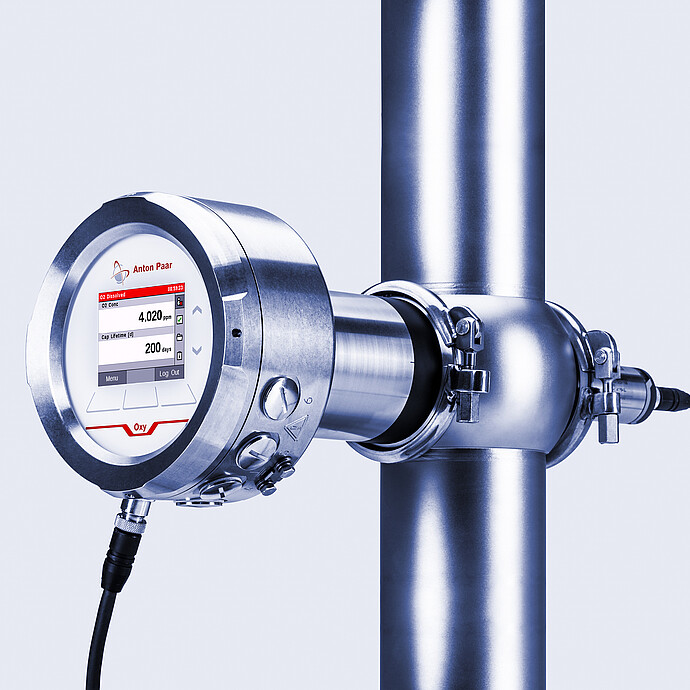

Inline Oxygen Sensor:

Oxy

- Hassle-free sensor-cap exchange with Toolmaster™

- Predictable cap exchange with lifetime estimator

- Ultimate comparability with Anton Paar solutions for laboratory and at-line measurements

- Quick return to operational status after hot CIP/SIP or hot-water rinsing

- Compact stand-alone solution for inline oxygen measurement in CO₂ recuperation lines

- Compact stand-alone solution with analog outputs and HMI

- Hassle-free sensor-cap exchange with Toolmaster™

- Digital input to process stop signal during CIP/SIP routine

- Quick return to operational status after CIP/SIP

- Optical measuring principle comparable to lab and at-line solutions

The Oxy 4100/5100 inline oxygen sensors measure dissolved oxygen (DO) in real-time, directly at the production line. They provide accurate, drift-free measurements throughout the entire production process.

Oxy 5100 can easily be combined with additional process sensors from Anton Paar to meet all future production- and quality-control requirements. The Oxy 4100 transmitter comes ready with analog outputs and a touchscreen interface.

The CO₂ Purity Monitor features a compact system for monitoring the O₂ content in pressurized CO₂ recuperation pipes.

Key features

Inline oxygen sensor: Clever sensor caps – no calibration needed

The Oxy 4100/5100 sensor caps embody the smart connection of the sensor with the sample. To match individual requirements, the right sensor cap can be chosen from a variety of caps. Conveniently switch between the ranges by simply exchanging the sensor cap.

All required calibration parameters are stored in the sensor cap of the inline oxygen sensor. The Toolmaster® technology automatically detects the sensor cap and transfers all setup parameters to the sensor. Once the cap is mounted, inline measurement can start immediately.

Lifetime estimator: Easy planning of sensor cap exchange

Only Oxy 5100 supports the steps involved in setting up a predictive maintenance schedule for inline measurement.

The Oxy 5100 lifetime estimator estimates the remaining service life of the sensor cap in days and warns you when a new sensor cap is required. Warnings are automatically shown on the sensor display, and an updated lifetime estimation can be requested at any time.

Hygienic design: EHEDG-certified and SIP-ready

The Oxy 4100/5100 inline oxygen sensors are suitable for hygiene applications in the beverage, pharmaceutical, and water treatment industries. Oxy 5100 fulfills international hygienic standards because it is EHEDG-certified Type EL – Class I and can be cleaned using all common CIP procedures. All materials that are in contact with the sample are FDA-compliant.

Oxy 4100/5100 is designed for cleaning and sterilization at temperatures up to 130 °C. The sensor is ready for in-spec operation only a few minutes after cleaning and sterilization, reducing downtimes to a minimum.

Plug and play: Easy setup with maximum compatibility

No special training is required to commission and operate the instrument. The sensor series are set up quickly and can be easily used with the touchscreen interface of the built-in evaluation unit, via the Pico 3000 software, or with the help of the Edge 7000/5000 process controller.

Oxy 5100 can be easily adapted to support several communications protocols including analog (4 mA to 20 mA), Modbus RTU, Modbus TCP, HART, PROFIBUS DP, PROFINET IO, and EtherNet/IP. The Oxy 4100 transmitter comes ready with analog outputs and a touchscreen interface.

Oxygen Monitor for Gas Purity

The Oxygen Monitor for Gas Purity incorporates a comprehensive system for monitoring oxygen levels throughout the carbon dioxide recovery process and in forming gases during welding activities, which include CO2, N2, and Argon-Hydrogen mixtures (95/5, 98/2). Powered by the Oxy 5100 and equipped with an integrated pressure sensor for automatic pressure compensation, this standalone solution ensures precise and reliable oxygen measurement for gas purity applications.

Specifications

| Sensor caps | Ultra-trace range** | Trace range* | Wide range | Ultra-wide range** |

| Measuring range (dissolved O₂ in liquids) | - (Gas phase only) | 0 ppb to 2000 ppb | 0 ppm to 22.5 ppm | 0 ppm to 45 ppm |

| Measuring range (gas phase O₂ in CO₂) | 0 ppmv to 200 ppmv (0 hPa to 0.2 hPa) | 0 % to 4.2 % O₂ (0 hPa to 40 hPa) | 0 % to 21 % O₂ (0 hPa to 500 hPa) | 0 % to 21 % O₂ (0 hPa to 1000 hPa) |

| Accuracy for liquids (the larger value is valid) | - (Gas phase only) | ≤ ± 1 ppb or ± 3 % | ≤ ± 0.042 ppm or ± 3 % | ≤ ± 0.1 ppm or ± 5 % |

| Accuracy in gas phase (the larger value is valid) | ≤ ± 2 ppmv or ± 5 % | ≤ ± 25 ppmv or ± 3 % | ≤ ± 0.1 % O2 or ± 3 % | ≤ ± 0.2 % O2 or ± 5 % |

| Sample temperature (non-freezing) | 0 °C to 40 °C | -5 °C to +65 °C (Oxy 4100: -5 °C to +40 °C) | -5 °C to +65 °C (Oxy 4100: -5 °C to +40 °C) | -5 °C to +40 °C |

| CIP/SIP temperature | Not suitable for CIP/SIP | max. 99 °C, max. 130 °C (max. 30 min) | ||

| Line pressure | max. 12 bar abs. (174 psi abs.), max. 5 bar abs. (72 psi abs.) for measurements in gas phase | |||

| Certifications | - | EHEDG (Type EL - Class I)** | ||

| Measuring Interval | 1 to 360 s (Oxy 4100: 15 s) | |||

| Ambient temperature / Humidity | -5 °C to +50 °C / 0 % rH to 90 % rH (non-condensing) | |||

| Power supply | SELV DC 24 V (DC 20 V to 30 V), max. 1.6 W | |||

| Dimensions (HxWxD) | Oxy 4100/5100: 162x162x215 / Pressure sensor for CO2 Purity Monitor: 80x80x120 | |||

* Special sensor cap type available for harsh process conditions. Contact your Anton Paar representative.

** Not available for Oxy 4100.

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Beverage / Soft Drinks | The importance of oxygen measurement in soft drinks Application Reports

-

Beverage | Beer and Cider | CO2 Purity Monitoring Application Reports

-

Beverage | Beer | Cheers to consistent beer quality: from filter to filler Application Reports

-

Beverage | Beer | Complete your Beer Analysis Application Reports

-

Beverage | Beer | Dissolved Oxygen in the Brewery! Where? Application Reports

-

Beverage | Beer | Wort Aeration: Monitoring Dissolved Oxygen Application Reports

-

Beverage | Soft Drinks | Complete Your Soft Drink Analysis Application Reports

-

Beverage | Soft Drinks | Online Process Measurement in the Soft Drink Industry Application Reports

-

Beverage | Wine | Complete your wine analysis Application Reports

-

Determining dissolved oxygen in milk Application Reports

-

E-Book - Field Guide to Food and Feed Testing Application Reports

-

E-Book - The Future of Plant-Based Foods Application Reports

-

Food | Dissolved Oxygen in Milk and Dairy Products Application Reports

-

Food | Ditch the cow - plant-based milk alternatives Application Reports

-

Metal | Oxygen monitoring of forming gases during welding Application Reports

-

Process Engineering Solutions | Overview Brochures

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

DSUB CANopen 9BU CONNECTOR 35°

Oxy 5100

Technical specifications D-SUB Connector, 9-pin Socket 2 Pcs. Cable glands under 35° at two terminal rows Bussystem: CAN, CANopen, SafetyBus-P Pin Assignment : 2, 3, 7, 9 Screw connecting terminals Max Cable outer diameter: 8.4 mm Min Cable outer diameter: 7.6 mm

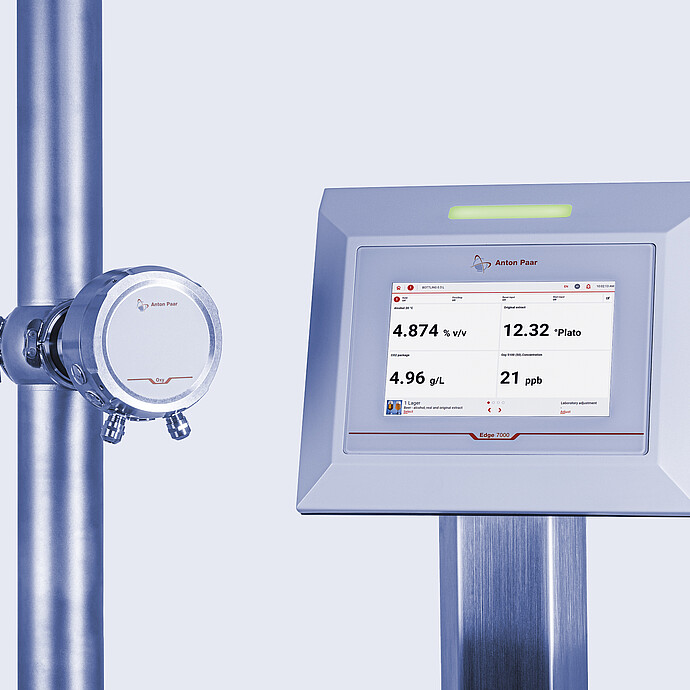

High Performance Process Controller:

Edge 7000

Oxy 4100 | 5100

- Cutting-edge performance with a 10.1-inch projective, multitouch display

- Long-term security and flexibility with a Linux-based operating system

- Intel® Atom® Processor power for unbeatable control

- Industrial-grade, fan-less design for reliability and durability

- Onboard communication with various fieldbus interfaces

High Performance Process Controller:

Edge 5000

Oxy 4100 | 5100

- Streamlined configuration without display (optional remote HMI)

- Linux-based operating system for long-term security and adaptability

- Unparalleled control power with an Intel® Atom® Processor

- Industrial-grade, optimized for cabinet integration (fan-less, DIN rail)

- Onboard communication with various fieldbus interfaces

OXY 4100 / 510 / 5100 SENSOR CAP WR 0 TO 22.5 ppm / 0 TO 21 % O2 (DO / GAS)

Oxy 4100 | 5100

Replaces material 176420 DO Sensor cap wide range.

OXY 4100 / 510 / 5100 SENSOR CAP TR 0 TO 2000 ppb / 0 TO 4.2 % O2 (DO / GAS)

Oxy 4100 | 5100

Replaces material 176421 DO Sensor cap trace.

OXY 4100 / 5100 SENSOR CAP TR PTFE 0 TO 2000 ppb (DO)

Oxy 4100 | 5100

Sensor cap for dissolved oxygen measurements with improved chemical resistance and highest measurement stability. All required calibration parameters are stored in the sensor cap. The Toolmaster technology detects the sensor cap and transfers all setup parameters to the sensor automatically for quick and easy cap exchange. Scope of delivery 1 Pcs. Sensor cap trace range PTFE Technical specifications

- Accuracy at 20 °C : max. ± 1 ppb or ± 3 %

- Measuring range: 0 ppb to 2000 ppb

- Sample temperature Oxy 4100: -5 °C to + 40 °C, non-freezing

- Sample temperature Oxy 5100: -5 °C to + 65 °C, non-freezing

- Wetted materials: Stainless steel 1.4404 (AISI 316L), PTFE (FDA-approved) and FKM 75.16-04 (FDA-approved)

- Response time: t90 < 100 s

OXY 5100 SENSOR CAP ULTRA-WIDE RANGE 0 TO 45 ppm / 0 TO 100 % O2 (DO / GAS)

Oxy 4100 | 5100

Sensor cap for oxygen measurements in liquids and gases. All required calibration parameters are stored in the sensor cap. The Toolmaster technology detects the sensor cap and transfers all setup parameters to the sensor automatically for quick and easy cap exchange. Scope of delivery 1 Pcs. Sensor cap ultra-wide range Technical specifications

- Accuracy at 20°C (liquid phase) : max. ± 0.1 ppm or ± 5 %

- Accuracy at 20°C (gas phase) : max. ± 0.2 % O2 or ± 5 %

- Measuring range (liquid phase) : 0 ppm to 45 ppm

- Measuring range (gas phase) : 0 % O2 to 21 % O2 (0 hPa to 1000 hPa)

- Sample temperature: -5 °C to +40 °C, non-freezing

- Wetted materials: Stainless steel 1.4404 (AISI 316L), Silicone (FDA-approved) and FKM 75.16-04 (FDA-approved)

- Certifications: EHEDG (Type EL Class I)

OXY 5100 SENSOR CAP ULTRA-TRACE RANGE 0 TO 200 ppmv (GAS)

Oxy 4100 | 5100

Sensor cap for oxygen measurement in ultra-pure gases such as highly purified CO2 and N2. All required calibration parameters are stored in the sensor cap. The Toolmaster technology detects the sensor cap and transfers all setup parameters to the sensor automatically for quick and easy cap exchange. Scope of delivery 1 Pcs. Sensor cap ultra-trace range Technical specifications

- Accuracy at 20°C : max. 2 ppmv or ± 5 %

- Measuring range: 0 ppmv to 200 ppmv (0 hPa to 0.2 hPa)

- Sample temperature: 0 °C to +40 °C, non-freezing

- Wetted materials: Stainless steel 1.4404 (AISI 316L), Silicone and FKM 75.16-04 (FDA-approved)

- Unsuitable for CIP/SIP