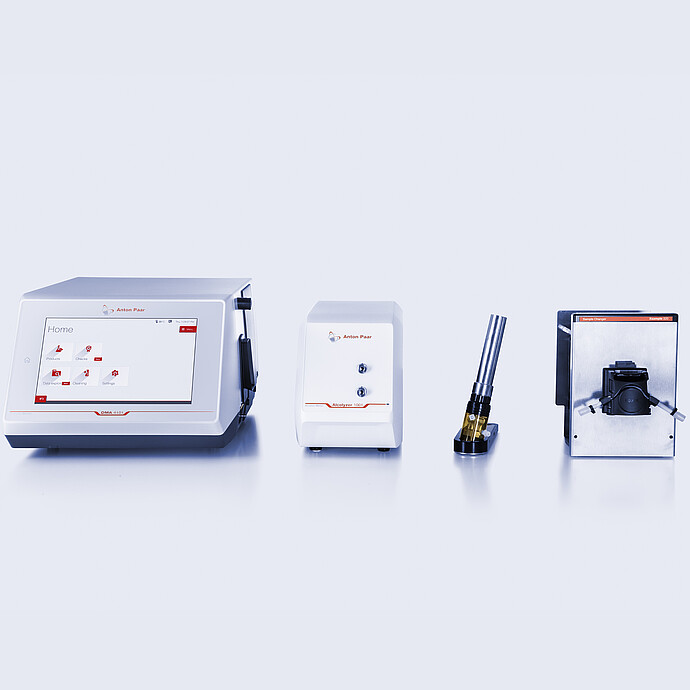

Alcohol Measurement Module:

Alcolyzer Module

- Alcohol determination in beer and beer mixed drinks

- Combine for a measurement system with up to 30 quality parameters

- Direct and selective alcohol determination from 0 % v/v to 12 % v/v

- Up to 10x faster than distillation

- Upgradable with an option color at 430 nm

Alcolyzer measurement modules are designed to monitor production and final product quality, meaning they are customized for every alcoholic beverage industry. Ensuring compliance with tax regulations and maintaining product quality, these modules offer precision and efficiency. Stay ahead of the curve with our tailor-made modular measurement system for seamless alcohol monitoring in your operations. Elevate your production standards with the Alcolyzer modules and our always-superior measurement systems.

Customized solutions

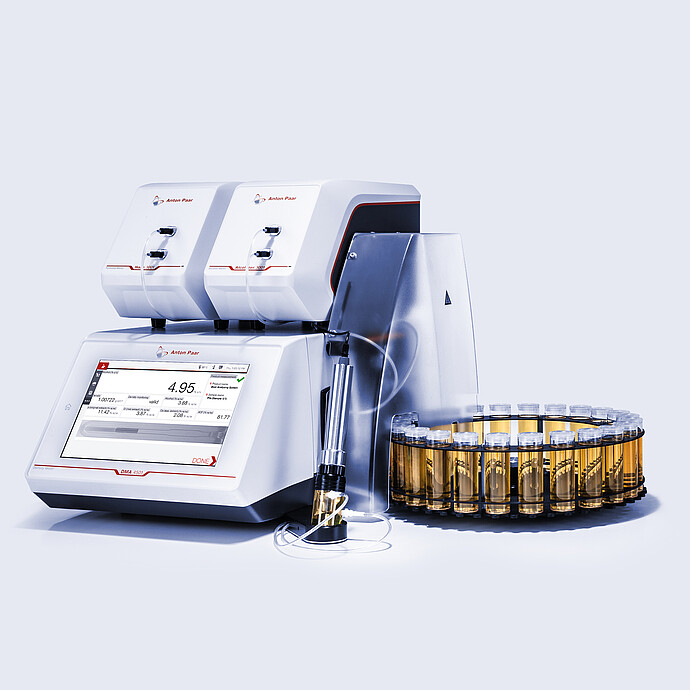

Packaged Beer Measurement Systems Configuration 3

Beer Measurement Systems Configuration 3

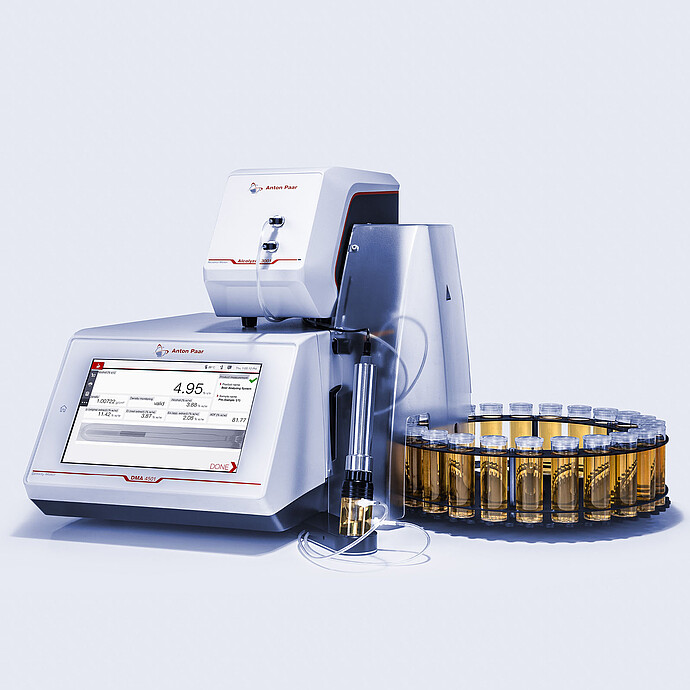

Packaged Beer Measurement Systems Configuration 1

Packaged Beer Measurement Systems Configuration 2

Beer Measurement Systems Configuration 1

Beer Measurement Systems Configuration 2

Key features

Direct, selective alcohol determination

Measurement systems containing Alcolyzer modules determine the alcohol content in your beer, wine, spirit, liqueur, and sake without influence from other sample ingredients. They don’t require any calibration model but can measure alcohol directly and based on a unique, selective NIR absorption method with the Alcolyzer modules. As there’s no need for distillation, measured results are available 10x quicker.

A system setup according to your needs

Combine your Alcolyzer 1001/3001 with a DMA density meter and other optional modules for tailor-made measurement systems. Choose from the preconfigured setups and upgrade anytime for additional parameters or automation solutions that can handle up to 24 samples in a row without any user interaction. Upgrade step by step to measure 50+ quality parameters out of a single sample and watch your business grow.

Compliance with international standards

Our instrument technology is recommended under industry-specific regulations, e.g., EBC, ASBC, MEBAK, and BCoJ for beer, or OIV and TTB for wine and spirits. In this way you can confidently declare your product, ensuring smooth export and import processes. Compliance with the acknowledged reference method distillation is also guaranteed.

Standards

AOAC

ASBC

BCOJ

EBC

Mebak

Standards

AOAC

ASBC

BCOJ

EBC

Mebak

Standards

OIV

Standards

OIV

Standards

AOAC

Standards

AOAC

ASBC

BCOJ

EBC

Mebak

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Beverage | Beer | Complete your Beer Analysis Application Reports

-

Beverage | Spirits | Complete your Spirits Analysis Application Reports

-

Beverage | Wine | Complete your wine analysis Application Reports

-

Cleaning recommendations for Alcolyzer Application Reports

-

Determination of alcohol and extract content in spirits and liqueurs Application Reports

-

Determination of alcohol content in hard seltzers Application Reports

-

Determination of alcohol content in tequila with the Spirits Measurement System Application Reports

-

Determination of the alcohol content in kombucha Application Reports

-

Quantifying beer - calorie determinations in beer Application Reports

-

Quantifying wine - calorie determinations Application Reports

-

Brochure | Beer analysis overview Brochures

-

Brochure | Spirits analysis overview Brochures

-

Brochure | Wine analysis overview Brochures

-

Data sheet | Alcolyzer 3001 Brochures

Similar products

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

SAMPLE CONDITIONER

Alcolyzer Module 1001 Beer | 3001 Beer | 3001 Wine | 3001 Sake | 3001

Heating system which allows the measurement of cold samples in PBA 5001 Beer and Wine by heating the sample almost to the measuring temperature in real time during filling.

Lab Execution System:

AP Connect Pharma one-time license

Alcolyzer Module 1001 Beer | 3001 Beer | 3001 Wine | 3001 Sake | 3001 Spirits | 3001

- One-time fee per instrument

- Time-saving processes: automatic, digital data transfer

- Assurance of lab data integrity

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Pharma subscription license

Alcolyzer Module 1001 Beer | 3001 Beer | 3001 Wine | 3001 Sake | 3001 Spirits | 3001

- Annual fee per instrument

- Time-saving processes: automatic, digital data transfer

- Assurance of lab data integrity

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Standard one-time license

Alcolyzer Module 1001 Beer | 3001 Beer | 3001 Wine | 3001 Sake | 3001 Spirits | 3001

- One-time fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Standard subscription license

Alcolyzer Module 1001 Beer | 3001 Beer | 3001 Wine | 3001 Sake | 3001 Spirits | 3001

- Annual fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Start

Alcolyzer Module 1001 Beer | 3001 Beer | 3001 Wine | 3001 Sake | 3001 Spirits | 3001

- Kickstart your paperless lab

- Featuring key benefits of the Standard edition

- Restricted to one instrument, single user access, one export rule

ETHANOL STANDARDS KIT

Alcolyzer Module 1001 Beer | 3001 Beer | 3001 Wine | 3001 Sake | 3001

The kit contains 6 x 50 mL ethanol-water binary solution in the range of 11.0 +/- 0.5 % v/v with accurately defined ethanol concentration

Lab Execution System:

AP Connect

Alcolyzer Module 3001 Beer | 3001 Wine | 3001 Sake | 3001 Spirits | 3001