Wines, Sparkling Wines

Precisely determine and monitor the alcohol content and numerous other quality parameters in wine and sparkling wine: Anton Paar specializes in high-precision laboratory and process wine analysis, with over 20 years of experience and many long-term partnerships with the biggest names in this industry. Find the measuring instrument that meets your particular needs – or let us help you find the best solution by contacting us directly.

Anton Paar Products

DMA

Abbemat Essential

CboxQC

L-Cor 8000

L-Cor 4000

L-Com 5500

DMA 5001 Sound Velocity

DMA 4200 M

SmartRef

Lyza 5000 Wine

DMA 35 Basic

L-Cor 6000

Cobrix

Fermentation Monitor

Wine Monitor

Oxy

L-Rix

Alcolyzer

Abbemat Advanced

Multiwave GO Plus

Alcohol Measurement System

Packaged Wine Measurement System

Wine Measurement Systems

CarboQC

OxyQC

EasyDens

TPO 5000

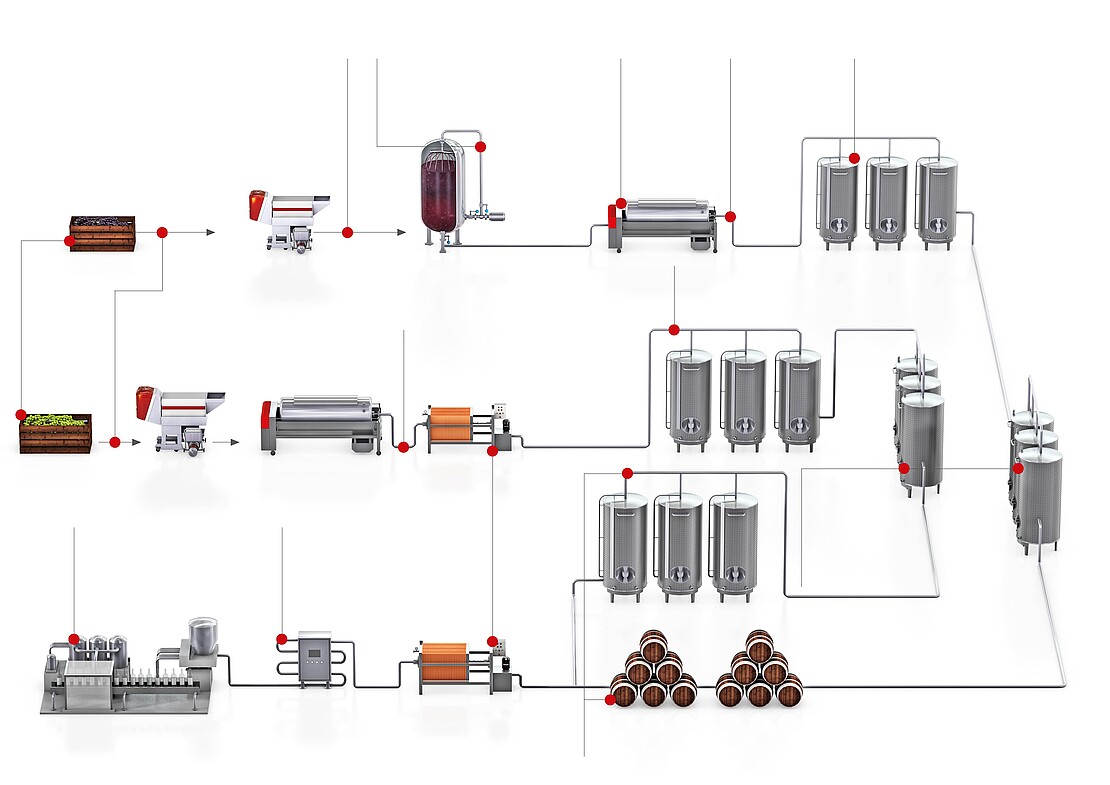

The winemaking process

Complete your wine analysis and measure key parameters from the incoming raw materials to the final quality control of the packaged wine. Your benefits:

- More than 20 years of expertise in inline, at-line, and laboratory wine analysis

- Choose from more than 15 laboratory and process instruments for your in-depth analysis

- Get more than 20 key parameters for your wine and must samples

- Benefit from global support and service from local specialists

Hover over the dots to learn which instrumentation you can use at this point in your production or to see how you will benefit from measurements at this point.

Alcoholic and malolactic fermentation

Alex 500 alcohol and extract meter OxyQC portable O₂ meter Lyza 5000 Wine FTIR analyzerCarbonation

CarboQC portable CO₂ meterAlcoholic and malolactic fermentation

Alex 500 alcohol and extract meter OxyQC portable O₂ meter Lyza 5000 Wine FTIR analyzerGrape maturity test

- Determine the stage of berry development

- Define the peak of ripeness and time of harvest

- Follow changes in the acidity level

Raw material monitoring

- Use only raw materials which meet your standards

- Make sure the final product quality is guaranteed right from the beginning

- Improve cost-effectiveness by avoiding faulty batches

Must enrichment

- Determine the alcohol content potential of future wine

- Refine the taste of your wine

- Stay within legal limits for addition of sugar

Maceration

- Manage oxygen exposure during fermentation

- Follow changes in ethanol concentration

- Influence your wine’s sensory properties and style

Pressing/Must inspection

- Determine yeast assimilable nitrogen content for a successful fermentation

- Manage acidity for microbiological stability

Pressing/Must inspection

- Determine yeast assimilable nitrogen content for a successful fermentation

- Manage acidity for microbiological stability

Filtration

- Ensure optimal refinement for proper mouthfeel, aroma, and flavor

- Guarantee microbial stability

Filtration

- Ensure optimal refinement for proper mouthfeel, aroma, and flavor

- Guarantee microbial stability

Alcoholic and malolactic fermentation

- Set actions in time to achieve the desired output

- Ensure consistently high product quality

- Ensure an optimal fermentation progress

- Avoid by-products of a stuck fermentation

- Guarantee savings by exact end point determination

Alcoholic and malolactic fermentation

- Set actions in time to achieve the desired output

- Ensure consistently high product quality

- Ensure an optimal fermentation progress

- Avoid by-products of a stuck fermentation

- Guarantee savings by exact end point determination

Clarification and stabilization

- Remove insoluble matter which can affect the wine

- Ensure the wine is stable before bottling

- Prevent fermentation restart

Storage and maturation

- Ensure that the final wine meets your quality specifications

- Optimize the maturation process

- Monitor the flavor profile development

Carbonation

- Achieve the right taste and sensation

- Ensure cost-effectiveness due to correct CO₂ dosage

- Ensure safety: No bursting bottles due to too much CO₂

- Safeguard consistent product quality for continuous customer satisfaction

Blending and bottling

- Establish consistent quality, leading to continuous consumer satisfaction

- Ensure proper product composition

- Make sure label specifications and legal requirements are fulfilled

Filtration

Oxy 5100 inline oxygen sensorFiltration

Oxy 5100 inline oxygen sensorAlcoholic and malolactic fermentation

Fermentation Monitor 5100 High performance process controller Edge 5000/7000 with Davis 5 softwareAlcoholic and malolactic fermentation

Fermentation Monitor 5100 High performance process controller Edge 5000/7000 with Davis 5 softwareStorage and maturation

Wine Monitor 5500 or 5600

L-Col 6100 color sensor Oxy 5100 inline oxygen sensor High performance process controller Edge 5000/7000 with Davis 5 softwareCarbonation (optional)

Inline CO₂ sensorsChoose the long-standing trusted partner of the wine industry

With more than 20 years of experience in developing and distributing wine analysis instrumentation for more than 20 key wine quality parameters, Anton Paar is the market leader in beverage analysis. The portfolio includes measuring instruments for inline, at-line, and laboratory wine analysis. Combining laboratory and process instruments yields many benefits, especially for bigger producers; at the same time, each solution can stand on its own for accurate, reliable, and safe measurements. Anton Paar instruments will help you to provide your wine products in consistent quality and control them at every production step – from harvesting until final bottling.

Go from fast screening to in-depth wine analysis in lab and process

More than 20 key quality parameters that you can analyze with Anton Paar instrumentation guarantee you in-depth knowledge about your wine and the right solution for your individual challenge in wine production. Solutions include the Lyza 5000 FTIR analyzer for fast screenings of more than 13 quality parameters in must, must in fermentation, and wine. Big wine producers and wine bottlers find many advantages in combining laboratory and process instrumentation, as shown in the graphic above, e.g. to control product quality or to reduce sample handling times. Wine farmers, on the other hand, might go for smaller solutions, such as DMA 35, while wine analysis labs need fast and comprehensive results that are delivered by FTIR.

Benefits for wine farmers

With the right analysis equipment you can easily answer questions such as:

- When is the best time to harvest my grapes?

- Do my grapes have the quality I expect?

Parameters you can measure to achieve this include grape sugar content and the acidity of grape juice. With this information you will be able to:

- Determine the stage of grape development

- Decide on the right time for harvest

- Follow changes in the acid composition

Benefits for wine producers and bottlers

Measuring solutions from Anton Paar for the wine industry will enable you to answer questions such as:

- Are the grapes our providers deliver of the expected quality?

- How is the fermentation progressing?

- Is my wine profile correct?

- Are product stability and appearance guaranteed?

- Is this must composition suitable for effective fermentation?

- And many more

Parameters you can measure to achieve this include sugar content, acidity, pH, turbidity, fructose, glucose, various acids and acid profile, alcohol, glycerol, specific gravity, and many more. For some parameters, you can use process meters to control the wine during production, and lab meters for quality control and calibrations. All in all, with this information you will be able to:

- Guarantee the quality of your wine product to your customers

- Control your product quality and production process all the way through, from grape to bottle

- Reduce costs by reducing sample handling time

To see your measuring possibilities at every process step in-depth, you can use the interactive graphic above.

Benefits for contract laboratories in wine analysis

Wine analysis instrumentation from Anton Paar will enable you to answer questions such as:

- Are parameters such as alcohol and CO₂ within product-specific and legal limits?

- What is the wine’s profile?

- Do I have enough analysis results to give an informed consultation to my customers?

- And many more

Parameters you can measure to achieve this include sugar content, acid profile, pH, yeast assimilable nitrogen, turbidity, various sugar types, and many more. With results from Anton Paar instruments you will be able to:

- Guarantee accurate, repeatable, and reproducible results to your customers

- Measure according to international standards

- Conduct screenings for more than 13 parameters in less than one minute

To learn more about all your measuring possibilities in the lab, you can turn to the laboratory part of the interactive graphic above.