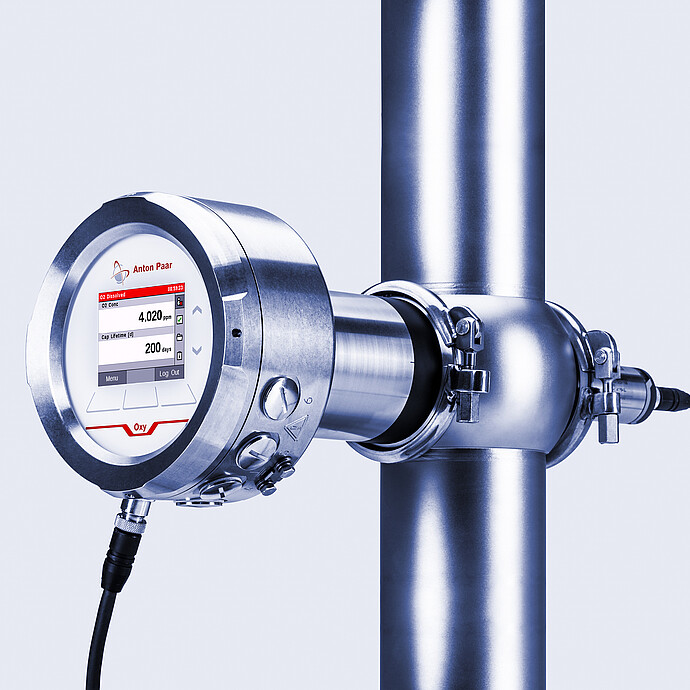

Capteur d'oxygène en ligne :

Oxy

- Remplacement facile du bouchon du capteur avec Toolmaster™

- Remplacement du bouchon prévisible grâce au Lifetime Estimator

- Comparabilité ultime avec les solutions Anton Paar en laboratoire et les mesures en ligne

- Retour rapide à l'état opérationnel après un CIP/SIP à chaud ou un rinçage à l'eau chaude

- Solution compacte et autonome pour la mesure en ligne de l'oxygène dans les lignes de récupération du CO₂

- Solution autonome compacte avec sorties analogiques et IHM

- Remplacement facile de la tête du capteur avec Toolmaster™

- Entrée numérique pour le signal d'arrêt du processus pendant la routine CIP/SIP

- Retour rapide à l'état opérationnel après un CIP/SIP

- Principe de mesure optique comparable aux solutions de laboratoire et en ligne

Les capteurs d'oxygène en ligne Oxy 4100/5100 mesurent l'oxygène dissous (OD) en temps réel, directement sur la ligne de production. Elles fournissent des mesures précises et sans dérive tout au long du processus de production.

L'Oxy 5100 peut être combiné aisément à des capteurs de process additionnels d'Anton Paar afin de répondre à toutes les exigences de production et de contrôle qualité à venir. Le transmetteur Oxy 4100 est équipé de sorties analogiques et d'une interface à écran tactile.

Le moniteur de pureté du CO₂ est un système compact permettant de contrôler la teneur en O₂ dans les conduites de récupération du CO₂ sous pression.

Caractéristiques principales

Capteur d'oxygène en ligne : Tête de capteur astucieuse - aucun étalonnage nécessaire

Les capuchons du capteur Oxy 4100/5100 permettent une connexion intelligente du capteur avec l'échantillon. Pour répondre aux besoins individuels, il est possible de choisir la tête de capteur appropriée parmi une variété de têtes. Passez d'une plage à l'autre en toute convivialité en changeant la tête de capteur.

Tous les paramètres d'étalonnage requis sont stockés dans le bouchon du capteur d'oxygène en ligne. La technologie Toolmaster® détecte automatiquement la tête du capteur et transfère tous les paramètres de réglage au capteur. La mesure inline peut démarrer dès que la tête est montée.

Lifetime Estimator : Planification simple du remplacement du bouchon du capteur

Seul l'Oxy 5100 prend en charge les étapes de la mise en place d'un programme de maintenance prédictive pour la mesure en ligne.

Le Lifetime Estimator de l'Oxy 5100 estime la durée de vie restante en jours du bouchon du capteur et vous avertit lorsque celui-ci doit être remplacé. Des avertissements sont automatiquement affichés sur l'écran du capteur, et une estimation actualisée de la durée de vie peut être demandée à tout moment.

Conception hygiénique – Certifié EHEDG et prêt pour SIP

Les capteurs d'oxygène en ligne Oxy 4100/5100 conviennent aux applications hygiéniques de l'industrie des boissons, des produits pharmaceutiques et du traitement de l'eau. L'Oxy 5100 est conforme aux normes internationales d'hygiène car il est certifié EHEDG Type EL – Classe I et peut être nettoyé à l'aide des procédures CIP communes. Tous les matériaux en contact avec l'échantillon sont conformes aux normes FDA.

L'Oxy 4100/5100 est conçu pour le nettoyage et la stérilisation à des températures allant jusqu'à 130°C. Le capteur est prêt pour une utilisation rien que quelques minutes après le nettoyage et la stérilisation, ce qui réduit les temps d'arrêt au minimum.

Plug and play – configuration facile avec compatibilité maximale

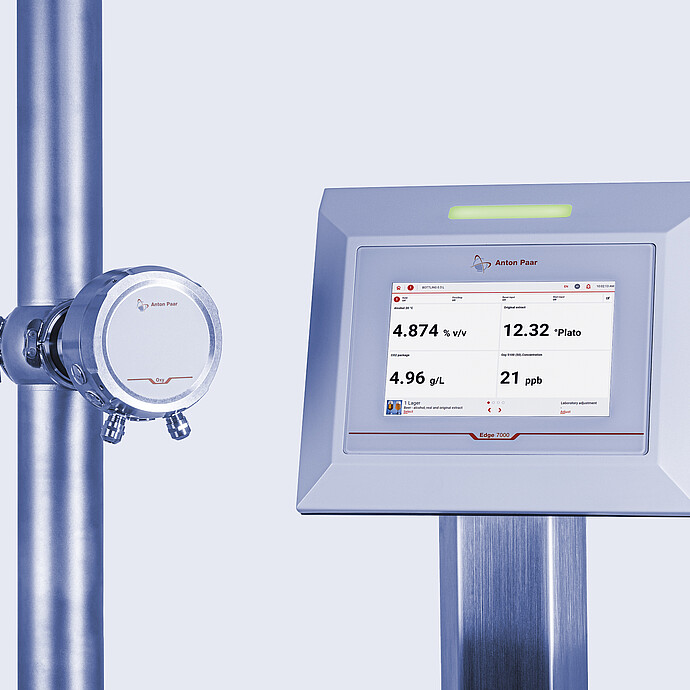

Aucune formation spécifique n'est requise pour mettre en service et utiliser l'instrument. Les séries de capteurs sont rapidement installées et peuvent être facilement utilisées avec l'interface à écran tactile de l'unité d'évaluation intégrée, via le logiciel Pico 3000 ou à l'aide du contrôleur de processus Edge 7000/5000.

L'Oxy 5100 peut être facilement adapté pour prendre en charge différents protocoles de communication, notamment les protocoles analogiques (4 mA à 20 mA), Modbus RTU, Modbus TCP, HART, PROFIBUS DP, PROFINET IO et Ethernet/IP. Le transmetteur Oxy 4100 est équipé de sorties analogiques et d'une interface à écran tactile.

Moniteur d'oxygène pour la pureté des gaz

Le moniteur d'oxygène pour la pureté des gaz intègre un système complet de contrôle des niveaux d'oxygène tout au long du processus de récupération du dioxyde de carbone et dans les gaz de formation pendant les activités de soudage, qui comprennent le CO2, le N2et les mélanges d'argon et d'hydrogène (95/5, 98/2). Alimentée par l'Oxy 5100 et équipée d'un capteur de pression intégré pour la compensation automatique de la pression, cette solution autonome garantit une mesure précise et fiable de l'oxygène pour les applications de pureté du gaz.

Spécifications

| Tête de capteur | Gamme ultra-trace | Plage à l'état de traces* | Plage étendue | Gamme ultra-large** |

| Plage de mesure (O₂ dissous dans les liquides) | - (Phase gazeuse uniquement) | 0 ppb à 2000 ppb | 0 ppm à 22,5 ppm | 0 ppm à 45 ppm |

| Plage de mesure (phase gazeuse O₂ en CO₂) | 0 à 200 ppmv (0 à 0,2 hPa) | 0 à 4,2 % O₂ (0 à 40 hPa) | 0 à 21 % O₂ (0 à 500 hPa) | 0 à 21 % O₂ (0 à 1.000 hPa) |

| Précision pour les liquides (la valeur supérieure étant valide) | - (Phase gazeuse uniquement) | ≤ ± 1 ppb ou ± 3 % | ≤ ± 0.042 ppm ou ± 3 % | ≤ ± 0.1 ppm ou ± 5 % |

| Précision en phase gazeuse (la valeur supérieure étant valide) | ≤ ± 2 ppmv ou ± 5 % | ≤ ± 25 ppmv ou ± 3 % | ≤ ± 0,1 % O₂ ou ± 3 % | ≤ ± 0,2 % O₂ ou ± 5 % |

| Température de l'échantillon (hors congélation) | 0 °C à 40 °C | -5 °C à +65 °C (Oxy 4100 : -5 °C à +40 °C) | -5 °C à +65 °C (Oxy 4100 : -5 °C à +40 °C) | -5 °C à +40 °C |

| Température CIP/SIP | Ne convient pas pour le CIP/SIP | max. 99 °C, max. 130 °C (max. 30 min) | ||

| Pression de ligne | max. 12 bar abs. (174 psi abs.), max. 5 bar abs. (72 psi abs.) pour les mesures en phase gazeuse | |||

| Certifications | - | EHEDG type EL classe I | ||

| Intervalle de mesure | 1 à 360 s (Oxy 4100 : 15 s) | |||

| Température ambiante / Humidité | -5 °C à 50 °C / 0 % rH à 90 % rH (hors condensation) | |||

| Alimentation électrique | SELV DC 24 V (DC 20 V à 30 V), max. 1,6 W | |||

| Dimensions (HxlxP) | Oxy 4100/5100 : 162x162x215 / Capteur de pression pour le contrôleur de pureté du CO2 : 80x80x120 | |||

* Un type de tête de capteur spécial est disponible pour les conditions de process difficiles. Contactez votre représentant Anton Paar.

** Non disponible pour Oxy 4100.

Service certifié Anton Paar

- Plus de 350 experts techniques certifiés par les fabricants dans le monde

- Assistance qualifiée dans votre langue locale

- Protection de votre investissement tout au long de son cycle de vie

- 3 ans de garantie

Documents

-

EHEDG Certificate of Compliance | Oxy 5100 Certificats

-

Beverage / Soft Drinks | The importance of oxygen measurement in soft drinks Rapports d'application

-

Beverage | Beer | Complete your Beer Analysis Rapports d'application

-

Beverage | Beer | Dissolved Oxygen in the Brewery! Where? Rapports d'application

-

Beverage | Beer | Wort Aeration: Monitoring Dissolved Oxygen Rapports d'application

-

Beverage | Soft Drinks | Complete Your Soft Drink Analysis Rapports d'application

-

Beverage | Soft Drinks | Online Process Measurement in the Soft Drink Industry Rapports d'application

-

Beverage | Wine | Complete your wine analysis Rapports d'application

-

Boisson | Bière et Cidre | Surveillance de la pureté du CO2 Rapports d'application

-

Boissons | Bière | Une bière de qualité constante : du filtre à la soutireuse Rapports d'application

-

Determining dissolved oxygen in milk Rapports d'application

-

E-Book - Field Guide to Food and Feed Testing Rapports d'application

-

E-Book - The Future of Plant-Based Foods Rapports d'application

-

Food | Ditch the cow - plant-based milk alternatives Rapports d'application

-

Industrie métallurgique | Contrôle de l'oxygène dans les gaz de formation pendant le soudage Rapports d'application

Produits complémentaires

Si vous ne trouvez pas l’article dont vous avez besoin, contactez votre représentant commercial Anton Paar.

CONNECTEUR DSUB CANopen 9BU 35°

Oxy 5100

Spécifications techniques Connecteur D-SUB, prise 9 broches 2 pièces. Presse-étoupes inférieurs à 35° sur deux rangées de bornes Système de bus : CAN, CANopen, SafetyBus-P Affectation des broches : 2, 3, 7, 9 Bornes de raccordement à vis Diamètre extérieur maximum du câble : 8,4 mm Diamètre extérieur minimum du câble : 7,6 mm

Contrôleur de process haute performance :

Edge 7000

Oxy 4100 | 5100

- Des performances de pointe avec un écran multitouch projectif de 10,1 pouces

- Sécurité et flexibilité à long terme grâce à un système d'exploitation basé sur Linux

- La puissance du processeur Intel® Atom® pour un contrôle imbattable

- Conception industrielle, sans ventilateur, pour une fiabilité et une durabilité accrues

- Communication embarquée avec diverses interfaces de bus de terrain

Contrôleur de process haute performance :

Edge 5000

Oxy 4100 | 5100

- Configuration simplifiée sans écran (IHM à distance en option)

- Système d'exploitation basé sur Linux pour une sécurité et une adaptabilité à long terme

- Une puissance de contrôle inégalée grâce au processeur Intel® Atom®

- Qualité industrielle, optimisée pour l'intégration en armoire (sans ventilateur, rail DIN)

- Communication embarquée avec diverses interfaces de bus de terrain

CAPTEUR CAPTEUR OXY 4100 / 510 / 5100 WR 0 À 22,5 ppm / 0 À 21 % O2 (DO / GAZ)

Oxy 4100 | 5100

Remplace le matériel 176420 Capuchon de capteur DO à large gamme.

CAPTEUR CAPTEUR OXY 4100 / 510 / 5100 TR 0 À 2000 ppb / 0 À 4,2 % O2 (DO / GAZ)

Oxy 4100 | 5100

Remplace le matériel 176421 Capuchon de capteur DO à large gamme.

CAPUCHON CAPTEUR OXY 4100 / 5100 TR PTFE 0 À 2000 ppb (DO)

Oxy 4100 | 5100

Capuchon de capteur pour les mesures d'oxygène dissous avec résistance chimique améliorée et stabilité de mesure maximale. Tous les paramètres d'étalonnage requis sont stockés dans le capuchon du capteur. La technologie Toolmaster détecte le capuchon du capteur et transfère automatiquement tous les paramètres de configuration au capteur pour un remplacement rapide et facile du capuchon. Contenu de la livraison 1 PCS. Capuchon du capteur gamme de traces PTFE Spécifications techniques

- Précision à 20 °C : max. ± 1 ppb ou ± 3 %

- Plage de mesure : 0 ppb à 2000 ppb

- Température de l'échantillon Oxy 4100 : -5 °C à + 40 °C, hors gel

- Température de l'échantillon Oxy 5100 : -5 °C à + 65 °C, hors gel

- Matériaux mouillés : Acier inoxydable 1.4404 (AISI 316L), PTFE (approuvé par la FDA) et FKM 75.16-04 (approuvé par la FDA)

- Temps de réponse : t90 < 100 s

CAPUCHON DE CAPTEUR OXY 5100 GAMME ULTRA LARGE 0 À 45 ppm / 0 À 21 % O2 (DO / GAZ)

Oxy 4100 | 5100

Bouchon de capteur pour les mesures d'oxygène dans les liquides et les gaz. Tous les paramètres d'étalonnage requis sont stockés dans le capuchon du capteur. Le La technologie Toolmaster détecte le capuchon du capteur et transfère toutes les configurations paramètres au capteur automatiquement pour un changement de bouchon rapide et facile. Contenu de la livraison 1 PCS. Capuchon de capteur ultra-large plage Spécifications techniques

- Précision à 20°C (phase liquide) : max. ± 0,1 ppm ou ± 5 %

- Précision à 20°C (phase gazeuse) : max. ± 0,2 % O2 ou ± 5 %

- Plage de mesure (phase liquide) : 0 ppm à 45 ppm

- Gamme de mesure (phase gazeuse) : 0 % O2 à 21 % O2 (0 hPa à 1000 hPa)

- Température de l'échantillon : -5 °C à +40 °C, hors gel

- Matériaux mouillés : Acier inoxydable 1.4404 (AISI 316L), Silicone (approuvé par la FDA) et FKM 75.16-04 (approuvé par la FDA)

- Certifications : EHEDG (Type EL Classe I)

CAPUCHON DE CAPTEUR OXY 5100 GAMME ULTRA-TRACE 0 À 200 ppmv (GAZ)

Oxy 4100 | 5100

Bouchon de capteur pour la mesure de l'oxygène dans les gaz ultra-purs tels que le CO2 et le N2 hautement purifiés. Tous les paramètres d'étalonnage requis sont stockés dans le capuchon du capteur. Le La technologie Toolmaster détecte le capuchon du capteur et transfère toutes les configurations paramètres au capteur automatiquement pour un changement de bouchon rapide et facile. Contenu de la livraison 1 PCS. Capuchon de capteur gamme ultra-trace Spécifications techniques

- Précision à 20°C : max. 2 ppmv ou ± 5 %

- Plage de mesure : 0 ppmv à 200 ppmv (0 hPa à 0,2 hPa)

- Température de l'échantillon : 0 °C à +40 °C, hors gel

- Matériaux mouillés : Acier inoxydable 1.4404 (AISI 316L), Silicone