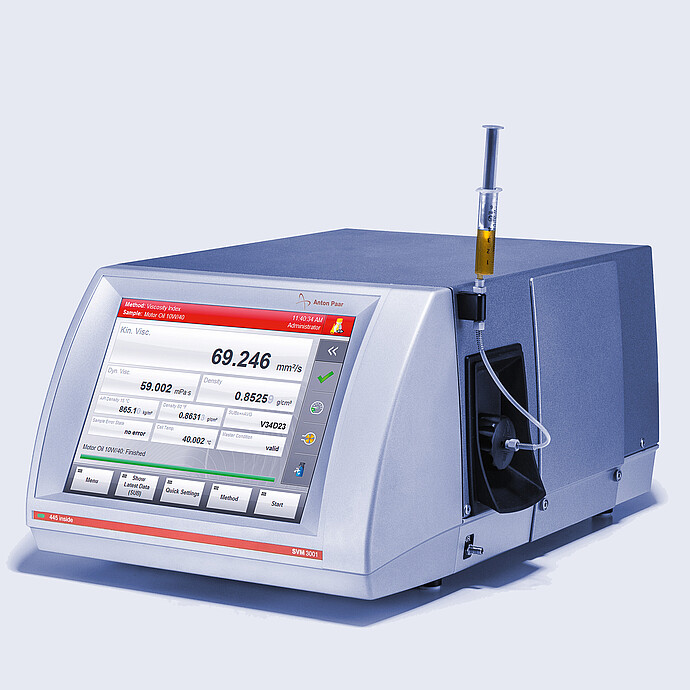

| | SVM 2001 | SVM 3001 | SVM 3001

Cold Properties | SVM 4001 |

| Patents | AT516058 (B1), US10036695 (B2), CN105424556, EP2995928 (B1) | AT516058 (B1), US10036695 (B2), CN105424556, EP2995928 (B1) AT516302 (B1), CN105628550 |

| Test methods | ASTM D7042, D445 bias-corrected, ISO 23581, ASTM D4052 (optional) | ASTM D7042, D445 bias-corrected, ISO 23581, ASTM D4052, ISO 12185 | ASTM D7042, D445 bias-corrected, ISO 23581, ASTM D4052, ISO 12185

ASTM D2386 equiv. or better ASTM D2500 equiv. or better | ASTM D7042, D445 bias-corrected, ISO 23581, ASTM D4052, ISO 12185 |

| Measuring Range |

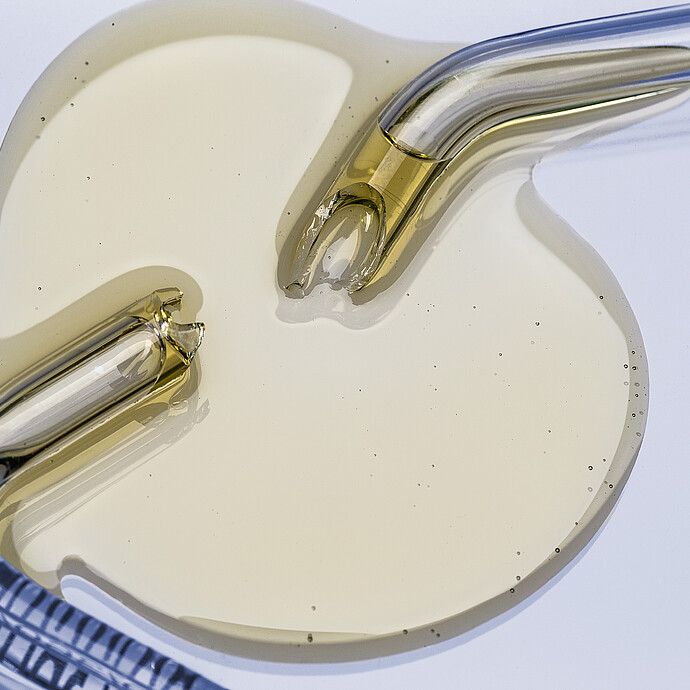

| Viscosity | 0.2 mm²/s to 30,000 mm²/s* |

| Density | 0 g/cm³ to 3 g/cm³ |

| Temperature | +15 °C to +100 °C | -60 °C to +135 °C | -60 °C to +100 °C | +15 °C to +100°C |

| Precision |

| Viscosity repeatability** and reproducibility** | 0.1 % and 0.35 % |

Density repeatability** and

reproducibility** | 0.0002 g/cm³

(0.00005 g/cm² with ASTM D4052 option) and 0.0005 g/cm³

(0.0001 g/cm² with ASTM D4052 option) | 0.00005 g/cm³ and 0.0001 g/cm³ |

Cloud/freeze point repeatability**

and reproducibility** | - | - | <0.5 °C / <0.5 °C and

<2.5 °C / <1.3 °C | - |

| Temperature repeatability | 0.005 °C |

| Temperature reproducibility | 0.03 °C from +15 °C to +100 °C | 0.03 °C from +15 °C to +100 °C | 0.03 °C from +15 °C to +100 °C |

| Performance |

| Sample volume min. / typical | 1.5 mL / 5 mL | 2.5 mL / 6 mL |

| Solvent volume min. / typical | 1.5 mL / 6 mL | 2.5 mL / 10 mL |

| Max. sample throughput | 33 samples per hour | 30 samples per hour | 24 samples per hour |

| Features |

| Optional upgrades | Automatic VI determination ASTM D4052-compliant density measurement | Chemical upgrade kit | - | - |

| Modularity with Abbemat refractometers 5001, 5101, 5201, 7001, and 7201 |

| Accessories | Magnetic particle trap (MPT), hot filling attachment (HFA) | Magnetic particle trap (MPT) |

| Automation | Optional sample changer +

High-Throughput Platform HTV | Optional sample changer + High-Throughput Platform HTV | Optional sample changer

+

High-Throughput Platform HTV |

| Technical Data |

| Data memory | 1,000 measurement results |

| HID (Human Interface Device) | 10.4" touchscreen, optional keyboard, mouse, and 2D bar code reader |

| Interfaces | 4 x USB (2.0 full speed), 1 x Ethernet (100 Mbit), 1 x CAN bus, 1 x RS-232, 1 x VGA |

| Power supply | AC 100 V to 240 V, 50 Hz to 60 Hz, 250 VA max. |

| Ambient conditions | 15 °C to 35 °C, max. 80 % r.h. non-condensing |

| Net weight in kg | 15.9 kg | 17.6 kg | 18.0 kg | 17.8 kg |

Dimensions

(W x D x H) | 33 cm x 51 cm x 23.1 cm |

| Trademarks | SVM (13411996), FillingCheck (6834725), Abbemat (1084545) |