Compact Digital Density Meter:

DMA

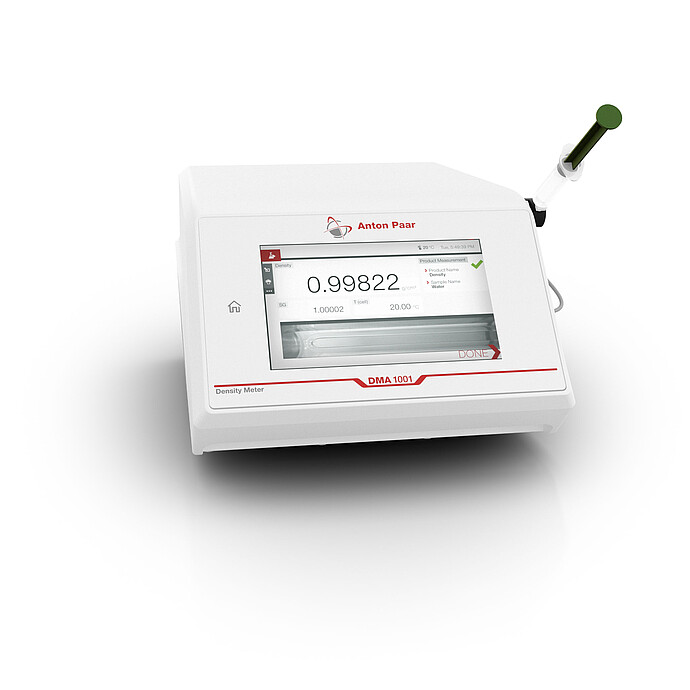

- The most advanced 4-digit density meter in this price segment

- 100 % consistent results due to repeatability of 0.00005 g/cm3

- Covers ASTM D4052, ASTM D5002, ISO 12185, USP <841>, Ph. Eur. 2.25, JP 17 2.56, ChP(Vol IV) 0601, and FDA CFR 21 Part 11

- Splash-proof, instrument self-diagnosis, no ventilation-related corrosion

This product is part of our current starter kits. Find out more about our exclusive offer here: Cosmetics Starter Kit, Chemical Starter Kit, Tank Terminal Kit

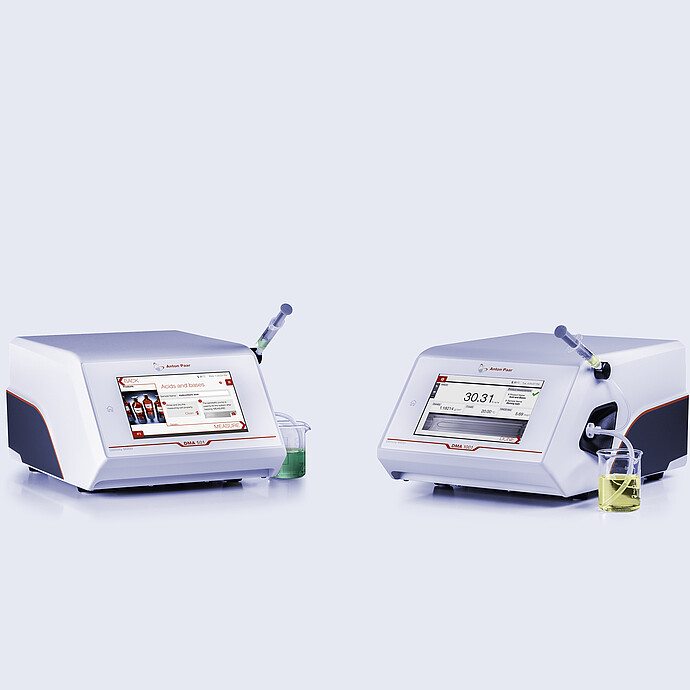

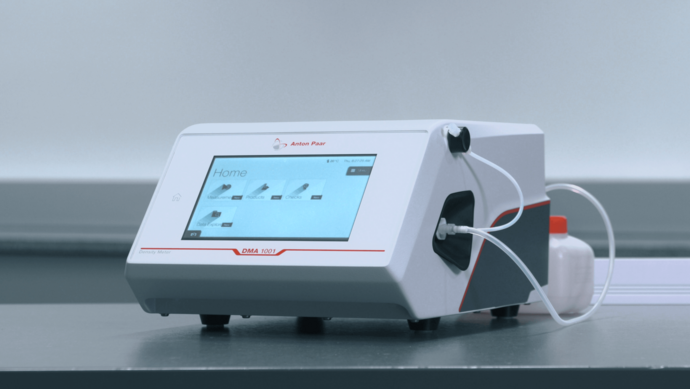

Change for the better: DMA 501 and DMA 1001 are entry-level digital density meters which will revolutionize your work in the lab as well as your quality checks at the production line and storage facilities. Developed and manufactured by the world market leader, they rise to the challenge of speeding up the measurement of pasty, inhomogeneous, sedimenting, and particle-containing samples, and even aerosol sprays. DMA 501 and DMA 1001 are Anton Paar's answer to the demands of our customers in industry. They are ready for all samples and work reliably in harsh conditions.

Both instruments make digital density measurement accessible for everybody: First, they come with an unmatched price tag. Second, their guided user workflows, customizable screen layouts, and many support features such as the FillingCheck™ and condition monitoring ensure they can be operated after only minimum training.

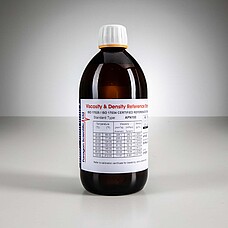

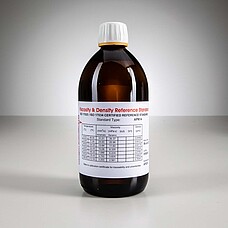

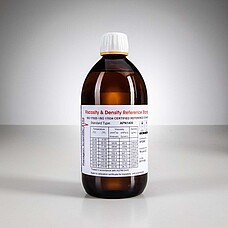

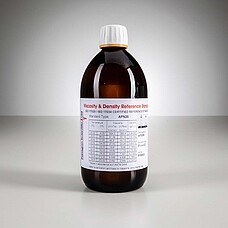

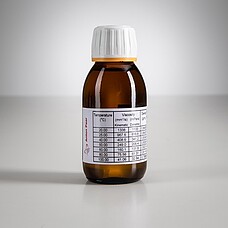

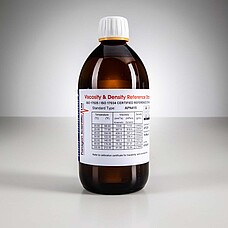

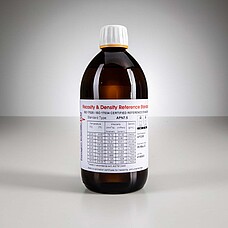

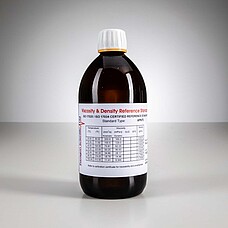

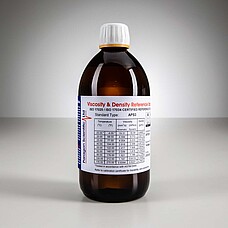

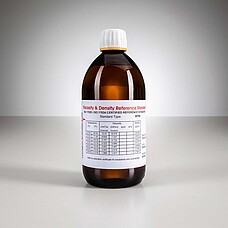

All products are delivered with factory calibration. Use our ISO 17034-certified reference material for density to ensure your instrument is perfectly calibrated.

Benefits

Upgrade your density measurements and leave your time-intensive, breakage-prone hydrometers behind. Over 60 integrated conversion tables, 400 freely configurable methods, and memory for up to 5000 data logs set the benchmark in this segment. Set up the device once with all your frequently used tests and return to them again and again to immediately see a clear “pass/fail” result based on your defined acceptable upper and lower limits. As DMA 501/1001 requires only 1 mL sample volume you won’t waste valuable product. Both instruments thrive in harsh environments and automatically compensate for external influences such as humidity, altitude, and ambient temperature. When linked to AP Connect, our lab execution software, all data is stored in a single digital space and accessible from any network computer.

DMA 501 is your entry-ticket to 3-digit digital density measurement. Choose DMA 1001 for 4-digit accuracy and full compliance with international standards, including all relevant Pharmacopeia (US, EU, JP, CN), data integrity (21 CFR Part 11, GMP 4 annex 11&15, ALCOA+), and ASTM D4052 & D5002.

- Designed for the harshest environments

- Spill-proof design

- Glove-friendly operation – even when wet

Challenge

Density checks are often carried out in cluttered and cramped workspaces by operators wearing wet gloves. Samples may be spilled on or around the instrument.

Solution

DMA 501/1001 has a splash-proof front display and a cover at the back which protects the interfaces and outlets from sample spills.

Your benefits

Uptime and product lifetime are maximized.

- Results from approximately 1 mL sample

- Low cost of analysis

- Reduced waste (just 10 mL of solvent)

Challenge

When measuring the density of expensive samples the top priority is to use as little as possible.

Solution

DMA 501/1001 delivers results from approximately 1 mL of sample, requires 5 mL to 10 mL of solvent for cleaning, and reduces your environmental impact.

Your benefits

Waste less sample, save costs, and still get the results you need for production control.

- Masters paste-like samples

- Finish your measurement in one minute

- Only 10 mL solvent required

Challenge

It is difficult and time-consuming to fill pasty samples (i.e. creams, lotions, ointments) into the pycnometer and the cleaning is time-intensive, too.

Solution

With DMA 501/1001 you fill pasty samples in minutes with the help of the pasty sample kit.

Your benefits

Using the syringe holder ensures bubble-free filling so you save 25 to 30 minutes per sample compared to using a pycnometer and the cleaning is fast and needs only a few milliliters of solvent each time.

- Minimum contact when filling dangerous substances

- Use the touchscreen wearing gloves

- Approximately 1 mL sample required

Challenge

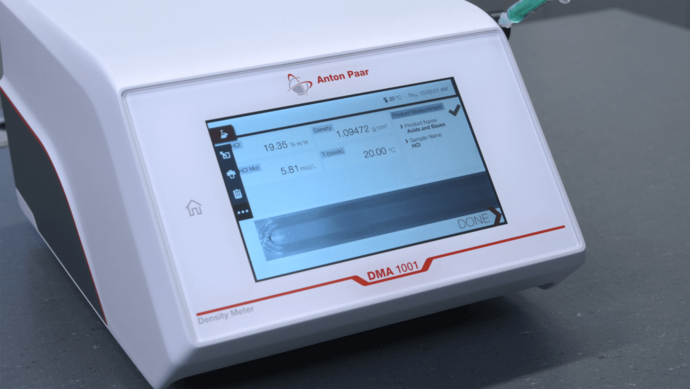

Monitoring the production process may include testing corrosive acids and bases. What is the best way to protect the operator?

Solution

Safety first: DMA 501 needs approximately 1 mL of sample and filling with the peristaltic pump reduces contact to a minimum. The touchscreen can be operated wearing gloves.

Your benefits

Operators have minimal contact with dangerous substances, especially when using a peristaltic pump (Xsample 200).

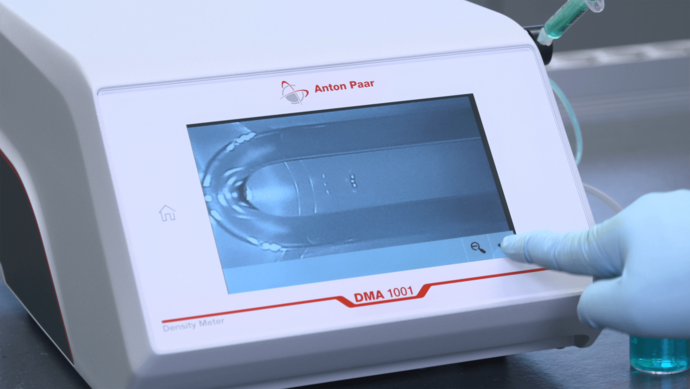

- 100 % correctly filled samples

- No need to repeat measurements

- Excellent results every time

Challenge

Viscous samples are tricky to fill with a syringe because bubbles occur easily. Is there a better way?

Solution

DMA 501/1001 has a built-in inspection camera (U‑View™) which gives you a clear picture of the filled-in sample, with zoom-in options and a backlight. FillingCheck™ automatically monitors filling and alerts you if a problem occurs.

Your benefits

100 % correctly filled samples. FillingCheck™ and U‑View™ reduce the likelihood of poor filling enormously so you do not have to repeat measurements and waste time and sample. No measuring errors due to bubbles in the sample.

- Get a result for all samples, including:

- • inhomogeneous, sedimenting, particle-containing samples

- • pastes and even aerosol sprays.

Challenge

Liquid samples with particles or inhomogeneous samples are difficult to measure but the protocol requires a result.

Solution

With DMA 501/1001 you can measure the density of all samples you are able to fill and remove, without limitations.

Your benefits

Density results for all samples, including pasty, inhomogeneous, sedimenting, and particle-containing samples, and even aerosol sprays.

- Full traceability to USP <841> and other Pharmacopeia

- Audit trail

- Full documentation of filling

Challenge

Measurements need to be compliant to USP <841> or other important Pharmacopeia (EU, JP, C) to be accepted in the target markets.

Solution

The measuring technology, accuracy, and repeatability provided by DMA 1001 are fully compliant with major Pharmacopeia (USP <841>, Ph.Eu. 2.2.5, JP 17 2.56, ChP (Vol IV) 0601).

DMA 1001 also provides full traceability and full documentation of each performed measurement: up to 5000 results as well as related potential filling warnings and camera images are stored in the instrument’s memory ready to be exported (USB, Ethernet, or RS232).

Your benefits

Compliance to all major Pharmacopeia allows you to sell your products to global markets.

Only available with:

- DMA 1001

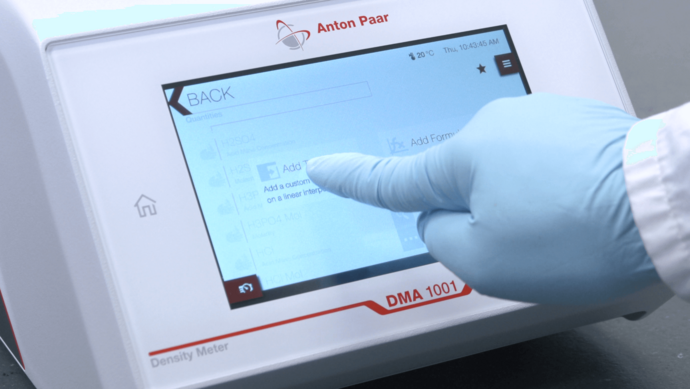

- Test many samples quickly and get 100 % comparable results

- Use the same test settings for the same product every time

- Define excellent production SOPs

Challenge

When developing new formulations, many different variations of products need to be tested quickly and reliably using the same test protocol. When a product is released, reference density and specific gravity values need to be defined for production and final QC.

Solution

A simple customization of the dashboard of DMA 501/1001 gives you quick access to your defined settings for repetitive measurements. Reference values can be defined based on previously measured data.

Your benefits

Defining and reusing measurement settings means your results are 100 % comparable. You can rely on trustworthy and accurate reference values for use in production SOPs.

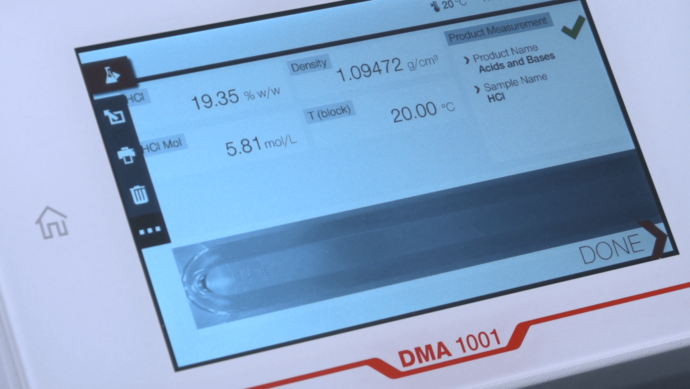

- Concentration values shown immediately

- No manual conversion: Saves you up to 10 min/measurement

- Make pass/fail decisions right away

Challenge

When checking the quality and/or purity of raw material before use I need to get the concentration value immediately, even when the substance is highly concentrated.

Solution

DMA 501 has stored tables for automatically calculating % w/w and % v/v for e.g. ethanol, isopropanol, hydrogen peroxide, glycerol, and many more. The density is measured, automatically converted into concentration, and shown within seconds. Your own tables can be imported if you need custom quantities and calculations. Determining the concentration of components of hand sanitizers, for example, takes only 2 to 3 minutes per measurement.

Your benefits

No need to look up values in tables or calculate the concentration yourself. This saves up to 10 minutes per measurement and eliminates the risk of calculation errors. Quickly getting a concentration result means you make pass/fail decisions quickly and based on correct information.

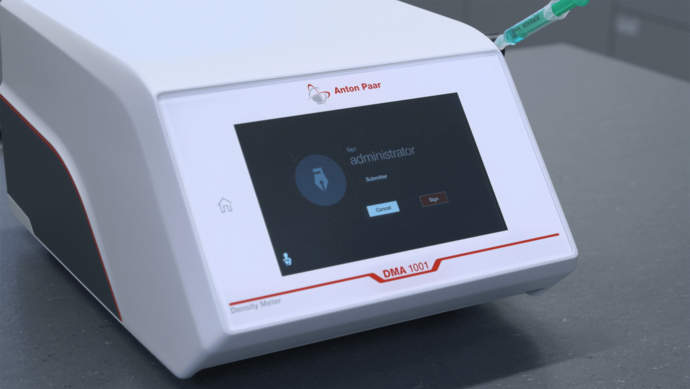

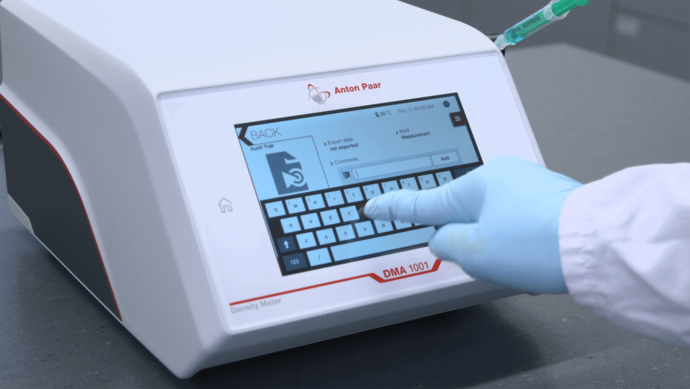

- Audit trail logs all activities

- All your lab data is just a click away with AP Connect

- Ready for audits and in case of complaints

- Full 21 CFR part 11 compliance

Challenge

I need to document the test results for each product and all actions carried out on the instrument. The values need to be traceable.

Solution

With DMA 1001 you can assign roles and responsibilities and implement audit trail to log all activities and electronically sign the final results.

Your benefits

Absolute certainty in your results and data. You can certify the quality of your products for shipment and sales and have all the right information at hand for audits by regulatory authorities and in case of customer complaints.

Only available with:

- DMA 1001

- Immediately see if measured values are outside specifications

- Take action to prevent costly production errors

- Minimum training required for operation

Challenge

In production control, I need a quick and easy way to check that the current production batch is according to specifications.

Solution

On DMA 501/1001 you can define the acceptable range of density values and what counts as “out-of-spec”. After a measurement time of 2 to 3 minutes the density meter shows a clear “pass” or “fail” result.

Your benefits

Immediately see if measured values are outside specifications and lose no time in correcting production. Minimizes your wasted product.

- 0.1 % accuracy gives you complete control over filling

- Never overfill, never underfill

- Automated calculation = no human error

Challenge

The final filling of packages must meet legal requirements while still being cost-efficient and error-free.

Solution

The 3-digit accuracy of DMA 501 is sufficient for converting the weight and measured density into the filling volume. For each product filled you can set the lower and upper limits for acceptable volumes and see the value at a glance.

Your benefits

Never overfill or underfill again while meeting all regulations and requirements.

- Verify the quality of a batch in less than 3 minutes

- Prevent out-of-spec batches leaving the warehouse

- Traceable documentation of results and final release signature

Challenge

As the final quality control step, we need to verify that each production batch is safe for patients before it can be shipped. Time is of the essence.

Solution

DMA 1001 flags out-of-spec batches immediately if they exceed the upper and lower limits you defined for the product.

The 21 CFR Part 11-compliant electronic signature function allows you to review, comment, and approve measured results.

The signature is stored with each data set and shown on the measurement report.

Your benefits

You can verify the quality in less than 3 minutes per batch. No out-of-spec product is released to the market. All measurements are traceably documented with a final release signature.

Only available with:

- DMA 1001

- One-click assessment

- Clear “pass/fail” result every time

- Forget calibrations and concentration tables

Challenge

We deal with many different substances every day and need to check that these delivered goods meet the specifications. I don’t have time for complicated setup, calibration, or concentration tables. What are my options?

Solution

Using DMA 1001 you can do a purity and anti-adulteration check in just one click. You can check the concentration of up to 400 different chemicals: fill the sample, wait 2 minutes for the result, and the job is done.

Your benefits

In-spec raw materials without adulteration are the key to 100 % consistent final product quality and customer satisfaction. Get these results in minutes and without compromises.

Only available with:

- DMA 1001

- Needs only 2 % of the sample required by manual methods

- Save sample, reduce production costs

- Monitored filling

Challenge

We deal with expensive raw materials, intermediate, and final products and using our current density method costs us up to 100 mL per measurement. Is there an alternative?

Solution

DMA 1001 makes it nearly impossible to waste sample. It needs approximately 1 mL of sample per measurement, much less than pycnometers or hydrometers. Technical features such as U-View™ (the built-in camera) and the automatic FillingCheck™ monitor the filling and document each filling with the result.

Your benefits

You save your expensive samples and reduce the cost of production.

Only available with:

- DMA 1001

- Maximized uptime

- No repair costs

- Maximum instrument lifetime, even in harsh industrial environments

Challenge

For our workspace we need a device that can cope with spills, knocks, and vapors in the air and still run reliably.

Solution

DMA 501 is splash-proof and protected from sample spills. Unlike other density devices, it works without needing ventilation so doesn’t suck contaminated air into the electronics.

Your benefits

With this ventilation-free density meter you get maximized uptime, have no repair costs, and maximum instrument lifetime, even in harsh industrial environments.

- No human error

- Minimum training required

- Saves costs

Challenge

The results depend on the experience and skill of the operator in charge of analysis

Solution

DMA 501 and DMA 1001 are so easy to handle they don't need qualified personnel or sample preparation.

The user interface provides useful features like dashboards for each product to give quick access to settings for measurements you repeat often.

Your benefits

This easy-to-use device saves training costs, increases work efficiency, and eliminates human errors.

- 5-times faster measurement

- Save solvents and reagents

- Quick release of the final product

- All data stored in a single digital space via AP Connect

Challenge

Titration is time-consuming and requires high amounts of solvents and reagents. What is the alternative?

Solution

DMA 501 is fast: it only takes 3 to 5 minutes to complete the analysis and there is no need to use solvents for the measurement.

Your benefits

Compared to using titration you save time and solvents. DMA 501 is 5 times faster than titration and saves you 100 mL solvents per measurement - and this reduces costs.

- Protection for operators when filling dangerous substances

- Glove-friendly touchscreen

- Approximately 1 mL sample required

Challenge

We need to test corrosive acids and bases while upholding the highest of safety standards.

Solution

Operators have only minimum contact with hazardous samples when using DMA 501. Approximately 1 mL of sample are needed and filled via the peristaltic pump. The touchscreen can be operated wearing gloves.

Your benefits

You protect your operators from dangerous substances and still get the results you need.

- Minimize mixups when loading and unloading

- One device covers the full range

- Virtually unbreakable, with 3-year warranty

Challenge

Mixups when loading and unloading fuels and lubes at the tank terminal are costly and therefore unacceptable. At the moment we are using hydrometers – is there a better way?

Solution

Whereas you need a number of different hydrometers to cover the whole range of samples, just one DMA 1001 will do the job. It covers the full range of fuels and lubes and withstands work in rugged environments. Hydrometers are prone to breakage whereas DMA 1001 is virtually unbreakable and comes with a 3-year warranty as proof of durability.

Your benefits

Minimizing mixups between product and storage location reduces the amount of wasted product and costly cleanups. One density meter will outlive many hundreds of hydrometers over the course of its working life.

Only available with:

- DMA 1001

- Zero errors converting to reference temperature

- The correct result every time

- According to API table 53 B or D (ASTM D1250)

Challenge

Using a hydrometer to measure the density of fuel or lubes at temperatures other than the reporting temperature and then converting the result to the reference temperature includes too many sources of error. Will going digital help?

Solution

For any kind of fuel or lube, DMA 1001 automatically compensates the density measured at elevated temperatures to the desired reference temperature according to API table 53 B or D.

Your benefits

Automatic conversion eliminates the need for manual calculations for all different product groups (fuels, lubes) and therefore reduces potential human calculation errors to zero.

Only available with:

- DMA 1001

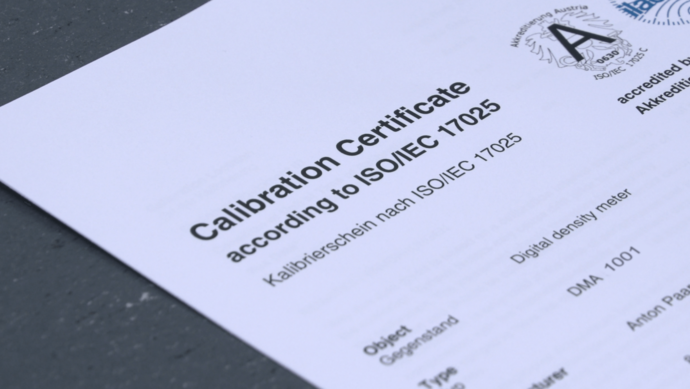

- Prevent reclamations or complaints

- Internationally acknowledged results

- 100 % certified use

Challenge

Some trading partners do not accept results from our density meter and raise concerns about the quality of the device as well as the calibration procedure. How can I counter this?

Solution

DMA 1001 can be calibrated according to ISO 17025 using traceable standards at a certified calibration laboratory. This 100 % certifies the use of DMA 1001 for volume-to-mass conversions in trade.

Your benefits

Calibration according to ISO 17025 paves the way for accurate and internationally acknowledged results. You benefit from 100 % traceability to the International System of Units (SI).

Only available with:

- DMA 1001

- Training takes around ten minutes

- Results 100 % independent of the operator

- Filling is monitored and documented

Challenge

When the density results deviate depending on the technician involved, retraining is required. Is there a way to avoid this?

Solution

DMA 1001 is so easy to operate even people with no dedicated lab training can handle it correctly. The standardized sample handling via syringe holder eliminates potential influences from different users, syringe types, or syringe filling volumes. Filling with the optional peristaltic pump ensures repeatable filling processes for samples with low viscosity. In addition, FillingCheck™ and U-View™ monitor the quality of filling, give alerts, and store a complete image for later verification.

Your benefits

Results are 100 % independent of the operator and only minimum training is required to operate the instrument.

Only available with:

- DMA 1001

- 100 % compliance with ASTM D4052 & ISO 12185

- Full traceability

- The easy way to official product certification

Challenge

Official product certification according to defined product specifications requires measurements in full compliance with established test methods, e.g. ASTM D4052 and ISO 12185.

Solution

DMA 1001 has everything ASTM D4052 stipulates: 4-digits in measuring accuracy in density, full-range viscosity correction, and real-time bubble detection via FillingCheck™.

Your benefits

No more disputes about standard compliance. Peace of mind that you can measure density in-house – in full compliance and with 100 % traceability.

Only available with:

- DMA 1001

Specifications

| DMA 501 | DMA 1001 | |

| Patents | EP3012612B1, AT520632B1, US10145771B2 | EP3012612B1, AT520632B1, US10145771B2 |

| Measuring range | Density: 0 g/cm³ to 3 g/cm³ Pressure: 0 bar to 10 bar (0 psi to 145 psi) | Density: 0 g/cm³ to 3 g/cm³ Pressure: 0 bar to 10 bar (0 psi to 145 psi) |

| Temperature: 15 °C to 40 °C (59 °F to 104 °F) | Temperature: 15 °C to 60 °C (59 °F to 140 °F) | |

| Repeatability, s.d.* | Density: 0.0002 g/cm³ Temperature: 0.1 °C (0.2 °F) | Density: 0.00005 g/cm³ Temperature: 0.02 °C (0.04 °F) |

| Reproducibility, s.d.* | Density: 0.0004 g/cm³ | Density: 0.00007 g/cm³ |

| Accuracy** | Density: 0.001 g/cm³ | Density: 0.0001 g/cm³ |

| Digital Resolution | Density: 0.0001 g/cm³ Temperature: 0.01 °C (0.01 °F) | Density: 0.00001 g/cm³ Temperature: 0.01 °C (0.01 °F) |

| U-View™ | Yes | Yes |

| FillingCheck™ | Yes | Yes |

| Full-range viscosity correction | Yes | Yes |

| Minimum sample volume | Approx. 1 mL | Approx. 1 mL |

| Integrated tables and functions | Density, Specific Gravity (SG), alcohol tables, sugar/extract tables, various acid/base tables, API functions | Density, Specific Gravity (SG), alcohol tables, sugar/extract tables, various acid/base tables, API functions |

| Wetted parts | Borosilicate glass, PTFE | Borosilicate glass, PTFE |

| Dimensions (L x W x H) | 375 mm x 265 mm x 180 mm (14.8 in x 10.4 in x 7.0 in) | 375 mm x 265 mm x 180 mm (14.8 in x 10.4 in x 7.0 in) |

| Weight | 13.5 kg (29.8 lb) | 13.5 kg (29.8 lb) |

| Power supply | AC 100 to 240 V; 47 to 63 Hz; DC 24V, 3A | AC 100 to 240 V; 47 to 63 Hz; DC 24V, 3A |

| Display | 7 inches, TFT WVGA (800 x 480 Px); PCAP touchscreen | 7 inches, TFT WVGA (800 x 480 Px); PCAP touchscreen |

| Controls | Touchscreen, optional keyboard, mouse, and bar code reader | Touchscreen, optional keyboard, mouse, and bar code reader |

| Communication interfaces | 1 x Ethernet, 3 x USB, 1 x RS232 | 1 x Ethernet, 3 x USB, 1 x RS232 |

| Internal storage | 5000 measured results; 400 products | 5000 measured results; 400 products |

| Other special functions | Integrated temperature and humidity sensor for intelligent condition monitoring Built-in pressure sensor for adjustments | Integrated temperature and humidity sensor for intelligent condition monitoring Built-in pressure sensor for adjustments Quick one-point water adjustment |

| Menu language | English, German, Chinese, Czech, French, Italian, Japanese, Korean, Polish, Portuguese, Russian, Spanish | English, German, Chinese, Czech, French, Italian, Japanese, Korean, Polish, Portuguese, Russian, Spanish |

| Available options & upgrades | Peristaltic pump Printers Aerosol filling adapter Filling kit for pasty samples ISO calibration AP Connect lab execution software | Peristaltic pump Printers Aerosol filling adapter Filling kit for pasty samples ISO calibration AP Connect lab execution software |

| Scope of supply | Compact density meter, power supply, power cable, waste vessel, density standard ultra-pure water, accessory kit (including syringes, hoses, adapters), instruction manual | Compact density meter, power supply, power cable, waste vessel, accessory kit (including syringes, hoses, adapters), instruction manual |

* according to ISO 5725

** under ideal conditions and for low densities/viscosities

Standards

ISO

Chinese Pharmacopoeia (ChP)

ASTM

DIN

JIS

IP

ABNT

US Pharmacopoeia (USP)

European Pharmacopoeia (Ph. Eur.)

Japanese Pharmacopoeia (JP)

RANP

Standards

ISO

Chinese Pharmacopoeia (ChP)

ASTM

DIN

JIS

IP

ABNT

US Pharmacopoeia (USP)

European Pharmacopoeia (Ph. Eur.)

Japanese Pharmacopoeia (JP)

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Checking the quality of maritime fuel on board Application Reports

-

Cleaning recommendations for Anton Paar DMA instruments Application Reports

-

Concentration determination of sodium hydroxide (NaOH) solutions Application Reports

-

Density measurement for inhalant supervision from aerosol cans Application Reports

-

Density measurement gets the battery industry going Application Reports

-

Density measurement of biodiesel Application Reports

-

Density measurement of cleaning agents and disinfectants Application Reports

-

Density measurement of lithium-containing electrolytes Application Reports

-

Density measurement of paints and coatings using digital density meters Application Reports

-

Density measurement of sauces and dressings with compact DMA density meter Application Reports

-

Density measurement to ensure the quality of aqueous urea solutions Application Reports

-

Determining filling volumes based on density measurement Application Reports

-

E-Book - Field Guide to Battery Materials Characterization – Revised and Updated Application Reports

-

E-Book - Field Guide to Food and Feed Testing Application Reports

-

E-Book - The Field Guide to Data Integrity in Regulated Industries Application Reports

-

E-Book - The Future of Plant-Based Foods Application Reports

-

Efficiency Meets Sustainability – Biodiesel Measurements Made Easy Application Reports

-

Ensuring quality in medical hemp extract products with DMA density meters Application Reports

Similar products

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

HOSE 145X3X2 PTFE 2X¼"–28 UNF

DMA 1001 | 501

HOSE 83X3X2 PTFE 2X1/4"-28 UNF

DMA 1001 | 501

SIDE PANEL DMA 501 / 1001

DMA 1001 | 501

PROTECTIVE COVER DMA 501/1001 V2

DMA 1001 | 501

made of PET/G Compatible with housing version 2 only (mat. no. 263677) - devices with serial number from 84300201

PROTECTIVE COVER DMA 501/1001 XS200HR V2

DMA 1001 | 501

made of PET/G for Xsample 200 High-Resistant (mat. no. 187548) For DMA 501/1001 only compatible with housing version 2 (mat. no. 263677) - devices with serial number from 84300201

PROTECTIVE COVER DMA 501/1001 XS200HR V1

DMA 1001 | 501

made of PET/G for Xsample 200 High-Resistant (mat. no. 187548) For DMA 501/1001 only compatible with housing version 1 (mat. no. 188229) - decives with serial number up to 84282385

PROTECTIVE COVER DMA 501/1001 V1

DMA 1001 | 501

made of PET/G For DMA 501/1001 only compatible with housing version 1 (mat. no. 188229) – decives with serial number up to 84282385

SYRINGE 5 mL LUER (WITHOUT SEAL)

DMA 1001 | 501

FOAM PACKAGE DMA™ 501 / 1001

DMA 1001 | 501

SYRINGES 10 ml LUER (100 pcs.)

DMA 1001

VISCOSITY STANDARD ANTON PAAR N100 100 ml - 280 / 86 / 9.7 mPa.s

DMA 1001

280 / 86 / 9.7 mPa.s

VISCOSITY STANDARD ANTON PAAR N100 500 ml - 280 / 86 / 9.7 mPa.s

DMA 1001

VISCOSITY STANDARD ANTON PAAR N14 500 ml - 25 / 12 / 2.7 mPa.s

DMA 1001

VISCOSITY STANDARD ANTON PAAR N1400 100 ml - 5000 / 1200 / 74 mPa.s

DMA 1001

VISCOSITY STANDARD ANTON PAAR N1400 500 ml - 5000 / 1200 / 74 mPa.s

DMA 1001

VISCOSITY STANDARD ANTON PAAR N26 (C) 100 ml - 50 / 21 / 4.2 mPa.s

DMA 1001

Recommended for DIN/SSA/UL spindles

VISCOSITY STANDARD ANTON PAAR N26 (C) 500 ml - 50 / 21 / 4.2 mPa.s

DMA 1001

VISCOSITY STANDARD ANTON PAAR N415 (H) 100 ml - 1100 / 330 / 32 mPa.sc

DMA 1001

Recommended for DIN/SSA/UL spindles

VISCOSITY STANDARD ANTON PAAR N415 (H) 500 ml - 1100 / 330 / 32 mPa.s

DMA 1001

VISCOSITY STANDARD ANTON PAAR N7.5 (M) 100 ml - 10 / 5.4 / 1.6 mPa.s

DMA 1001

Recommended for DIN/SSA/UL spindles

VISCOSITY STANDARD ANTON PAAR N7.5 (M) 500 ml - 10 / 5.4 / 1.6 mPa.s

DMA 1001

VISCOSITY STANDARD ANTON PAAR N75 500 ml - 164 / 61 / 8.8 mPa.s

DMA 1001

VISCOSITY STANDARD ANTON PAAR S3 (L) 100 ml - 3.7 / 2.3 / 0.9 mPa.s

DMA 1001

Recommended for DIN/SSA/UL spindles

VISCOSITY STANDARD ANTON PAAR S3 (L) 500 ml - 3.7 / 2.3 / 0.9 mPa.s

DMA 1001

VISCOSITY STANDARD ANTON PAAR S6 500 ml - 8.8 / 4.7 / 1.5 mPa.s

DMA 1001

ANGULAR SCREWDRIVER TORX T10

DMA 1001

HOSE 250x3x2 FEP 2x1/4"-28 UNF "BB"

DMA 1001

HOSE 5x8 VITON-BK ISO VERSINIC

DMA 1001

AP DENSITY STANDARD DODECANE 1x10 mL WITH ISO 17034 CERTIFICATE

DMA 1001 | 501

- Density standard with low density (750 kg/m³)

- Organic liquid

- Measuring uncertainty: 0.015 kg/m³

- Specified temperature range: 15 °C – 50 °C

- Durability: 18 months

- Volume: 10 mL

- ISO 17034-certified reference material

- Complies with ISO 17025 and ISO 17034 requirements

AP DENSITY STANDARD SODIUM BROMIDE 1x10 mL WITH ISO 17034 CERTIFICATE

DMA 1001 | 501

- Density standard with high density (1250 kg/m3)

- Aqueous liquid

- Measuring uncertainty: 0.03 kg/m³

- Specified temperature range: 15 °C – 25 °C

- Durability: 18 months

- Volume: 10 mL

- ISO 17034-certified reference material

- Complies with ISO 17025 and ISO 17034 requirements

AP DENSITY STANDARD GLUCOSE / WATER 10% 1x10 mL WITH ISO 17034 CERTIFICATE

DMA 1001 | 501

- Density standard with medium density (1040 kg/m3)

- Aqueous liquid

- Measuring uncertainty: 0.02 kg/m³

- Specified temperature range: 15 °C – 25 °C

- Durability: 18 months

- Volume: 10 mL

- ISO 17034-certified reference material

- Complies with ISO 17025 and ISO 17034 requirements

AP DENSITY STANDARD WATER 1x10 mL WITH ISO 17034 CERTIFICATE

DMA 1001 | 501

- Density standard with medium density (998 kg/m3)

- Aqueous liquid

- Suitable for density adjustments

- Measuring uncertainty: 0.015 kg/m³

- Specified temperature range: 15 °C – 35 °C

- Durability: 18 months

- Volume: 10 mL

- ISO 17034-certified reference material

- Complies with ISO 17025 and ISO 17034 requirements

AP DENSITY STANDARD OIL 30 cSt @ 40 °C 1x10 mL, WITH ISO 17034 CERTIFICATE

DMA 1001 | 501

- Density standard with low density (830 kg/m3)

- Organic liquid

- Viscous liquid

- Measuring uncertainty: 0.015 kg/m³

- Specified temperature range: 15 °C – 50 °C

- Durability: 18 months

- Volume: 10 mL

- ISO 17034-certified reference material

- Complies with ISO 17025 and ISO 17034 requirements

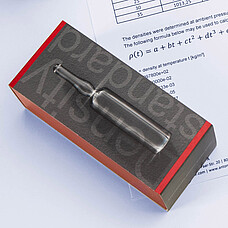

ISO 17034-Certified Reference Material:

Density Standards

DMA 1001 | 501

- Market-leading uncertainty of 0.015 kg/m³ (ISO 17034)

- Application-specific density standards, available via webshop

- Online certificate with lifetime reference values guarantee

- Conformity with ISO requirements ISO 17025 and even ISO 17034

- Safety glass ampoule for zero contamination

GENDER CHANGER DB9F/DB9F

DMA 1001 | 501

HOSE 3.2x6.4 mm TYGON A-60-G, BLACK (FORMERLY:

NORPRENE A-60-G)

DMA 1001 | 501

DENSITY STANDARD SODIUM BROMIDE

DMA 1001 | 501

SYRINGE HOLDER 5 ml FOR 5 ml PLASTIC SYRINGE

DMA 1001 | 501

HOSE 3x5 SILICONE

DMA 1001 | 501

HOSE 4X6 SILICONE

DMA 1001 | 501

SYRINGES 2 ml LUER (10 PCS)

DMA 1001 | 501

PRINTER CONNECTION CABLE

DMA 1001 | 501

ADAPTER UNF 1/4"-LUER MALE

DMA 1001 | 501

DRYING CARTRIDGE

DMA 1001 | 501

KEYBOARD USA USB

DMA 1001 | 501

KEYBOARD GERMAN USB

DMA 1001 | 501

PRINTER PAPER FOR EPSON TM-U220

DMA 1001 | 501

RIBBON CARTRIDGE FOR EPSON PRINTER TM-U220

DMA 1001 | 501

PRINTER EPSON TM-U220

DMA 1001 | 501

PROTECTING COVER FOR KEYBOARD

DMA 1001 | 501

In combination with keyboard (80809 or 80807)

FILTER SET DMA 501 / 1001

DMA 1001 | 501

ACCESSORY KIT FOR PASTY SAMPLES DMA 501 / 1001

DMA 1001 | 501

A syringe holder, mat. no. 25921, has to be ordered separately.

HOSE CLAMP DMIN 5.8 DMAX 6.5

DMA 1001 | 501

ACCESSORY KIT DMA 501 / 1001

DMA 1001 | 501

ACCESSORIES Xsample 200 HIGH-RESISTANCE

DMA 1001 | 501

SYRINGE HOLDER

DMA 1001 | 501

TUBE CLIP SET FOR 2mm (9QQ)

DMA 1001 | 501

TUBE CLIP SET FOR 3 AND 3.5mm (9QQ)

DMA 1001 | 501

ADAPTER LUER 1/4" UNF

DMA 1001 | 501

MALE LUER PLUG

DMA 1001 | 501

ADAPTER LUER CONE

DMA 1001 | 501

HOSE 140x3x2 PTFE 2x1/4"-28 UNF

DMA 1001 | 501

HOSE 3.2x6.4 mm TYGON CHEMICAL (FORMERLY:

NORPRENE CHEMICAL)

DMA 1001 | 501

For use with Xsample modules from Serial Nr. 80977476 - 81464920 please contact Anton Paar GmbH.

HOSE 2.5 x 4.5 NOVOPRENE

DMA 1001 | 501

SYRINGE 2 ml LUER (1 PCS)

DMA 1001 | 501

SYRINGES 2 ml LUER (1000 PCS)

DMA 1001 | 501

SYRINGES 5 ml LUER (100 pcs.)

DMA 1001 | 501

SYRINGES 5 mL LUER-LOCK (100 PCS)

DMA 1001 | 501

SYRINGE 10 mL LUER-LOCK

DMA 1001 | 501

One-way syringe (volume: 10 ml) with Luer-Lock fitting

PRINTER PAPER 57x30 STANDARD

DMA 1001 | 501

RIBBON CARTRIDGE FOR CITIZEN PRINTER CBM910 / IDP3110

DMA 1001 | 501

PRINTER CONNECTION CABLE

DMA 1001 | 501

For printer DP1014, CBM910 and Epson TM-U220. D SUB 25P-Male/9P-Female

Lab Execution System:

AP Connect Start

DMA 1001 | 501

- Kickstart your paperless lab

- Featuring key benefits of the Standard edition

- Restricted to one instrument, single user access, one export rule

Lab Execution System:

AP Connect Standard one-time license

DMA 1001 | 501

- One-time fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Standard subscription license

DMA 1001 | 501

- Annual fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Pharma one-time license

DMA 1001 | 501

- One-time fee per instrument

- Time-saving processes: automatic, digital data transfer

- Assurance of lab data integrity

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Pharma subscription license

DMA 1001 | 501

- Annual fee per instrument

- Time-saving processes: automatic, digital data transfer

- Assurance of lab data integrity

- Fast decisions: data at your fingertips

CABLE TIE HEAT-RESISTANT 100 pcs

DMA 501

DENSITY STANDARD ANTON PAAR N100HT 100 ml - 0.818/0.788 g/cm³ at 100/150 °C

DMA 1001 | 501

DENSITY STANDARD DICHLOROTOLUENE 1x10mL WITH UKAS CERTIFICATE

DMA 1001 | 501

1250 kg/m³, 10 °C - 50 °C

ADAPTER LUER LOCK 1/8"

DMA 1001 | 501

Filling Device for Aerosols:

Aerosol Adapter

DMA 1001 | 501

- Equips your density meter to fill aerosols

- Valves are available to fit all types of spray can: Just remove the spray nozzle, insert, and fill

- Results after 1 to 3 min

Peristaltic Pump for DMA 501/1001:

Xsample 200 High-Resistance

DMA 1001 | 501

- Peristaltic pump for DMA 501/1001, to fill fluids up to 3,000 mPa·s

- Replaces sample in seconds, without intermediate cleaning

- Minimizes your contact with hazardous substances

- Highly resistant wetted parts for handling aggressive samples