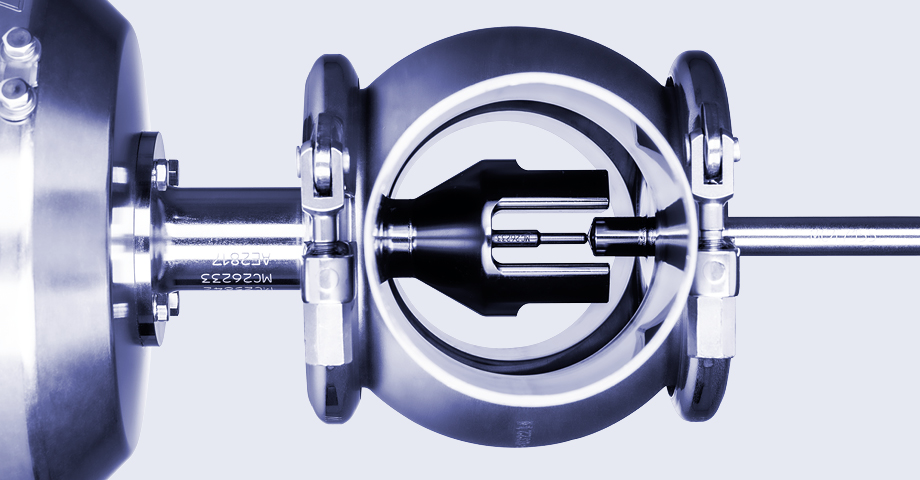

Inline Sound Velocity Sensor:

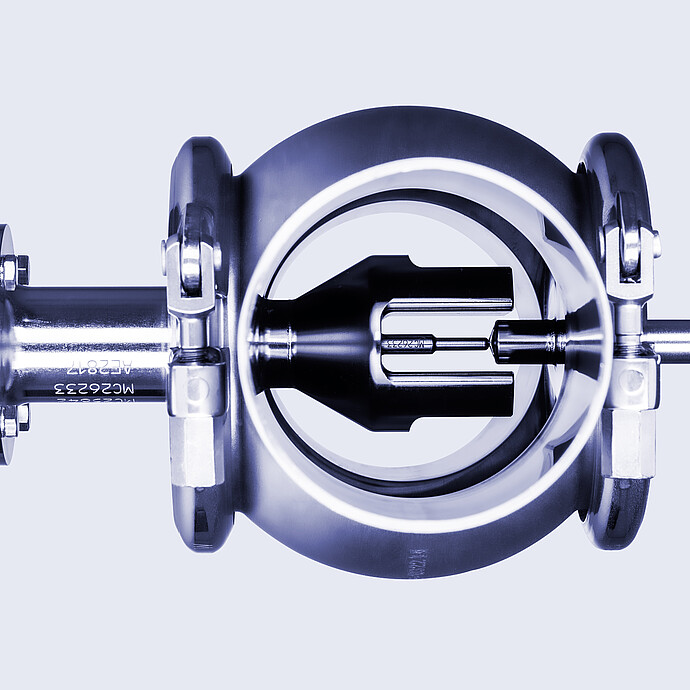

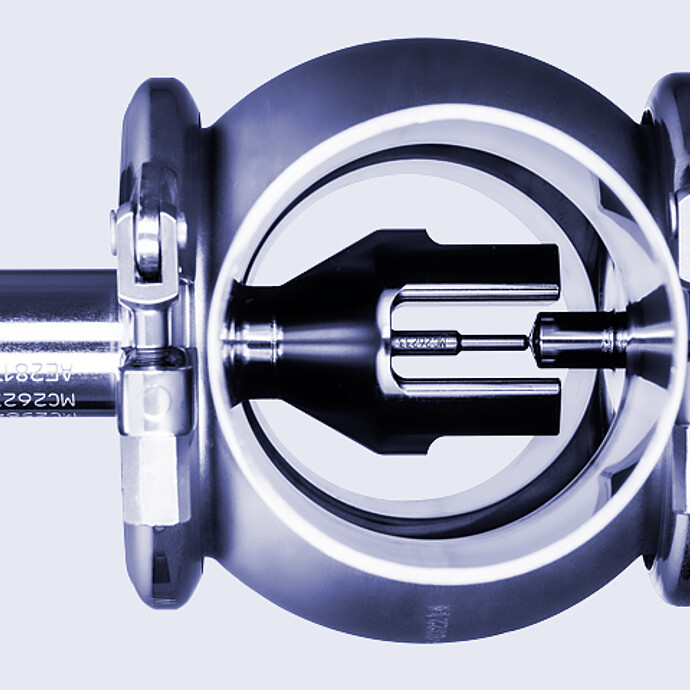

L-Sonic

- Perfect sound velocity sensor for inline concentration measurement, interface detection, product identification, and quality control

- Robust, durable, precise

- Wetted parts, even for the toughest chemical applications

- No bypass, no pumps, no valves needed

Consisting of two types of sensors, our L-Sonic series builds on more than 30 years of experience developing sound velocity measurement technology. L-Sonic 5100 is a fork-type sound velocity meter, while L-Sonic 6100, a tube type meter, is tailor-made for high-precision OCR measurements.

Our sensors are made of wetted part materials, such as SST, Hastelloy, or Monel. From the chemistry, petroleum, and mining industries to the HVAC and beer ones, these easy-to-use sensors are used in industries all over the world.

Key features

Conduct highly accurate measurements

- Measure with repeatability up to 0.005 m/s for highly accurate results

- Conduct measurements that are insensitive to gas bubbles

- Measure even at flow rates at around 0 m/s- with high precision and reliability

- Conduct high-precision temperature measurement for accurate formula compensation

- Get peace of mind: Changes in flow-rate, pressure, and viscosity don’t affect your results

Withstand tough environments with the sound velocity sensor’s robust design

- Build your sensors from a range of high-quality materials:

- 1.4404 stainless steel as high-quality standard fork material

- Hastelloy as high-tech material for sulfuric acid and other harsh chemical environments

- Monel alloy for potassium hydroxide (KOH) and saltwater applications

- 24k gold and rhodium for the toughest situations

- Get ex-d and hygienic certificates

- Minimize downtime as the complete L-Sonic series is maintenance-free

- CIP/SIP-ready and EHEDG certificate available

Integrate quickly and easily: No bypass, no pumps, no valves

- Integrate cost-efficiently and benefit from a great price-performance ration

- Optimize project costs due to fast ROI

- Install directly in a tank or in a pipe within seconds

- Measure at flow rates at around 0 m/s- with the highest precision and reliability

- Access customized flange connections and fork lengths for your requirements

Enjoy various adapters and cleaning solutions

- Access a wide range of different adapter solutions for convenient and fast sensor integration

- PTFE/ PFA coated T-pieces and adapters for chemical installations

- Reductions and sample cups for integration in small pipe diameters

- Transition adapters for sensor integration in large tank and pipe connectors

- Utilize several cleaning options that keep the fork clean without having to remove the sensor

- Directly integrated cleaning nozzles for tank or kettle installations

- Separated cleaning nozzles for flexible pipe installation

Choose only the best sensor for your industry needs

Along with other industries, our sound velocity meters have been best engineered for:

- Concentration measurement in the chemical and petroleum industry

- Concentration measurement of rolling oil emulsions in the steel, aluminum, and copper industry

- Phase detection and product identification for all industries

- Product quality control for all industries

- Wort measurement in the beer and brewery industry

- Sugar concentration measurement

- Ethanol concentration measurement

- Oil Circulation Ratio (OCR) optimization for the automotive and HAVAC industry

Optimize OCR measurements with L-Sonic 6100

- Use L-Sonic 6100’s plug and measure system

- Access our extensive formula portfolio, which has been developed over decades

- Formulas for classical refrigerants (R-1234yf, R-32, R-134a, and many more)

- Formulas for Propane (R-290) and CO2 (R-744)

- Optimized for automotive companies, parts suppliers, research institutes, and various companies from the HVAC industry

Specifications

| L-Sonic 5100 | L-Sonic 6100 | |

| Measuring range | 800 m/s to 2500 m/s | 200 m/s to 1560 m/s |

| Wetted parts material | Stainless Steel 1.4404 (316L) HASTELLOY® Monel 400 24k gold-coated Rhodium-coated | Stainless Steel 1.4404 (316L) |

| Fork length | 56 mm, 125 mm (Standard) or customer-specific | - |

| Repeatability*) sound velocity | 0.005 m/s | 0.01 m/s |

| Accuracy temperature | 0.1 °C | |

| Process temperature | -25 °C to +125 °C | |

| CIP/SIP temperature and duration | 145 °C for max. 30 min. | |

| Ambient temperature (for non-Ex versions) | -25 °C to +65 °C without HMI -20 °C to +55 °C with HMI | |

| Process pressure absolute | According to flange specifications | Up to 70 bar @ 125 °C or Up to 100 bar @ 50 °C |

| Recommended flow rate | > 0 to 6 m/s | 50 L/h to 700 L/h |

| Communication | Pico 3000: Analog and Analog/Digital mPDS 5: PROFIBUS DP | |

| Process connections | VARIVENT® N VARIVENT® G DIN 11851 EN 1092-1 ANSI B16.5 JIS B2220 Customer-specific – on request | Tube end OD 12 mm Compression type fitting (12 mm, 1/2") Compression type fitting with external thread (NPT 3/4", G 3/4") |

| Dimensions: Non-Ex version (L x W x H) Ex version (L x W x H) | Standard fork length: 56 mm, 125 mm, or customer-specific design | 149 mm x 142 mm x 147 mm 149 mmx 156 mm x 166 mm |

*) Measure of the accuracy of a single L-Sonic 5100/6100 sensor

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Beverage | Beer | Complete your Beer Analysis Application Reports

-

Beverage | Spirits | Complete your Spirits Analysis Application Reports

-

Chemistry | Automatic product identification during unloading Application Reports

-

Chemistry | Concentration Measurement Application Reports

-

Chemistry | KOH | Inline concentration analysis of KOH using L-Sonic 5100 Application Reports

-

Chemistry | NaOH | Online concentration measurement of binary NaOH solutions Application Reports

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

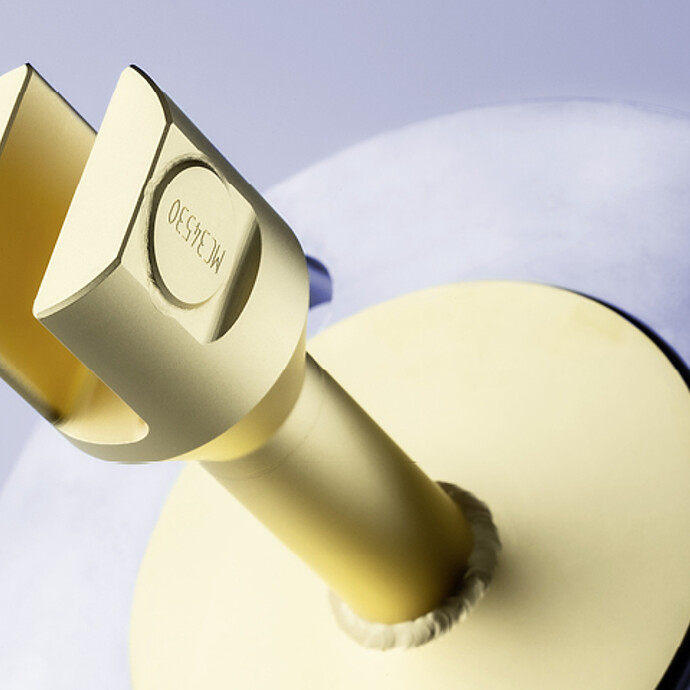

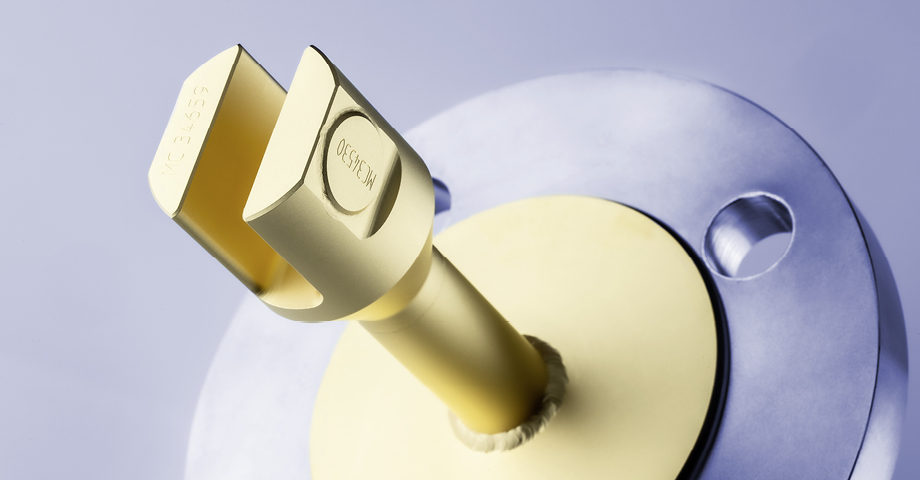

HOOK SPANNER ELECTRONICS HOUSING Ex d

L-Sonic 5100 | 6100

Hook spanner for opening and closing the Pico 3000 electronics housing. Mandatory to close the cover ring at Pico 3000 HMI Ex d.

High Performance Process Controller:

Edge 7000

L-Sonic 5100 | 6100

- Cutting-edge performance with a 10.1-inch projective, multitouch display

- Long-term security and flexibility with a Linux-based operating system

- Intel® Atom® Processor power for unbeatable control

- Industrial-grade, fan-less design for reliability and durability

- Onboard communication with various fieldbus interfaces

High Performance Process Controller:

Edge 5000

L-Sonic 5100 | 6100

- Streamlined configuration without display (optional remote HMI)

- Linux-based operating system for long-term security and adaptability

- Unparalleled control power with an Intel® Atom® Processor

- Industrial-grade, optimized for cabinet integration (fan-less, DIN rail)

- Onboard communication with various fieldbus interfaces

O-RING 60x3 EPDM 70 FDA COMPLIANT

L-Sonic 5100 | 6100