Nanoindentation Tester:

NHT³

- Measurement of hardness, elastic modulus, and other surface mechanical properties from nanometer to micrometer scale

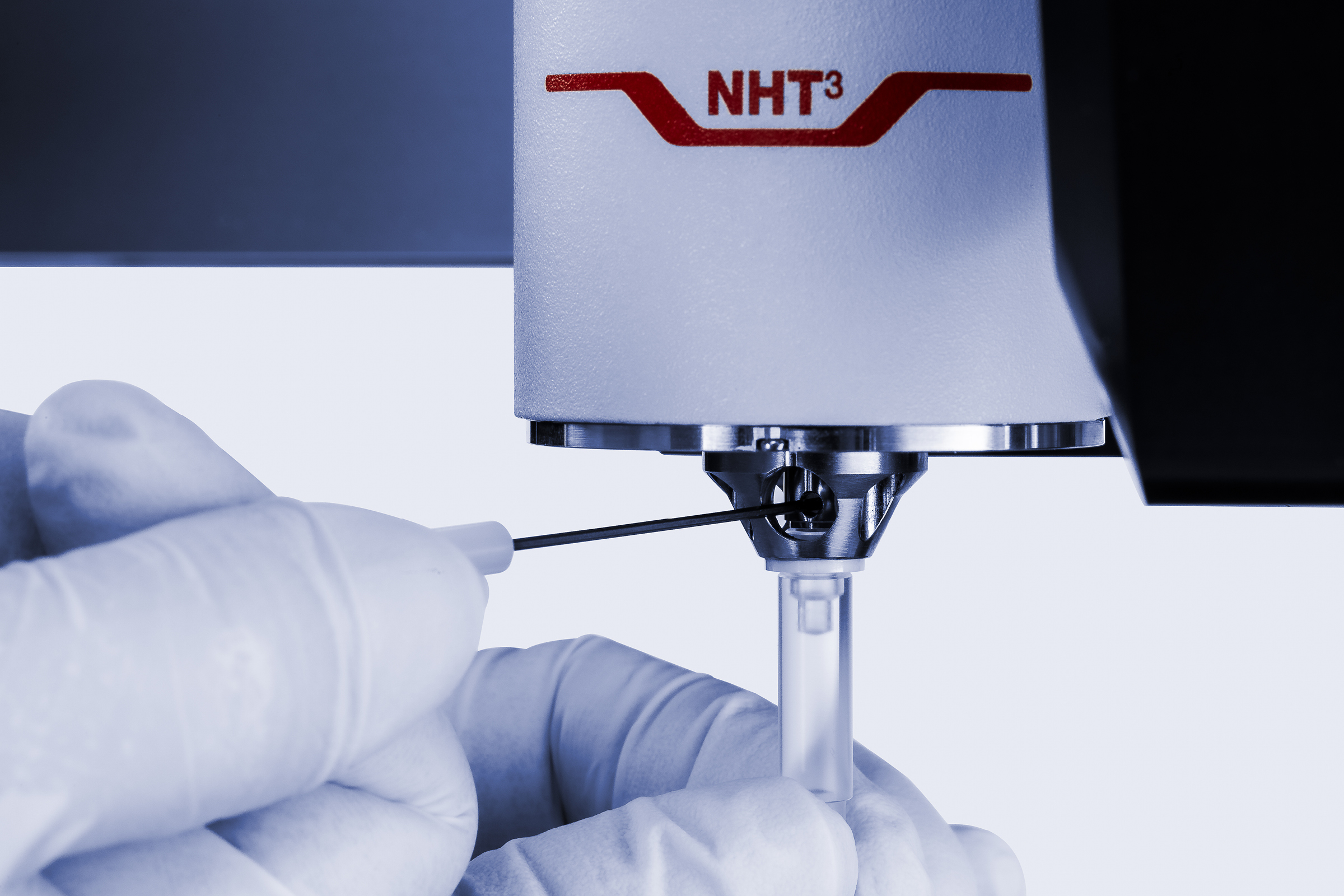

- Immediate start of measurement after sample installation

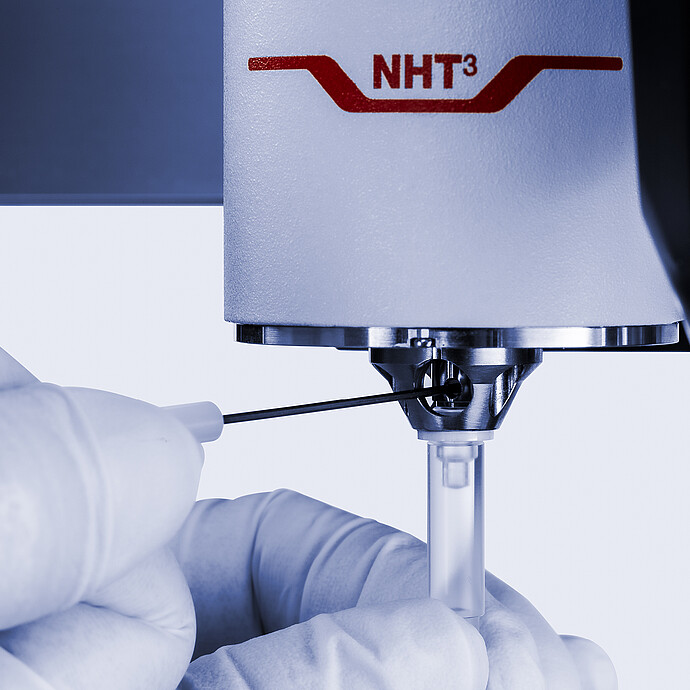

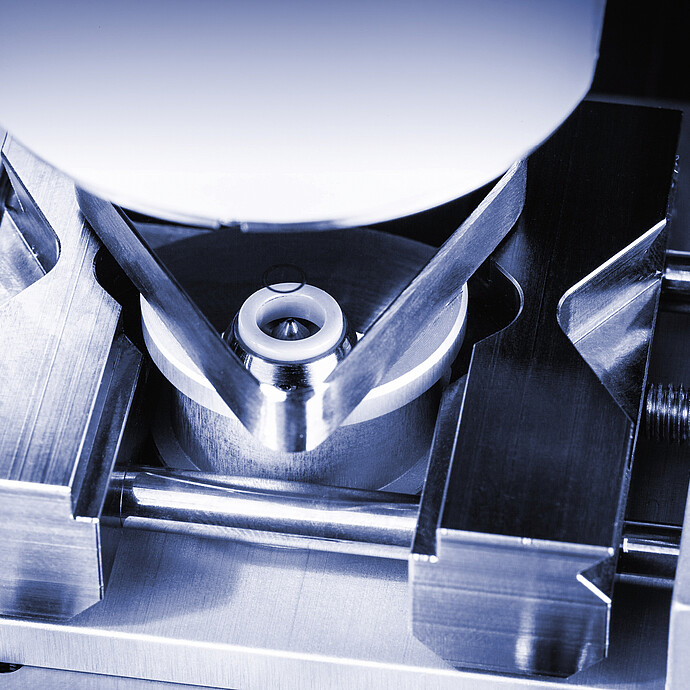

- Fast and easy indenter exchange

- Force measurement up to 500 mN

- Also available for electrical contact resistance measurements (ECR version)

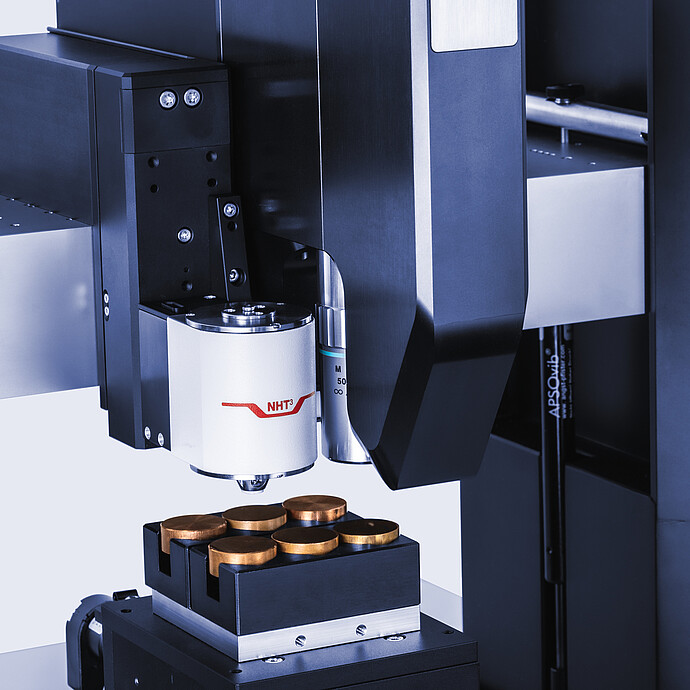

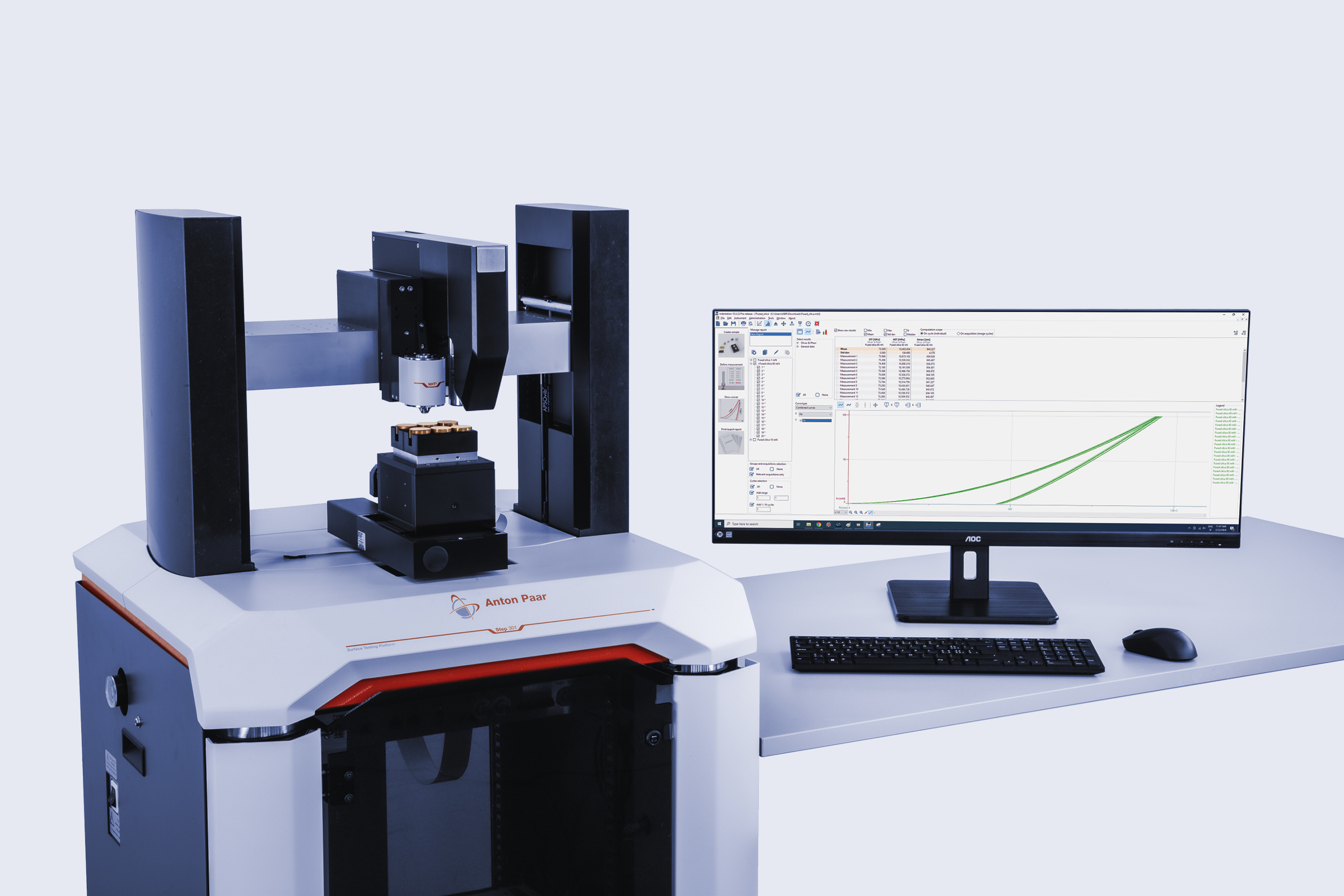

The NHT³ Nanoindentation tester is designed for measuring hardness, elastic modulus, creep, and other surface properties from the nanometer to the micrometer scale. Its force ranges from 0.1 mN to 500 mN for maximum versatility. With the unique top surface referencing technique, an instrumented indentation measurement can be made immediately without waiting for thermal stabilization. The “Quick Matrix” indentation mode allows high throughput (up to 600 measurements per hour).

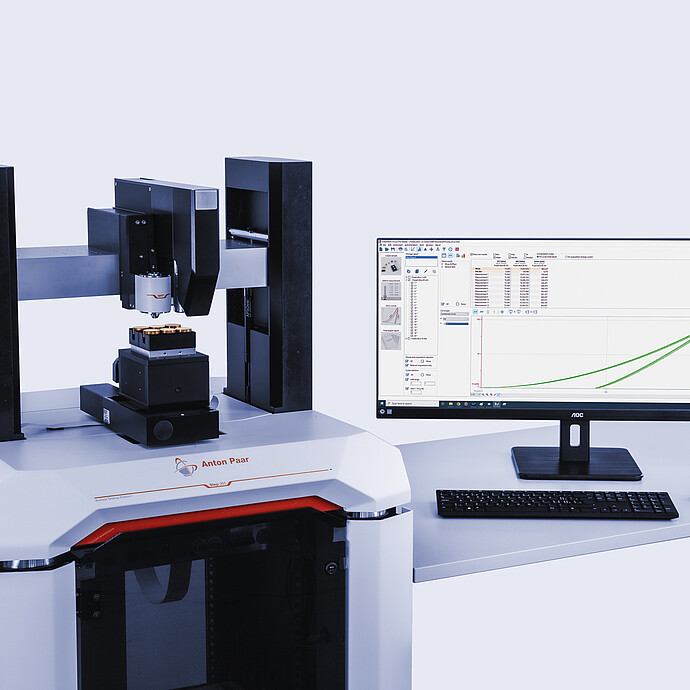

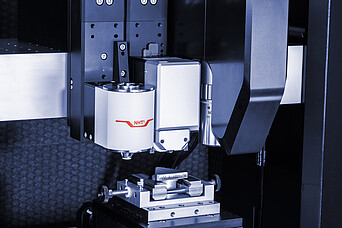

Add another mechanical surface testing method (e.g. scratch testing) to the NHT3: The platform accommodates several testing heads to cover all force ranges and provides you with a bigger picture of your sample.

Key features

Straightforward nanoindentation measurements

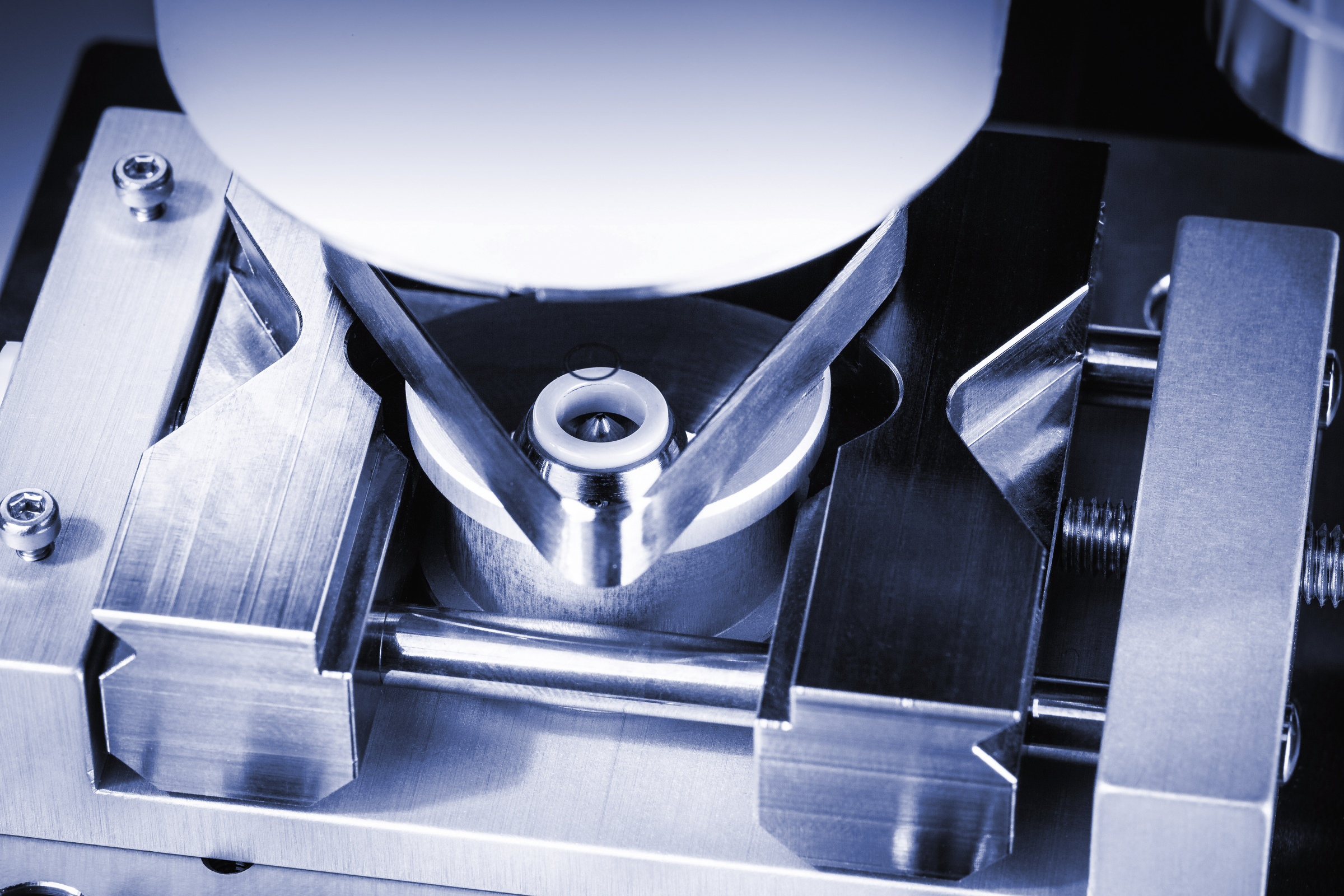

With Anton Paar’s intuitive software you can easily define and analyze each type of instrumented indentation measurement, from standard to highly advanced methods. The integrated microscope offers a very large magnification range so you can observe the sample’s surface and allows you to directly define the measuring position. Moreover, the indenter is fully protected from collision by the reference ring and the exchange of a measuring tip can be done in less than 2 minutes.

High accuracy and short time to measure

The unique design of the instrument integrates a top surface reference ring that follows the sample’s surface throughout the indentation measurement. This means the indentation depth is always directly measured with respect to the current surface position. Anton Paar’s nanoindentation tester is the only instrument with this unique feature, meaning NHT³ delivers accurate results and not error-prone software corrections. A further advantage of this technique is that you can immediately start your measurement after the sample installation without waiting hours for thermal stabilization.

High throughput with quick matrices

The fast measuring mode allows you to perform up to 600 measurements per hour with real indentation curves. Thanks to our referencing design, no thermal stabilization is needed, which allows you to install and immediately measure a high number of samples per day. With its user profiles, measurement protocols, multi-sample measurements, and customizable reporting, NHT³ has the highest throughput on the market.

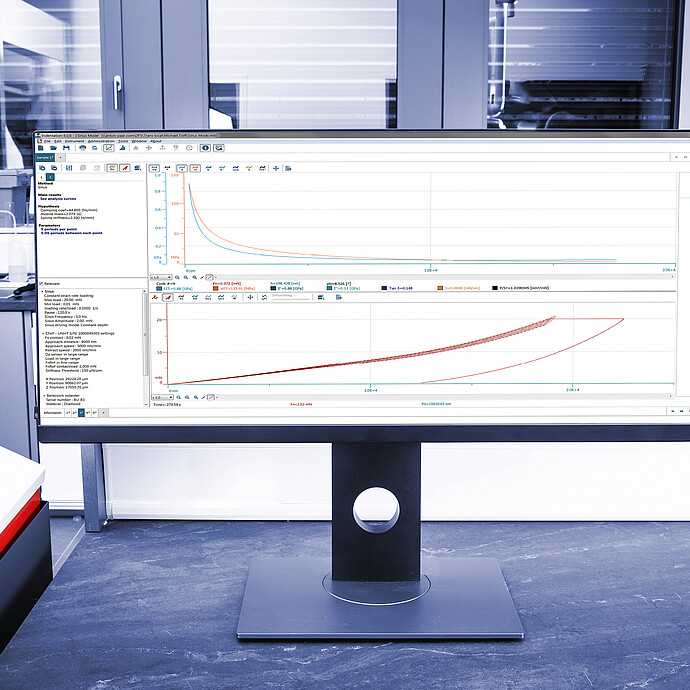

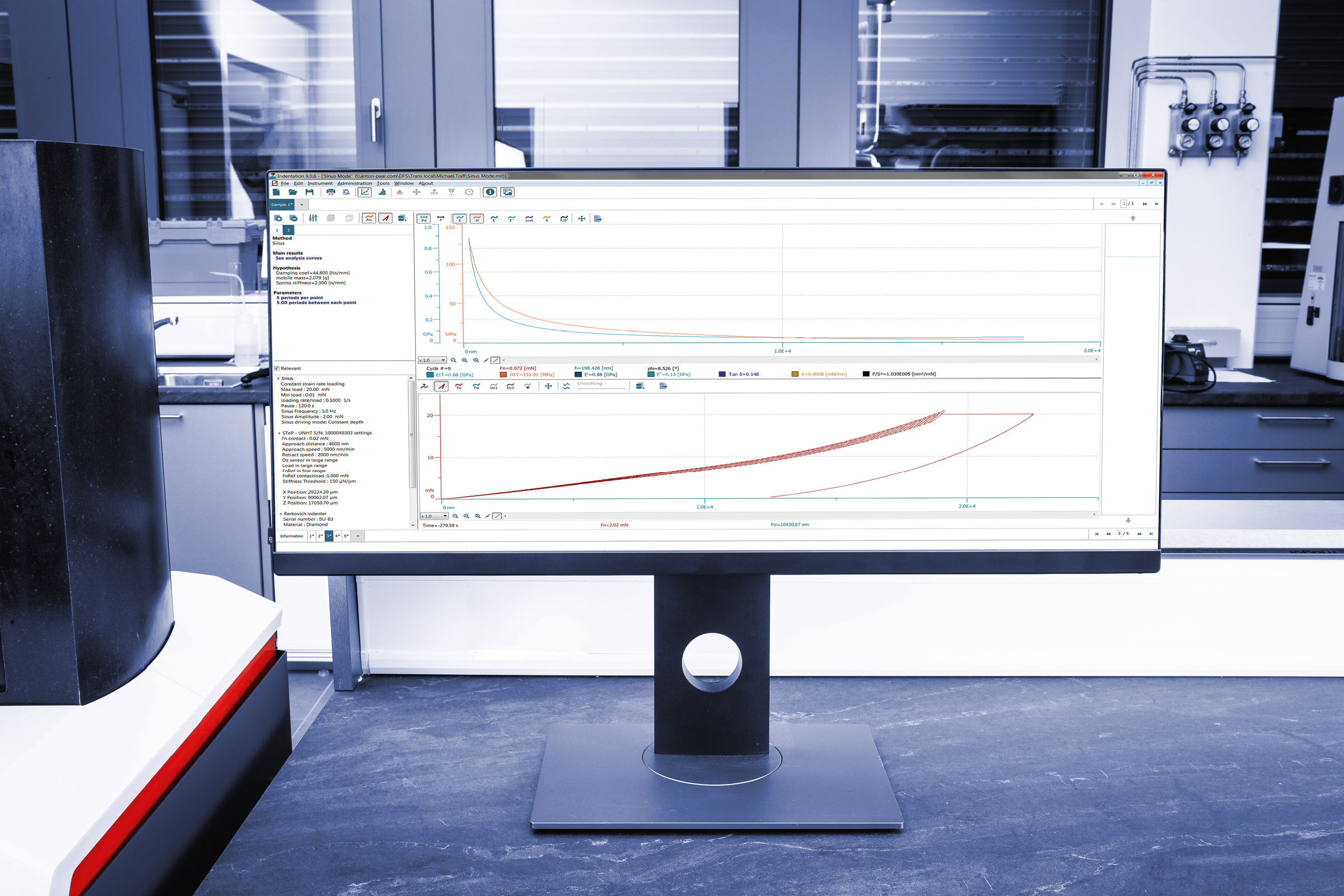

Additional dynamic mechanical analysis (DMA) with “Sinus Mode”

Sinus Mode enables you to perform DMA analysis in order to study the evolution of mechanical properties over depth (HIT, EIT vs. depth) and characterize the sample’s viscoelastic properties (E', E'': storage and loss moduli, tan δ). Sinus Mode offers additional features, such as quick indenter calibration and stress-strain analysis.

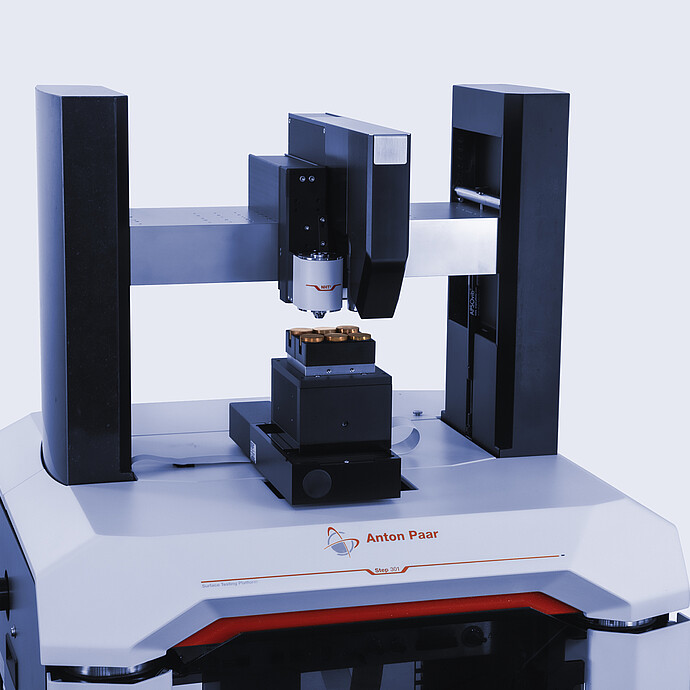

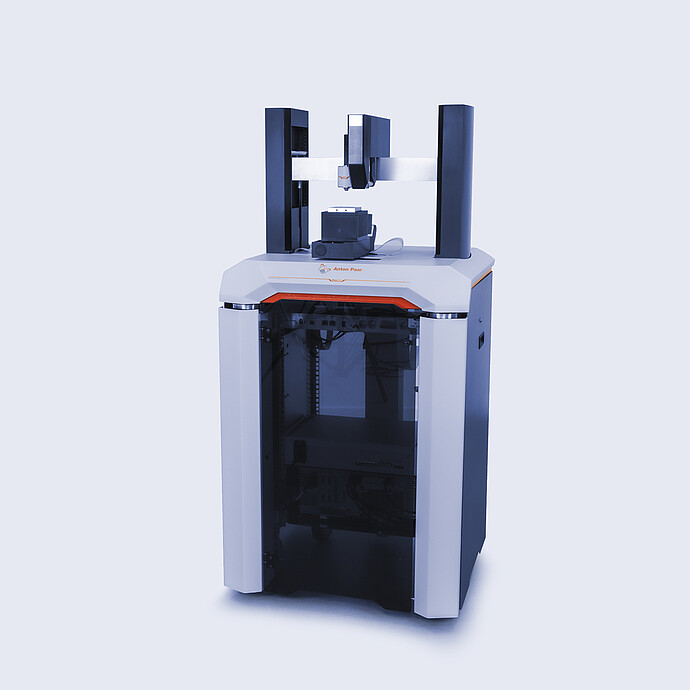

Step platform: Maximum nanoindentation tester versatility

Need a single measuring head for your QC indentation testing or a multiple-head setup for complete surface mechanical characterization testing? The Step platform covers single-application use in dedicated laboratories, as well as shared instruments across multiple departments.

Specifications

| Maximum load [mN] | 500 |

| Load resolution [nN] | 20 |

| Load noise floor [rms] [μN] | ≤0.5 |

| Loading rate [mN/min] | Up to 10000 |

| Depth range [μm] | 200 |

| Depth resolution [nm] | 0.01 |

| Depth noise floor [rms] [nm] | ≤0.15 |

| Data acquisition rate [kHz] | 192 |

| Options | |

| Liquid testing | ✔ |

Standards

ASTM

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Adhesion and hardness of galvanic layers by scratch test and nanoindentation Application Reports

-

Applications of indentation and scratch in automotive industry Application Reports

-

Applications of indentation in polymer industry Application Reports

-

Applications of nanoindentation in biology and medicine Application Reports

-

Characterization of diamond-like coatings (DLC, ta-C) from ANTACON Application Reports

-

Characterization of electrodes in Lithium-ion batteries by nanoindentation Application Reports

-

Characterization of hard coatings - Part I: DLC coatings Application Reports

-

Comparison of nanoindentation with conventional hardness Application Reports

-

Compression of microparticles by cylindrical flat punch using a nanoindenter Application Reports

-

Contribution of nanoindentation and tribology to investigation of welds Application Reports

-

Dynamic mechanical analysis by nanoindentation Application Reports

-

E-Book - Polymer Processing Application Reports

-

Elastic modulus of compacted powders measured by nanoindentation Application Reports

-

Electric contact resistance (ECR) by indentation, scratch and tribology Application Reports

-

Fracture toughness measurements by nanoindentation Application Reports

-

How to deal with roughness in nanoindentation measurements Application Reports

Similar products

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

Accessory for Step Platforms:

Atomic Force Microscope (AFM)

- Versatile AFM solution for various scientific and industrial applications

- Imaging and analysis capabilities offering nanoscale surface information

- Non-destructive interaction with samples