001 | 3001 Cold Properties | 4001

VISCOSITY STANDARD ANTON PAAR N2B 100 ml - 7.6 / 3.9 mPa.s at -20 / 0 °C

SVM 2001 | 3001 | 3001 Cold Properties | 4001

Sample Changer:

Xsample 520

SVM 2001 | 3001 | 4001

- The multi-sample changer that provides first-class filling at a snap

- Handles up to 96 samples in one magazine

- Ideal for beer, wine, soft drinks, syrups, and other aqueous samples which can be replaced without intermediate cleaning

- Multiple fillings from the same vial if required

QUICK COUPLING COUNTER COOLING SVM X001

SVM 3001 | 3001 Cold Properties

HOSE 380x3x2 FEP 2x1/4"-28 UNF

SVM 4001

Connection hose FEP for SVM X001 labeled with "Cell" - "Sense"

O-RING 3x1 KALREZ 6375 SPECTRUM

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

SYRINGES 5 ml LUER (100 pcs.)

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

SYRINGES 10 ml LUER (100 pcs.)

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

VISCOSITY STANDARD ANTON PAAR N100 100 ml - 280 / 86 / 9.7 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

280 / 86 / 9.7 mPa.s

VISCOSITY STANDARD ANTON PAAR N100 500 ml - 280 / 86 / 9.7 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

VISCOSITY STANDARD ANTON PAAR N14 500 ml - 25 / 12 / 2.7 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

VISCOSITY STANDARD ANTON PAAR N1400 100 ml - 5000 / 1200 / 74 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

VISCOSITY STANDARD ANTON PAAR N1400 500 ml - 5000 / 1200 / 74 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

VISCOSITY STANDARD ANTON PAAR N26 (C) 100 ml - 50 / 21 / 4.2 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

Recommended for DIN/SSA/UL spindles

VISCOSITY STANDARD ANTON PAAR N26 (C) 500 ml - 50 / 21 / 4.2 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

VISCOSITY STANDARD ANTON PAAR N415 (H) 100 ml - 1100 / 330 / 32 mPa.sc

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

Recommended for DIN/SSA/UL spindles

VISCOSITY STANDARD ANTON PAAR N415 (H) 500 ml - 1100 / 330 / 32 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

VISCOSITY STANDARD ANTON PAAR N7.5 (M) 100 ml - 10 / 5.4 / 1.6 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

Recommended for DIN/SSA/UL spindles

VISCOSITY STANDARD ANTON PAAR N7.5 (M) 500 ml - 10 / 5.4 / 1.6 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

VISCOSITY STANDARD ANTON PAAR N75 500 ml - 164 / 61 / 8.8 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

VISCOSITY STANDARD ANTON PAAR S3 (L) 100 ml - 3.7 / 2.3 / 0.9 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

Recommended for DIN/SSA/UL spindles

VISCOSITY STANDARD ANTON PAAR S3 (L) 500 ml - 3.7 / 2.3 / 0.9 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001

VISCOSITY STANDARD ANTON PAAR S6 500 ml - 8.8 / 4.7 / 1.5 mPa.s

SVM 1001 | 1001 Simple Fill | 1101 Simple Fill | 2001 | 3001 | 3001 Cold Properties | 4001