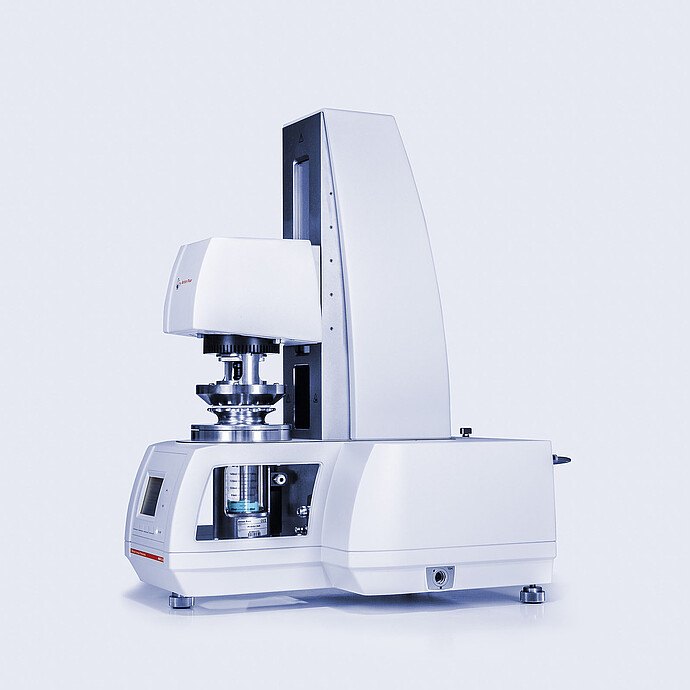

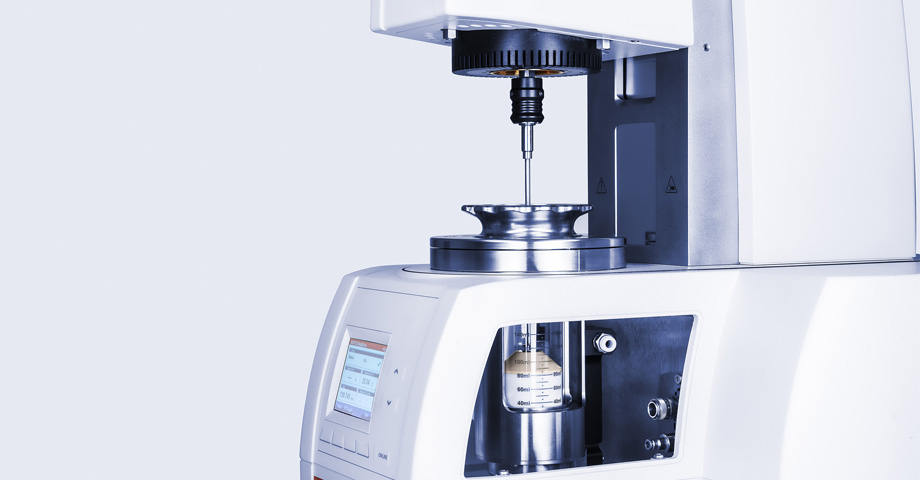

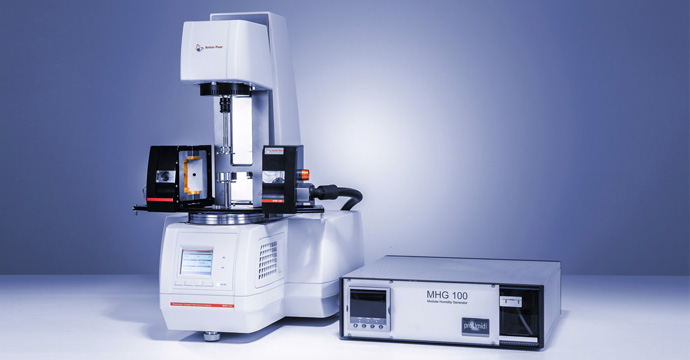

MCR Rheometer Setups for:

Powder

- Accurate powder analysis with the powder flow cell and shear cell

- True powder rheology to analyze bulk solids in any state, from fluidized to consolidated powders

- Wide range of dedicated powder measurement methods for quality control and R&D

- Suitable for measurements from -160 °C to +980 °C (and combinable with humidity control)

- Enables the characterization of powders under low to high loads and their time-dependent behavior

- Shear, compressibility, and wall friction tests

The two cells for true powder rheology help you to really characterize and understand your powders. A wide range of dedicated powder measurement methods is available putting the advantages of rheometers to use: fast and easy-to-perform tests but also elaborate measurements for both quality control and R&D purposes.

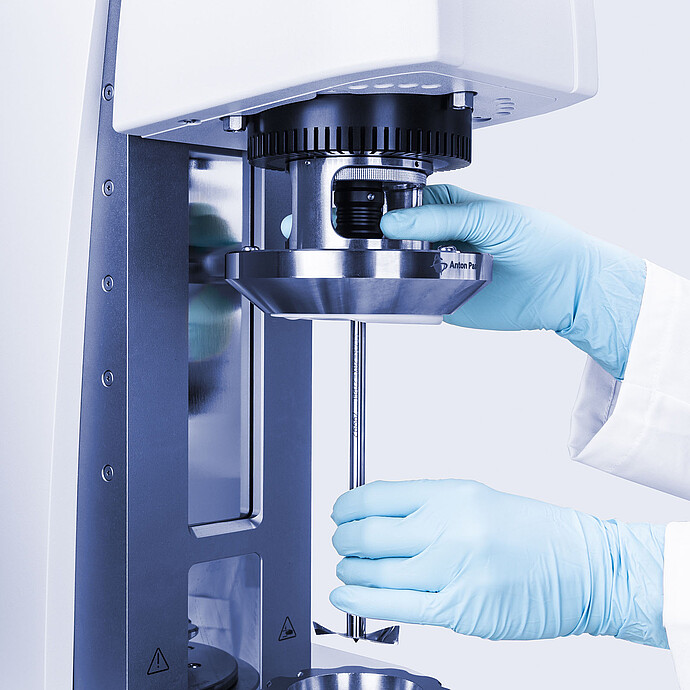

The powder shear cell is ideal for determining the flow behavior of consolidated powders and their time-dependent behavior. Additional accessories provide full control over temperature and humidity.

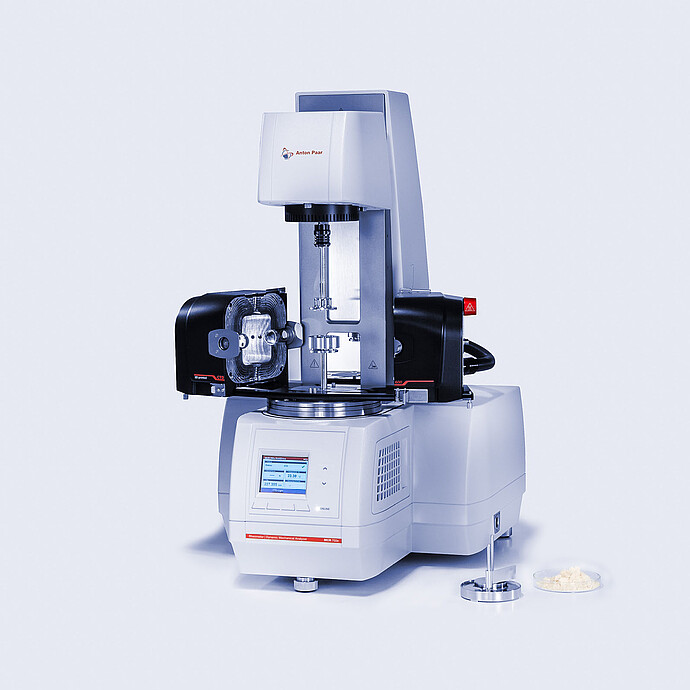

The powder flow cell is an innovative and scientific approach towards powder characterization offering a wide range of test methods. Powder behavior can be characterized under various processing conditions: simulating, adjusting, and optimizing – for example – manufacturing processes.

Key features

Two cells to cover all your needs

The complete powder rheology setup with the powder shear cell and the powder flow cell gives you all the possibilities you need for the characterization of your powders and granular media. The combination of a rheometer with a system to determine the behavior of powders guarantees the highest sensitivity and absolute results.

The most versatile powder characterization with the powder flow cell

Due to its high versatility, the powder flow cell can be used for in-depth powder characterization or as an easy-to-use quality control tool: You can use it to control the quality of your products with quick tests while benefitting from the precision of Anton Paar’s MCR rheometers. Use one of the many measurement methods, such as basic flowability energy, cohesion strength, pressure drop, deaeration time, etc., to characterize your powder as it is during processing, handling, and storage. On top of that, you can also determine envelope density using the powder flow cell with a dedicated measuring geometry and displacement powder.

The only powder shear cell with temperature and humidity control

Control the temperature and find out how this impacts your powders. An MCR rheometer can be equipped with heating chambers for an extreme temperature range from -160 °C to 980 °C. Humidity is known to heavily change powder behavior during storage, handling, and processing and can be controlled in the range between 5 %rH and 95 %rH with a dedicated humidity kit. Temperature and humidity control are also available for the powder flow cell on request as a customized solution.

Powerful software for incomparable control

With the intuitive user interface of the rheometer software you can run fully automatized measurements with only two clicks while maintaining full autonomy over all measurement parameters. You can adapt all measurements to your needs. The system complies with QM requirements, such as 21 CFR Part 11 for the pharmaceutical industry, and can be used with Windows 10 or higher.

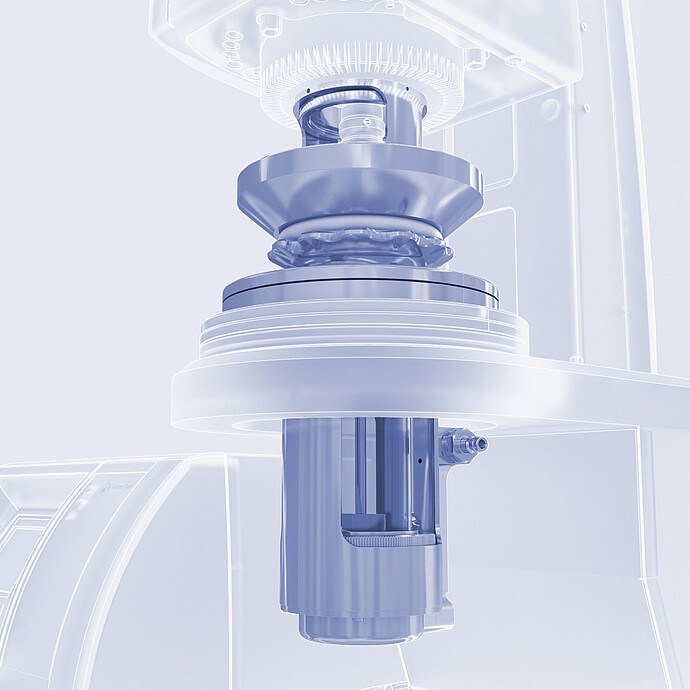

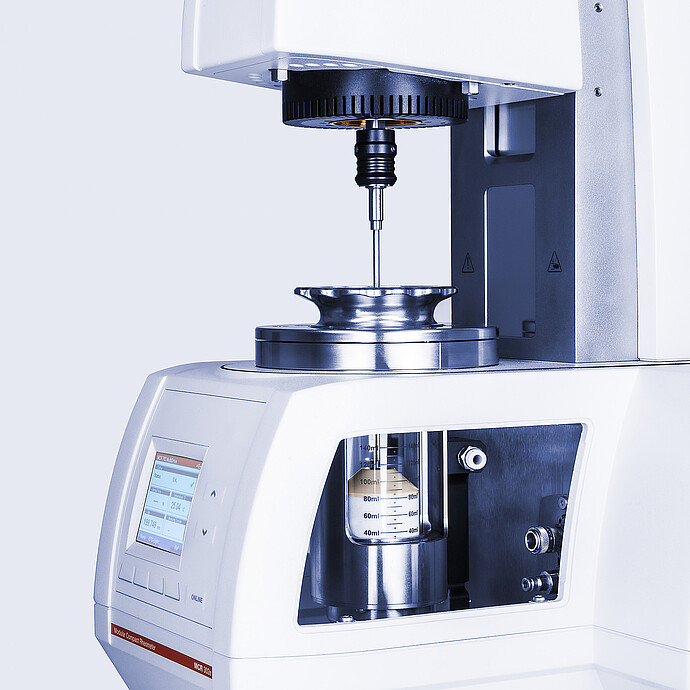

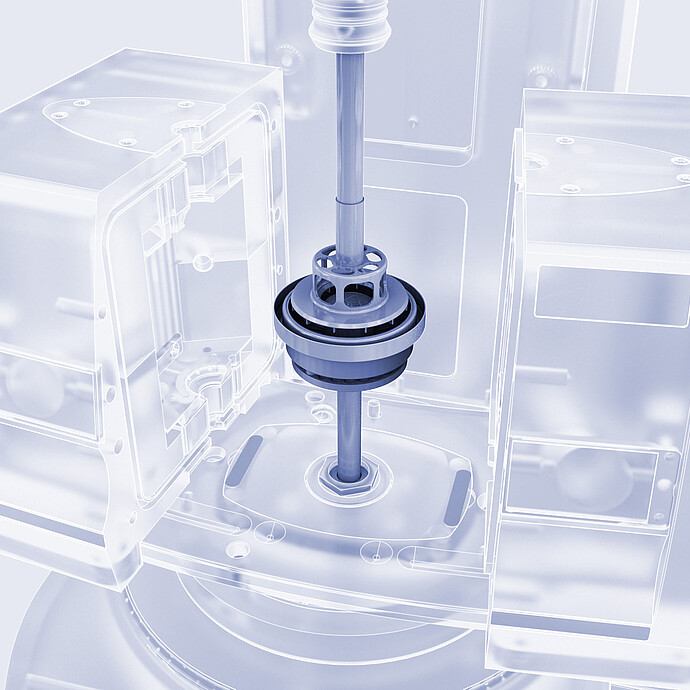

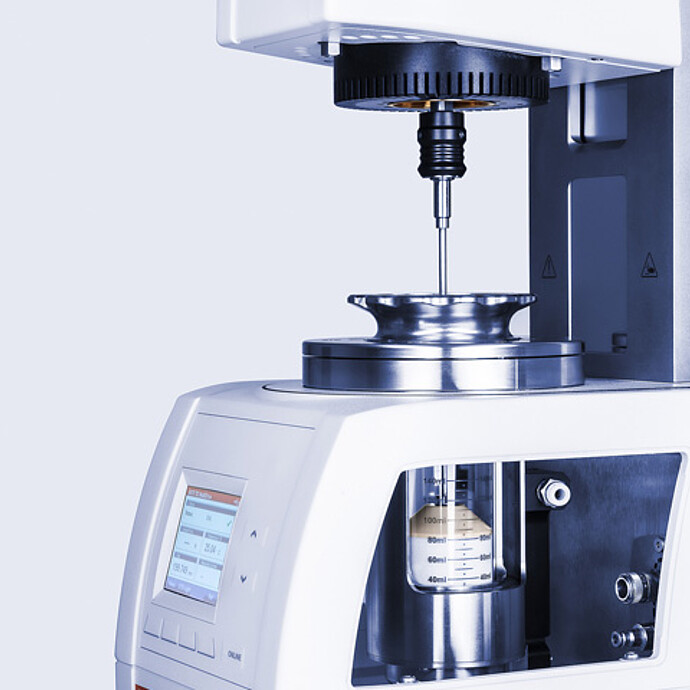

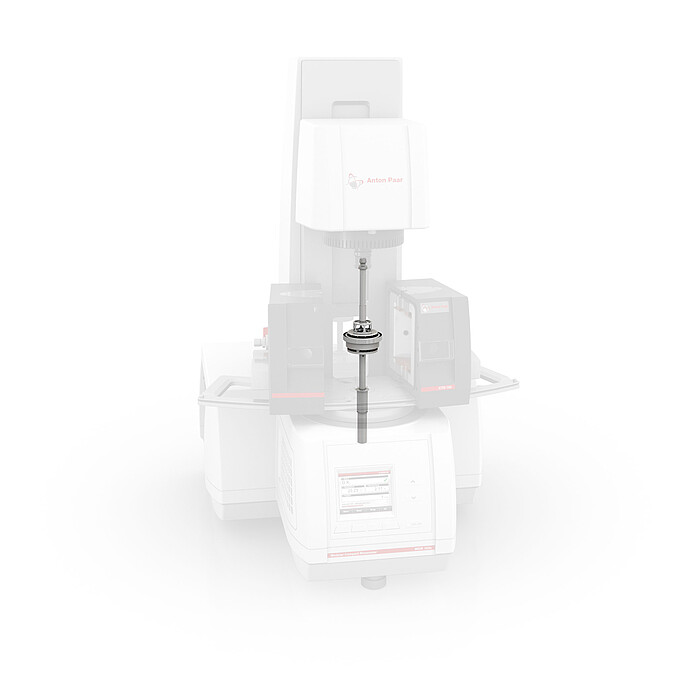

Patented dust protection for the powder flow cell

The unique patented dust protection system (EP 3067684) enables clean and safe sample handling. The fourfold sealing concept protects the operator and the instrument from fine and potentially hazardous powder even when it is fully fluidized. The air seal technology of the powder flow cell is dustproof without any friction on the measurement axis and thus maintains the MCR rheometer’s extraordinary accuracy and resolution down to 10 nNm and below.

Designed for sensitivity and reproducibility

Expect reproducible measurements for both the powder shear cell and the powder flow cell. The MCR’s sensitivity helps to differentiate even very similar powders and detect even small changes within your samples. A sample preparation bench is included in the powder shear cell setup. It ensures that the samples are always prepared identically, strongly reducing operator influence and thereby increasing reproducibility. The powder flow cell applies automated sample preparation modes for an unrivalled reproducibility of up to 0.5 %.

Specifications

| Powder shear cell | PFC 30 | PFC 20 | PFC 10 | |

| Sample volume | 4.3 mL and 18.9 mL | 60 mL to 120 mL | 60 mL to 120 mL | 21 mL |

| Torque range | 1 nNm to 300 mNm | 10 nNm to 300 mNm | ||

| Normal stress | While shearing: up to 30 kPa While compacting: up to 110 kPa (sample- and cell-dependent) | 22 kPa | - | |

| Temperature option | -20 °C to +180 °C with CTD 180 HR -150 °C to +450 °C with CTD 450 -160 °C to +600 °C with CTD 600 MDR up to +980 °C with CTD 1000 MDR | -15 °C to +80 °C | -160 °C to +600 °C | |

| Humidity option | 5 %rH to 95 %rH from 5 °C to 120 °C with CTD 180 HR and humidity option | Customizable on request | -5 %rH to +95 %rH from 5 °C to 120 °C with CTD 180 HR and humidity option | |

| Meaurement systems compatible | Included in the setup:

| Two-blade stirrer - helical two-blade stirrer - warren-springs geometry - powder preparation set with exchangeable disks (stainless steel, air-permeable, PTFE, further materials on request) - Cylinder - profiled cylinder | Basic flowability energy stirrer (further stirrers on request); not compatible with PFC 20 and 30 stirrers | |

| Measurement method |

| For fluidized, aerated and low-load conditions | For non-fluidized, aerated and low-load conditions | For non-fluidized, aerated conditions (BFE and SE) |

| Dust protection | Not necessary | incl. | Upgrade kit to PFC 30 available | no |

| Fluidization option | Not necessary | Choice of 3 mass flow controllers for volumetric flow from 0.05 L/min up to 80 L/min. | Only with upgrade kit | no |

| Accessories | Included in the setup:

| Included in the setup: ø 50 mm PFC with uncoated glass; dust protection hood and fluidization option | Included in the setup: ø 50 mm PFC with uncoated glass | Included in the setup: ø 24 mm PFC made of stainless-steel, funnel for PFC, basic flowability stirrer |

| Optional: FTO-coated glass/ steel tube | Optional: Measuring cup made of inconel or disposable cup | |||

Standards

ASTM

DIN

US Pharmacopoeia (USP)

European Pharmacopoeia (Ph. Eur.)

Standards

ISO

DIN EN ISO

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

A Qualitative Fluidization Segregation Test for Pneumatic Transport Application Reports

-

An Example of Silo Design Using a Shear Cell Application Reports

-

Basic Flowability Energy Measured by Powder Flow Cell Application Reports

-

Catalyst Characterization - From Fresh to Spent Application Reports

-

Characterization of Cement and Fly Ash in Quality Control Application Reports

-

Characterization of Rice Grains Application Reports

-

Characterizing Modified Low-Temperature Powder Coatings Application Reports

-

Determination of the Glass Transition Temperature of Polymer Powders Application Reports

-

E-Book - A Practical Guide for Great Building Materials Application Reports

-

E-Book - Field Guide to Food Powder Characterization Application Reports

-

E-Book - Field Guide to Food and Feed Testing Application Reports

-

E-Book - Praxisleitfaden zur Pulvercharakterisierung für Pharmazeutika Application Reports

-

E-Book - The Field Guide to Pharmaceutical Powder Characterization Application Reports

-

Envelope Density and Porosity of solids measured with Powder Flow Cell Application Reports

-

Flowability of Detergent Powder under Dry and Humid Conditions Application Reports

-

Foam Alone: How to Generate and Analyze Foams in the Powder Flow Cell. Application Reports

Compatible instruments

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

FTO-COATED MEASURING TUBE FOR POWDER FLOW CELL

Powder Shear Cell | Flow Cell

UNCOATED GLASS MEASURING TUBE FOR POWDER FLOW CELL

Powder Shear Cell | Flow Cell

ENVELOPE POWDER

Powder Shear Cell

Spare part for Envelope Density Set

- Glass beads 800g

COMPRESSION DISCS FOR ENVELOPE DENSITY

Powder Shear Cell

Spare part for Envelope Density Set

- 5 pcs of PEEK compression discs

ENVELOPE DENSITY SHAFT FOR XX2

Powder Shear Cell

- PP50/187/PE/PFC

- Spare part for Envelope Density Set

GLAS FRIT, POROSITY 4 FOR POWDER FLOW CELL

Powder Flow Cell

- One piece

GLAS FRIT, POROSITY 3 FOR POWDER FLOW CELL

Powder Flow Cell

- One piece