Dynamic Mechanical Analyzer:

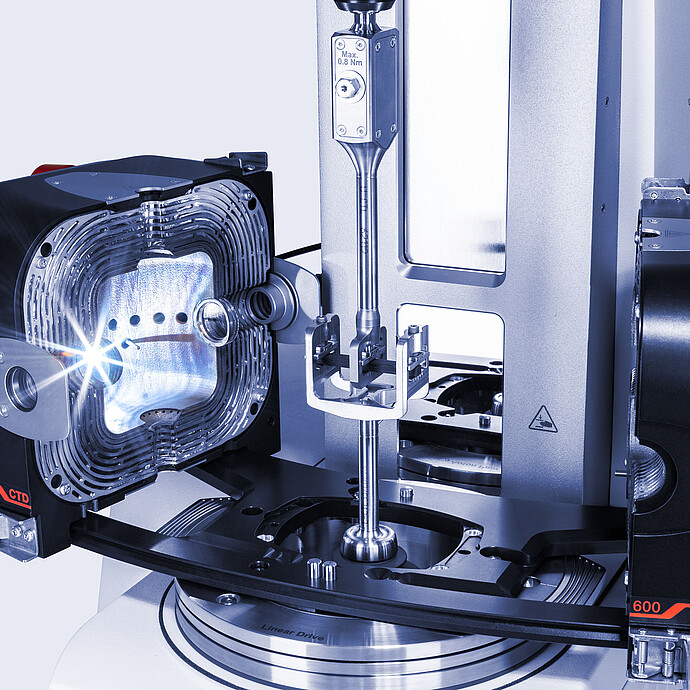

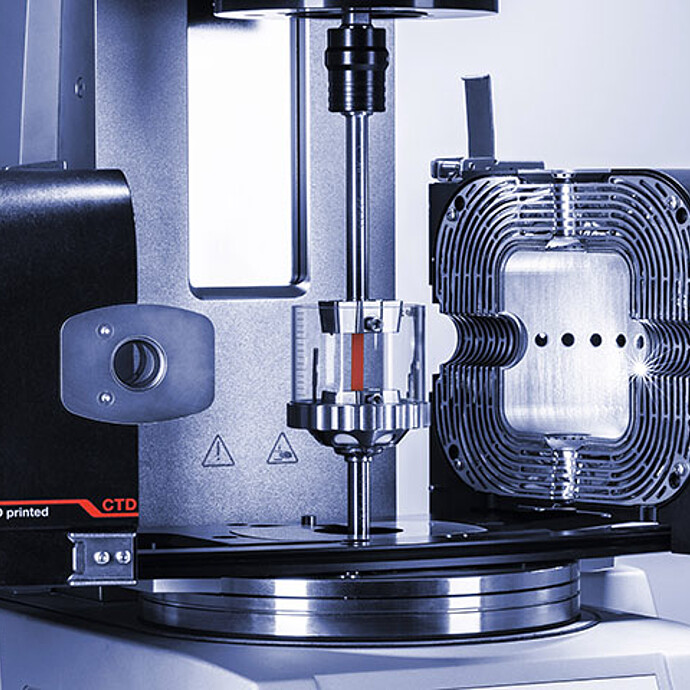

MCR 702e MultiDrive

- The world’s most versatile platform for DMA in tension, torsion, bending and compression

- Unique axial-torsional DMA to determine complex Young’s and shear modulus within one test definition of the same specimen

- Air-bearing-supported moving-magnet drive for precise force measurements from 0.5 mN to 40 N to characterize soft and stiff materials

- Temperature control from -160 °C up to 1,000 °C

- Ready for all types of rheological investigations

The MCR 702e MultiDrive is the most versatile and powerful dynamic mechanical analyzer platform of solid, soft, and liquid samples. Users can perform dynamic mechanical analysis in tension, torsion, bending, and compression, standard and highly sophisticated rheological measurements, and thermomechanical analysis (TMA) with one instrument. The device also determines Young's modulus and shear modulus within one test of one specimen, opening up a new field of material characterization. The modularity of the system can integrate a wide range of temperature devices, as well as application-specific accessories and measuring systems to cover all requirements of different applications.

Key features

Make use of two drive units for all of your applications

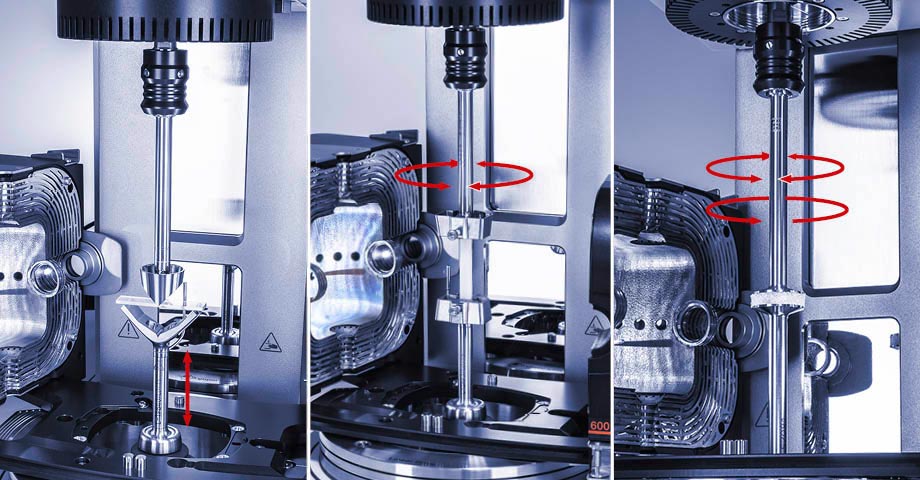

The combination of an air-bearing-supported upper rotational drive, air-bearing-supported lower linear drive and optical encoder technology enables you to perform linear dynamic mechanical analysis in a force range from 0.5 mN to 40 N, as well as torsional dynamic mechanical analysis in a torque range from 0.5 nNm to 230 mNm. With just one instrument, DMA in tension, bending, compression and torsion, rheological investigations and experiments in thermomechanical analysis can be carried out. This flexible concept allows you to perform a variety of different measurement tasks that are unique to the Dynamic Mechanical Analyzer. It is the application alone that determines which measurement mode you work in.

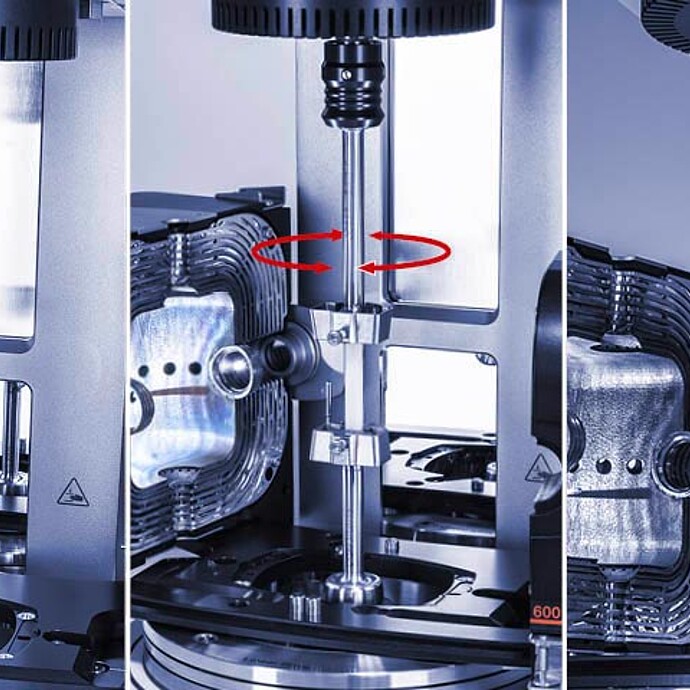

Material characterization like never before

The state-of-the-art moving-magnet motor and EC motor technology performs dynamic mechanical analysis in tension and torsion within one test definition and one specimen. This axial-torsional DMA determines the complex Young’s (E*) and shear (G*) modulus as a function of temperature, frequency, time or humidity within a single experiment. For the first time, the Poisson's ratio of isotropic materials can be determined using a single sample. In addition, when investigating anisotropic materials, fast direction-dependent characterization is possible, enabling a more comprehensive analysis of the sample properties.

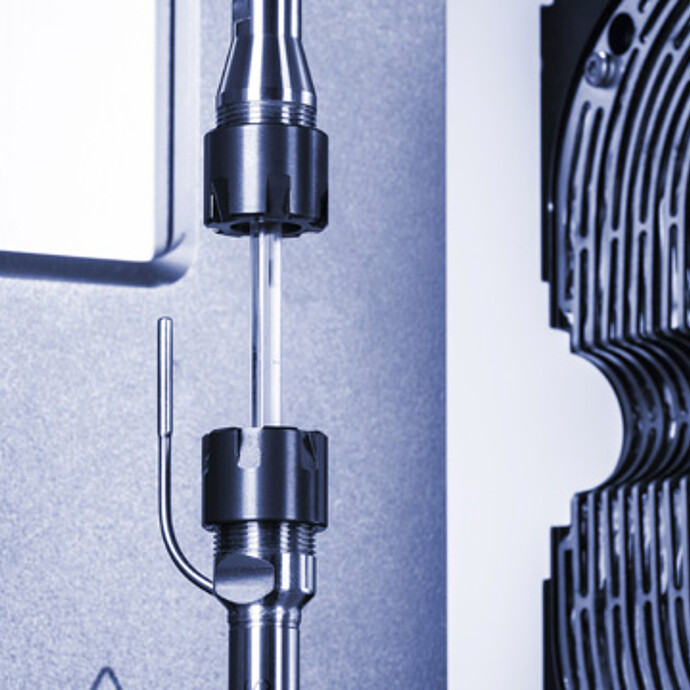

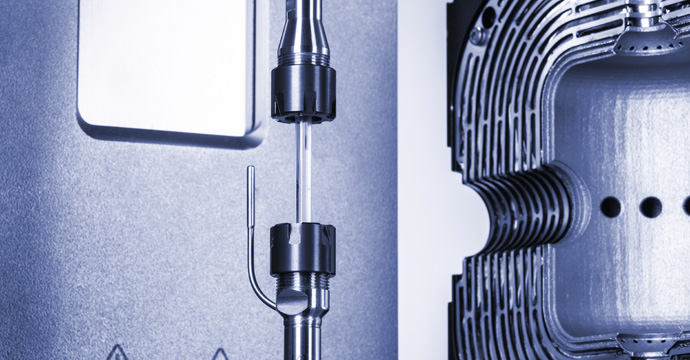

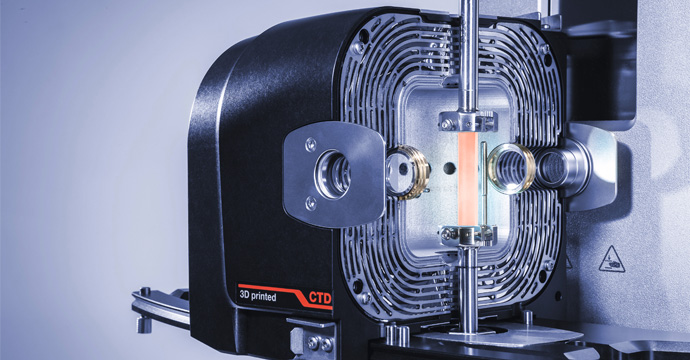

Control the greatest influence of all – temperature

Convection temperature devices are optimized to generate a homogeneous temperature distribution necessary for accurate control of the sample temperature. Additionally, low-temperature options based on a gas chiller (-90 °C) or liquid nitrogen (-160 °C) option can be used for precisely controlled cooling. Furthermore, a controlled relative humidity can be applied to the sample in combination with temperature. Each standard measuring system includes an integrated temperature sensor located close to the clamped sample. In this way, the measured temperature offers high precision and reproducibility over the entire temperature range without human intervention.

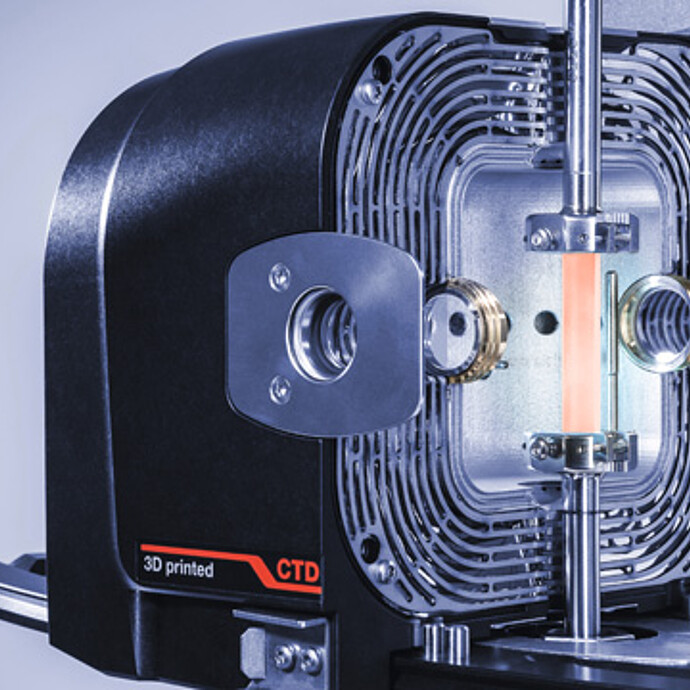

Customize with special accessories and customized solutions

Anton Paar, with its in-house development and production team, is able to provide devices and accessories for special applications. MCR 702e Space MultiDrive, for example, maximizes working space to accommodate accessories and complementary measuring instruments. Accessories are available for characterizing solids which are immersed in a liquid or which have to be characterized at temperatures down to -170 °C or up to 1,000 °C. Shafts can also be combined with any disposable or customized geometry. For testing powdery samples Anton Paar offers material pockets in combination with the typical DMA measuring systems in bending mode.

Broaden your capacities with over 200 rheological accessories

In addition to classic dynamic mechanical analysis, rheological measurements open up the possibility of characterizing the deformation behavior of solids and the flow behavior of liquids. To measure different kinds of samples, users require a variety of different measuring systems, accessories, and temperature devices. With the linear motor unit removed, MCR 702e MultiDrive is ready to be equipped with any measuring geometry, temperature device, and/or application-specific accessory from the Anton Paar MCR series in order to carry out standard and sophisticated rheological analyses of samples.

Convenient setup and ease of use

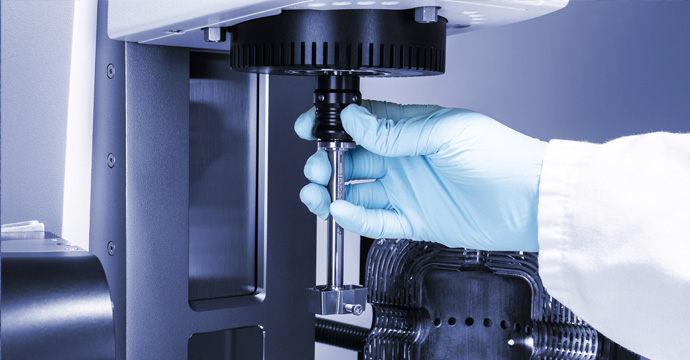

All temperature devices and measuring geometries can be integrated and exchanged, and your MCR 702e MultiDrive can adapt to each new setup as a versatile dynamic mechanical analyzer. The QuickConnect function allows one-hand connection and ensures fast, convenient system changes within seconds without a screwing mechanism. The patented Toolmaster feature automatically recognizes and configures all connected devices and measuring geometries. To control the MCR 702e MultiDrive, you can rely on our multifunctional and intuitive RheoCompass software which helps you find the predefined or customized test templates you need, customize tests and analysis definitions, export your data, and generate reports.

Specifications

| MCR 702e MultiDrive MCR 702e Space MultiDrive | ||

| Unit | Specifications | |

| Linear drive for DMA in tension, bending and compression | ||

| Maximum force | N | 40 |

| Minimum force | N | 0.0005 |

| Maximum displacement | μm | 9,400 (1 |

| Minimum displacement | μm | 0.01 |

| Maximum frequency | Hz | 100 |

| Minimum frequency | Hz | 0.001 |

| Rotational drive for DMA in torsion and rheology | ||

| Maximum torque | mNm | 230 |

| Minimum torque (rotation) | nNm | 1 |

| Minimum torque (oscillation) | nNm | 0.5 |

| Maximum angular deflection (set value) | µrad | ∞ |

| Minimum angular deflection (set value) | µrad | 0.05 |

| Maximum angular velocity | rad/s | 314 |

| Minimum angular velocity | rad/s | 0 (2 |

| Maximum angular frequency | rad/s | 628 (3 |

| Minimum angular frequency (4 | rad/s | 10 -7 (5 |

| Normal force range | N | -50 to 50 |

| Further information regarding general features, measuring systems, accessories, and specifications when using only rotational drives can be found here. | ||

| Temperature Control | ||

| Maximum temperature range | °C | -160 to + 1,000 (6 |

| Maximum heating rate | K/min | 60 (6 |

| Maximum cooling rate | K/min | 30 (6 |

| Further information regarding general features, measuring systems, accessories, and specifications when using only rotational drives can be found here. | ||

| Features | |

| DMA in tension, bending and compression | ✔ |

| DMA in torsion | ✔ |

| DMA in combined axial-torsional mode | ✔ |

| Rheology | ✔ |

| Thermomechanical analysis | ✔ |

| Toolmaster™, measuring system | ✔ |

| Toolmaster™, measuring cell | ✔ |

| QuickConnect for measuring systems, screwless | ✔ |

| T-Ready™ | ✔ |

| Low temperature option, nitrogen evaporation unit | o |

| Low temperature option, customized gas chiller | o |

| Humidity option | o |

✔ included | o optional

1) In oscillation a maximum displacement of ± 4,500 μm.

2) In controlled shear stress (CSS) mode. In controlled shear rate (CSR) mode depending on measuring point duration and sampling rate.

3) Higher frequencies are possible using multi-wave functionality (942 rad/s (150 Hz) or even higher, depending on measuring system and sample).

4) Set frequencies below 10-4 rad/s are of no practical relevance due to the measuring point duration >1 day.

5) Theoretical value (length of one cycle = 2 years).

6) Limits depend on convection temperature device used and measuring systems. Customized low-temperature option for temperatures down to -170 °C available upon request.

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

3-PB of Bitumen Using a Rheometer Equipped with an Additional Lower Linear Drive Application Reports

-

Accelerated Creep Testing of Polymers by the Stepped Isothermal Method Application Reports

-

Characterization of Shape-Memory Materials Application Reports

-

DMA: Polymeric Foam Immersed in Fluid Media Application Reports

-

Das MCR 702 MultiDrive in der Verbundwerkstoffindustrie Application Reports

-

Dynamic Mechanical Characterization of Fully Bio-Based Composites Application Reports

-

E-Book - Field Guide to Pharmaceutical Powder Characterization Application Reports

-

E-Book - Polymer Processing Application Reports

-

Efficient Creep Investigation of Wood-Plastic Composites in Bending Mode Application Reports

-

How to Characterize Damage in DMA Measurements Application Reports

-

How to Prevent Sample Slip in Tensile DMA Measurements Application Reports

-

Indirect Method to Measure the Poisson’s Ratio Application Reports

Similar products

Consumables & Accessories

Consumables & Accessories

Accessories

Accessories

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

P-PTD 220/AIR FOR MCR xx2 / MCR xx2e PELTIER TEMPERATURE DEVICE (PLATE)

- plate with active Peltier temperature control (heating/cooling)

- for cone/plate and parallel plate measuring geometries

- with built-in fan for air counter-cooling

- with universal plate holder (screw-on thread) for use of measuring plates (also disposable) and other accessories

- with Toolmaster for automatic tool recognition and configuration

- installation in the rheometer through three-point support without the risk of misalignment

- maximized torsional stiffness due to constructional torque support

MEAS. CONE CP40-1 FOR X2/XX2

Accessory for MCR:

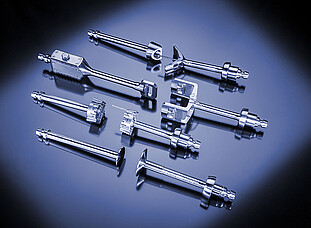

DMA Measuring Systems

- For dynamic mechanical analysis (DMA) in bending, tension, torsion, and compression

- Solid rectangular fixtures, three-point bending geometries, cantilevers, compression systems

- Compatible with MCR 702e MultiDrive

MEAS. CONE CP40-2 FOR X2/XX2

Accessory for MCR:

Humidity Option

- Accessory for “Additional Parameter Settings”

- Control the impact of the relative humidity on a material’s rheological behavior

Temperature Control:

Convection Temperature Devices (-160 °C to +1000 °C)

- For temperature-controlled rheological and DMA measurements on melts, solids, films, and fibers from -160 °C to 1000 °C

- Homogeneous temperature distribution for accurate & stable results

- For MCR measuring systems: parallel-plate, cone-plate, DMA in torsion or extension, controlled relative humidity, and more

Accessory for MCR Temperature Devices:

Low Temperature Options

- Combinable with electric and convection temperature devices

- Choice of solutions for different low temperature requirements: down to -40 °C, -90 °C, or -160 °C

- Toolmaster functionality for automatic system configuration and error-proofing

SPATULA