Surface characterization

Researching surface modification to develop high-performing materials is one of the main objectives in surface characterization today. Similar to the quality control of manufacturers, it calls for accurate analysis of a range of parameters, including mechanical, chemical, and tribological surface properties: hardness, stiffness or elasticity, resistance, potential/charge, structure, and many more. Anton Paar provides different solutions for surface characterization, suited for researchers and manufacturers alike.

Surface characterization of biomaterials

When measuring the surface properties of biomaterials, researchers and also manufacturers face special challenges. A main objective is to predict how a material will react when implanted into the human body and how it will interact with biological tissues, fluids, etc. Clinical trials on immune response are costly so measuring everything before that, with the aim of predicting the materials’ behavior, is key. Other research fields are devoted to the development of new, better materials to advance medical treatment of a range of illnesses, or to providing better medical products for their customers.

Typical studies on biomaterials include measuring hardness and structural properties, characterization of surface charge, surface interaction, hydrophobic/hydrophilic properties, and many more. Anton Paar has developed specialized solutions for the surface analysis of biomaterials such as prostheses, implants, tissues, biopolymers and biofilms, teeth, various ophthalmic applications, and for medical devices such as stents, pills, and membranes.

By gaining the right analysis data it becomes possible to understand materials and their behavior at a molecular level. Having the right – and accurate – data has an enormous impact on really knowing a material and seeing how even subtle changes affect the performance of a material. Find out more about the analysis of a range of important biomedical samples right below.

Tribology of urinary catheters and artificial skin

Medical devices face high demands in terms of performance and product safety as well as from FDA and MDR regulations. Here we present a methodology in which you can run tribological model system tests with urinary catheters and artificial skin. An MCR tribometer with sample holders that allow for fixation of medical device components as well as soft tissues is used for catheter testing. The temperature-, force-, and speed control of the MCR tribometer enable you to define test parameters to simulate real-world conditions.

Developing better dental implants

When researching biocompatible coatings for implant materials, one crucial parameter is the interaction of the implant with its biological environment.

You can use the SurPASS 3 surface zeta potential analyzer to study the interaction of proteins in solution with the implant material. In-depth knowledge in this field will enable you to develop dental implants that are resistant to bacterial biofilm formation and thus help diminish the risk for infections or implant failure.

Download the SurPASS 3 biomaterials folder to see how zeta potential analysis combines the determination of adsorption kinetics with the characteristics of the adsorbed surface layer.

Mechanical characteristics of tooth enamel

Analyzing mechanical properties on and below the treated enamel surface is of great interest for teeth treatments, e.g. in caries (cavities) prevention or for the minimally invasive treatment of early caries lesions.

Nanoindentation is one of the most adapted methods for such samples and provides a clear insight into the hardness gradient of tooth enamel (teeth hardness). The obtained analysis data is an essential basis for selecting new materials for dental repair materials.

Download the application report to see how the NHT³ benchtop nanoindentation tester has been used for an according study.

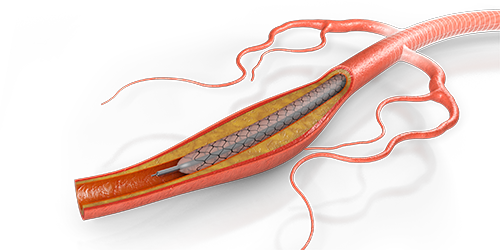

A clear testing method for the quality control of stent coatings

Stents are a medical mass application. They underlie strict regulation from state authorities such as the FDA and need to pass severe quality control before they may be used on the patient.

Scratch testing is one of the few methods that can verify the adhesion of a coating and thereby ensure a sufficiently long lifetime of the implant. To make sure stents behave as required – e.g. release certain chemical products – and are not damaged in the body, adhesion and scratch resistance of the coating are measured with an NST³ nano scratch tester.

Download the application report to see how stents can be mounted in the scratch tester and how the critical load of the coating is determined.

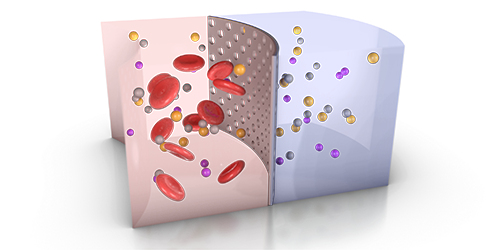

Biocompatibility of hemodialysis membranes

If you want to prove the existence of a certain surface modification that improves the biocompatibility on the inner surface of a hemodialysis membrane, zeta potential measurements are the right analysis method for you.

The zeta potential is sensitive even to small changes in the surface chemistry. Zeta potential measurement thus assists with improving the biocompatibility of hemodialysis membranes. Dedicated sample holders for hollow fiber membranes make it possible to directly characterize the inner surface of the membranes.

You can easily conduct zeta potential measurements with the SurPASS 3 electrokinetic analyzer.

More about zeta potential in general is explained in this Wiki article: Zeta Potential

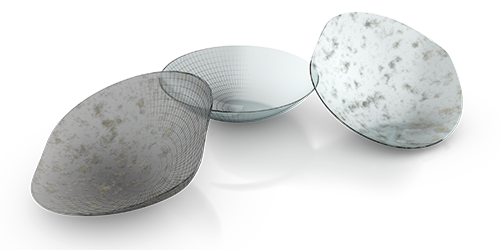

Improvement of contact lenses comfort

Soft contact lenses are used by many people, so their wearing comfort is essential for everyone who wears them on a daily basis.

Friction and elasticity are key factors for determining the wearing comfort. With excellent resolution and research-oriented special features such as controlled force vs. depth measurements, you gain a deep insight into the characteristics of contact lenses. You can then use the results to improve their friction properties to satisfy the demands of your customers even better.

Download the application report to see how the UNHT³ Bio bioindenter (with a special contact lens sample holder) is used for research.

Aging behavior of contact lenses

Contact lenses often are intended for use over a certain period of time (e.g. 1 month, 1 year). They should be as good on the last day of use as they were on the first which is why their aging behavior is of great interest.

Aging of materials is usually difficult to estimate, but knowing the elasticity of a material provides a valid scientific insight into the aging process. The UNHT³ Bio bioindenter measures the elasticity of a contact lens; this data can be used to verify the change of mechanical properties due to aging.

Download the application report to see how the bioindenter can be used to characterize the mechanical behavior of contact lenses and biomaterials.

Hydrogel testing under real-life conditions

Testing of hydrogels is perceived as complicated due to the difficulty of mounting them in or on a sample holder, and because even minor changes in the pressures exerted on them can lead to a significant influence on their tribological properties.

Accurate testing results, not influenced by external factors, are achieved with an MCR tribometer with a special sample holder for hydrogels. Beyond that, it allows the optimal adaption to real-life conditions in terms of contact pressure, sliding velocities, and temperature, and has a high sensitivity when measuring friction, especially over a broad range of sliding velocities – from a few nm/s to an excess of 1 m/s.

Simulating human conditions when testing contact lens fluids

Ophthalmic solutions need to have low friction and it is difficult to mimic human conditions on a machine. However, the need to test these solutions arises from, both an economic and a comfort aspect.

An MCR tribometer measures the friction coefficient at different sliding velocities and normal forces. Its extreme low-speed capability allows you to characterize both static and kinetic friction. In most cases, the accurately determined boundary friction is critical in testing the overall performance of the fluid.

Read more

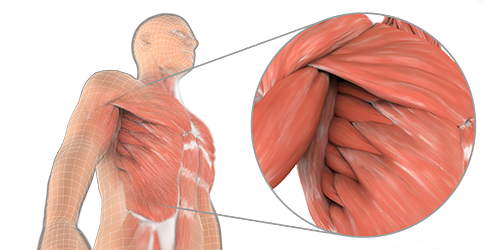

Investigating (human) tissue to research disease evolution and treatment

Properties of human and artificial tissues are a wide field as researchers around the world work on understanding and healing diseases of all kinds.

Many human tissues are subject to mechanical loading and their mechanical characterization can provide valuable information for disease evolutions, treatments, and developments of artificial replacements (implants, scaffolds). The initial lack of sensitive instrumentation in this area has recently been addressed by Anton Paar with the UNHT³ Bio bioindenter.

Download the application report to see how it is used to test, both, tissues and their potential replacement materials.

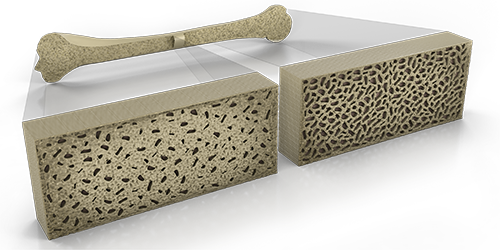

Test methods for the development of osteoporosis medication

Osteoporosis is decreasing bone hardness (increased bone weakness), in most cases due to age.

Active substances in medications have a direct effect on the characteristics of the bone, so bone hardness, elastic modulus of bone, and bone creep are key parameters in the development of new medication. High-resolution analysis of those parameters is an essential support of research results when filing patents or promoting new active substances for testing processes or market launch.

All parameters can be measured with the UNHT³ Bio bioindenter: elastic modulus and creep properties of bones.

Additional benefit for researchers: Anton Paar cooperates closely with several universities to develop affordable artificial bone materials for research purposes. These cooperations give you access to know-how and special developments, such as sample holders for complex samples, and help us develop individual solutions for you if you need them. Contact an Anton Paar representative to get more information.

Finding medically and economically valuable cartilage substitutes

The quest for a substitute for cartilage material is still ongoing. However, issues such as sample preparation and mounting make the investigation of mechanical properties of cartilage challenging. Also, when dealing with biological fluids, the sample volume available for testing is limited. All of this calls for an appropriate test setup.

The low-speed, low-torque capabilities of the MCR tribometer comprise a time- and cost-efficient test setup which offers unique possibilities for friction and wear tests of natural and artificial cartilage as well as substitutes of synovial fluids.

Download the application report to see how MCR is used for the biotribological investigation of cartilage.

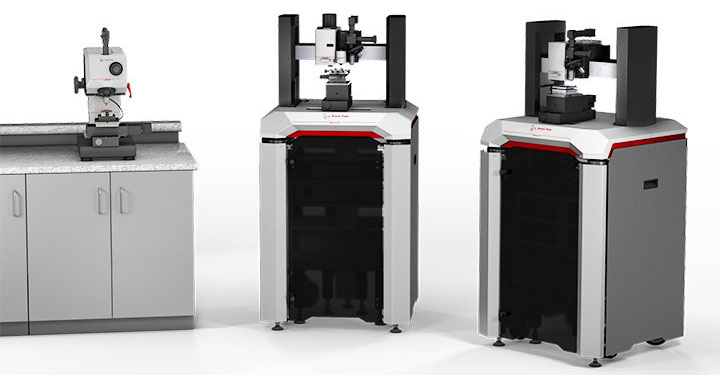

Testing equipment for laboratories and manufacturers of biocompatible materials

Biomaterials are often sensitive, easily influenced by external factors, and difficult to mount in measuring instruments. This calls for highly accurate testing equipment that can easily be adapted for samples such as contact lenses, tissues, gels, fluids, and more.

Anton Paar offers specialized instruments that are widely used in biocompatibility testing laboratories:

- UNHT³ Bio bioindenter

- MCR tribometer

- NST³ nano scratch tester

- NHT³ nanoindentation tester

- SurPASS 3 surface zeta potential analyzer

- Abbemat refractometer

A range of special sample holders for contact lenses, hydrogels, and other accessories is available to optimally support labs in their biomedical research as well as manufacturers in biomaterial processing and quality control.

If you want to try our instrumentation hands-on, have a look at the seminars and offers in the Anton Paar Technical Centers or directly contact an Anton Paar representative to request more information or a demo:

Contact us

3-year warranty

- Effective January 1, 2020, all new Anton Paar instruments* include repair for 3 years.

- Customers avoid unforeseen costs and can always rely on their instrument.

- Alongside the warranty there is a wide range of additional services and maintenance options available.

* Due to the technology they use, some instruments require maintenance according to a maintenance schedule. Complying with the maintenance schedule is a prerequisite for the 3-year warranty.

Events

Quantifying Mouthfeel – Tribology and it’s Applications in Food Analysis

20-Mar-2025

12:00 – 13:00

Application of instrumented indentation, scratch testing and tribology for thermal spray coatings

05-Nov-2024

09:00 – 09:45

+ additional 1 events

Anton Paar Solutions for Nano Formulation-Size and Stability Studies

19-Nov-2024

12:00 – 13:00

Master the Science of Polymers. Dominate the Industry Unleash Your Potential!

19-Nov-2024

08:30 – 17:00

Seminar

Basic training |

Montreal, Canada

Beyond the Surface Module 1 - Indentation Series: From Basic to Advanced Indentation Testing

19-Nov-2024, 12:00 – 07-Jan-2025, 13:00

Workshop Farmacêutica – Uma parceria Veolia e Anton Paar

26-Nov-2024

Workshop

São Paulo, Brazil

Beyond the Surface Module 2 - Scratch Series: From Basic to Advanced Scratch

21-Jan-2025, 13:00 – 18-Feb-2025, 14:00

Optimizing Animal Feed Production: Mixing, Extrusion, Texture, and Tribology

04-Feb-2025

12:00 – 13:00

Beyond the Surface Add on Module 3 - Indentation and Scratch Applications: Gain Industry-specific application knowledge

04-Mar-2025

13:00 – 14:00

+ additional 3 events

Surface characterization solutions by Anton Paar

Tribology

Studying materials under in-service conditions with all necessary measuring geometries

To obtain information on a material’s performance under the influences of various external conditions

such as temperature and humidity, knowledge of the tribological behavior is essential. Tribometers

determine the friction, wear, and lubrication properties of all kinds of materials.

To obtain information on a material’s performance under the influences of various external conditions

such as temperature and humidity, knowledge of the tribological behavior is essential. Tribometers

determine the friction, wear, and lubrication properties of all kinds of materials.

Anton Paar’s longstanding expertise is reflected in an instrument range which spans from standard pin-on-disk models to models for high temperatures, nanomaterials, humidity and vacuum applications, as well as an MCR tribometer combining tribology with rheology.

I want to know moreScratch testing

The best possible view of a scratch in full compliance with international standards

Scratch testers are used to characterize film-substrate systems in terms of coating adhesion,

scratch resistance, and mar resistance. Anton Paar scratch testers stand out for their patented

technologies such as a synchronized panorama view of the actual scratch and the scratch curve.

Scratch testers are used to characterize film-substrate systems in terms of coating adhesion,

scratch resistance, and mar resistance. Anton Paar scratch testers stand out for their patented

technologies such as a synchronized panorama view of the actual scratch and the scratch curve.

The documentation of measurements complies with international standards and samples can be reanalyzed or compared with previous results at any time.

I want to know moreCoating thickness measurement (Calo tests)

Quick and simple determination of coating thicknesses

Since the coating thickness has an impact on the final product, accurate yet inexpensive measurements

are of great importance to guarantee reliable coating quality.

Since the coating thickness has an impact on the final product, accurate yet inexpensive measurements

are of great importance to guarantee reliable coating quality.

To meet those needs, Anton Paar Calotesters employ the simple ball-cratering method. This cost-efficient characterization technique allows for measurements within 1 to 2 minutes, in compliance with international standards, thereby ensuring data quality, enhancing throughput, and saving costs.

I want to know moreSurface charge analysis

A fast and direct analysis of real samples reflecting individual surface properties

Many materials are subject to modifications due to storage, aging, or wear during operation.

To predict these changes and to develop optimized, new, and high-performance materials, the materials

are tested under real-life conditions. Properties such as surface charge, adsorption/desorption,

or electrostatic attraction/repulsion enable us to understand membrane fouling, the cleaning

effects of detergents, adhesion of biological substances, and much more. These insights are gained

by simply measuring the zeta potential of a surface.

Many materials are subject to modifications due to storage, aging, or wear during operation.

To predict these changes and to develop optimized, new, and high-performance materials, the materials

are tested under real-life conditions. Properties such as surface charge, adsorption/desorption,

or electrostatic attraction/repulsion enable us to understand membrane fouling, the cleaning

effects of detergents, adhesion of biological substances, and much more. These insights are gained

by simply measuring the zeta potential of a surface.

Anton Paar is a pioneer in analyzing the zeta potential of macroscopic solid materials and has transformed this surface analysis technique into a routine application in daily laboratory work.

I want to know moreIndentation testing

Measure what others estimate and get results quicker

Indentation tests provide information on the mechanical properties such as hardness and elastic

modulus of thin films, coatings, and substrates. Anton Paar is the only company to provide a

nanoindentation tester with a real force sensor that actually measures the force applied to a

sample instead of estimating the values based on an actuator.

Indentation tests provide information on the mechanical properties such as hardness and elastic

modulus of thin films, coatings, and substrates. Anton Paar is the only company to provide a

nanoindentation tester with a real force sensor that actually measures the force applied to a

sample instead of estimating the values based on an actuator.

The new generation of indentation testers is equipped with the “Quick Indentation” mode that delivers results 8 times faster than previous instrument generations.

I want to know moreGrazing-incidence small-angle X-ray scattering (GISAXS)

Best equipped for particle surface studies with the laboratory SAXS/WAXS/GISAXS beamline

GISAXS is an important tool for investigating nanostructured surfaces and thin films. The nanostructure

determines a material’s properties and affects the usability of industrial coatings, printing

techniques, electronics, medical sensors, energy storage media, and many more. Investigating

nanostructures under changing or extreme external conditions such as elevated temperatures and

humidity enables you to tune and optimize materials.

GISAXS is an important tool for investigating nanostructured surfaces and thin films. The nanostructure

determines a material’s properties and affects the usability of industrial coatings, printing

techniques, electronics, medical sensors, energy storage media, and many more. Investigating

nanostructures under changing or extreme external conditions such as elevated temperatures and

humidity enables you to tune and optimize materials.

Since the 1950s, Anton Paar has been a leader in the field of SAXS. This leading expertise is embodied by SAXS/WAXS/GISAXS systems with the highest resolution on a compact footprint for daily nano research, efficient characterization of diverse samples (from liquid to solid), and new method development.

I want to know moreRefractometry

Fast determination of the refractive index for optical surface characterization

One of the most important optical parameters for the characterization of modern visual aids is the refractive index, which influences the refraction of light when it passes through the respective material, for example polymer films and glasses. The refractive index is used for material checks or material characterization to ensure a constantly high product quality.

One of the most important optical parameters for the characterization of modern visual aids is the refractive index, which influences the refraction of light when it passes through the respective material, for example polymer films and glasses. The refractive index is used for material checks or material characterization to ensure a constantly high product quality.

Measure the refractive index and concentration of biomaterials from contact lenses to modern glasses using the Abbemat series of laboratory refractometers from Anton Paar.

I want to know more