Microwave Reactor:

Monowave

- Monowave 400 with on-top automation, in an attractive package

- Unattended processing of 24 vials of different sizes

- Specially designed vessels for solvent extraction or bulky samples

- Remote control via VNC

- Environmental footprint reduction

- 21 CFR Part 11-compliant

The Anton Paar Monowave product line is a series of high-performance monomode microwave reactors designed for small- to medium-scale microwave synthesis.

Attain temperatures up to 300 °C and pressures up to 30 bar with advanced all-the-time safety features for high-speed, high-pressure, high-temperature reactions. Improve productivity and product purity across all applications in research and development laboratories with precise heating profiles. Reduce consumable costs and your environmental footprint by using the reusable vials, caps, and septa.

Visit our world of microwave synthesis to find your optimum reaction conditions and to browse through a database of more than 1000 applications which have been successfully performed in Anton Paar reactors.

Key features

Fast and effective: 24 sequential reactions, unattended

The Autosampler MAS 24 allows 24 unattended reactions, in sequence – saving time, and increasing efficiency. High field density produces fast, uniform heating for all kinds of reactions, up to 300 °C. Powerful stirring of up to 1200 rpm assures temperature homogeneity. The powerful 850 W magnetron adjusts its unpulsed microwave power automatically to the sample. This software-driven self-tuning eliminates any guesswork about sample absorption. Achieve high yields and clean reactions with maximum reproducibility.

The key factor in synthesis: Precise, scalable temperature measurement

Current scientific practice is to use reaction temperature as the relevant parameter in microwave reactions. And accurate measurement of the reaction temperature is the key to correct transferal and scale-up of reaction protocols between different reactors. Monowave reactors measure the temperature via an IR temperature sensor – a robust and reliable method for temperature control ensuring absolutely precise temperature measurement. For accurate control of even more demanding reactions, such as an exothermic reactions, or those involving extremely sensitive samples, simultaneous internal temperature measurement with the optional fiber-optic ruby thermometer is available.

Vials for heating any solvent and any reaction mixture

In addition to the standard glass vials, silicon carbide (SiC) vessels are available. They absorb microwave energy efficiently, while shielding the interior from microwave radiation – a method that reveals microwave effects caused by selective absorption, and allows comparison between direct microwave heating and conventional heating of reaction mixtures. All parameters, such as the heating and cooling rate, the form factor of the reaction vessel, and the stirring efficiency are identical, apart from the heating mode. All solvents, from non-absorbing ones such as hexane to excellent absorbers such as ionic liquids, can be heated to achieve equal performance – making Monowave the ideal instrument for solvent comparison across chemical reactions. Finally, even chemicals not suitable for glass vials (fluorination agents or alkaline samples) can be processed in the chemically inert, robust SiC vessels.

Save time, expenditure, and the environment with tool-free and reusable consumables

Choose from reaction vials for any scale between 0.5 mL and 20 mL. For bulky samples and extraction applications, a special wide-neck vessel offers convenience without compromising performance. Establish a hassle-free workflow in your laboratory with tool-free handling, and reduce the cost of ownership and the environmental footprint of your research by using reusable vials, septa, and caps.

See everything: Watch your synthesis and analyze it in real-time

With Monowave 400 and Monowave 450 you can record images and videos with the integrated digital camera. You can follow color changes and precipitation, check the dissolution of substrates, and optimize the stirring efficiency. Monowave 400 R can be combined with Anton Paar’s Cora 5001 Raman spectrometer for in-situ Raman spectroscopy measurements of chemical reactions. Identify intermediates and short-lived transition states, investigate reaction kinetics and optimize reaction conditions with real-time information about the chemical composition of your reaction. The contactless measurement removes any worries about cross-contamination and the need for cleaning in between experiments.

Technical specifications

| Monowave 400/450 | Monowave 200 | |

|---|---|---|

| Max. filling volume | 6 mL for 10 mL vial 20 mL for 30 mL vial 2 mL for 4 mL vial | 6 mL for 10 mL vial 20 mL for 30 mL vial 2 mL for 4 mL vial |

| Max. operation pressure | 30 bar (435 psi) | 20 bar (290 psi) (upgradable) |

| Max. IR temperature | 300 °C | 260 °C (upgradable) |

| Max. fiber-optic temperature | 300 °C | 260 °C (upgradable) |

| Max. power | 850 W | 850 W |

| Vial material | Borosilicate glass, silicon carbide | Borosilicate glass, silicon carbide |

| Cap material | PEEK | PEEK |

| Camera | Integrated | Optional after upgrade |

| Autosampler MAS24 | Optional | Optional after upgrade |

| Seal material | Teflon-coated silicone | Teflon-coated silicone |

| Typical applications | Method development Optimization Basic academic and industrial research | Method development Optimization Basic academic and industrial research |

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Biofuels | Microwave Extraction and Synthesis of Fatty Acid Methyl Esters Application Reports

-

Cancer Diagnosis with Persistent Luminescent Nanoparticles Application Reports

-

Downscaling of Standard Norms for Microwave-Assisted Extraction Methods Application Reports

-

Extraction and Quantification of Diterpenes from Green Coffee Oil Application Reports

-

Extraction | MCPD Esters from Food Application Reports

-

Features | Detective Monowave helps to reveal the truth Application Reports

-

MAE of PAHs from Dietary Matrices Application Reports

-

Microwave-Assisted Large-Scale Synthesis of Photoresists Application Reports

-

Microwave-assisted Extraction of Additives from Polymers Application Reports

-

Monowave 400 with Camera - Watching Microwave Synthesis Live Application Reports

-

Silicon Carbide Vessel | Applications of Silicon Carbide Vessels Application Reports

-

Standard Extraction Methods in Multiwave 5000 or Monowave 450 Application Reports

-

Synthesis | Gas Loading | Inert Gas Atmosphere in Microwave Reactions Application Reports

-

Synthesis | Solids in Microwave Reactors? Application Reports

-

Microwave Synthesis Family Brochures

Consumables & Accessories

Consumables & Accessories

Accessories

Accessories

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

IR WINDOW

Monowave 450 | 400 | 200

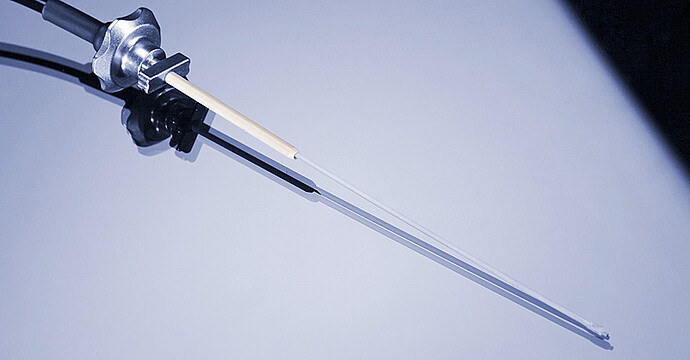

REACTION VESSEL C30 WIDE NECK ASSEMBLED

Monowave 450 | 400 | 200

REACTION VIAL G30 (20 PCS.)

Monowave 450 | 400 | 200

REACTION VIAL G10 (100 PCS.)

Monowave 450 | 400 | 200

SNAP CAPS (20 PCS.)

Monowave 450 | 400 | 200

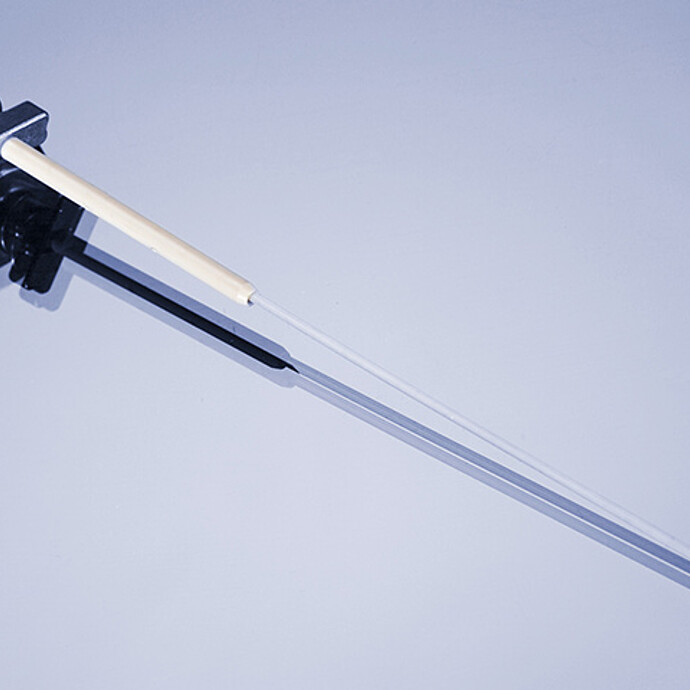

SILICONE SEPTUM FOR RUBY THERMOMETER

Monowave 450 | 400 | 200

SILICONE SEPTUM (20 PCS.)

Monowave 450 | 400 | 200

IMMERSION TUBE FOR RUBY THERM.(5 pcs)

Monowave 450 | 400 | 200

STIR BAR PTFE D = 3, L = 10 (10 PCS.)

Monowave 450 | 400 | 200

STIR BAR PTFE D = 2, L = 5 (10 PCS.)

Monowave 450 | 400 | 200

REACTION VIAL G4 (10 PCS.)

Monowave 450 | 400 | 200

CAVITY INSERT FOR CAMERAOPTION

Monowave 450 | 400 | 200

REACTION VIAL G30 WIDE NECK (10 PCS)

Monowave 450 | 400 | 200

SNAP CAP WIDE NECK ASSEMBLED (10 PCS)

Monowave 450 | 400 | 200

PTFE SEPTUM WIDE NECK (50 PCS.) Package of 50 pcs. disposable PTFE septa for tight sealin

Monowave 450 | 400 | 200

PTFE DISK D = 22 MM (5 PCS) Package of 5 pcs. PTFE disks supporting the tight sealing of

Monowave 450 | 400 | 200

PTFE SEPTUM D = 22 MM (50 PCS)

Monowave 450 | 400 | 200

PTFE SEPTUM D= 22 MM FOR RUBY THERMOMETER (50 PCS.)

Monowave 450 | 400 | 200

STIR BAR OVAL 15x6 MM (10 PCS)

Monowave 450 | 400 | 200

LONG IMMERSION TUBE FOR PTFE SEPTUM D = 22 mm (5 PCS) Package of 5 pcs. immersion tubes m

Monowave 450 | 400 | 200

REACTION VESSEL C10 PACKAGE

Monowave 450 | 400 | 200

SHORT IMMERSION TUBE FOR G30 WIDE NECK (3 PCS.) Package of 3 pcs. immersion tubes made of

Monowave 450 | 400 | 200

PTFE SEPTUM WIDE NECK FOR RUBY THERMOMETER (50 PCS) Package of 50 pcs. disposable perfora

Monowave 450 | 400 | 200

REACTION VESSEL C10

Monowave 450 | 400 | 200

RACK 40

Monowave 450 | 400 | 200

Reaction Vial G4

Monowave 450 | 400 | 200

- Vial for Monowave 300

- Designed for volumes between 0.5 mL and 2.0 mL

- For efficient method development with the lowest quantities

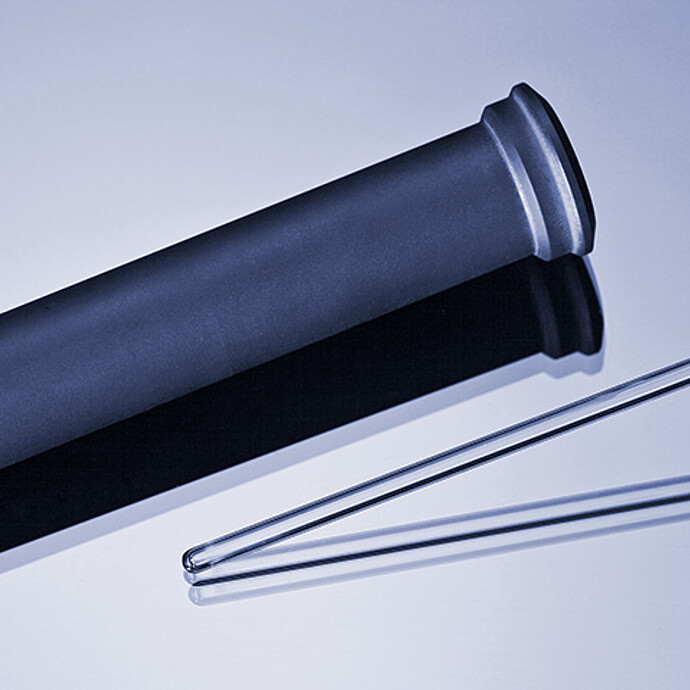

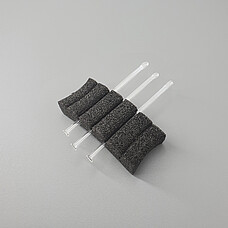

Silicon Carbide Vessel

Monowave 450 | 400 | 200

- Accessory for microwave synthesis reactors

- Shortens overall process time

- Heating rates >10 °C/second, even for non-absorbing solvents

- Ideal for fluorinations and other challenging reactions

Racks

Monowave 450 | 400 | 200

- Different racks for storing vessels, liners, and vials

- For Multiwave 5000: Rack 12 for HVT vessels, Rack 10 for SVT vessels, Rack 16 for 16 vessels or liners of Rotor 8 and Rotor 16

- For Monowave 200/400/450: 24 x 30 mL vials and 40 x 10 mL vials

ETHERNET CABLE FOR PC CONNECTION CAT5E, RJ45G-RJ45G, SFTP, 2 m, CROSSED

Monowave 450 | 400 | 200

Only for ViscoQC 300. Cable for LIMS Bridge connection to PC for transferring measurement data.