Color Sensor:

L-Col 6100

- Inline color measurement for all kinds of beverages

- EBC/MEBAK®/ASCB-compliant

- Tailor-made wavelength configurations

- Seamless integration with beverage analyzers

- Easy installation at your plant

The color of beverages is an important key property for guaranteeing the quality of all kinds of beverages. MEBAK®-compliant inline color measurement allows you to follow your entire production process, detect the maturity level of your beverage during storage, and control the dosing of additives and the blending process.

Key features

Ensure color consistency right where you need it

Inline color measurement with L-Col 6100 gives you the certainty that your product looks exactly the way you want it to at any point in the production line. Most commonly, color measurement is employed at the end of production for a final inspection of the product, ensuring a consistent quality of the beverage you pass on to your customers. Typical applications include beer color measurement or controlling blending procedures.

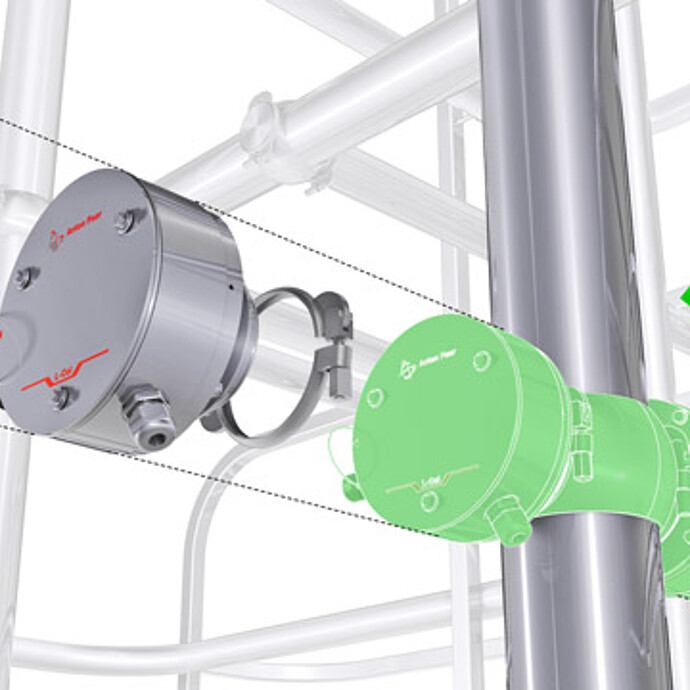

The no-fuss solution for inline color measurement

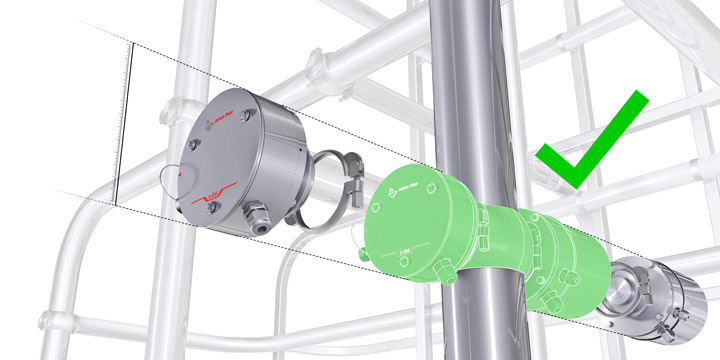

The optical measurement principle makes it possible: To integrate L‑Col 6100 in your production line, you don’t need any extra device. Installation takes less than one hour. The color sensor is mounted inline via the VARIVENT® Type N connector. This EHEDG-certified connection is easy to mount. No hoses, no bypass, and no additional supplies are necessary. A nice side effect: You don’t need any floor space for color measurement, keeping your production line clutter-free.

The sensor is also easy-care during its whole lifetime: Long-lasting LED light sources reduce the maintenance effort significantly and lead to very low power consumption.

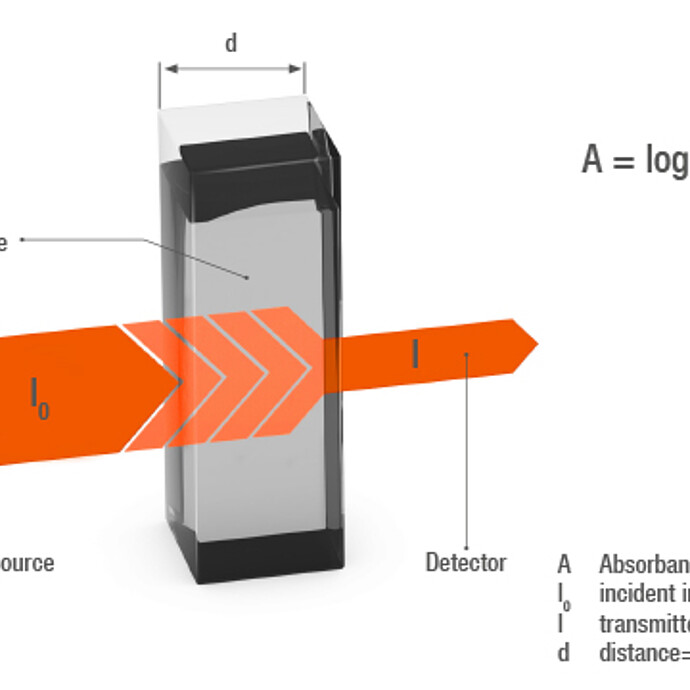

High-resolution optical measurement in a wide absorbance range

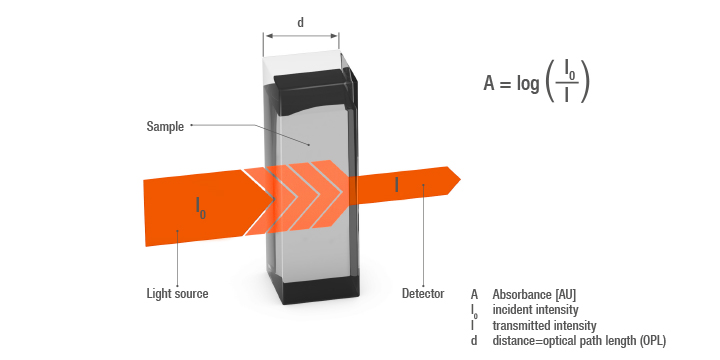

L-Col 6100 employs an optical measurement principle based on light absorption. From 0 AU to 3 AU (absorbance units) the color sensor delivers results fast and with a resolution of 0.001 AU. Together with a linearity above ±0.5 % transmission, this leads to highly reliable beer color measurements.

For the beer industry, the sensor converts results to beer color at 430 nm according to EBC/MEBAK®/ASCB. Turbidity can be compensated at 700 nm to eliminate the influence of sediments, e.g. yeasts in unfiltered beers.

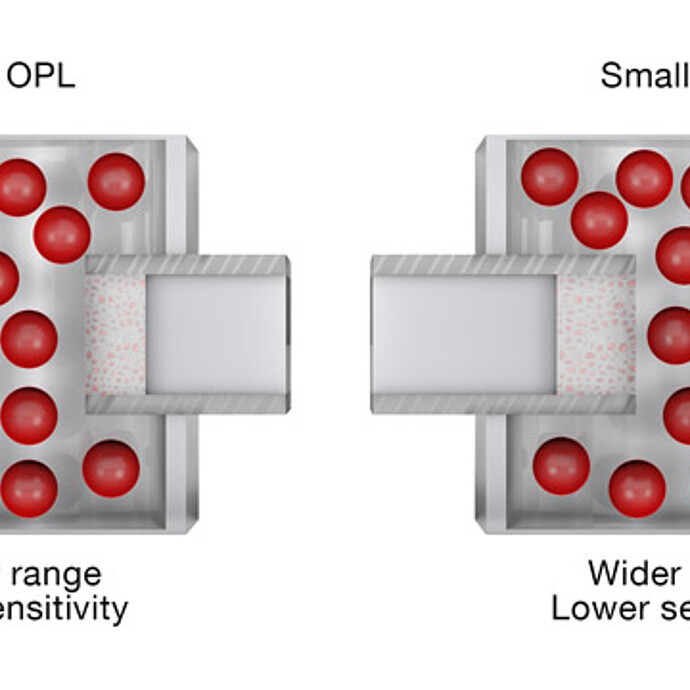

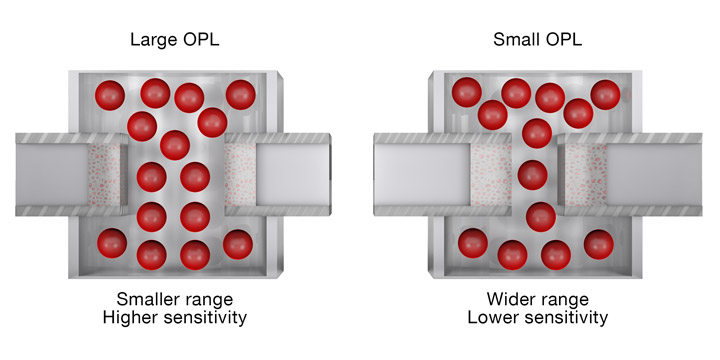

492840 individual configuration possibilities

By selecting one of the ten predefined sets of optical path lengths (OPL) various applications for most common line diameters are covered. In addition, L-Col 6100 can be equipped with up to three wavelengths of choice:

- UV options: 280 nm, 340 nm, 380 nm

- Vis options: 390 nm to 700 nm (in 10 nm intervals), 455 nm and 760 nm

Individual configurations for special requirements are available. For detailed information about configuration possibilities, contact our product specialists here.

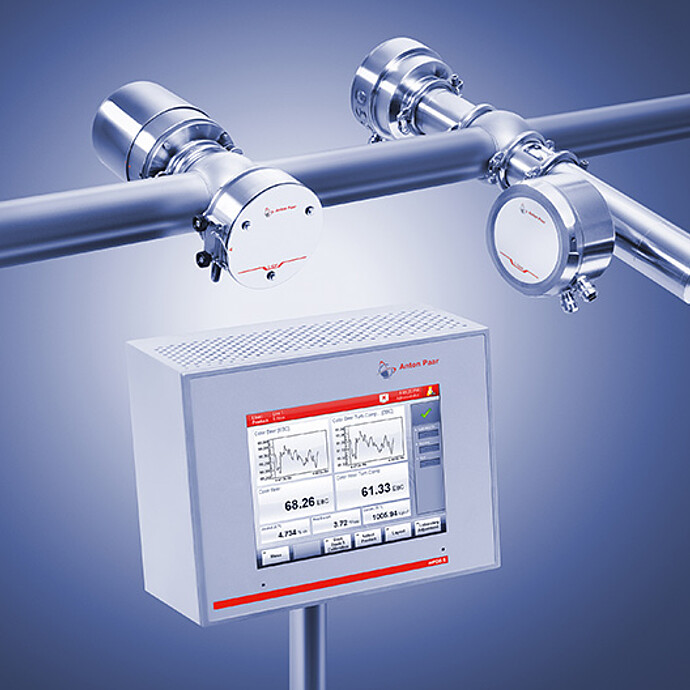

Seamless integration with new and existing beverage analyzers

The L-Col 6100 color sensor is an optional add-on for all Anton Paar inline beverage analyzers for beer, soft drinks, spirits, liqueurs, and wine. This makes color an additional quality control parameter you can measure and display together with your other results on the evaluation unit mPDS 5.

The link to the Davis 5 software connects your inline color measurement with your lab world, making it easy to compare inline to laboratory results (e.g. from packaged beverage analyzers). The software visualizes statistical and production data and trends from all around the production plant. With this integrated system, your color measurement is traceable and documented in the accustomed Anton Paar quality.

Specifications

| Measuring principle | Absorption |

| Measuring range | 0 AU to 3 AU |

| Measuring units | EBC, SRM, AU, IU (others on request) |

| Resolution | 0.001 AU |

| Reproducibility | ±1 % transmission |

| Linearity | Better than ±0.5 % transmission |

| Wavelength absorption | 1 to 3 wavelengths of choice: 280, 340, 380, 390, 400, 410, 420, 430, 440, 450, 455, 460, 470, 480, 490, 500, 510, 520, 530, 540, 550, 560, 570, 580, 590, 600, 610, 620, 630, 640, 650, 660, 670, 680, 690, 700, 760 nm (all with LED) |

| Supply voltage | DC 24 V – 1 A (supplied via mPDS 5) |

| Process temperature | 0 °C to 110 °C CIP/SIP up to 121 °C for 120 min |

| Sample pressure | max. 10 bar |

| Ambient temperature range | -20 °C to +50 °C |

| Ambient humidity | 0 % RH to 100 % RH |

| Degree of protection | IP65 |

| Weight | max. 4.3 kg |

| Process wetted parts | Stainless steel 1.4301, fused silica, EPDM |

| Stainless steel 1.4301, fused silica, EPDM | Tuchenhagen VARIVENT® Type N |

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Beverage | Beer | Complete your Beer Analysis Application Reports

-

Beverage | Beer | How to ensure color consistency of beer Application Reports

-

Beverage | Color | Monitoring the sugar color of sugar in syrups Application Reports

-

Beverage | Wine | Complete your wine analysis Application Reports

-

Process Engineering Solutions | Overview Brochures

Compatible instruments

Beer Monitor 5501

Beer Monitor 5601

Cobrix 5501

Cobrix 5601

Cobrix 7501

Cobrix 7601

Wine Monitor 5501

Wine Monitor 5601

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

O-RING 60x3 EPDM 70 FDA COMPLIANT

O-RING 22x3 EPDM 70

O-ring sitting on the bottom plug of cups of the following DIN/SSA systems.