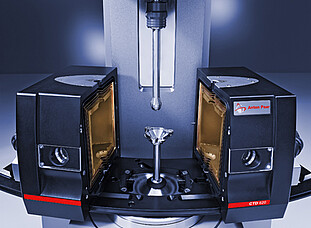

MCR Plus Tribology Cells:

Tribometer

- Test lubricants, greases, polymers, etc.

- Use special setups for food and beverages, cartilages, implants, tissues, and others

- Obtain extended Stribeck and breakaway torques with a click

- Precisely control temperature and normal force

Employ the precise motion and force control of MCR tribometers for your tribological measurements. Use a range of accessories designed to work at their best with the MCR Evolution series.

The systems’ user-friendly application software enables flexible test programming in rotation and oscillation for all accessories, featuring all tribological parameters and pre-defined measuring templates.

You can use this unique setup to acquire extended Stribeck curves, static friction, limiting friction (including break-away torque) and to apply specific motion profiles combined with normal force and temperature control. This allows for the characterization of a broad range of applications from the characterization of lubricants, biomaterials, polymers to food and beverages. You can also run component tests at model scale for bearings or the like.

Key features

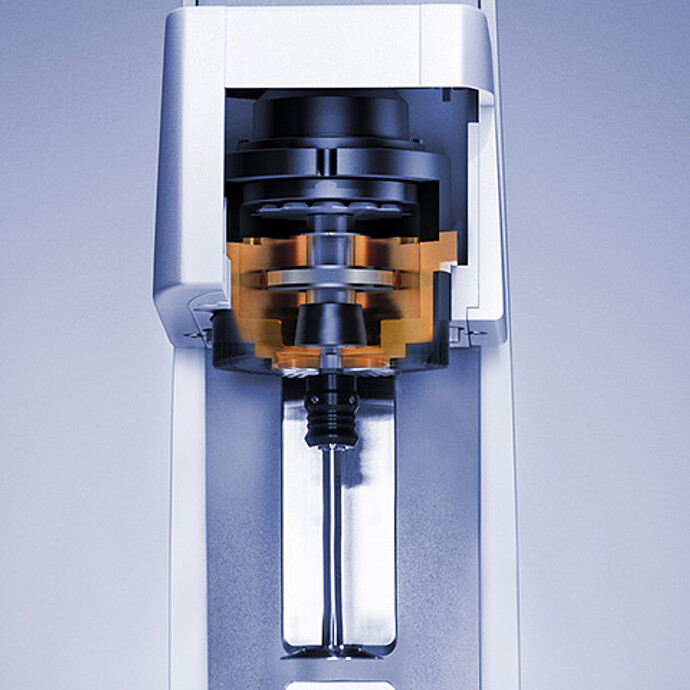

Your key to accuracy – the motor technology

25 years of experience in one motor – you only get this asset with tribometers from Anton Paar. The combination of the EC motor (Permanent Magnet Synchronous Motor) using a high-precision air bearing with active thermal management, integrated normal force sensor, and a high-resolution optical encoder, for example, allows for most sensitive and therefore most precise movements.

Step-by-step software

The intuitive software helps you find the test template you need, customize tests and analysis definitions, export your data, and generate reports. You are guided through your first tribological measurements with predesigned but individually adaptable templates, including integrated videos and pictures for extra support. Different accounts can be created for each operator working in the lab.

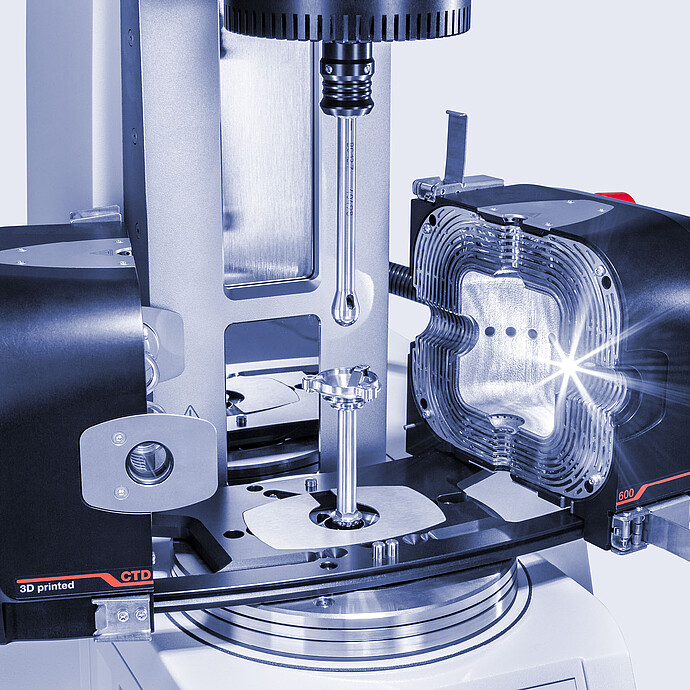

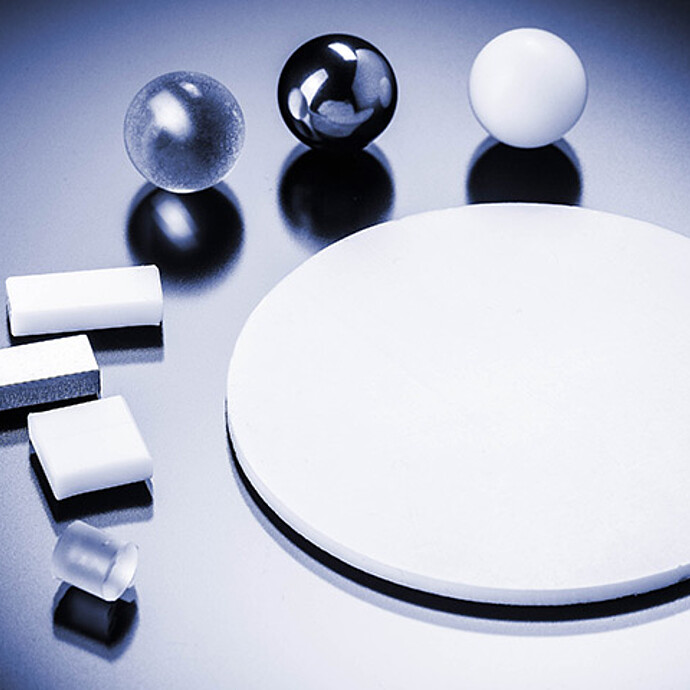

Contact Condition Control

Sample holders and measuring setups are available to customize your MCR tribometer to achieve significant and representative results for each measurement. Benefit from developments in close collaboration with research and industry partners. Measuring setups for both model tribosystems as well as components, e.g. bearings, and custom-tailored solutions are available to meet your specific needs. Test dry and lubricated systems. Even small quantities of lubricants can be tested effectively. Test point and flat contacts by merely exchanging a sample holder. Furthermore, options for optical and electrical investigations may be added.

Specifications

| MCR Tribometer Base | |||||

| Temperature Control Technology | Peltier | Electrical | |||

| Measuring Cell | T-PTD 200 | T-PTD 200E | T-PID/44 | T-BTP | |

| Environmental conditions | |||||

| Temperature Range | -40 °C to +200 °C | -40 °C to +200 °C | -30 °C to +210 °C | -20 °C to +180 °C | -160 °C to +600 °C |

| Relative Humidity Level | 5 % to 95 % | ||||

| Contact conditions | |||||

| Normal Force Range | 1 N to 50 N | 1 N to 50 N | 1 N to 50 N | 0.1 N to 70 N | |

| Normal Force Resolution | 0.005 N | ||||

| Contact Type | Point, Bearing | Point | Point, Line, Flat | Point | |

| Motion conditions | |||||

| Continuous rotation | |||||

| Speed Range | 10⁻⁶ rpm to 3,000 rpm | 10⁻⁶ rpm to 3,000 rpm | 10⁻⁶ rpm to 1,000 rpm | 10⁻⁶ rpm to 3,000 rpm | |

| Sliding Speed Range | 10⁻⁸ m/s to 3.3 m/s | 10⁻⁸ m/s to 1.4 m/s | 10⁻⁸ m/s to 2.3 m/s | 10⁻⁸ m/s to 1.4 m/s | |

| Electro-Tribology | - | Yes Voltage: 0 - 4 kV Current: up to 1 mA | - | - | |

| Torque Range | 1 nNm to 300 mNm | ||||

| Torque Resolution | 0.1 nNm | ||||

| Oscillatory rotation | |||||

| Frequency | 10⁻⁷ Hz to 100 Hz | ||||

| Angular Amplitude | 1 μrad to ∞ μrad | ||||

| Angular Resolution | 10 nrad | ||||

| Additional parameters | |||||

| Min. Online Wear Depth | 0.65 μm | ||||

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

A Combined Rheological and Tribological Study on Different Types of Chocolate Application Reports

-

Active Control of Friction Coefficient with Electro-sensitive Biolubricants Application Reports

-

Advanced Capabilities for Testing Medical Needles on an MCR Application Reports

-

Advanced Tribological Characterization of Limiting Friction of Greases Application Reports

-

Analysis of Stribeck Curves of Spreadable Food Using Rolling Correlations Application Reports

-

Basics of Characterizing Limiting Friction of Greases Application Reports

-

Biotribological Investigation of Cartilage Application Reports

-

Comparison of Conventional and Bio-based Friction Modifiers – Stribeck Curves Application Reports

-

Determining Static Friction in Dry Contacts Application Reports

-

Effect of Soot on Friction and Wear Behavior of Engine Oils Application Reports

-

Friction and Wear Behavior of Polymeric Coatings in Cartons Application Reports

-

Joe Flow - Tribology and Rheology: Everything running smoothly? Application Reports

-

Oscillatory Tribology Applications in Biolubrication Application Reports

-

Reproducibility in Tribological Measurements of Spreadable Foodstuff Application Reports

-

Rheological, Tribological and Mechanical Characterization of Hydrogels Application Reports

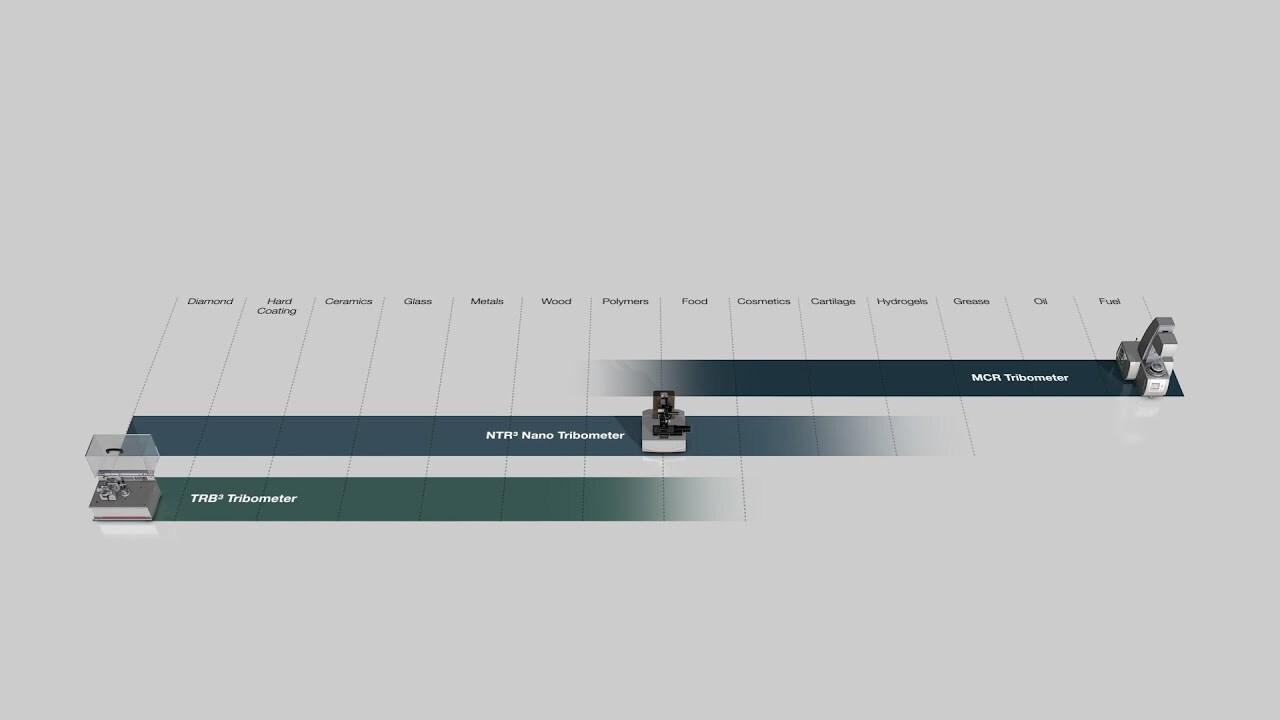

Similar products

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

MCR Tribology Cell:

T-PID/44

- Based on the pin-on-disc measuring principle

- Excellent temperature control from -30 °C up to +200 °C

- Adjustable spring stiffness in z-direction

- Sliding speed control of up to 2.3 m/s

MCR Tribology Cell:

T-BTP

- Based on the ball-on-three-plates measuring principle

- Excellent temperature control from -160 to +600 °C

- Adjustable spring stiffness in z-direction

- Normal force range expanded down to 0.1 N

MCR Tribology Cell:

T-PTD 200

- Based on the ball-on-three-plates measuring principle

- Excellent temperature control from -40 °C to +200 °C

- Sliding speed control of up to 3.3 m/s

- Rolling bearing attachment optional