Mining solutions

Sustainable mining of natural resources is a cornerstone for our standard of living and prosperity. Mined materials have a wide array of applications. They play a critical role in construction (e.g., building frameworks) and power generation, and are used as commodities and minerals for industrial applications. They contribute to current green technologies – like wind turbines, solar panels, and electric vehicles – and the exploration of new exploitable deposits as part of the effort to counter climate change. And they are used to produce luxury goods. To play a positive and sustainable economic role in society, mined metals and minerals must be explored for, extracted, transported, and processed according to quality control processes that deliver safe and high-quality products. A wide array of Anton Paar instruments can contribute to every step of this development and production chain.

| Instrument | Samples | Measurement | ||

|---|---|---|---|---|

|

High temperature viscometer and

rheometer:

|

|

Rheometry |

Coal combustion for energy production: Find out the temperature

and composition at which a predefined viscosity (viscosity for flow down

the reactor wall) is reached

|

|

Inline Density

Meter:

|

|

Concentration Measurement |

Platinum mining: Concentration measurement of HCl,

HNO3, and diluted H2SO4 in the PMR

|

|

Inline Sound Velocity

Concentration Meter:

|

|

Concentration Measurement |

Gold mining: HCl dilution control for calcium removal (carbon

regeneration)

Gold mining: Lixiviant concentration measurement (Au-leach)

Uranium mining: H2SO4 concentration

measurement (U-leach)

Uranium mining: Oxidant concentration measurement (U-leach)

Uranium mining: NaOH precipitant concentration measurement

(U-leach)

Platinum mining: H2SO4, NaOH,

Na2SO4 concentration measurement (BMR, PMR)

Copper mining: H2SO4 concentration

measurement (acid plant)

Nickel mining: H2SO4 concentration

measurement (acid plant)

|

|

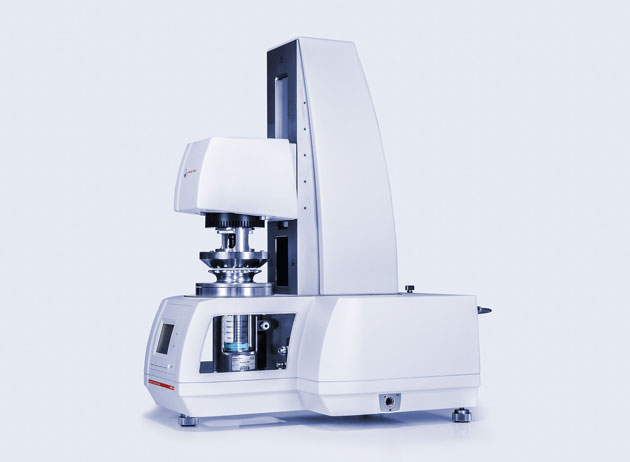

Modular Compact Rheometer:

|

|

Rheometry |

Hydraulic fracturing: Predict the flow behavior of the mixture of

water, chemicals and sand used for fracking at high pressures and

various shear rates

Slurry transport (ore and tailings): Analyze and lower the yield

point of ore slurry to avoid downtime of the processing plant and assure

an efficient transportation process

Slurry storage (ore and tailings): Determine the necessary shear

rate to keep mineral particles suspended during storage

Dilution of tailings slurry: Efficiently dilute tailings to

enable pumping, while minimizing discarded material

|

|

Hot block digestion

system:

|

|

Hot Block Digestion |

Refinining, extraction, smelting (=purification) of various ores:

Perform digestion of lead prill after fire assay or fusion process with

48 digestion positions at once

Quality control: Perform digestion of lead prill after fire assay

or fusion process with 48 digestion positions at once

Environmental control of mining site and refining site: Analyze

water and soil (48 samples at once) for contamination with harmful

elements

|

|

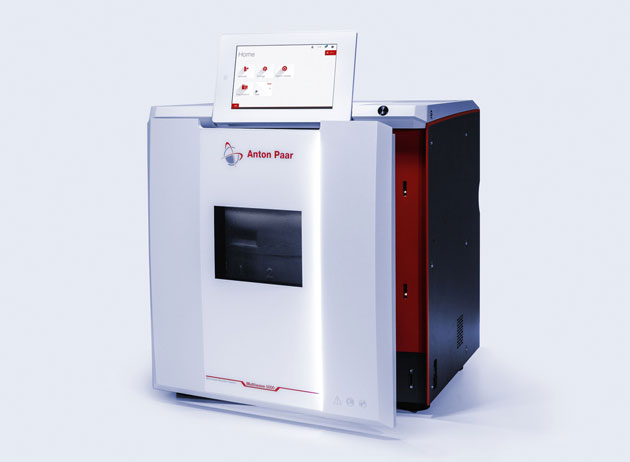

Microwave digestion

system:

|

|

Microwave Digestion |

Exploration of possible mining sites: Analyze metal content in

mineral samples from exploration

Sludge analysis: Perform

robust and easy-to-use acid digestion of sludge prior to environmental

trace analysis of toxicologically and environmentally relevant elements

(ICP, AAS, etc.).

|

|

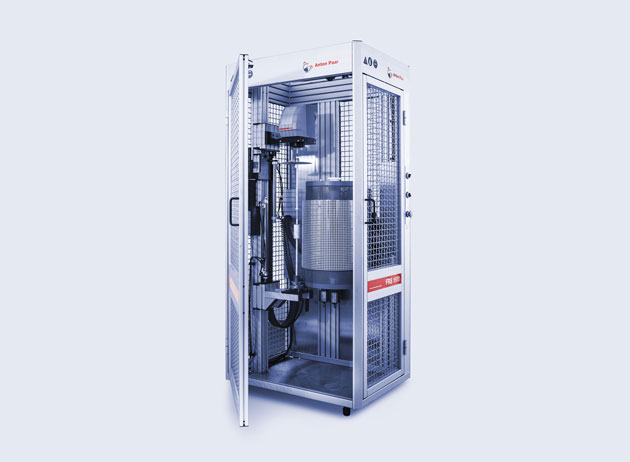

Microwave digestion

system:

|

|

Microwave Digestion |

Mining and excavation: Dissolve rocks containing elements of

interest prior to subsequent analysis (ICP, AAS, etc.)

Refinining, extraction, smelting (=purification) of various ores:

Perform fast and trouble-free acid digestion with high throughput,

without contamination or loss of analyte

Quality control: Perform fast and trouble-free acid digestion

with high throughput, without contamination or loss of analyte

Caustic leaching of bauxite: Simulate the industrial Bayer

process on a lab scale to determine optimum conditions for the

industrial process

Extraction, refining and quality control of coal and graphite:

Reliably digest highly reactive samples such as coal, coke and graphite,

which require high temperatures

|

|

Microwave digestion

system:

|

|

Microwave Digestion |

Exploration of possible mining sites: Analyze metal content in

mineral samples from exploration

Waste water

quality determination: Perform microwave digestion on waste

water so that it is ideally prepared for further elemental analysis

|

|

Surface area and pore

analyzers:

|

|

Vacuum Volumetric Gas Sorption Analysis |

Slurry stabilization: Calculate the proper amount of

dispersant/stabilizer to reduce costs by eliminating unnecessary, excess

dispersant/stabilizer

|

|

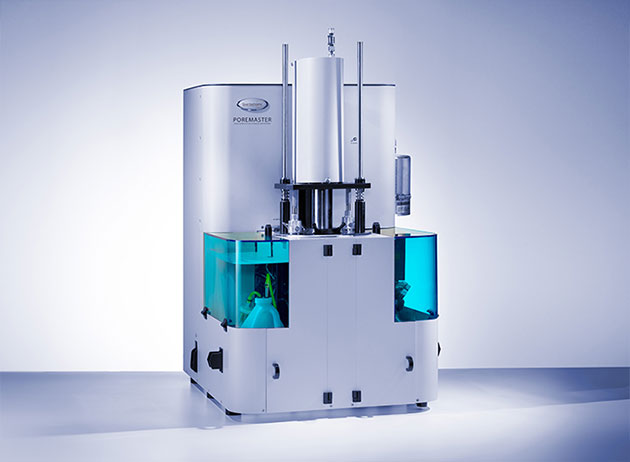

Mercury intrusion pore size

analyzers:

|

|

Mercury Intrusion Porosimetry |

Site evaluation: Evaluate groundwater movement and pollution by

quantifying pore size

|

|

Particle size

analyzer:

|

|

Laser Diffraction |

QC of drilling fluids: Maximize the (re)usage of drilling muds by

detecting low-gravity solids (LGS) as they build up, via monitoring of

particle size distribution (PSD)

Ore grinding: Prevent energy wastage on unnecessary grinding, by

determining and thus eliminating fine and ultrafine particles

Ore grinding and separation: Produce uniform particle size to

prevent ore separation bias, via particle size optimization to control

the separation behavior

Quality control of processed ore: Determine and monitor the

particle size distribution of processed ore to ensure consistent quality

of the final product

|

|

Rotational

Rheometer:

|

|

Rotational Rheometry |

QC of drilling fluids: Smoothly transport drilling muds via

determination of viscosity at rest and during pumping of bentonite

|

|

Powder Cells for

MCR:

|

|

Powder Rheometry, Rheometry |

Ore transport: Avoid issues during transport and storage of

powdery materials by simulating mechanical transport

Processed ore transport: Improve the pneumatic transport of

processed powders by determining fluidization behavior

|

|

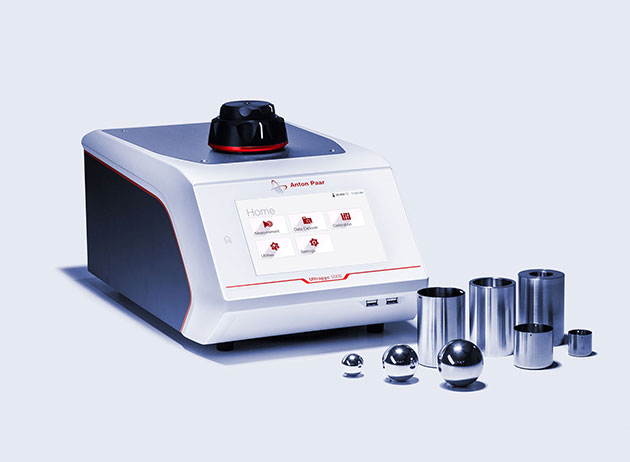

Single-station gas pycnometers

for true density:

|

|

Gas Pycnometry |

Site evaluation: Evaluate groundwater movement and pollution by

quantifying rock porosity

Formulating well cement: Calculate target solid % and improve

accuracy of Blaine measurement, to produce a cement with proper support

and thermal insulation

Formulation of drilling fluids: Obtain the optimum density for

hydrostatic pressure and circulation

Ocean transport of ore fines: Perform safety calculations to

avoid loss of vessel at sea via evaluation of the risk of liquefaction

for a particular load

Settling tank/pond/basin design: Calculate the sedimentation

times of tailings/washings for more efficient operation and lifecycle

management to reduce overall costs and land use

Froth flotation (separation of beneficial minerals): Optimize the

slurry concentration from pulp density by determining the size and

number of flotation cells for a given capacity

Coal washability test: Maximize the economics of separating coal

from rock and minerals by optimizing the density of fluids in float-sink

tanks

Quality control, packaging and transportation: Receive the

correct volume of pulverized rock (ore)

Tailings dam safety: Measure the density of dry tailings,

saturated tailings, fines and slime for improved risk assessment

Waste gypsum: Determine the suitability of recovered waste

material for use in mortars, and calculate formulation

|

|

Rotational

viscometer:

|

|

Rotational Viscometry |

QC of drilling fluids: Smoothly transport drilling muds via

determination of viscosity at rest and during pumping of bentonite

|

|

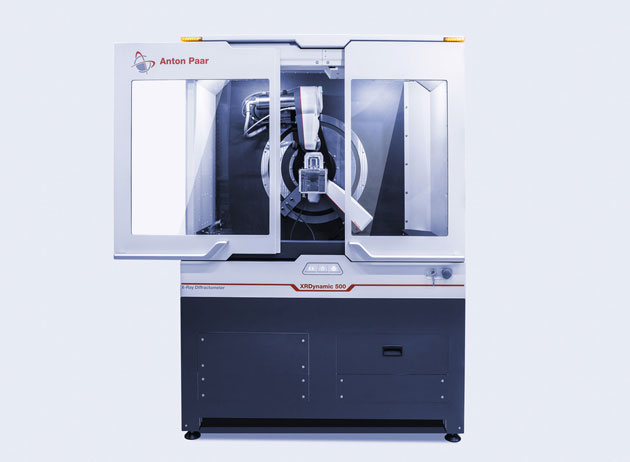

Automated Multipurpose Powder

X-Ray Diffractometer:

|

|

X-Ray Diffraction |

Exploration: Optimize the mining process and effectively plan

downstream processing requirements by identifying high-value deposits

and the mineral forms present

Exploration: Discover possible recovery losses ahead of time, to

optimize the extraction process, by identifying non-extractable ore

forms

QC and grade control: Increase efficiency and stabilize plant

conditions by selecting the optimal grade

Ore processing: Optimize the operational efficiency of the mining

process and the beneficiation process of the ore by rapidly analyzing

the qualitative and quantitative mineral composition of the mined

material

Ore processing: Reduce the costs and environmental impact of ore

processing by identifying the iron oxidation state via phase analysis of

the mineral ore

Quality control: Continuously monitor the processed ore quality

in order to quickly respond to changes

Tailings analysis: Reduce wastage and potential environmental

damage by identifying compounds of value that can be recovered from

tailings

|