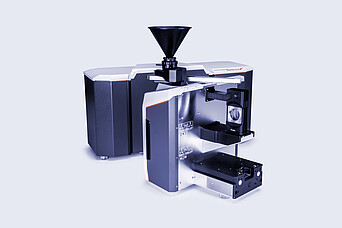

Dynamic Image Analyzer:

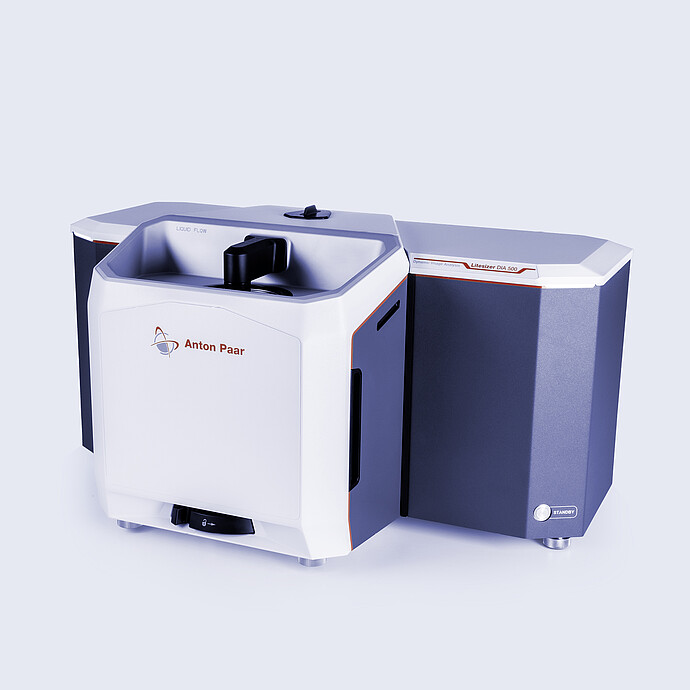

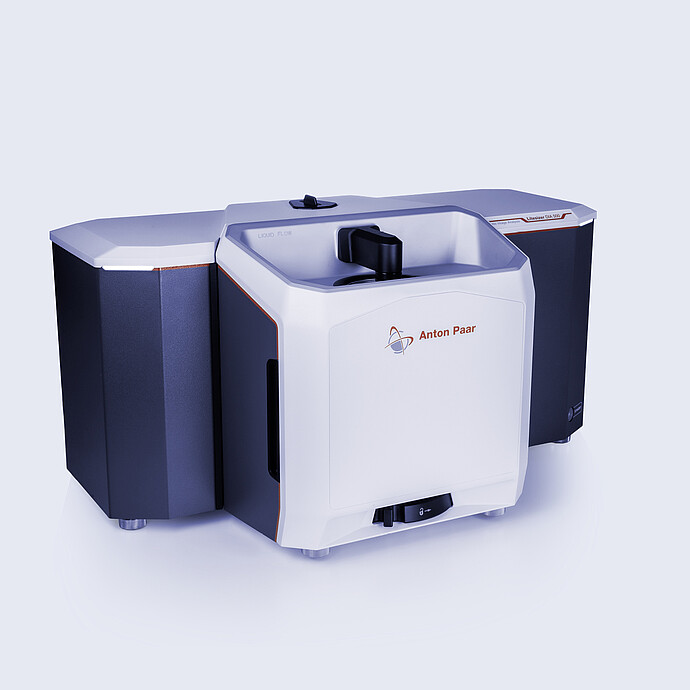

Litesizer DIA

- Measure samples between 0.8 µm and 8,000 µm and even detect and analyze single particles

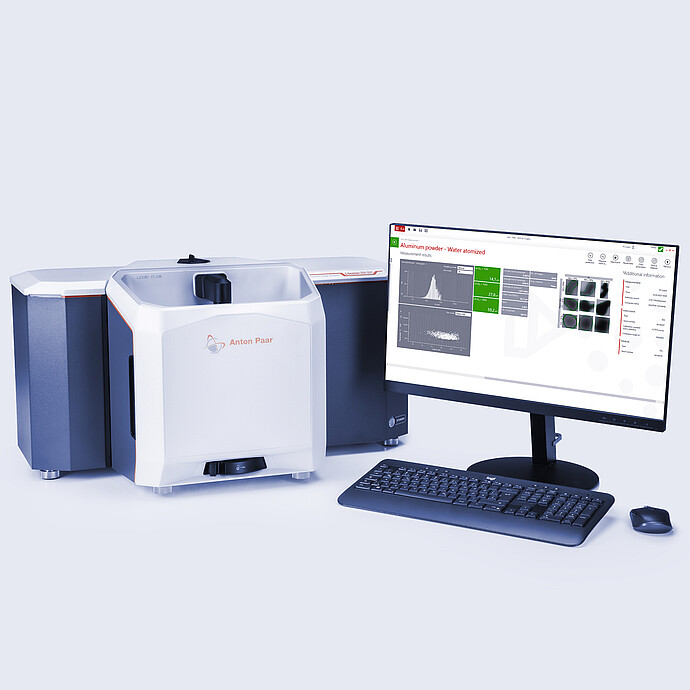

- Use the operating software Kalliope to get started quickly and work in one digital space

- Comply with relevant safety standards and avoid any operation errors

- Leverage the instrument’s automation features so you can focus on more important tasks

- Single magnification for efficient sample measurement

- Analyze 10 µm to 16,000 µm samples with single particle resolution

- Streamline your workflow with user-friendly Kalliope software

- Automate tasks, freeing up valuable time for critical work

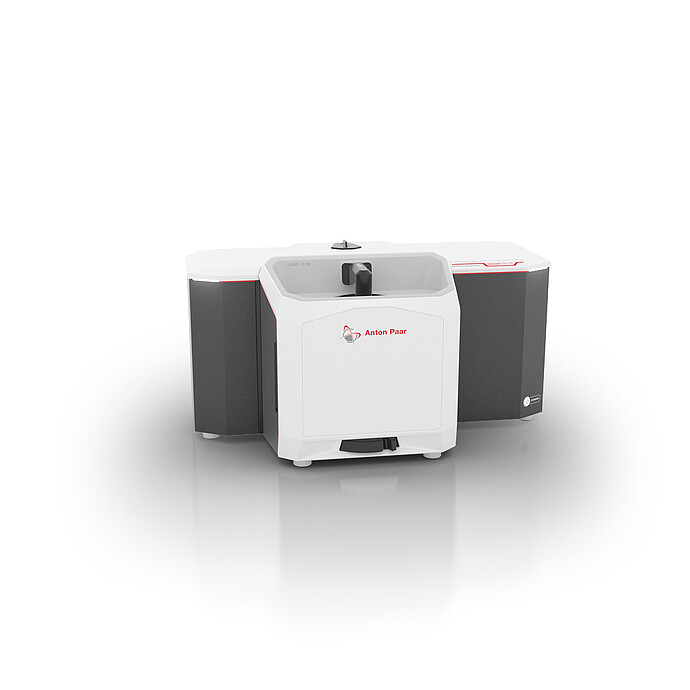

- Compatible with Liquid Flow, Dry Jet, Free Fall units

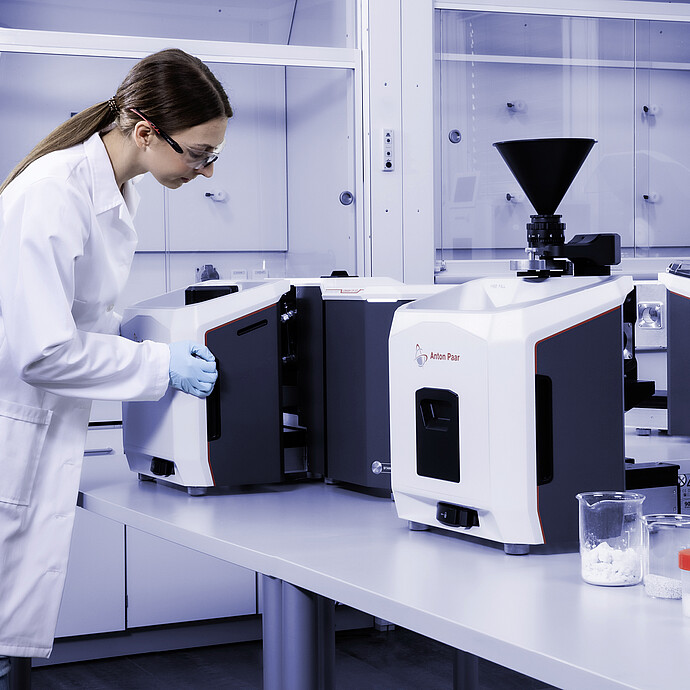

With Litesizer DIA Series, our dynamic image analyzer, you can easily and reliably characterize the size and shape of particles via analysis of their direct images. In just one step, quickly switch among three modules that use dispersion liquid, compressed air or free-fall for excellent dispersion of your sample. Rely on the automation of feeding rate adjustment and rinsing of liquids, and conduct measurements with only minimal training.

That’s particle analysis at the touch of a button - only with our dynamic image analyzer.

Key features

Get particle size and shape in one measurement

Measure particle sizes ranging from 0.5 µm to 16,000 µm with precision, and detect single outlier particles in large samples. Utilize a market-leading liquid dispersion range of up to 2,500 µm. Replace traditional sieve analysis with fast, safe, and dynamic image analysis to gain a deeper understanding of how particle size measurement can optimize your processes.

Optimize measurements with Kalliope software

Start your measurements in just three clicks. Analyze particle size, shape, and images all in one digital space with our dynamic image analyzer. Easily filter particles by specific size and shape using Kalliope’s powerful features. Control all your Anton Paar particle-sizing instruments from the Kalliope particle analysis software platform.

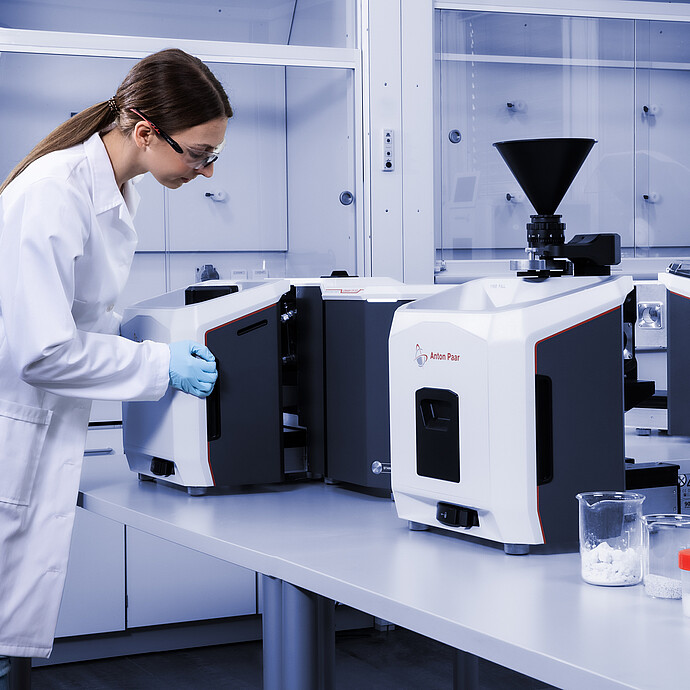

Prioritize operator safety

The Litesizer DIA dynamic image analyzer incorporates multiple safety features to protect the operator. Stay safe with a cover that prevents dangerous sample spread. Prevent overheating with liquid level recognition before sonication. Ensure containment of hazardous samples with automatic suction checks. Comply with relevant safety standards, including EN 61010:2010 and ISO 12100:2011.

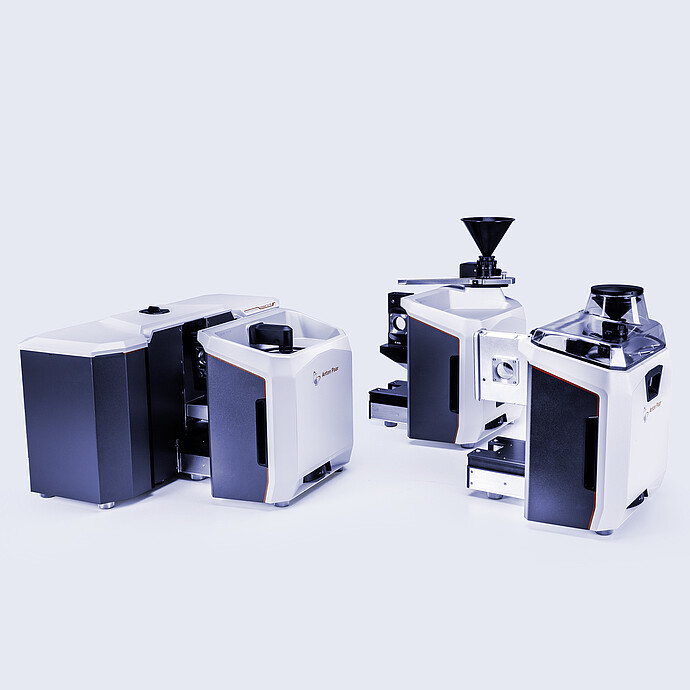

Three dispersion units in one dynamic image analyzer

Measure samples using Liquid Flow (liquid dispersion), Dry Jet (compressed air), and Free Fall (gravitational fall) dispersion units. Experience unmatched flexibility in a dynamic image analyzer with the ability to quickly and easily switch between units with the Quick-Click feature, eliminating the hassle of cables and tubes.

Save time with automation

Automatically optimize sample feeding rates, and automate filling, draining, and rinsing tasks to focus on more important work. Enhance data quality and speed up analysis with auto-filtering of particles.

Specifications

| Feature | Litesizer DIA 700 | Litesizer DIA 500 | Litesizer DIA 100 |

| Measurement Principle | Dynamic Image Analysis | ||

| Measurement Ranges (Liquid Flow) | 0.5 μm to 2,500 μm | 0.8 μm to 2,500 μm | 10 μm to 2,500 μm |

| Measurement Ranges (Dry Jet) | 0.5 μm to 5,000 μm | 0.8 μm to 5,000 μm | 10 μm to 5,000 μm |

| Measurement Ranges (Free Fall) | 0.5 μm to 16,000 μm (restrictions apply for particles >8,000 μm) | 0.8 μm to 16,000 μm (restrictions apply for particles >8,000 μm) | 10 μm to 16,000 μm (restrictions apply for particles >8,000 μm) |

| Camera | 5 Mpix (2,448 pixels x 2,048 pixels) / 0.5 μm per pixel | 5 Mpix (2,448 pixels x 2,048 pixels) / 0.8 μm per pixel | 5 Mpix (2,448 pixels x 2,048 pixels) / 10 μm per pixel |

| Data Collection Rate | 220 fps/camera at 5 Mpix | 144 fps/camera at 5 Mpix | 20 fps/camera at 5 Mpix |

| Magnification | 0.3x, 1x and 6x | 0.3x and 4x | 0.3x |

| Optical Features | Automatic switch between objectives Automatic merge of size ranges All magnifications are included in the standard configuration | - | |

| Data Transfer | 1x 10 Gigabit Ethernet, 1x USB-A 3.0 | ||

| Measurement Output | Number-, surface-, and volume-weighted results Size descriptors (ISO 9276-compliant): Minimum and maximum Feret diameters, projected area equivalent diameter, length, geodesic length and thickness (e.g., for fibers), minimum and maximum axes of the Legendre ellipse Shape descriptors (ISO 9276-compliant): aspect ratio, ellipse ratio, irregularity, elongation or eccentricity, circularity, form factor, compactness, extent or bulkiness, solidity, convexity Image parameters: sharpness and contrast | ||

| Instrument Data | Dimensions: 400 mm x 790 mm x 290 mm (H x W x D) * Weight: 41 kg (90 lb) * Power supply: 100 V to 240 V ±10 %, 50/60 Hz Compressed air supply: 5 bar - 10 bar (72 psi to 145 psi) Water supply: max. 8 bar (116 psi) | ||

| Compatible Dispersion Units | Liquid Flow: Dispersion using a liquid carrier, mixing, and ultrasonication Dry Jet: Dispersion via compressed air Free Fall: Dispersion via gravitational fall | ||

| Exchange of the Dispersion Unit | Less than 10 seconds via Quick Click | ||

| Automation | Automatic adjustment of the image acquisition rate | ||

| Accessories | Calibration tool Pre-configured PC | ||

Standards

ISO

ASTM

US Pharmacopoeia (USP)

European Pharmacopoeia (Ph. Eur.)

Standards

ISO

ASTM

US Pharmacopoeia (USP)

European Pharmacopoeia (Ph. Eur.)

Standards

ISO

ASTM

US Pharmacopoeia (USP)

European Pharmacopoeia (Ph. Eur.)

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Behind the Shine: Particle Size and Shape Analysis of Acrylic Paints Application Reports

-

E-Book - A Practical Guide for Great Building Materials Application Reports

-

E-Book - Field Guide to Food and Feed Testing Application Reports

-

E-Book - The Field Guide to Data Integrity in Regulated Industries Application Reports

-

Full Blast: Monitoring of Size and Shape of Abrasive Materials Application Reports

-

Golden grains: Mastering malt for extraordinary brews Application Reports

-

Grain by Grain: Particle Composition of Scratch Coats Application Reports

-

Know Your Beans: Quality Control of Coffee by Dynamic Image Analysis Application Reports

-

Stir up your measurements: Measuring different particle sizes in one sample Application Reports

-

Your Concrete Answer: Size and Shape Analysis of Cement Application Reports

-

Brochure | Litesizer DIA (US Letter) Brochures

-

Litesizer DIA - IMSI Manuals

Similar products

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

LIQUID FLOW MESSFENSTER FÜR LITESIZER DIA/DIF

Litesizer DIA 100 | 500 | 700

O-RING FOR DRY JET AND FREE FALL MEASUREMENT CELL WINDOW

Litesizer DIA 100 | 500 | 700

O-ring 41 X 1.5 FPM 80+-5 VITON for the glass in the Free Fall and Dry Jet measurement window

O-RING FOR TUBE CONNECTION LIQUID FLOW DISPERSION UNIT

Litesizer DIA 100 | 500 | 700

O-ring connecting the Liquid Flow measurement cell with the tubing

Particle Analysis Software:

Kalliope

Litesizer DIA 100 | 500 | 700

- Particle analysis software for all Litesizer instruments

- Start your particle measurements in just three clicks

- One-page workflow user interface

- Live monitoring of measurement results, analysis function, customizable reporting, and multiple exporting capabilities

HOSE FOR COMPRESSED AIR SUPPLY 6x8 MM

Litesizer DIA 100 | 500 | 700

O-RING FOR MEASUREMENT WINDOW LIQUID FLOW DISPERSION UNIT

Litesizer DIA 100 | 500 | 700

O-RING 37 X 1.5 FKM 80 SW for measurement window in Liquid Flow measurement cell

HOSE CLAMP 16-27MM 1.4301

Litesizer DIA 100 | 500 | 700

O-RING FOR MEASUREMENT WINDOW LIQUID FLOW DISPERSION UNIT

Litesizer DIA 100 | 500 | 700

O-ring 40 X 2 FKM 75 SW for measurement window in Liquid Flow measurement cell

COVER FOR LIQUID TANK - TRANSPARENT

Litesizer DIA 100 | 500 | 700

Transparent cover for the liquid tank in the Liquid Flow dispersion unit

COVER FOR LIQUID TANK - STAINLESS STEEL

Litesizer DIA 100 | 500 | 700

Stainless steel cover for the liquid tank in the Liquid Flow dispersion unit

PROTECTIVE GLASS FOR ILLUMINATION UNIT

Litesizer DIA 100 | 500 | 700

Protective glass 76.2 X 3 mm for the illumination unit in the main unit

PROTECTIVE GLASS FOR CAMERA UNIT

Litesizer DIA 100 | 500 | 700

Protective glass 50.8 X 3 mm for the camera window in the main unit

O-RING FOR MEASUREMENT FRAME LIQUID FLOW DISPERSION UNIT

Litesizer DIA 100 | 500 | 700

O-ring 75 X 2.5 FKM for measuring cell glass frame in Liquid Flow measurement cell

SAMPLE FUNNEL SMALL

Litesizer DIA 100 | 500 | 700

A small sample funnel (max. 150 mL) Compatible with Dry Jet dispersion unit and Free Fall dispersion unit

SAMPLE FUNNEL LARGE

Litesizer DIA 100 | 500 | 700

A large sample funnel (max. 600 mL) Compatible with Dry Jet and with Free Fall dispersion unit

DIFFUSER PIPE 3.5 MM FOR DRY JET DISPERSION UNIT

Litesizer DIA 100 | 500 | 700

Venturi tube of 3.5 mm diameter. Works only with Diffuser 3.5 mm Compatible with Dry Jet dispersion unit

DIFFUSER PIPE 5 MM

Litesizer DIA 100 | 500 | 700

Venturi tube of 5 mm diamater. Works only with Diffuser 5 mm Compatible with Dry Jet dispersion unit

MEASUREMENT WINDOW DRY JET AND FREE FALL MEASUREMENT CELL

Litesizer DIA 100 | 500 | 700

Compatible with Free Fall and Dry Jet dispersion units

MEASUREMENT WINDOW FOR LIQUID FLOW (UNCOATED)

Litesizer DIA 100 | 500 | 700

Glass for the measurement cell of the Liquid Flow For use with DIA only

O-RING FOR DRY JET AND FREE FALL MEASUREMENT CELL WINDOW

Litesizer DIA 100 | 500 | 700

O-ring 44 X 2 for the glass in the Free Fall and Dry Jet measurement window

CHUTE COVER FOR FREE FALL

Litesizer DIA 100 | 500 | 700

ANGULAR PIPE CONNECTION VACUUM CLEANER

Litesizer DIA 100 | 500 | 700

Steel angular pipe for connecting vacuum cleaner suction

DIFFUSER SET 5 MM DRY FOR DRY JET DISPERSION UNIT

Litesizer DIA 100 | 500 | 700

5 mm nozzle forming a stream of particles in Dry Jet dispersion unit

MEASUREMENT CELL 8 MM FOR FREE FALL DISPERSION UNIT

Litesizer DIA 100 | 500 | 700

A measurement cell for Free Fall dispersion unit with 8 mm gap Compatible with Free Fall dispersion unit

MEASUREMENT CELL 4 MM FREE FALL DISPERSION UNIT

Litesizer DIA 100 | 500 | 700

A measurement cell for Free Fall dispersion unit with 4 mm gap Compatible with Free Fall dispersion unit.

CHUTE COVER FOR DRY JET

Litesizer DIA 100 | 500 | 700

DRAIN AND OVERFLOW HOSE HOSE 19X27 PVC

Litesizer DIA 100 | 500 | 700

TEXTILE COVER FOR DISPERSION UNIT

Litesizer DIA 100 | 500 | 700

A textile cover for protectng the dispersion unit while not in use.

ANGULAR HOSE CONNECTOR "19 MM (3/4"")"

Litesizer DIA 100 | 500 | 700

Angled hose connectors that facilitate assembly to the drain

SAMPLE AND CLEANING KIT

Litesizer DIA 100 | 500 | 700

PARTICLE SIZE STANDARD PS 413 SIZE RANGE 10 - 100 µm

Litesizer DIA 100 | 500 | 700

Particle size standard for validating Zoom and Standard objectives with Liquid Flow dispersion unit

PARTICLE SIZE STANDARD PS 234 SIZE RANGE 150 - 650 µm

Litesizer DIA 100 | 500 | 700

Particle size standard for validating Standard objective with Free Fall dispersion unit

DIFFUSER SET 3.5 MM DRY FOR DRY JET DISPERSION UNIT

Litesizer DIA 100 | 500 | 700

3.5 mm nozzle forming a stream of particles in Dry Jet dispersion unit

Accessory for Litesizer DIA and DIF:

Dispersion Unit Liquid Flow

Litesizer DIA 100 | 500 | 700

- Disperse samples using a carrier liquid

- Automate filing, draining, and rinsing of the dispersion liquid

- Prevent overheating with automatic recognition of liquid

- Use nearly any carrier liquid: Circuit is chemically resistant

- Available for the Litesizer DIA series and Litesizer DIF 500

Accessory for Litesizer DIA and DIF:

Dispersion Unit Dry Jet

Litesizer DIA 100 | 500 | 700

- Disperse samples using pressurized air

- Leverage automation for optimal sample feeding rate

- Prevent toxic or explosive sample spread with the safety cover

- Contain dangerous samples with automatic suction check

- Available for the Litesizer DIA series and Litesizer DIF 500

Accessory for Litesizer DIA and DIF:

Dispersion Unit Free Fall

Litesizer DIA 100 | 500 | 700

- Sample dispersion using gravitational free-fall

- Leverage automation for optimal sample feeding rate

- Access the measurement cell for cleaning in one click

- Recover your samples with the built-in drawer

- Only available for the Litesizer DIA series

Accessory for Litesizer DIA and DIF:

Dispersion Unit

Litesizer DIA 100 | 500 | 700