BET Surface Area Analyzer:

Nova

- Optimize BET surface area, pore size, and volume analysis

- Boost throughput with 4 analyses, and up to 8 degassing stations

- Analyze 4 BETs in 20 minutes, 4 isotherms in 8 hours

- Achieve 2 % reproducibility with ≥2 m2 measurement surface area

- Simplify the analysis process with built-in profiles

The Nova BET surface area analyzers have set a new benchmark in surface area and pore size analysis.

Up to eight degassing stations plus up to four analysis stations let you degas samples while analyzing others. Analyze four 5-point BETs in approximately 20 minutes, with 2 % reproducibility. Automated degassing means no operator intervention is necessary.

Simple. Precise. Fast. Nova.

Key features

Integrated sample preparation simplifies your process

Eliminate the clutter, cost, and complexity of external degassing devices with eight integrated degassing stations and up to four analysis stations in one space-saving design. Prepare a range of samples within a vacuum or for flow degassing at temperatures up to 425 ºC. Degassing is software programable and linked with an individual sample ID, ensuring full traceability. These integrated degassing stations ensure that samples are fully prepared before analysis with the BET surface area analyzer.

Speed up your surface area and pore size analysis, and save costs

Utilize the Nova Mode. Use pre-calibrated sample cells – no need to measure void volumes before every analysis – and accelerate your analyses while maintaining a high level of measurement precision.

Benefit from the Nova Nitro ReGen concept: Channel the pure nitrogen gas evaporating from its Dewar to the instrument to use in experiments. This eliminates cylinders and simplifies setup while delivering accurate, repeatable BET results, and reduces environmental impact and lab costs.

Nova Degassing Accessory can degas your samples using vacuum or flow degassing. This offers users flexibility and cost savings as they don’t have to buy multiple degassers.

TruZone – active coolant level control

With TruZone, create and maintain a small cold zone on the sample cell and maximize the measurement sensitivity of your surface area and pore size analyzer. Increase sensitivity when measuring gas molecules that are adsorbed by the sample results in exceptional measurement performance. Nova BET surface area analyzers deliver better than 2 % reproducibility with as low as 2 m2 total surface area in the sample cell. This best-in-class performance lets you measure materials with specific surface areas as low as 0.01 m²/g.

Suite of smart dosing algorithms for effortless method creation

Intelligent dosing algorithms, such as DoseWizard, VectorDose, and Initial Fill, simplify the creation of analysis profiles to accelerate analyses without sacrificing precision. In combination with the 20+ built-in analysis profiles for standardized methods like ASTM, ISO, USP, and DIN, our surface area and pore size analyzer delivers operational simplicity from start to finish.

A surface area and pore size analyzer with smart software

Combine instrument control and data processing with Kaomi for Nova. Set up and perform analyses, and process, report, and store data easily. Control up to four Nova BET surface area analyzers from one PC.

21 CFR Part 11-compliant software

Enhance data integrity for the pharmaceutical industry with Kaomi for Nova 21 CFR Part 11 Software (user management, audit trail, customizable reporting, and electronic signature).

This guarantees that your BET surface area analyzer meets FDA’s 21 CFR Part 11 requirements, ensuring complete data traceability and security, backed by a comprehensive pharma qualification and requalification package.

Specifications

| Nova 600 BET | Nova 800 BET | Nova 600 | Nova 800 | |

| Analysis specifications | ||||

| Measurement principle | Vacuum Volumetric | |||

| Analysis gases | N2 only | N2, Ar, CO2, and other non-corrosive gases | ||

| Analysis stations | 2 | 4 | 2 | 4 |

| Independent P0 station | Yes | |||

| Relative pressure range (P/P0 ) | 10-4 to 0.5 | 10-4 to 0.999 | ||

| Pressure measurement accuracy | 0.1 % (of full scale) * | |||

| Pressure resolution | Absolute : 1.2 x 10-4 Torr Relative : 1.5 x 10-7 P/P0 | |||

| Lower specific surface area limit | From 0.01 m2/g | |||

| Lower absolute surface area limit | From 0.5 m2 | |||

| Surface area reproducibility | 2 %** | |||

| Pore size range | N/A | 0.35 - 500 nm (Diameter) (0.35 - 1.1 nm with CO2) (1.1 - 500 nm with N2) | ||

| Minimum pore value | N/A | 1.2x10-8 cm3 | ||

| Truzone | Yes | |||

| Powerprotect | Yes | |||

| Dosewizard | Yes | |||

| Vectordose | Yes | |||

| Analysis dewar | Volume: 1 L Duration: Up to 7 Hours | Volume: 2 L Duration: Up to 40 Hours | ||

| Sample preparation | Integrated Degassing Stations : 4 Temperature Control: 2 Heating Zones, Ambient to 425 oC Available Methods: Flow & Vacuum, Programable Multi-Step Heating Profiles | |||

| Physical specifications | ||||

| Dimensions (DxWxH) | 44 cm x 63 cm x 84 cm | |||

| Weight | 63 kg | |||

| Operating environment | Temperature : 15 to 35 oC Humidity : 20 to 80 % relative, non-condensing | |||

| Wetted parts | Stainless steel, Viton elastomers | |||

| Gas | Ports: 5 (3 Analysis, 1 Helium, 1 Degas/Backfill) Purity: 99.999 % (He, N2) Input Pressure: 8 to 10 PSIG | |||

| Vacuum connection | Rotary Pump Exhaust Port, KF 16 | |||

| Vacuum requirements | Ultimate vacuum of 2.3 x 10-3 Torr | |||

| Electrical | Supply : AC 100~240 V AC , 50 / 60 Hz Consumption: 345 VA (Maximum) | |||

| Additional specifications | ||||

| Display | 10-inch Touchscreen | |||

| PC connection | Ethernet | |||

| Kaomi for Nova Software | Instrument Control: Up to 4 Instruments 6 Languages: English, French, German, Japanese, Chinese, Spanish | |||

| Kaomi for Nova 21 CFR Part 11 Software | Features: User management, audit trail, customizable reporting, and electronic signature to enhance data integrity for use in the pharmaceutical industry | |||

| Pharma Qualification Package | Yes | |||

| Pre-loaded analysis profiles | 20+ (ASTM, USP, DIN, ISO) | |||

| ROHS 3 compliant | Yes | |||

| CE certified | Yes | |||

* Includes precision, linearity, and hysteresis s of the complete pressure measurement system

** Performed with BAM P115 certified reference material

Standards

ASTM

ISO

DIN

US Pharmacopoeia (USP)

Standards

ASTM

ISO

DIN

US Pharmacopoeia (USP)

Standards

ASTM

ISO

DIN

US Pharmacopoeia (USP)

Standards

ASTM

ISO

DIN

US Pharmacopoeia (USP)

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Advantages of QSDFT for Pore Size Analysis of Carbons Application Reports

-

Analysis of Carbon Black Surface Area: NSA (BET) and STSA Application Reports

-

Biochar characterization using gas adsorption Application Reports

-

Defining Nova 600 | 800 Series Equilibration Parameters Application Reports

-

Demonstrating accuracy and speed of BET surface area using Nitro ReGen Mode Application Reports

-

E-Book - Field Guide to Battery Materials Characterization – Revised and Updated Application Reports

-

E-Book - Field Guide to Food Powder Characterization Application Reports

-

E-Book - Praxisleitfaden zur Pulvercharakterisierung für Pharmazeutika Application Reports

-

E-Book - The Field Guide to Data Integrity in Regulated Industries Application Reports

-

E-Book - The Field Guide to Pharmaceutical Powder Characterization Application Reports

-

Graphene Characterization Application Reports

-

Lactose Monohydrate: Density and Surface Area - Nova and Ultrapyc Application Reports

-

Material Brief: Battery Cathode BET Surface Area – Nova 600 | 800 Series Application Reports

-

Material Brief: Graphite – BET Surface Area – Nova 600 | 800 Series Application Reports

-

Material Brief: Manganese Dioxide – BET Surface Area Nova 600 | 800 Series Application Reports

-

Material Brief: Microcrystalline Cellulose – BET Surface Area – Nova 600 Application Reports

-

Material Brief: Quartz – BET Surface Area Nova 600 | 800 Series Application Reports

-

Material brief: Lithium iron phosphate (LFP) - BET surface area - Nova 800 Application Reports

-

Measuring Low Surface Area Materials Using Nova 600 | 800 Series Instruments Application Reports

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

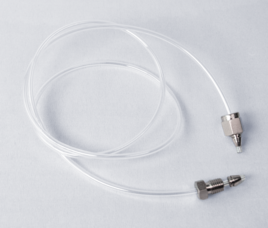

NOVA NITRO REGEN FLEXIBLE TUBE ASSEMBLY

Nova 800 | 600 | 800 BET | 600 BET

O-RING, VITON 030, BROWN, PACK OF 2

Nova 800 | 600 | 800 BET | 600 BET

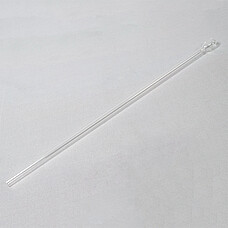

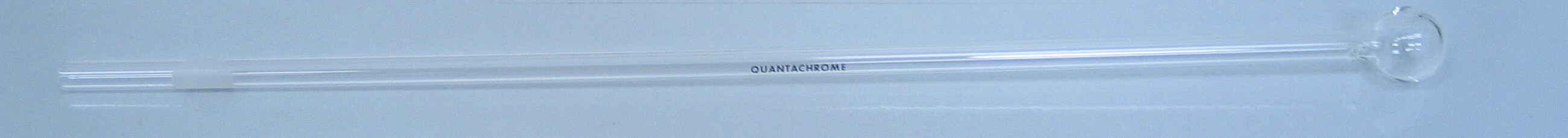

TYPE C LONG CELL, 6 mm SM BULB, DIMPLE

Nova 800 | 600 | 800 BET | 600 BET

Type C long cell with 6 mm stem, small bulb, and dimple. For use with non-elutriating kits. Borosilicate Glass. Nominal Dimensions: 6 mm OD (4 mm ID), cell length 266 mm, bulb diameter 11 mm, 1 cm3 capacity.

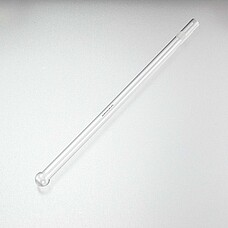

TYPE B LONG NON-ELUTRIATING, 9MM LG BULB

Nova 800 | 600 | 800 BET | 600 BET

Type B long non-elutriating cell kit, 9 mm large bulb with dimple. For prevention of elutriation of fine particles into the instrument. Kit consists of dimpled cell, filter plug and specially shortened filler rod (cell insert). Filter plug fits into neck of cell stem.

TYPE B NON-ELUTRIATING, 9MM SM BULB

Nova 800 | 600 | 800 BET | 600 BET

Type B long non-elutriating cell kit, 9 mm small bulb with dimple. For prevention of elutriation of fine particles into the instrument. Kit consists of dimpled cell, filter plug and specially shortened filler rod (cell insert). Filter plug fits into neck of cell stem.

.850 O.D. O-RING COMPRESSION NUT

Nova 800 | 600 | 800 BET | 600 BET

CENTERING RIING ASSEMBLY 16KF, SS

Nova 800 | 600 | 800 BET | 600 BET

Nova Degasser Flow Degas Adapter

Nova 800 | 600 | 800 BET | 600 BET

Flow degas adapter compatible with Nova Degassing Accessory Includes one set of tubing sufficient for degassing 1 sample at a time

Nova Heating Mantle Accessory

Nova 800 | 600 | 800 BET | 600 BET

Heating Mantles compatible with Nova series instruments Can be used for Vacuum and Flow degassing Supplied with the below parts: 226870 Heating Mantle 2 pcs 239956 Nova Heating Mantle Holder 1 pc 193696 Heating Mantle Clamp 2 pcs 323127 Nova Mantle vacuum Degas Adapter 4 pcs 193362 Sample cell Adapter 6 mm 4 pcs 193820 O-Ring, FKM 6 mm 4 pcs 193300 Sample Cell cooling Rack 1 pc

Nova Degasser Vacuum Degas Adapter

Nova 800 | 600 | 800 BET | 600 BET

Compatible with Nova Degassing Accessory Set of tubing designed for vacuum degassing 2 samples at a time

Nova Mantle Vacuum Degas Adapter

Nova 800 | 600 | 800 BET | 600 BET

Compatible for Nova Heating Mantle Recommended for vacuum degassing Supplied with all required parts for vacuum degassing one sample

Nova 12mm Adapter Kit

Nova 800 | 600 | 800 BET | 600 BET

Contains the sample cell adapters, o-rings, and dowel pins

TYPE B ROD, FOR 6 mm SHORT DIMPLE CELL

Nova 800 | 600 | 800 BET | 600 BET

Non-flared filler rod (cell insert) for 6 mm, short, dimpled, type B cells. For use with non-elutriating cell kits. Nominal Dimensions: 3 mm diameter, 107 mm long.

Enhancement option for Nova:

Degassing Accessory

Nova 800 | 600 | 800 BET | 600 BET

- Degas eight samples while eight are cooling

- Heat up to 425 °C with the flexibility of two heating zones

- Option to keep the heater on for faster turnaround time

- Capable of performing vacuum and flow degassing

- Keep track of degassing information, even on analysis reports

NOVA GAS INLET TUBE

Nova 800 | 600

NOVA GAS INLET TUBE BET

Nova 800 | 600 | 800 BET | 600 BET

NOVA DESSICANT COLUMN

Nova 800 | 600 | 800 BET | 600 BET

TYPE B LONG CELL, 9 mm LG BULB

Nova 800 | 600

Type B long cell with 9 mm stem and large bulb. Borosilicate Glass. Nominal Dimensions: 9 mm OD (7 mm ID), cell length 287.5 mm, bulb diameter 26 mm, 6 cm3 capacity.

TYPE B LONG CELL, 6 mm NO BULB

Nova 800 | 600

Type B long cell with 6mm stem and no bulb. Borosilicate Glass. Nominal Dimensions: 6 mm OD (4 mm ID), cell length 292 mm, 0.2 cm3 capacity

TYPE B LONG CELL, 9 mm NO BULB

Nova 800 | 600

Type B long cell with 9 mm stem and no bulb. Borosilicate Glass. Nominal Dimensions: 9 mm OD (7 mm ID), cell length 287.5 mm, 0.5 cm3 capacity.

TYPE B LONG CELL, 6 mm SM BULB

Nova 800 | 600

Type B long cell with 6 mm stem and small bulb. Borosilicate Glass. Nominal Dimensions: 6 mm OD (4 mm ID), cell length 292 mm, bulb diameter 16 mm, 1 cm3 capacity.

TYPE B LONG CELL, 6 mm LG BULB

Nova 800 | 600

Type B long cell with 6 mm stem and large bulb. Borosilicate Glass. Nominal Dimensions: 6 mm OD (4 mm ID), cell length 292 mm, bulb diameter 26 mm, 6 cm3 capacity.

TYPE B LONG CELL, 9 mm SM BULB

Nova 800 | 600

Type B long cell with 9 mm stem and small bulb. Borosilicate Glass. Nominal Dimensions: 9 mm OD (7 mm ID), cell length 287.5 mm, bulb diameter 15.9 mm, 1 cm3 capacity.

TYPE B LONG CELL, 12 mm SM BULB

Nova 800 | 600

Type B long cell with 12 mm stem and small bulb. Borosilicate Glass. Nominal Dimensions: 12 mm OD (10 mm ID), cell length 283 mm, bulb diameter 16 mm, 1 cm3 capacity.

TYPE B LONG CELL, 12 mm LG BULB

Nova 800 | 600

Type B long cell with 12 mm stem and large bulb. Borosilicate Glass. Nominal Dimensions: 12 mm OD (10 mm ID), cell length 283 mm, bulb diameter 26 mm, 6 cm3 capacity.

TYPE B LONG CELL, 12 mm NO BULB

Nova 800 | 600

Type B long cell with 12 mm stem and no bulb. Borosilicate Glass. Nominal Dimensions: 12 mm OD (10 mm ID), cell length 283 mm, 0.8 cm3 capacity.

2L Aluminum Dewar with handle

Nova 800 | 600

TYPE B ROD, FOR 12 mm SHORT CELL

Nova 800 | 600 | 800 BET | 600 BET

Flared filler rod (cell insert) for 12 mm, short, type B cells. Nominal Dimensions: 9 mm diameter, 128.5 mm long.

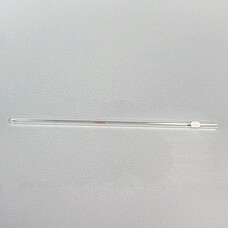

LEVEL SENSOR, CLS TYPE, CRYOGEN, LONG

Nova 800 | 600

CLS type coolant level sensor for use with liquid argon (87 K) or liquid nitrogen (77 K). Appropriate for use with long cells.

TYPE B LONG CELL, 9 mm LG BULB, DIMPLE

Nova 800 | 600

Type B long cell with 9 mm stem, large bulb, and dimple. For use with non-elutriating kits. Borosilicate Glass. Nominal Dimensions: 9 mm OD (7 mm ID), cell length 287.5 mm, bulb diameter 26 mm, 6 cm3 capacity.

GAS SORPTION CALIBRATION CELL ASSEMBLY

Nova 800 | 600 | 800 BET | 600 BET

NON-ELUTRIATING PLUG, 12 mm

Nova 800 | 600 | 800 BET | 600 BET

Replacement non-elutriating plug for use with 12 mm OD (10 mm ID) sample cells.

CIRCULATING BATH, -20 C TO 150 C, 220 V

Nova 800 | 600 | 800 BET | 600 BET

Refrigerated/heating circulator capable of controlling temperatures from -20 C to 150 C. Temperature stability +/- 0.03 C with 0.1 C resolution. Reservoir volume 4 L max. Pumping flow rate of 15 L/min. Includes 2 barbed fittings for 8 and 12 mm ID tubing.

DEWAR CRYOGEN LEVEL INDICATOR

Nova 800 | 600 | 800 BET | 600 BET

SURFACE AREA REFERENCE MATERIAL, 2001

Nova 800 | 600 | 800 BET | 600 BET

Surface area reference material catalog number 2001 for gas sorption instruments. Aluminum oxide powder with 14 m2/g nominal BET surface area using nitrogen.

REGULATOR (CGA)-N2/HE/AR/KR, 25 PSIG

Nova 800 | 600 | 800 BET | 600 BET

Two stage, gas regulator for inert gasses nitrogen, helium, argon, krypton, etc. North American CGA-580 fitting. Output pressure range 0 - 1.7 bar (0 - 25 psig). Includes isolation valve and 1/8 inch Swagelok output fitting.

REGULATOR (CGA)-CO2, 30 PSIG

Nova 800 | 600 | 800 BET | 600 BET

Two stage, gas regulator for carbon dioxide. North American CGA-320 fitting. Output pressure range 0 - 2 bar (0 - 30 psig). Includes isolation valve and 1/8 inch Swagelok output fitting.

REGULATOR (CGA)-H2/CO/CH4, 60 PSIG

Nova 800 | 600 | 800 BET | 600 BET

Two stage, gas regulator for reactive gasses hydrogen, carbon monoxide, methane, etc. North American CGA-350 fitting. Output pressure range 0 - 4 bar (0 - 60 psig). Includes isolation valve and 1/8" Swagelok output fitting.

CONTROLLER/DATA MANAGEMENT MODULE (PC)

Nova 800 | 600 | 800 BET | 600 BET

Dell Optiplex or equivalent, equipped with Windows 10 Professional or newer. Includes 20 inch flat screen monitor.

O-RING, VITON 007, BROWN, PACK OF 2

Nova 800 | 600 | 800 BET | 600 BET

TYPE B LONG CELL, 6 mm SM BULB, DIMPLE

Nova 800 | 600

Type B long cell with 6 mm stem, small bulb, and dimple. For use with non-elutriating kits. Borosilicate Glass. Nominal Dimensions: 6 mm OD (4 mm ID), cell length 292 mm, bulb diameter 16 mm, 1 cm3 capacity.

TYPE B LONG CELL, 9 mm SM BULB, DIMPLE

Nova 800 | 600

Type B long cell with 9 mm stem, small bulb, and dimple. For use with non-elutriating kits. Borosilicate Glass. Nominal Dimensions: 9 mm OD (7 mm ID), cell length 287.5 mm, bulb diameter 15.9 mm, 1 cm3 capacity.

TYPE B LONG CELL, 9 mm NO BULB, QUARTZ

Nova 800 | 600 | 800 BET | 600 BET

Type B long cell with 9 mm stem and no bulb. Quartz for temperatures above 350 C. Nominal Dimensions: 9 mm OD (7 mm ID), cell length 287.5 mm, 0.5 cm3 capacity.

TYPE B ROD, FOR 6 mm LONG DIMPLE CELL

Nova 800 | 600 | 800 BET | 600 BET

Non-flared filler rod (cell insert) for 6 mm, long, dimpled, type B cell For use with non-elutriating cell kits. Nominal Dimensions: 3 mm diameter, 243 mm long.

TYPE B ROD, FOR 9 mm LONG DIMPLE SM CELL

Nova 800 | 600 | 800 BET | 600 BET

Non-flared filler rod (cell insert) for 9mm, long, small bulb dimpled, type B cells. For use with non-elutriating cell kit. Nominal Dimensions: 6 mm diameter, 248 mm long.

TYPE B ROD, FOR 9 mm SHORT DIMPLE LG

Nova 800 | 600 | 800 BET | 600 BET

Non-flared filler rod (cell insert) for 9 mm, short, large bulb dimpled, type B cells. For use with non-elutriating cell kit. Nominal Dimensions: 6 mm diameter, 102 mm long.

DEWAR, STORAGE, 5 L

Nova 800 | 600 | 800 BET | 600 BET

5 L cryogen dewar for the transport and storage of liquefied gasses.

DEWAR, STORAGE, 10 L

Nova 800 | 600 | 800 BET | 600 BET

10 L cryogen dewar for the transport and storage of liquefied gasses.

DEWAR, STORAGE, 30 L

Nova 800 | 600 | 800 BET | 600 BET

30 L cryogen dewar for the transport and storage of liquefied gasses.

WITHDRAWAL DEVICE, 30 L STORAGE DEWAR

Nova 800 | 600 | 800 BET | 600 BET

Withdrawal device (hose) for use with the 30 L Storage Dewar.

ROLLER BASE, 30 L STORAGE DEWAR

Nova 800 | 600 | 800 BET | 600 BET

Rolling trolley for the easy transport of the 30 L Storage Dewar.

CIRCULATING BATH, -20 C TO 150 C, 110 V

Nova 800 | 600 | 800 BET | 600 BET

Refrigerated/heating circulator capable of controlling temperatures from -20 C to 150 C. Temperature stability +/- 0.03 C with 0.1 C resolution. Reservoir volume 4 L max. Pumping flow rate of 15 L/min. Includes 2 barbed fittings for 8 and 12 mm ID tubing.

DEWAR, STORAGE, 50 L

Nova 800 | 600 | 800 BET | 600 BET

50 L cryogen dewar for the transport and storage of liquefied gasses.

ROLLER BASE, 50 L STORAGE DEWAR

Nova 800 | 600 | 800 BET | 600 BET

Rolling trolley for the easy transport of the 50 L Storage Dewar.

WITHDRAWAL DEVICE, 50 L STORAGE DEWAR

Nova 800 | 600 | 800 BET | 600 BET

Withdrawal device (hose) for use with the 50 L Storage Dewar.

TYPE B ROD, FOR 9 mm SHORT DIMPLE SM

Nova 800 | 600 | 800 BET | 600 BET

Non-flared filler rod (cell insert) for 9 mm, short, small bulb dimpled, type B cells. For use with non-elutriating cell kit. Nominal Dimensions: 6 mm diameter, 112 mm long.

ETHERNET CABLE, 25 FEET

Nova 800 | 600 | 800 BET | 600 BET

CELL-SEAL, OPENER 9MM

Nova 800 | 600 | 800 BET | 600 BET

TYPE B LONG CELL, 9 mm LG BULB, QUARTZ

Nova 800 | 600 | 800 BET | 600 BET

Type B long cell with 9 mm stem and large bulb. Quartz for temperatures above 350 C. Nominal Dimensions: 9 mm OD (7 mm ID), cell length 287.5 mm, bulb diameter 26 mm, 6 cm3 capacity.

Vacuum Pump, 100-120V

Nova 800 | 600 | 800 BET | 600 BET

Two stage, direct drive oil vacuum pump with ultimate vacuum to 3.0x10-3 mbar. Noise level 54 dB(A).

Vacuum Pump, 200-240V

Nova 800 | 600 | 800 BET | 600 BET

Two stage, direct drive oil vacuum pump with ultimate vacuum to 3.0x10-3 mbar. Noise level 54 dB(A).

Nova X00 DEWAR COVER, 2 L, FOAM

Nova 800 | 600 | 800 BET | 600 BET

Replacement foam cover for Nova X00 2 L analysis dewars

P0 COLLAR, LARGE

Nova 800 | 600 | 800 BET | 600 BET

NOVA X00, RECIRCULATING DEWAR KIT

Nova 800 | 600 | 800 BET | 600 BET

Recirculating dewar kit for the Nova X00 series

BALANCE CELL HOLDER 6, 9, 12 mm CELL

Nova 800 | 600 | 800 BET | 600 BET

TYPE B SHORT CELL, 6 mm LG BULB, QUARTZ

Nova 800 | 600 | 800 BET | 600 BET

Type B short cell with 6 mm stem and large bulb. Quartz for temperatures above 350 °C. Nominal dimensions: 6 mm OD (4 mm ID), cell length 155.5 mm, bulb diameter 26 mm, 6 cm3 capacity

TYPE B SHORT CELL, 12 mm LG BULB, QUARTZ

Nova 800 | 600 | 800 BET | 600 BET

Type B short cell with 12 mm stem and large bulb. Quartz for temperatures above 350 °C. Nominal dimensions: 12 mm OD (10 mm ID), cell length 146.5 mm, bulb diameter 26 mm, 6 cm3 capacity

External Vacuum and Flow Degassing:

FloVac

Nova 800 | 600 | 800 BET | 600 BET

- Degas six samples at a time while six others cool

- Heat samples from ambient to 425 °C

- Keep the heater ON for a faster turnaround time

- Perform vacuum and flow degassing

- Set up heating and cooling rates with ease

TYPE B SHORT CELL, 9 mm NO BULB

Nova 800 BET | 600 BET

Type B short cell with 9 mm stem and no bulb. Borosilicate Glass Nominal Dimensions: 9 mm OD (7 mm ID), cell length 151 mm, 0.5 cm3 capacity.

TYPE B SHORT CELL, 9 mm SM BULB

Nova 800 BET | 600 BET

Type B short cell with 9 mm stem and small bulb. Borosilicate Glass. Nominal Dimensions: 9 mm OD (7 mm ID), cell length 151 mm, bulb diameter 16 mm, 1 cm3 capacity.

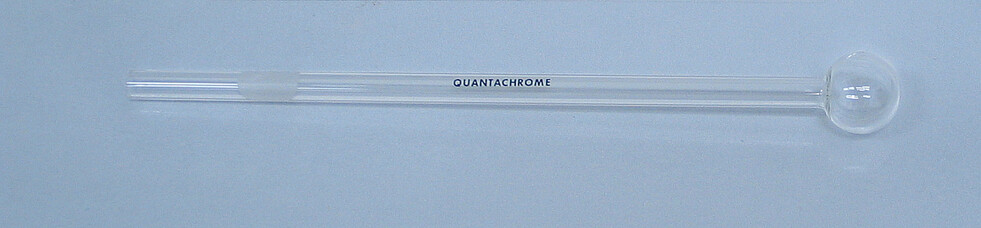

TYPE C LONG CELL, 6 mm SM BULB

Nova 800 BET | 600 BET

Type C long cell with 6 mm stem and small bulb. Borosilicate Glass. Nominal Dimensions: 6 mm OD (4 mm ID), cell length 266 mm, bulb diameter 11 mm, 1 cm3 capacity.

TYPE B SHORT CELL, 9 mm LG BULB

Nova 800 BET | 600 BET

Type B short cell with 9 mm stem and large bulb. Borosilicate Glass. Nominal Dimensions: 9 mm OD (7 mm ID), cell length 151 mm, bulb diameter 26 mm, 6 cm3 capacity.

TYPE B SHORT CELL, 12 mm LG BULB

Nova 800 BET | 600 BET

Type B short cell with 12 mm stem and large bulb. Borosilicate Glass. Nominal Dimensions: 12 mm OD (10 mm ID), cell length 146.5 mm, bulb diameter 26 mm, 6 cm3 capacity.

LEVEL SENSOR, CLS TYPE, CRYOGEN, SHORT

Nova 800 BET | 600 BET

CLS type coolant level sensor for use with liquid argon (87 K) or liquid nitrogen (77 K). Appropriate for use with short cells.

O-RING, PFE 019, BLACK

Nova 800 BET | 600 BET

TYPE C SHORT CELL, 6 mm SM BULB

Nova 800 BET | 600 BET

Type C short cell with 6 mm stem and small bulb. Borosilicate Glass. Nominal Dimensions: 6 mm OD (4 mm ID), cell length 130 mm, bulb diameter 11 mm, 1 cm3 capacity.

TYPE B SHORT CELL, 6 mm SM BULB

Nova 800 BET | 600 BET

Type B short cell with 6 mm stem and small bulb. Borosilicate Glass. Nominal Dimensions: 6 mm OD (4 mm ID), cell length 155.5 mm, bulb diameter 16 mm, 1 cm3 capacity.

TYPE B SHORT CELL, 6 mm LG BULB

Nova 800 BET | 600 BET

Type B short cell with 6 mm stem and large bulb. Borosilicate Glass. Nominal Dimensions: 6 mm OD (4 mm ID), cell length 155.5 mm, bulb diameter 26 mm, 6 cm3 capacity.

TYPE B SHORT CELL, 9 mm LG BULB, DIMPLE

Nova 800 BET | 600 BET

Type B short cell with 9 mm stem, large bulb, and dimple. For use with non-elutriating kits. Borosilicate Glass. Nominal Dimensions: 9 mm OD (7 mm ID), cell length 151 mm, bulb diameter 26 mm, 6 cm3 capacity.

TYPE B SHORT CELL, 6 mm NO BULB

Nova 800 BET | 600 BET

Type B short cell with 6 mm stem and no bulb. Borosilicate Glass. Nominal Dimensions: 6 mm OD (4 mm ID), cell length 155.5 mm, 0.1 cm3 capacity.

TYPE B SHORT CELL, 9 mm SM BULB, DIMPLE

Nova 800 BET | 600 BET

Type B short cell with 9 mm stem, small bulb, and dimple. For use with non-elutriating kits. Borosilicate Glass. Nominal Dimensions: 9 mm OD (7 mm ID), cell length 151 mm, bulb diameter 16 mm, 1 cm3 capacity.

TYPE B SHORT CELL, 12 mm SM BULB

Nova 800 BET | 600 BET

Type B short cell with 12 mm stem and small bulb. Borosilicate Glass. Nominal Dimensions: 12 mm OD (10 mm ID), cell length 146.5 mm, bulb diameter 16 mm, 1 cm3 capacity.

1L ALUMINUM SHORT DEWAR WITH HANDLE

Nova 800 BET | 600 BET

1L Dewar used for the Nova x00 BET series

TYPE B SHORT CELL, 12 mm NO BULB

Nova 800 BET | 600 BET

Type B short cell with 12 mm stem and no bulb. Borosilicate Glass. Nominal Dimensions: 12 mm OD (10 mm ID), cell length 146.5 mm, 0.8 cm3 capacity.

PYC, LARGE NON-ELUTRIATING CELL

Nova 800 | 600 | 800 BET | 600 BET

- Special two piece large (135 cm3) sample cell

- Designed to prevent fluidization (elutriation) of fine powders

- Compatible with all (non-micro) models of pycnometers