Density and Sound Velocity Concentration Sensor:

L-Com 5500

- Highly accurate concentration sensor

- Ideal for measuring 3-component mixtures

- Modular and compact minimizes integration effort and costs

- Easy commissioning and operation

- No consumables, no maintenance

L-Com 5500 is a smart density and sound velocity sensor combined into one instrument with an accuracy of 0.05 kg/m³ for density measurement and 0.1 m/s for sound velocity measurement. This lets you conduct concentration measurements of 3-component mixtures with just one instrument. This concentration sensor meets the requirements of a wide variety of applications in the chemical, beverage, and pharmaceutical industries.

Key features

One concentration sensor to measure 3-component mixtures

- Enjoy the benefits of an L-Dens 7500 density sensor and an L-Sonic sound velocity sensor in one instrument to measure 3-component mixtures in different industries

- Use L-Com 5500 for a range of applications like

- Breweries: measure alcohol and extract concentration in beer

- Chemical industry: measure formaldehyde-methanol-water concentration in formaldehyde production, where in this application the explosion proof version is used.

Accuracy and reliability under changing process conditions

- Get the best accuracy on the market

- 0.05 kg/m³ for density measurement

- 0.1 m/s for sound velocity measurement

- The metallic sensor technology, without thermal insulation by plastic coating, enables exact concentration measurements – even with temperature fluctuations

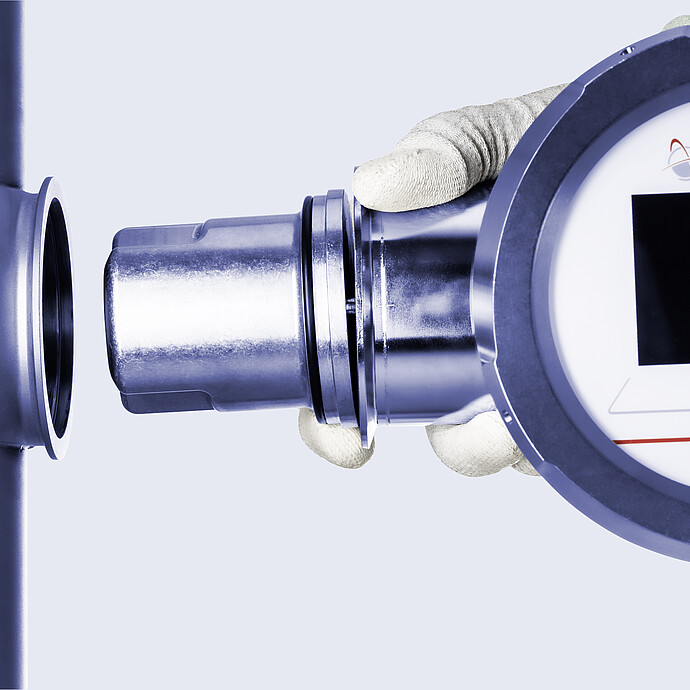

One instrument, three installation options

- Know you won’t need maintenance or consumables since there’s no moving parts

- Install the concentration sensor with low integration costs thanks to its modular design

- Benefit from flexible installation options: inline, bypass, or tank installation

- Use our small pumps – integrated into the instrument unit – that are controlled by the instrument itself for either extremely fluctuating or no flow

- Do this even in hazardous areas with the Inline Pump 300 Ex d

Easy commissioning, simple operation

- Connect the concentration sensor to the powerful mPDS 5 evaluation unit or combine it with the smart transmitter Pico 3000

- Choose from a variety of communication protocols, according to your needs

- Start measuring immediately after installation

In-house experts ready to help

- Specialized team of experts leverages its deep industry knowledge to develop solutions for any application

- Rely on our comprehensive database and application know-how for a wide range of industries

- Send your sample to our lab for a tailored formula that fits your needs if your application isn’t in our database

Specifications

| L-Com 5500 | |

| Measuring range | Max. 2000 kg/m³ 800 m/s to 2000 m/s |

| Standard adjustment range density Standard adjustment range sound velocity | 700 kg/m³ to 1200 kg/m³ 800 m/s to 2000 m/s |

| Material of the wetted parts | Alloy C-276 |

| Accuracy density in the adjusted range Repeatability sound velocity in the adjusted range | 0.05 kg/m³ 0.01 m/s |

| Process temperature | -25 °C to +125 °C (145 °C for max. 30 min.) |

| Ambient temperature (non-Ex versions) | -25 °C to +65 °C (without Pico 3000) |

| Process pressure absolute | Max. 50 bar |

| Recommended flow rate | 100 L/h to 500 L/h |

| Communication | Can be combined with Pico 3000, Pico 3000 RC, and mPDS 5 |

| Process connections | Adapter for inline, bypass, and tank installation Flange: EN, ANSI, JIS, Tri-Clamp, Varivent®; G 3/8”, Tube OD 12 mm; others on request |

| Ex-Version | ATEX, IECEx, cQPSus, INMETRO |

Dimensions: non-Ex version (L x W x H) |

258 mm x 142 mm x 192 mm |

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Beverage | Beer | Complete your Beer Analysis Application Reports

-

Beverage | Soft Drinks | Complete Your Soft Drink Analysis Application Reports

-

Beverage | Soft Drinks | Online Process Measurement in the Soft Drink Industry Application Reports

-

Chemistry | Automatic product identification during unloading Application Reports

-

Chemistry | CH2O | Online measurement of formaldehyde and methanol concentration Application Reports

-

Chemistry | Concentration Measurement Application Reports

-

Process Engineering Solutions | Overview Brochures

-

DEKRA Japan Ex Certificate | L-Com 5500 HAS Ex d Certificates

-

EU Declaration of Conformity | L-Com 5500 Ex d Certificates

Similar products

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

High Performance Process Controller:

Edge

High Performance Process Controller:

Edge 7000

- Cutting-edge performance with a 10.1-inch projective, multitouch display

- Long-term security and flexibility with a Linux-based operating system

- Intel® Atom® Processor power for unbeatable control

- Industrial-grade, fan-less design for reliability and durability

- Onboard communication with various fieldbus interfaces

High Performance Process Controller:

Edge 5000

- Streamlined configuration without display (optional remote HMI)

- Linux-based operating system for long-term security and adaptability

- Unparalleled control power with an Intel® Atom® Processor

- Industrial-grade, optimized for cabinet integration (fan-less, DIN rail)

- Onboard communication with various fieldbus interfaces