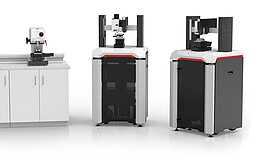

Products from Anton Paar

Insights that change everything. Which of Anton Paar's products will make your day?

Anton Paar develops and manufactures analytical instruments that enable you to understand your materials. Reliable data enables scientists, researchers and engineers to proceed with confidence in research and product development, manage and control manufacturing quality and optimize their output.

Alcohol Meters

Alcoholic beverages analyzed at the push of a button

Automation & Robotics Solutions

Where precision meets performance

Beverage Measurement Systems

Complete solutions based on decades of experience

CO2, Oxygen, and TPO Meters

For reliable quality control in beverage production

Coating Thickness Testers

Save time and costs in coating thickness determination

Consistency Analyzers

High precision in material texture testing

Density Meters

Solutions from the market leader in density measurement

Distillation Analyzers

Perfection from the first drop

Dynamic Mechanical Analyzers

Your most flexible and precise option for DMA

Extruders

Process and Material Development with Brabender Extruders

FTIR Instruments

Outstanding FTIR Analysis for a World of Samples

Flash Point Testers

Innovation in flash point testing

Flow Meters

Mass Flow and Inline Concentration Measurements

Gas Adsorption Analyzers

Analysis of pore size, surface area, and gas/solid interactions

Inline Beverage Analyzers

Complete your beverage analysis

Instrumented Indentation Testers

The widest range of high-precision indentation testing

Laboratory Mills

From Fibrous to Fine: Brabender Lab Mills Master Every Grind

Laboratory Software

Manage your laboratory instrument measurement results with ease

Measurement Systems

Up to 7 parameters in one go

Microwave Digestion Systems

Microwave acid digestion, microwave acid leaching, and much more

Microwave Synthesizers

Responding to your synthesis needs

Moisture Analyzers

Brabender Moisture Analyzers: The Reference for Precision

Oxidation Stability Analyzers & CFPP Testers

Know your sample's environmental behavior

Particle Size Analyzers

Particle analysis at the touch of a button

Polarimeters

Measure. Comply. Perform.

Porometers and Porosimeters

Quick, safe, and easy-to-use porometers and porosimeters

Process Controllers and Analysis Software

Expand control, with visualization and reporting

Process Sensors

Next-generation process sensors by Anton Paar

Process Systems and Integration

Ready-to-go process engineering solutions

Raman Spectrometers

Cora: Compact Raman Analyzer

Refractometers

Accurate and efficient QC for food, beverages, chemicals, and pharmaceuticals

Rheometers

The most trusted rheometer series with more than 10,000 installations worldwide

SAXS Instrumentation

Pure Brilliance

Sample Changers

Choose your Xsample

Scratch Testers

Solutions from the market leader in scratch testing

Semi-Solid and Solid Density Analyzers

A Complete Solution for the Density Measurement of Powders, Solids, and Semi-Solids

Sugar Analyzers

Maximum accuracy based on decades of experience

Surface Charge and Zeta Potential Analyzers

Unrivaled quality, speed, and convenience

Thermal Analyzers

Expand the Limits of Material Characterization

Thermometers

Maximum accuracy at an unrivaled price

Torque Rheometers

Brabender Torque Rheometers: A Century of Precise Analysis

Tribometers

The widest range of instruments for studying friction and wear

Turbidity Meters

A clear look at cloudy media

Universal Testing Machines

Testing of materials and components in the micro range

Viscometers

The World’s Most Successful Viscometers

X-Ray Sources / X-Ray Optics

X-ray sources and optics for brilliant X-ray analysis

XRD Instrumentation

Versatile X-ray diffraction solutions