| | Autosorb 6100 | Autosorb 6200 | Autosorb 6300 |

| Dimensions (W x D x H) | 79.5 cm x 70.1 cm x 107.9 cm (31.3 in x 27.6 in x 42.5 in) dependent on instrument configuration |

| Weight | 136.4 kg (300 lbs) dependent on instrument configuration |

| Operating environment | - Temperature: 15 °C to 35 °C (59 °F to 95 °F)

- Humidity: 20% RH to 80% RH, non-condensing

|

| Gas distribution manifold elastomers | FKM | FKM or EPDM (dependent on instrument configuration) | PFE |

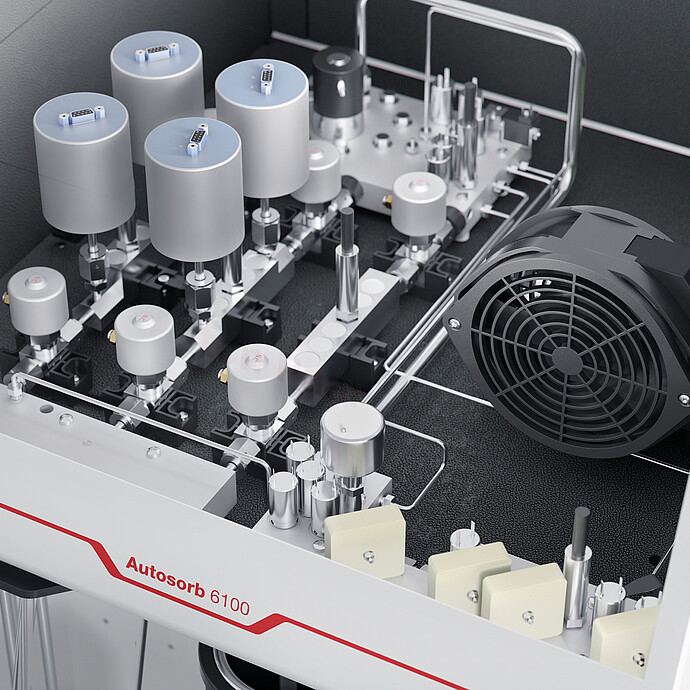

| Analysis manifold construction | Vacuum-brazed manifold block in stainless steel |

| Analysis manifold temperature | - Range: user adjustable 35 °C to 50 °C

- Stability: ±0.05 °C

|

| Analysis manifold valves | - Type: stainless steel, air-operated bellows valve

- Cycle life: 5,000,000 cycles

- External leak rate: 5x10-12 Pa m3/sec

- Seat leak rate: 5x10-12 Pa m3/sec

|

Pressure transducer (1550 Torr)

-Analysis and degas | - Number: 3 to 5 (dependent on instrument configuration)

- Accuracy: ±0.065% full scale* (*This value incorporates precision, linearity, and hysteresis for the entire pressure measurement system)

- A/D data acquisition: 32 bit

|

Pressure transducer (10 Torr)

– MP or XR | - Number: 1 to 3 (dependent on instrument configuration)

- Accuracy: ±0.15 % reading up to 10 Torr

- Resolution: 0.002 % full scale

|

Pressure transducer (1 Torr)

– MP only | - Number: 1 to 3 (dependent on instrument configuration)

- Accuracy: ±0.15 % reading up to 1 Torr

- Resolution: 0.002 % full scale

|

Pressure transducer (0.1 Torr)

– XR only | - Number: 1 to 3 (dependent on instrument configuration)

- Accuracy: ±0.15 % reading up to 0.1 Torr

- Resolution: 0.001 % full scale

|

Pirani vacuum gauge

– Degas only | - Number: 1

- Accuracy:

5×10-4 to 1x10-3 Torr: ±10 % of reading

1×10-3 to 100 Torr: ±5 % of reading - 100 Torr to atmosphere: ±25 % of reading

|

| Vacuum system | - Turbo molecular drag pump and dry diaphragm pump

- Manufacturer’s specification: 5x10-10 mbar

- Typical pressure at analysis port: 2.67x10-5 mbar

|

| Thermal conductivity detector (TCD) | N/A | - Two-filament TCD with rhenium/tungsten filaments (optional)

- Detection Limit: 0.5 uL (air injected into helium)

| - Two-filament TCD with rhenium/tungsten filaments (standard)

- Detection Limit: 0.5 uL (air injected into helium)

|

| Gas ports | - 7 ports standard (5 analysis, 1 helium, 1 degas/backfill)

- 7 additional analysis ports optional

| - 7 ports standard (5 analysis, 1 helium, 1 degas/backfill)

- 7 additional analysis ports optional

- 1 titration gas port optional

| - 15 ports standard (12 analysis, 1 helium, 1 degas/backfill, 1 titration)

|

| Gas supply | - Purity: 99.999 %

- Input pressure: 8 psig to 10 psig (0.55 bar to 0.69 bar)

|

| Air | - Input pressure: 50 psig to 100 psig (3.45 bar to 6.9 bar)

|

| Electrical | - Supply: 100 to 240 VAC ±10%, 50 or 60Hz

- Maximum consumption: 1600W (dependent on instrument configuration)

|

| PC connection | Ethernet |

| RoHS3 compliant | Yes |

| CE / UKCA certified | Yes |

| Indoor/outdoor use | For indoor use only |