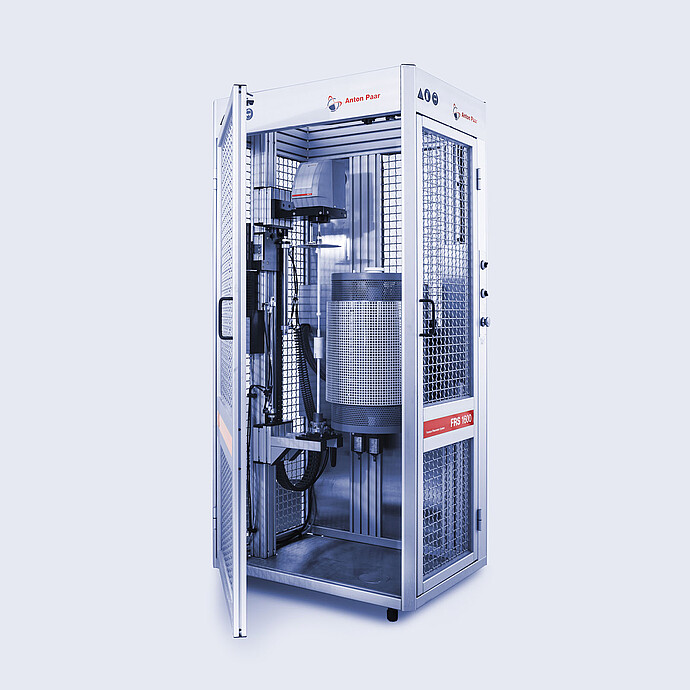

High Temperature Viscometer and Rheometer:

FRS

- Temperature range from 300 °C up to 1530 °C

- Ideal for research and process optimization of slags, metals, and glass melts

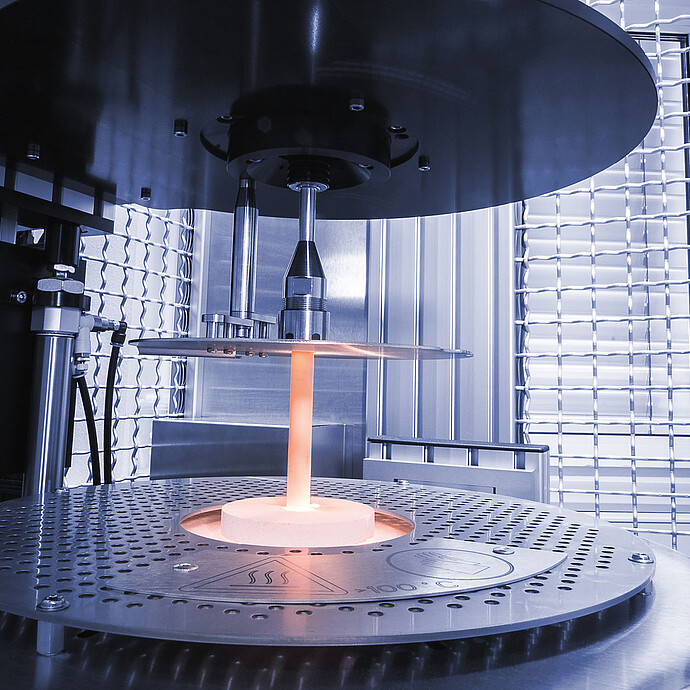

Materials which are in regular use in everyday life, such as glasses, ceramics, and metals, are processed or refined as melts at temperatures above 1000 °C. By determining the melt viscosity of these materials with FRS, you can achieve a consistent high quality of the final product and optimize the energy-intensive production process. These systems open up new possibilities in the R&D of materials with a high melting point. The Furnace Rheometer Systems (FRS) each combine a highly accurate air-bearing rheometer head and a lab furnace for high temperature viscosity measurements of melts at furnace temperatures up to 1800 °C (1730 °C sample temperature).

For more information about the application of high temperature viscometer and rheometer, see this Wiki article.

Key features

Highest safety and easy sample loading

The CE safety concept ensures full protection of the whole system. After the solid sample has been placed, the combination of pneumatic pre-positioning and the stepper-motor-driven fine positioning ensures a controlled and accurate immersion of the measuring system into the sample. This is done automatically as soon as the sample has been melted. During this process the operator is outside the safety cage, protected from the lab furnace, and works with the Anton Paar’s proven RheoCompass™ software, which supports fully automatic operation during high-temperature viscosity measurement, and enables simple reporting and evaluation of the results.

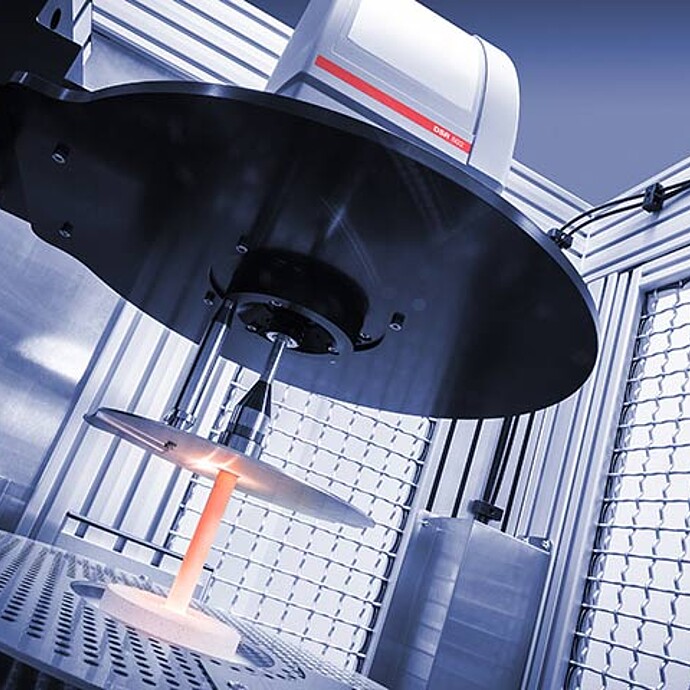

Measure very low viscosities with the unique air-bearing motor

25 years of experience in one motor – you only get this with rheometers from Anton Paar. The air-bearing-supported synchronous EC motor deploys a frictionless synchronous movement of the rotor inside which enables the most sensitive and therefore most precise movements at a large shear rate range. In this way, even low-viscosity samples can be measured using the high temperature viscometer and rheometer system – with unprecedented precision.

Normal force control for detecting the melting point

The normal force sensor in the rheometer head allows for precise detection of the melting point during heating. The solidification point can be detected in the oscillation and rotation mode. Furthermore, the robust laboratory furnace with its air- and water-cooled system allows best-in-class temperature stability and accuracy of the sample temperature.

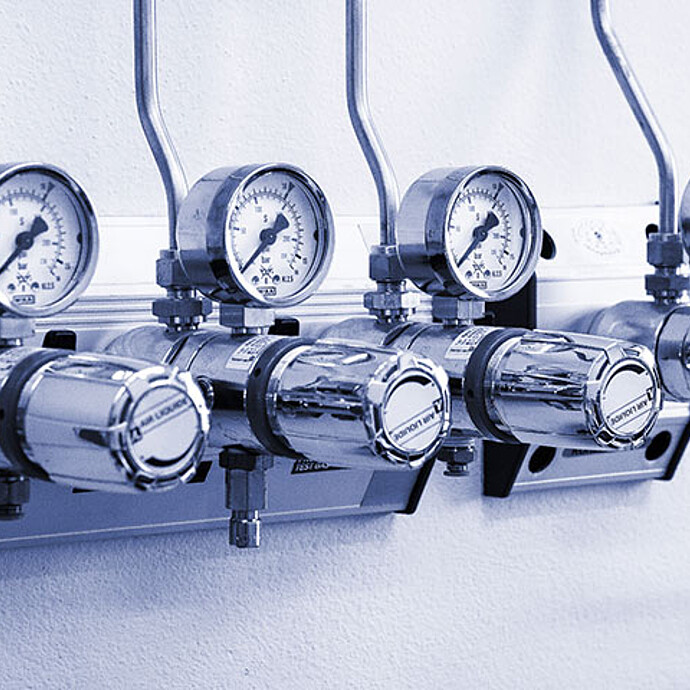

Measure under inert gas atmosphere

With the FRS systems, you can either chose to measure under air, or also under inert gas atmosphere. The inert gas atmosphere protects the sample from unwanted chemical reactions, such as oxidation, during measurement with the high temperature viscometer and rheometer.

High temperature viscometer measurements in compliance with international standards

The furnace rheometer systems FRS are compliant with international industry standards: ASTM C965 (Standard Practice for Measuring Viscosity of Glass Above the Softening Point), and ISO 7884-2 (Glass Viscosity and viscometric fixed points; part 2: Determination of viscosity by rotation viscometers).

Technical specifications

| Unit | FRS 1600 | FRS 1800 | |

|---|---|---|---|

| Bearing | - | Air | Air |

| EC motor (brushless DC) with high resolution optical encoder | - | ✔ | ✔ |

| Permanent torque (60 min), no signal drift | - | ✔ | ✔ |

| EC mode (controlled shear rate and shear stress) | - | ✔ | ✔ |

| Rotation mode | - | ✔ | ✔ |

| Oscillation mode | - | ✔ | ✔ |

| Measuring of newtonian samples | - | ✔ | ✔ |

| Measuring of non-newtonian samples | - | ✔ | ✔ |

| Maximum torque | mNm | 230 | 230 |

| Minimum torque, rotation | nNm | 10 | 10 |

| Minimum torque, oscillation | nNm | 2 | 2 |

| Torque resolution | nNm | 0.1 | 0.1 |

| Viscosity range | Pa.s | 0.001–107 | 0.001–107 |

| Angular deflection, set value | µrad | 0.1 to ∞ | 0.1 to ∞ |

| Angular deflection, resolution | nrad | 10 | 10 |

| Minimum angular velocity | rad/s | 10-9 | 10-9 |

| Maximum angular velocity | rad/s | 314 | 314 |

| Minimum speed (CSS/CSR) | 1/min | 10-9 | 10-9 |

| Maximum speed FRS | 1/min | 300 | 300 |

| Maximum speed measuring head | 1/min | 3000 | 3000 |

| Minimum angular frequency | rad/s | 10-7 | 10-7 |

| Maximum angular frequency | rad/s | 628 | 628 |

| Normal force range | N | 0.005 to 50 | 0.005 to 50 |

| Normal force resolution | mN | 0.5 | 0.5 |

| Dimensions | mm | 680 x 1950 x 920 mm | 680 x 1950 x 920 mm |

| Weight | kg | 120 | 150 |

| Oven temperature range | °C | 20, 300 to 1600 | 20, 600 to 1800 |

| Minimum sample temperature | °C | Room temperature | Room temperature |

| Maximum sample temperature | °C | 1530 | 1730 |

| Temperature gradient optimized | - | ✔ | ✔ |

| Sample temperature sensor | - | Typ S or B | Typ S or B |

| Temperature resolution | °C | 0.1 | 0.1 |

| Safety housing | - | ✔ | ✔ |

| Inert gas atmosphere possible | - | ✔ | ✔ |

| Measuring system material | - | Al2O3, graphite, Pt, and customized | Al2O3, graphite, Pt, and customized |

| Measuring system rotor diameter | mm | 11 to 27.6 | 11 to 27.6 |

| Maximum measuring system cup height | mm | 100 | 100 |

| DMA™ Option | - | on request | on request |

| Compliant standards ASTM C965, ISO 7884-2 | - | ✔ | ✔ |

Standards

ASTM

ISO

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Glass Containers for Packaging of Pharmaceutical Products Application Reports

-

Introduction to High Temperature Viscosimetry and Rheometry Application Reports

-

Liquid Density Measurements with a High-Temperature Rheometer Application Reports

-

Oxygen-Free Viscosity Measurements up to 1800 °C Application Reports

-

Rheological Characterization of Metal Melts Application Reports

-

Rheological Characterization of Slags Application Reports

-

Rheological Investigation of Coal Ash Application Reports

-

Rheological Investigations of Glass Application Reports

-

Rheological Investigations of Glass for Glass Wool Production Application Reports

-

Rheological Investigations of Metal-Melts for Additive Manufacturing Application Reports

-

The Furnace Rheometer System FRS for the Measurement of Glass Melts Application Reports

-

Datasheet | High-Temperature Rheology Brochures