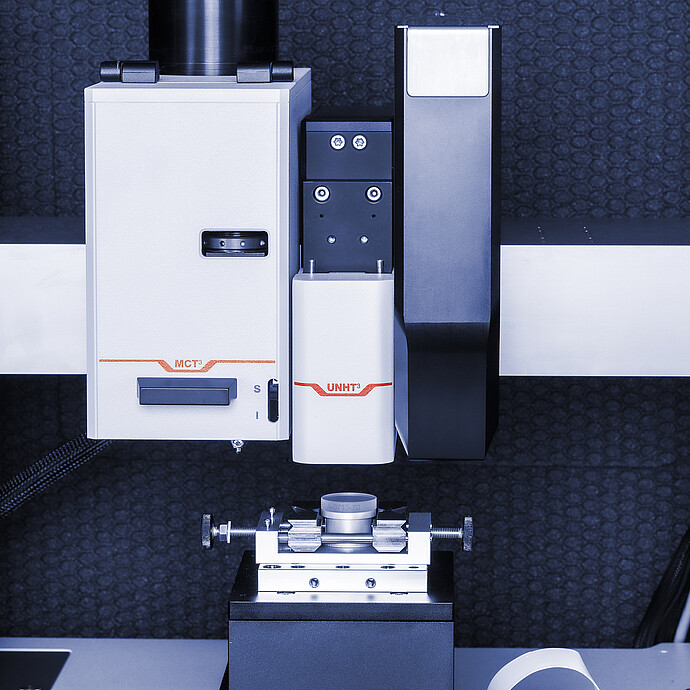

Ultra Nanoindentation Tester:

UNHT³

- Measurements under ambient conditions

- Variable temperature testing from room temperature up to 200 °C

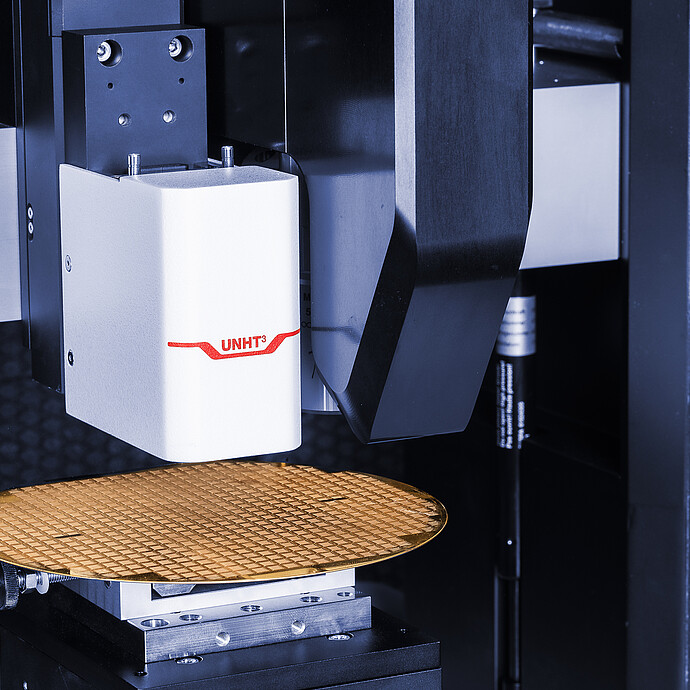

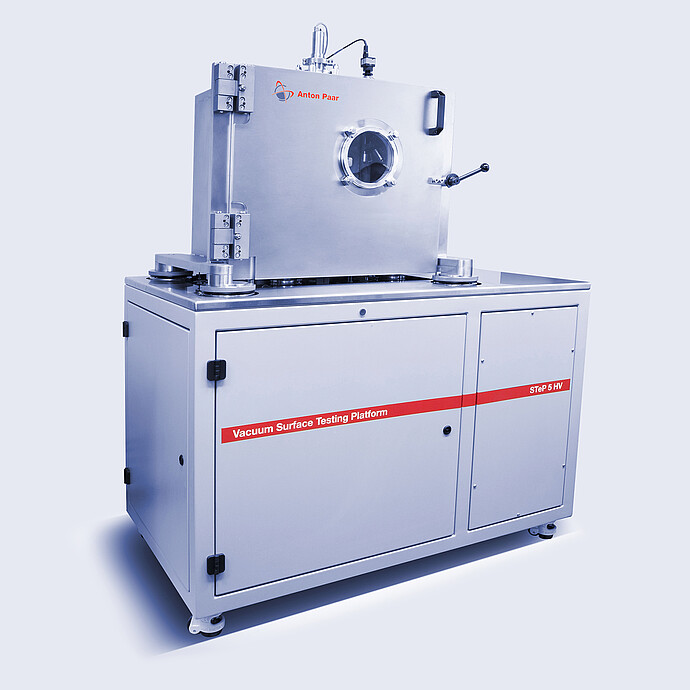

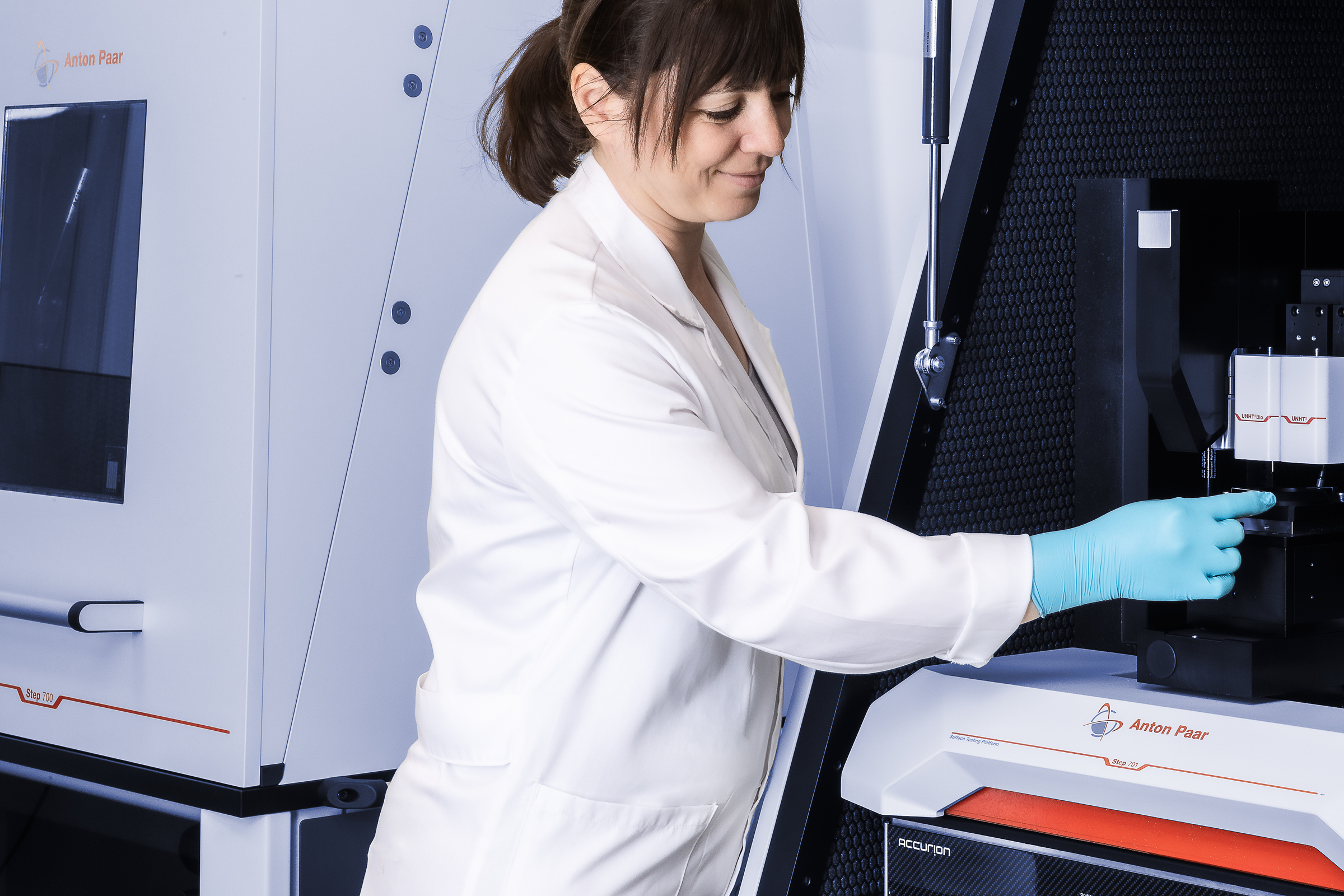

The UNHT³ ultra-high-resolution nanoindenter with real force and displacement sensors examines the mechanical properties of a material to the nanoscale. UNHT³ virtually eliminates the effect of thermal drift and compliance due to its patented active surface referencing system. It is suited for long-term measurements on all types of materials from the atomic to the nanoscale, including polymers, very thin layers, and soft tissues. For measurements at very low or very high temperatures, a vacuum chamber version (UNHT³ HTV) is available (up to 800 °C; down to 10-7 mbar).

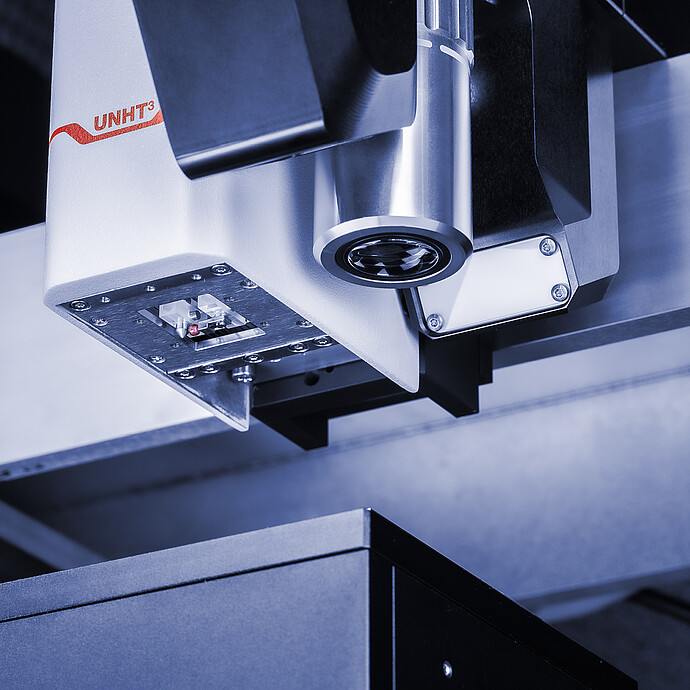

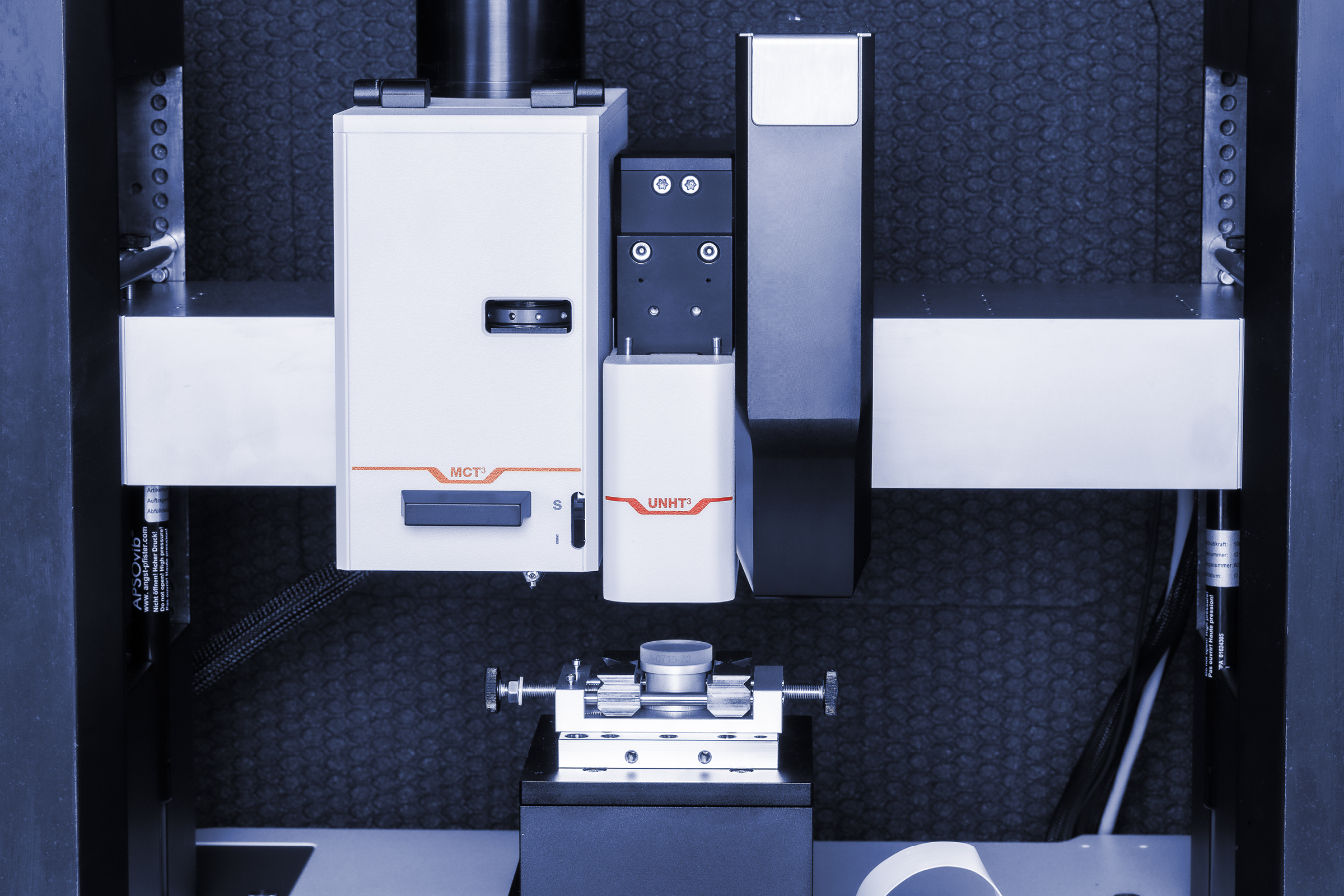

Combine the UNHT3 head with another scratch or indentation tester on the Step platform to fully cover the nano/micro/macro range. Add an AFM module to obtain complete mechanical surface characterization with a single instrument.

Key features

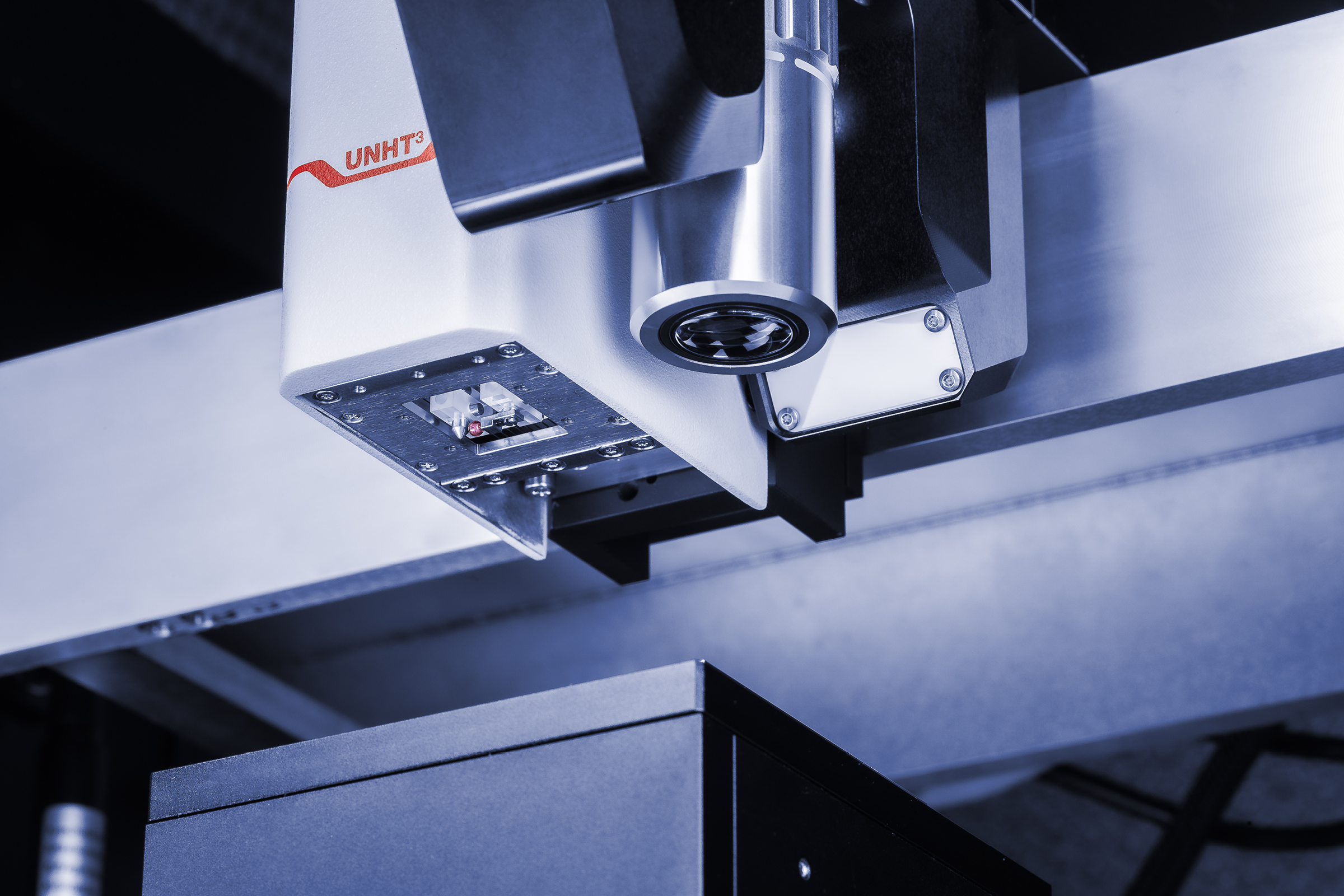

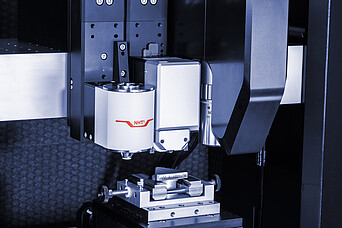

The most accurate nanoindentation tester

UNHT³ measures what others estimate: two independent depth and load sensors provide true control of forces and indentation depth. In addition, UNHT³ offers the patented design of active top referencing: One reference indenter monitors the sample’s surface position while a measuring indenter performs the measurements, eliminating any thermal drift and compliance issues. This allows for a large range of indentation depths (from a few nm up to 100 μm) and indentation loads (from a few μN up to 100 mN).

The nanoindenter with the highest stability on the market

The use of the unique patented active top surface referencing and Zerodur, a material with no thermal expansion, means UNHT³ is the only nanoindentation tester to reach a negligible thermal drift down to 10 fm/sec without any depth correction. That makes the UNHT³ the only nanoindentation tester that can be used for lengthy measurements, such as creep tests.

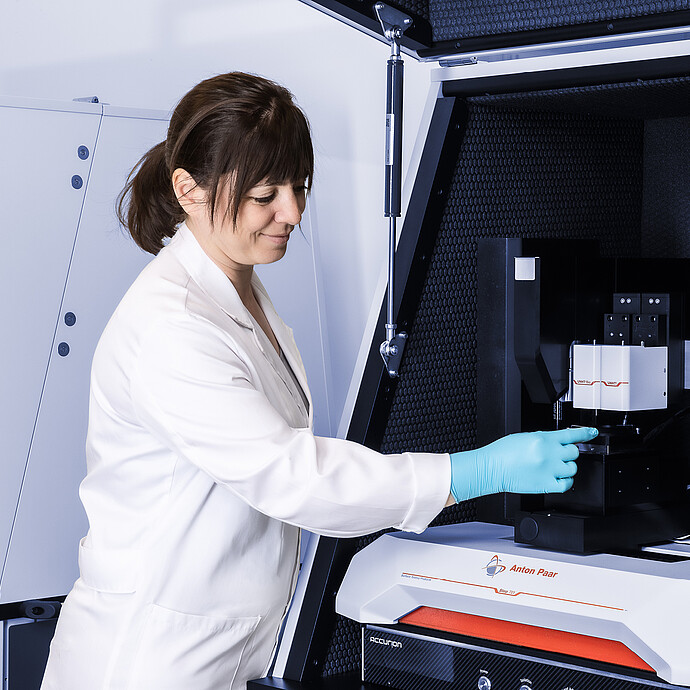

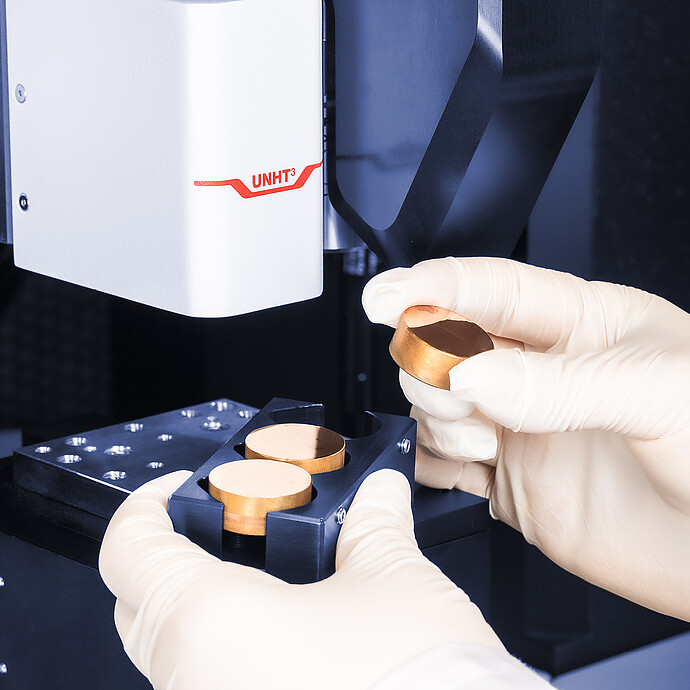

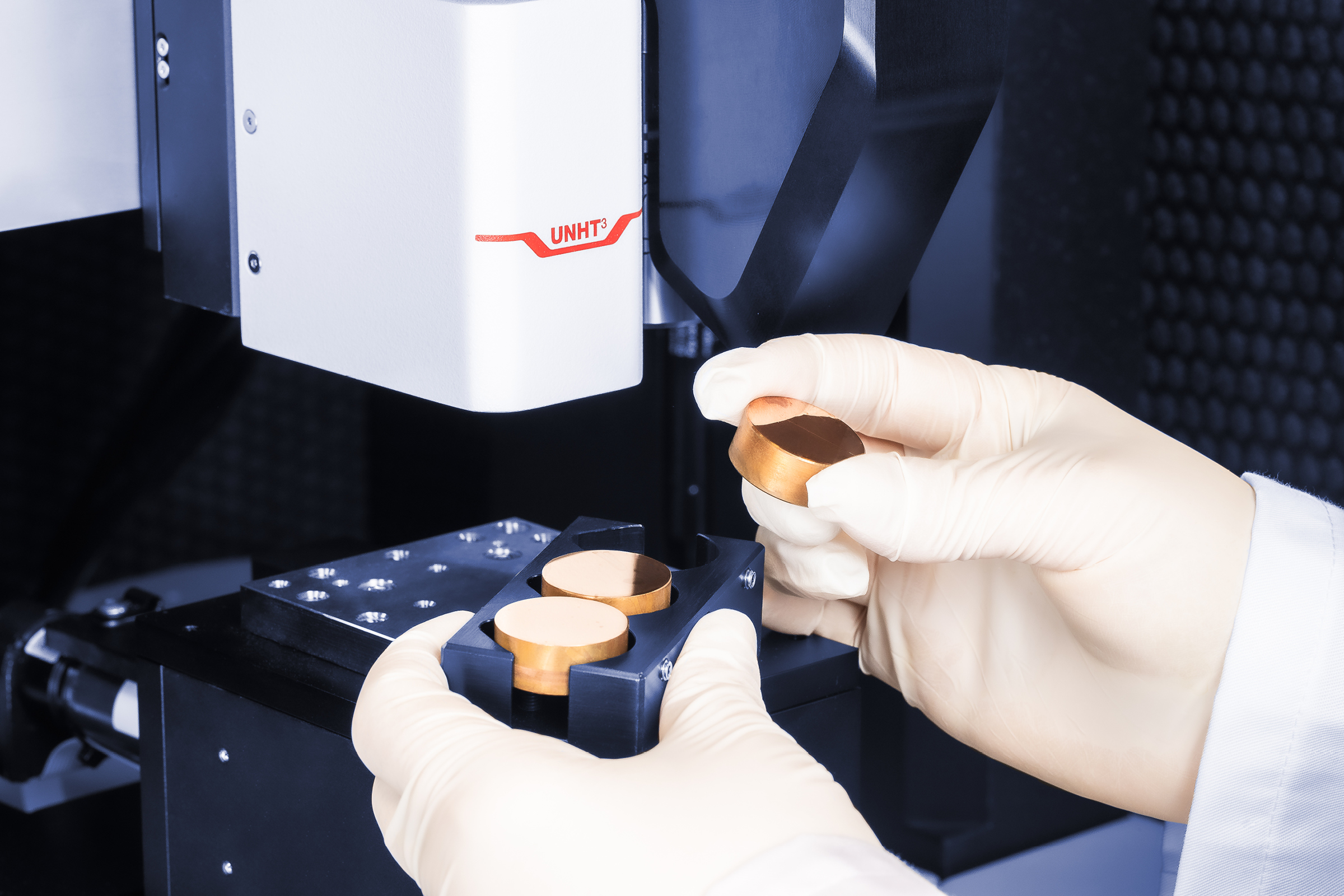

More than 600 measurements per hour

Thanks to the UNHT³ Ultra Nanoindentation Tester’s unique thermal stability, a sample can be measured immediately after installation without waiting hours for thermal stabilization. Many samples can therefore be individually measured during the day. The Quick mode enables performance of more than 600 measurements per hour with real indentation curves. User profiles, measurement protocols, multi-sample measurements, and customizable reporting deliver the highest throughput on the market.

Additional dynamic mechanical analysis (DMA) with “Sinus Mode”

The integrated Sinus Mode allows DMA analysis for depth profiling of mechanical properties (HIT, EIT vs. depth) and measurement of viscoelastic properties (E', E'': storage and loss moduli, tan δ) on samples from thin films to bulk materials. The Sinus Mode also offers additional features, such as quick indenter calibration and stress-strain analysis.

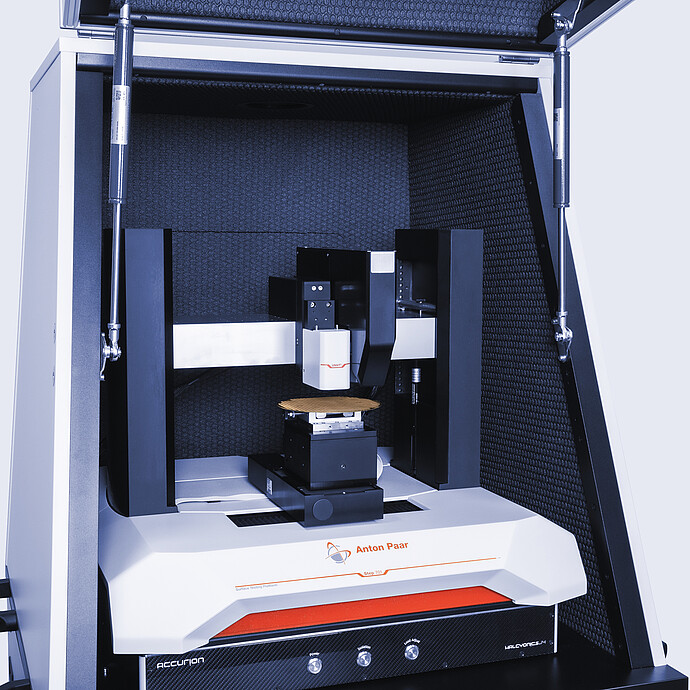

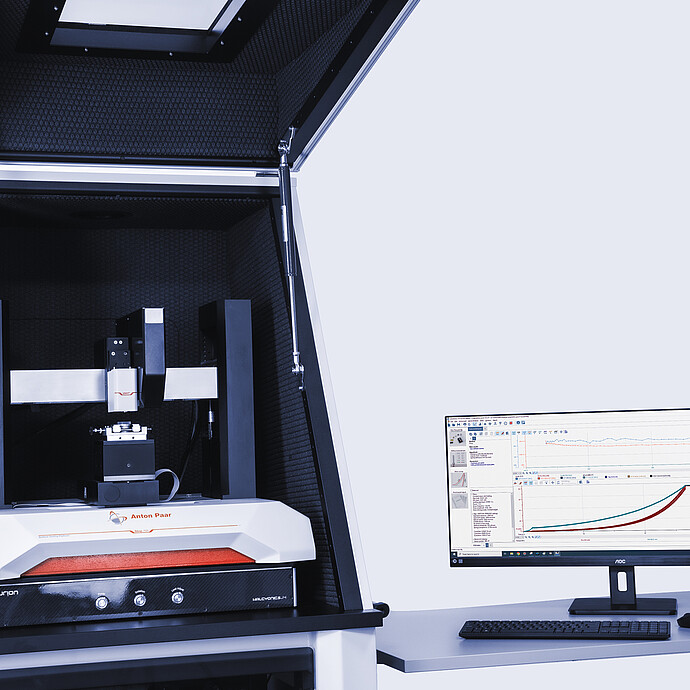

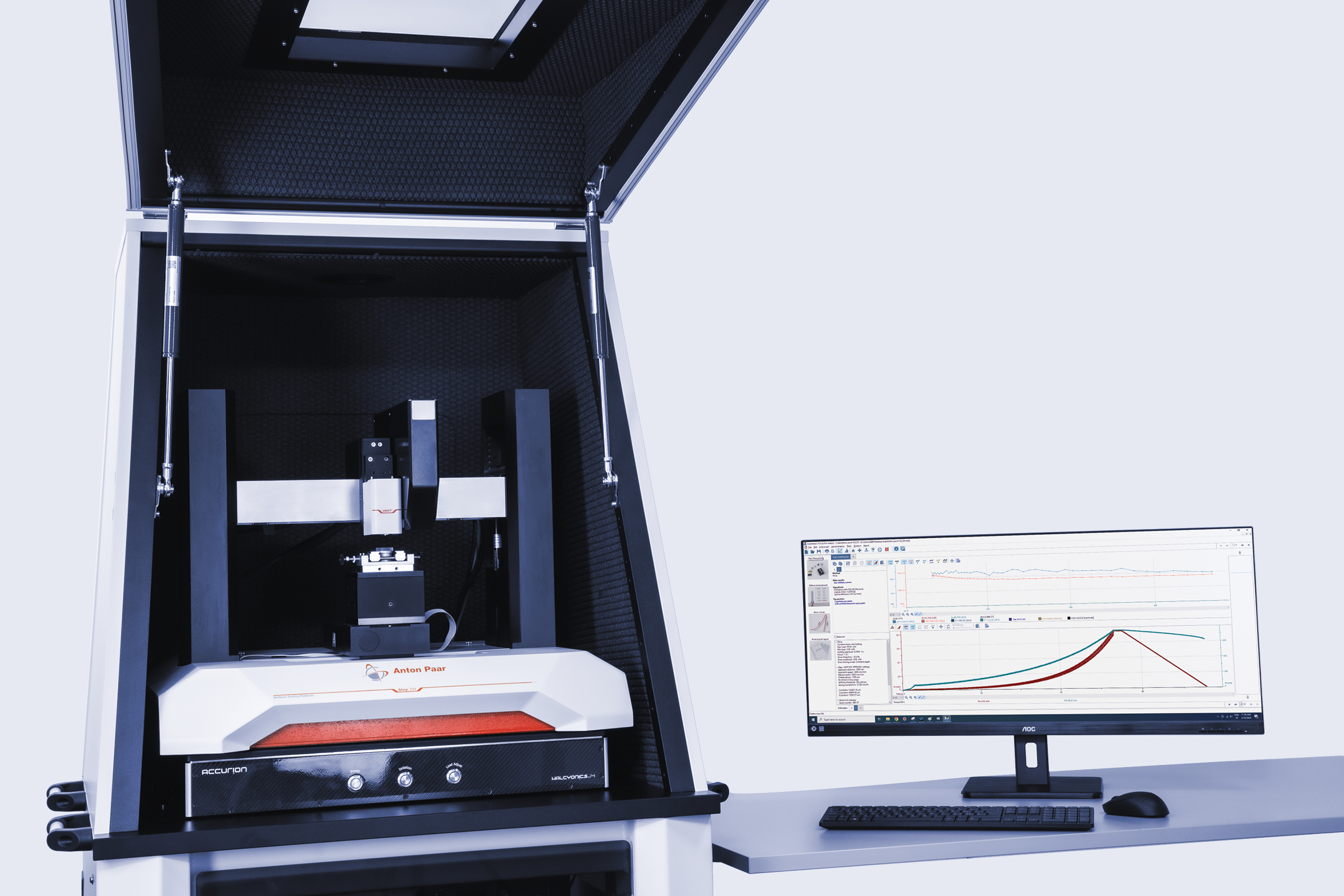

Step platform: Maximum instrument versatility

The Step platform enables complete mechanical surface characterization testing. Whether you want to perform just nanoindentation tests, or complement the results with scratch or AFM measurements, the Step platform always offers the best solution in terms of stability, noise isolation and modularity.

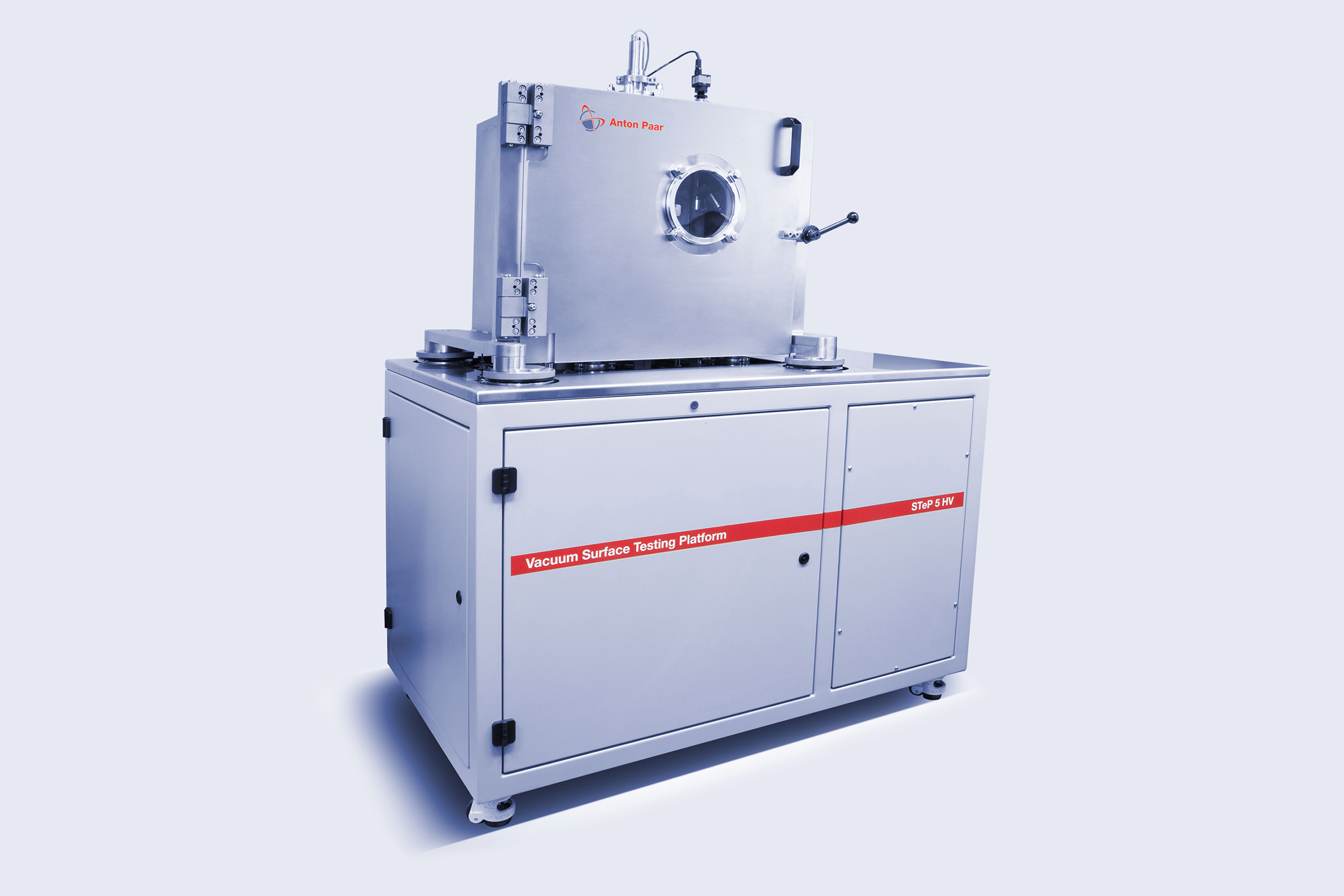

Measurements under high vacuum and high temperatures up to 800 °C

The HTV version of UNHT³ is the only ultra nanoindenter with a fully automatic procedure for minimizing thermal drift which is able to achieve <3 nm/min over the entire temperature range. This is done via unique and patented heating management which simultaneously controls the sample and indenter temperature with a precision of 0.1 °C. The indentation software takes control of the heating and environmental conditions, interacting in real-time with the system to minimize thermal drift and launch all the desired measurements. You can plan a set of any kind of indents (also possible with the standard UNHT³) with different temperature steps, and the instrument automatically conducts the measurements according to the preset matrix.

Specifications

| Maximum load [mN] | 50 / 100(1) |

| Load resolution [nN] | 3 |

| Load noise floor [rms] [μN] | ≤0.05 |

| Loading rate [mN/min] | Up to 1000 |

| Depth range [μm] | 50 / 100(1) |

| Depth resolution [nm] | 0.003 |

| Depth noise floor [rms] [nm] | ≤0.03 |

| Data acquisition rate [kHz] | 192 |

| Options | |

| Heating stage up to 200 °C | ✔ |

| Liquid testing | ✔ |

(1) optional

Patents

Active top surface referencing for UNHT³: US 7,685,868 B2

Standards

ASTM

Standards

ASTM

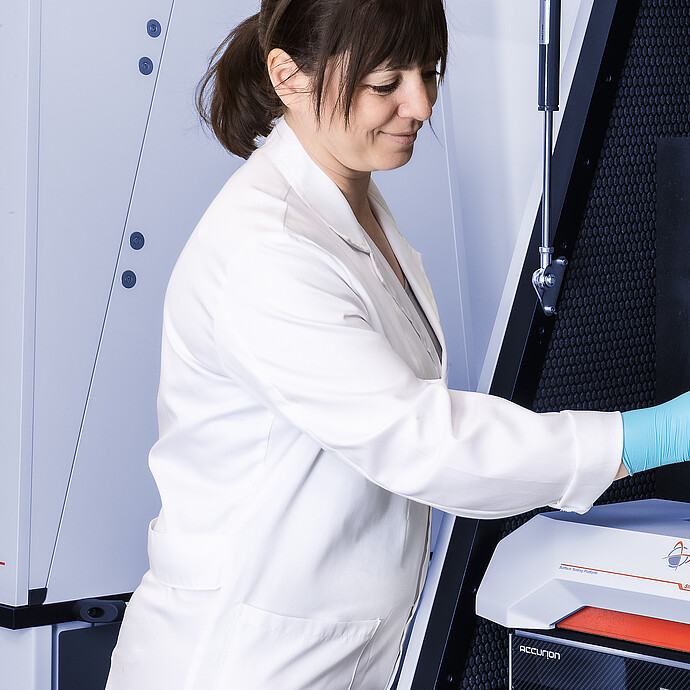

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Adhesion and hardness of galvanic layers by scratch test and nanoindentation Application Reports

-

Adhesion and mechanical properties of anti-reflective coatings Application Reports

-

Applications of indentation and scratch in automotive industry Application Reports

-

Applications of indentation in polymer industry Application Reports

-

Applications of nanoindentation in biology and medicine Application Reports

-

Characterization of diamond-like coatings (DLC, ta-C) from ANTACON Application Reports

-

Characterization of hard coatings - Part I: DLC coatings Application Reports

-

Comparison of nanoindentation with conventional hardness Application Reports

-

Compression of microparticles by cylindrical flat punch using a nanoindenter Application Reports

-

Dynamic mechanical analysis by nanoindentation Application Reports

-

Electric contact resistance (ECR) by indentation, scratch and tribology Application Reports

-

Fracture toughness measurements by nanoindentation Application Reports

-

High temperature stress-strain analysis of P91 steel Application Reports

-

How to deal with roughness in nanoindentation measurements Application Reports

-

Measurement of adhesive properties by nanoindentation Application Reports

Similar products

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

Accessory for Step Platforms:

Atomic Force Microscope (AFM)

UNHT³ Standard | HTV

- Versatile AFM solution for various scientific and industrial applications

- Imaging and analysis capabilities offering nanoscale surface information

- Non-destructive interaction with samples

Accessory for Step Platforms:

Heating module

UNHT³ Standard | HTV

- Excellent thermal stability with testing temperatures up to 450 °C

- Correlation of surface mechanical properties with temperature

- Installation directly on the Step platform