Quality control and research in the paints and coatings industry

Gain insights

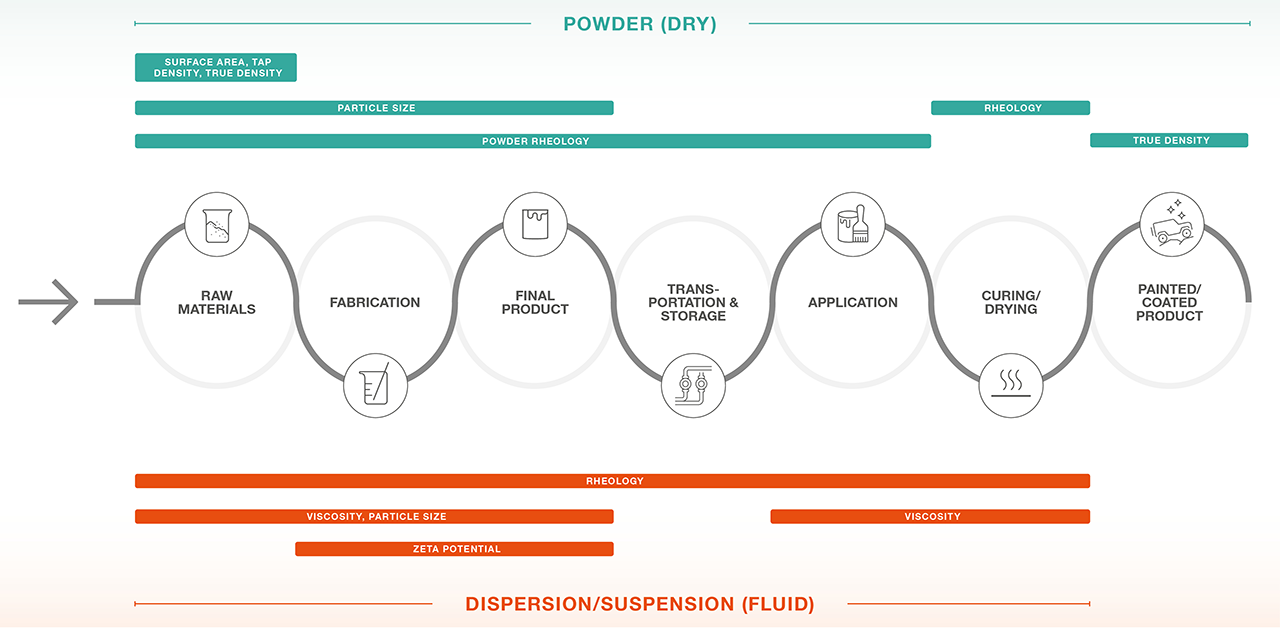

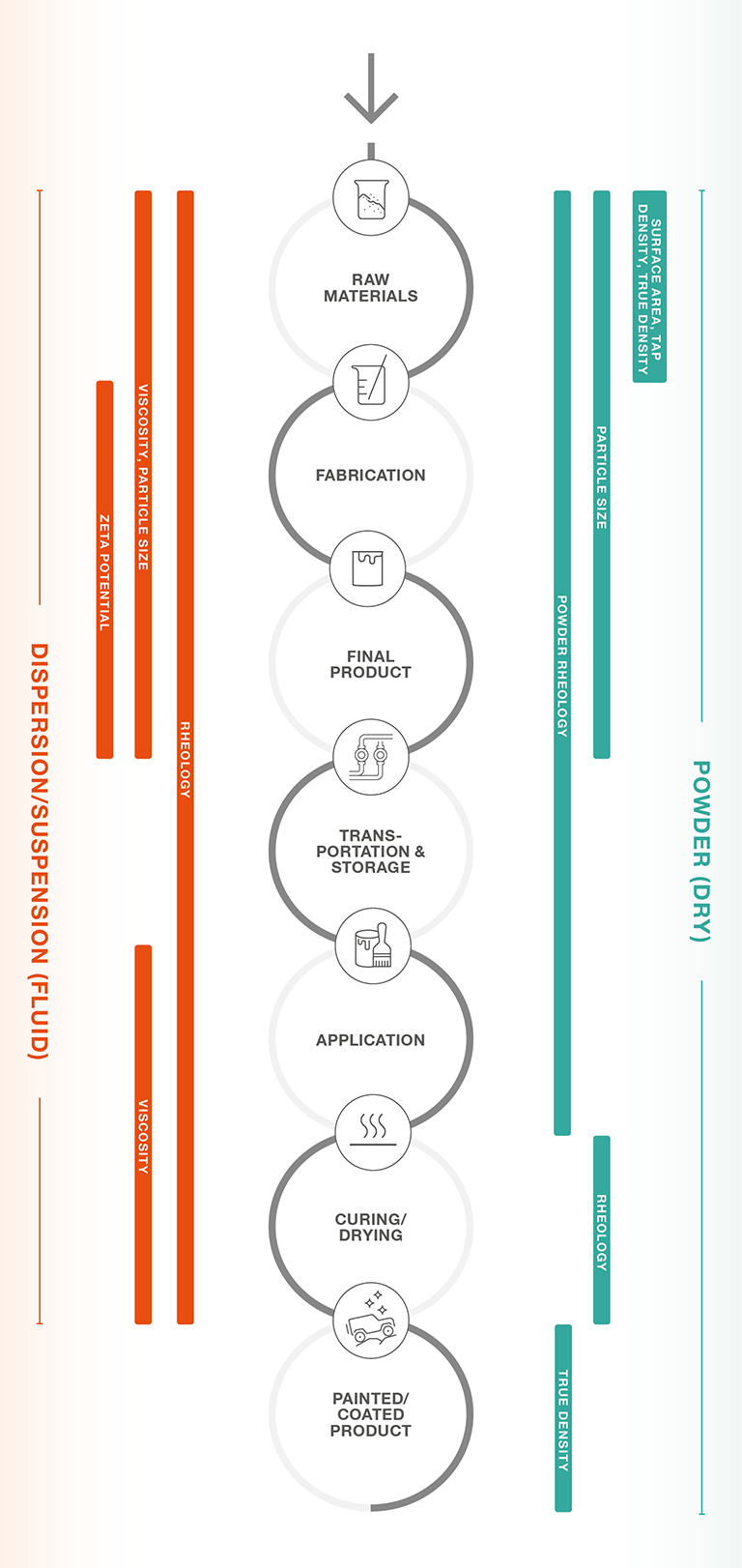

Anton Paar’s instruments deliver information on your materials’ structure, behavior, and consistency. Any type of sample can be analyzed – liquid and particulate – from the incoming raw materials to intermediate products and the final paints, inks, and coatings (also coated and painted surfaces). All devices are designed to make it easy to characterize your samples whether in dry particulate form, in liquid, or on surfaces.

Anton Paar offers a comprehensive portfolio of instruments for characterizing paints and coatings throughout the complete life cycle from the raw materials to the applied product.

Find your solution

Paints and coatings can be challenging. Anton Paar offers a variety of solutions to determine the essential parameters, from the raw materials to the finished product.

| Solution | Your benefit | Instrument | |

| DISPERSION/SUSPENSION - LIQUID | |||

The wood coating is too thin or too thick for the application. | Determine the viscosity of the coating by performing quick quality control checks at a constant speed to adapt the consistency. | The wood coating is neither running off nor leaves uneven ridges on the surface. | |

The wood coating is too thin or too thick for the application. | Determine the viscosity at different shear rates to gain insight into the viscosity of the coating at rest and during application. | Use the results to adjust the flow behavior of the wood coating so it is ideal at each stage of its usage. | |

The paint gets stuck while pumping or during application. | Analyze the yield point of the paint with a rheometer or a viscometer and lower the yield point so that less force is needed to initiate sample flow. | Zero downtime of your production plant thanks to a smooth and efficient transportation process during paint production | |

The wall paint produces an inadequate layer thickness or shows sagging after application. | Analyze the structural decomposition and recovery of the inner structure of the paint to adjust the formulation. | Your wall paint has a sufficiently high wet layer thickness and shows no sagging. | |

The automotive paint is too thick for spraying and produces small visible droplets that lead to a bumpy finish. | Analyze the viscosity of the paint at high shear rates (1,000 s-1 to 10,000 s-1) and adjust the ingredients. | You can be sure that your product has just the right viscosity for high-shear applications, e.g. spraying, brushing, and has a smooth finish. | |

Pigments and fillers in the architectural paint settle during (short term) storage. | Analyze the viscosity at low shear rates (<1 s-1) and adjust the formula. | Use the results to change the formulation and prevent premature sedimentation of the paint. The higher the viscosity in the low-shear range, the better the stability. | |

The paint shows phase separation or sedimentation after a certain time at rest (long term). | Check the storage stability with a frequency sweep and adjust your formulation. | Long storage stability of your paint is guaranteed. | |

The paint is too thin for the application at 50 °C. | Determine and adjust the viscosity exactly at the defined temperature. | The paint has the ideal formulation for the application conditions. | |

The hardening of the two-component epoxy coating already occurs during application. | Analyze the viscosity to find out when it is doubled compared to its state at the beginning of the reaction. With this knowledge you can adjust the formula of the epoxy coating. | Your epoxy coating hardens at the right time after the application period. | |

The paint does not dry after application in environments with high humidity. | Adjust the humidity and temperature of the measurement environment during the rheological characterization of your paint. | Your paint dries under predefined temperature and humidity conditions. | |

The UV-sensitive coating did not cure as expected and the surface shows scratches and bumps. | Simulate crosslinking reactions with different intensities of UV light while measuring the rheological properties. | A coating that cures within seconds under UV light and perfectly covers and protects the coated material | |

The film of a wood coating is too brittle or too soft after curing. | Determine the DMA behavior of the film and adapt the formulation. | Sufficient elasticity of the film and a good coating finish. | |

The paint does not achieve the desired final appearance (paint sheen). | Determine and adjust the pigment particle size. | A flawless product that shows the desired matt or glossy finish and is bought again by the satisfied end customer |

|

The paint does not show the desired color intensity. | Measure and adjust the pigment particle size as color intensity increases as particle size decreases. | Your paint has just the right color intensity and the user is happy with the result after application. |

|

The material shows inconsistent coating behavior. | Determine the particle size of the paint or coating dispersion to identify and prevent particle aggregation prior to the coating process. | Uniform coating behavior |

|

The dispersion shows an unwanted tendency to aggregation. | Determine the zeta potential of the particles in your dispersion with Litesizer to improve your formulation and stabilize your production processes. | Speed up the production process and avoid possible drop-outs of precious batches due to early recognition of zeta potential issues. | |

| POWDER - DRY | |||

Powder raw materials cannot be pumped. | Simulate the pumpability of solid raw materials using a powder cell. | Use the results to avoid issues during transport and storage of powdery materials. | |

The powder coating either doesn't cure nicely or cannot be transported pneumatically. | Determine fluidization and curing behavior and correlate the influence of flow aids on fluidization as well as the curing process. | Increased customer satisfaction with powders that can be easily applied and show good curing behavior | |

The powder coating does not appear even. | Analyze the particle size distribution with a particle size analyzer and optimize it to achieve the desired outer appearance of the powder coating. | The powder coating shows high durability and meets the visual requirements. |

|

You did not find your specific sample? Anton Paar still has the solution for your challenge. Just contact us for more information.

The whole world of viscometry and rheometry

Flow and deformation behavior are essential parameters when it comes to material characterization. Viscometers and rheometers are the ideal tools to see whether your sample is in the right flow.

Particle characterization

Anton Paar offers you instrumentation for all of them and more – it’s the broadest particle characterization portfolio available from one single provider worldwide. Make use of this wide choice and also benefit from decade-long expertise in the field – all at only one point of contact.

Quality control and R&D for paints and coatings

Viscometers

Viscosity measurements of paints and coatings are essential for quality control at every step in the production line. They ensure consistency of incoming raw materials, provide immediate information on the processability and pumpability of a material, and help with verifying the consistency of end products as well as their specifications. A rotational viscometer like ViscoQC 100/300 is commonly used for quality control in paint production and fulfills standards such as ISO 2555, ASTM D2196, and many more. Perform a single-point dynamic viscosity determination with ViscoQC 100 for quick coating quality control or start a multi-point viscosity measurement with ViscoQC 300 to determine, for example, the flow behavior and yield point of the paint. Receive outstanding results using an easy-to-use stand-alone instrument with intelligent, valuable features:

- Ready to use out of the box

- Built-in digital leveling function to check proper alignment

- Magnetic coupling for one-hand removal/attachment of spindle

- Automatic spindle/guard detection and digital instrument alignment check

- TruMode™ for when spindle/speed combination is unknown

- Air-counter-cooled Peltier temperature device with T-Ready™ shows when sample has reached temperature equilibration

The rotational rheometer RheolabQC further enables you to study the structural regeneration of your samples and adapt it properly. With our huge variety of measuring systems available for RheolabQC high shear rates typical for spraying can be simulated. Special Krebs stirrers according to ASTM D562 enable viscosity determination in Krebs units. All measuring systems are automatically recognized by Toolmaster™ to prevent user errors and enhance traceability.

Rheometers

With a rheometer you can follow the change in your paint’s and coating’s viscosity – from one measuring point to the next. You instantly gain deeper insights into your sample’s deformation, flow behavior, and structure – so you can change matters in your favor right away. Rheometers enable measurements in both rotational and oscillatory mode. The choice of rheometer depends on the application:

- To investigate the deformation and flow behavior of a sample consider MCR 72.

- For observing the samples’ structure, MCR 92 is recommended.

- For the full range, starting from routine quality control to high-end research and development measurements, MCR 102e, MCR 302e, or MCR 502e is the best choice.

- All these rheometers – MCR 72 and 92; MCR 102e, 302e, and 502e – offer application-specific accessories to fully characterize the rheological properties of your paint and coating sample.

Anton Paar rheometers provide a wide range of accessories and measuring systems to guarantee future-proof measurements for your specific application. Choose from entry-level and quality control rheometers to R&D rheometers, all with one and the same software, error-proofing, and time savings:

- Toolmaster™: automatic recognition of measuring system and accessories

- QuickConnect coupling: allows one-hand connection of the measuring system

- TruStrain: swiftly adjusts to the desired shear rate step or step in strain without overshoots

- TruRate: precisely controls sample strains, shear rates, or stresses without any pre-testing

- TruRay: lights the measurement surface for MCR 72 and MCR 92 to provide a clear view of the sample

Rheometers can also be equipped with powder cells for powder rheology, helping you understand the behavior of your powders. They can be used as a quick quality control tool but also for in-depth powder analysis. Two different powder cells make it possible to analyze powders, whichever state they are in during your process, from compacted and consolidated to fully fluidized. In this way you can simulate all steps of the process – from mixing to storage, pneumatic transport, and spraying.

Particle size analyzers

Particle size relates to the final appearance including color, gloss, and opacity and also to the processability of paints, inks, and coatings. Anton Paar’s PSA is the ideal instrument for monitoring particle size and particle size distribution as it can analyze dry powders as well as particles in suspension within one device. The Litesizer particle size analyzer can measure zeta potential in order to analyze formulation stability and agglomeration behavior in dispersions and also the particle size in the nanometer range.

Surface area, pore size, and solid density analyzers

The surface area of powders is determined in order to understand quickly and in more detail powder behavior such as Critical Pigment Volume Concentration (CPVC) and dispersion formulation. Surface area can be measured with Anton Paar’s Novatouch, Quadrasorb, or autosorb iQ. The true density of powders is measured by Ultrapyc to determine the density of solids (ASTM D5965) which is used to formulate blends, to assist calculations of cured film thickness/coverage/CPVC (ASTM D5965), and to know the Percent Volume Nonvolatile Matter in Coatings (ASTM D6093). Tapped density is a method used by Autotap to quickly evaluate fresh and recycled material and flowability.

3-year warranty

- Effective January 1, 2020, all new Anton Paar instruments* include repair for 3 years.

- Customers avoid unforeseen costs and can always rely on their instrument.

- Alongside the warranty there is a wide range of additional services and maintenance options available.

* Due to the technology they use, some instruments require maintenance according to a maintenance schedule. Complying with the maintenance schedule is a prerequisite for the 3-year warranty.

Applications

Application reports

Anton Paar Wiki

On the Anton Paar Wiki you can find extensive information about the basics of viscometry containing helpful calculators and viscosity tables to get to know the theory. Rheology knowledge is also represented on the Wiki, for example in an article about the basics, but also more specific articles on powder rheology, the thixotropic effect, and suspension rheology. Theory about zeta potential determination, particle size analysis with laser diffraction as well as the BET theory and gas adsorption as methods for surface area and pore size determination is also covered.

Webinars

How to understand paint and coating powders at each step of their life cycle in order to improve their processability and quality

Paints and coatings come with considerable requirements, simply because of all the different applications and situations they are used for and the different materials they are made of. Covering and understanding the whole life cycle of paints and coatings means being able to measure and analyze the right properties at any step – from the incoming raw materials across all intermediary steps like mixing to the final and finished product. But the life cycle doesn’t end with the finished paint or coating. Transportation, long-term storage, and the applicability are crucial, as are the durability and scratch resistance of the applied materials. No matter whether in development or production, there are many parameters influencing the manufacturing and application process which should be addressed, for example particle size, zeta potential, powder rheology, surface area, and true density.

- Knowing the crucial powder parameters

- Knowing why these parameters are important for stability and processability

- Learning about the simplicity of obtaining these parameters

Time to evolve 14 – Get the perfect finish of your paints and coatings

Did you ever ask yourself how the composition of your paint influences the quality of your final product? With this webinar you will learn how leveling and sedimentation becomes a thing of the past. You will get insights on:

- Rheological behavior of paints and coatings

- Rotational test methods like yield point and thixotropy determination

- Interpretation of test results and how to optimize the rheology of coatings to guarantee a perfect application behavior

Master the flow of your coatings

Did you ever ask yourself how your quality control can be made more efficient and reliable? Or how rheology can help you in every step of the R&D process of your coatings? From quality or process control at the production line up to specific measurements in the development process of new products – register today and learn how Anton Paar rheometers and viscometers can help you with:

- Analysis of viscosity

- Yield and flow point determination

- Decomposition and regeneration behavior

- Investigation of curing and drying behavior