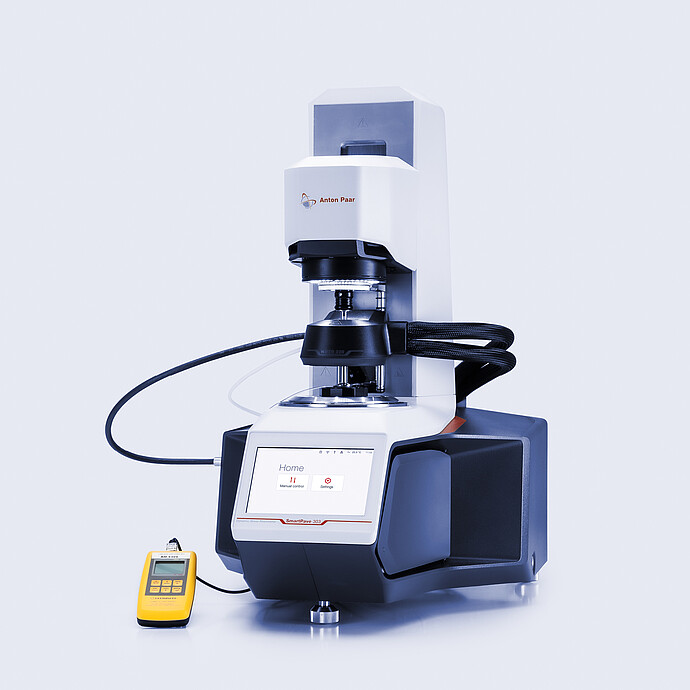

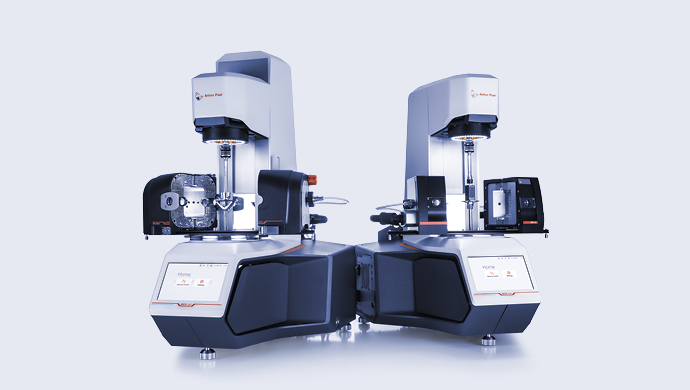

| Technical Data | Unit | SmartPave 92 | SmartPave 303 |

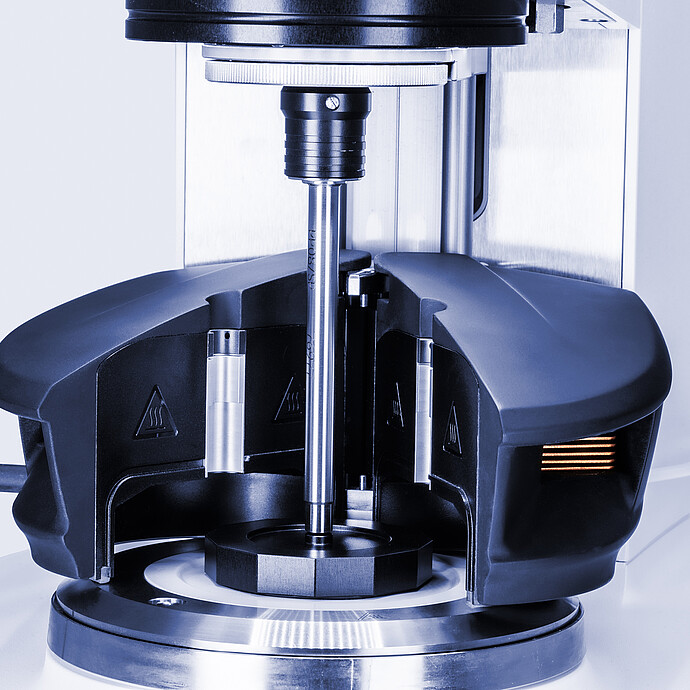

| Bearing design | - | Air, fine-pored carbon |

| Motor design | - | Electronically Commutated (EC) - Permanent Magnet Synchronous Motor |

| Displacement transducer design | - | High-resolution optical encoder |

Normal force measurment design

(US Pat. 6167752,1996) | - | - | 360 ° capacitive sensor, non-contacting, fully integrated in bearing |

| Working mode | - | Combined Motor Transducer (CMT) |

Minimum torque

(rotation) | nNm | 0.4 µNm | 5 |

Minimum torque

(oscillation) | nNm | 0.4 µNm | 1 |

| Maximum torque | mNm | 125 | 215 |

| Minimum angular velocity[1] | rad/s | 0 | 0 |

| Maximum angular velocity | rad/s | 157 | 314 |

| Maximum speed | 1/min | 1500 | 3000 |

| Minimum frequency[2] | Hz | 10-4 | 2 x 10-8 |

| Maximum frequency[3] | Hz | 100 | 200 |

| Normal force range | N | - | -50 to 50 |

| Normal force sensitivity | N | - | 0.001 |

| Dimensions (W x H x D) | mm | 380 x 660 x 530 | 453 x 725 x 673 |

| Weight | kg | 33 | 48 |

| Additional Device Features |

| Device display with remote control of software (decoupled from measuring sensor for mechanical and electromagnetic interference prevention) | - | Yes | Yes |

| Direct strain/stress controller | - | Yes | Yes |

| TruStrain™ (sample adaptive controller) | - | No | Yes |

| TruRate™ (sample adaptive controller) | - | No | Yes |

| Raw data (LAOS, waveform) | - | No | Yes |

| Normal force profiles (set and read) | - | No | Yes |

| Velocity profiles, tack, squeeze | - | No | Yes |

| Automatic gap control/setting (AGC/AGS) | - | Yes | Yes |

| Electronic trim lock for measuring geometry | - | Yes | Yes |

Toolmaster™

(measuring geometries and accessories, storing of zero-gap)

(US Pat. 7275419, 2004) | - | Yes | Yes |

QuickConnect Coupling for measuring geometries

(one-hand operation, screwless) | - | Yes | Yes |

Trimming mirror

(360° blind sample spot prevention) | - | No | Yes |

Three-point support of device

(three robust feet for tool-free one hand alignment) | - | Yes | Yes |

Three-point support for mounting of measuring cells

(wobble prevention, no misalignment after changing of cells) | - | Yes | Yes |

| Maximum temperature range[4] | °C | -50 to +400 | -160 to +1000 |

Virtually gradient-free temperature control

(horizontal,vertical) | - | Yes | Yes |

| Temperature gradient <0.1 °C according to AASHTO and ASTM | - | Yes | Yes |

| CoolPeltier™ Peltier System with built-in cooling option that does not require additional accessories for counter cooling | °C | -5 to +200 | -5 to +200 |

| Pressure Cell | bar | No | up to 1000 |

| Safe Gap™ normal force limiter during gap setting | - | Yes | No |

| TruRay™ dimmable illumination of sample area | - | Yes | Yes |

| RheoCompass Software |

| Asphalt standard operation procedures (SOP) with regular updates | - | Yes | Yes |

| Auto Update via Network | - | Optional | Optional |

| Fully automatic temperature calibration | - | Yes | Yes |

| Test and analysis designer | - | Yes | Yes |

Report designer

(with all test information for export and print) | - | Yes | Yes |

| Managed lab multiple clients and servers | - | Optional | Optional |