Extruders

Process and Material Development with Brabender Extruders

The Brabender Extruder portfolio is a comprehensive set of tools with which to oversee your production process and explore your materials on a lab or pilot scale. Drive product innovation with rigorous testing of novel formulations and their suitability for your production. Test samples of any quantity, while preserving your valuable manufacturing resources. The extensive portfolio includes both single- and twin-screw extruder solutions, all underpinned by a modular framework letting you seamlessly tailor the components of the extrusion process to your specific materials and application requirements.

Anton Paar Products

Lab- and Pilot-Scale Twin Screw Extruders:

TwinLab

Brabender:

Blown Film Take-Off Unit

Brabender:

Conveyor Belt

Brabender:

CuttingDevice

Brabender:

Film-Blowing Die Head

Brabender:

Filtratest

Brabender:

Garvey Die Head

Brabender:

Modular Cooling Die

Brabender:

Multi Strand Die

Brabender:

Pasta Die Head

Brabender:

Pelletizer

Brabender:

Rheometric Round Capillary Die Head

Brabender:

Rheometric Slot Capillary Die Head

Brabender:

Ribbon Die Head

Brabender:

Round Strand Die Head

Brabender:

Swelltest

Brabender:

Tubing Die Head

Brabender:

Univex

Brabender:

Vertical Forced Feeder

Brabender:

Water Bath

Brabender:

Winder

Brabender:

Wire Coating Die Head

Brabender:

Wire Take-Off Unit

Brabender:

FQA Film Quality Analyzer

Brabender:

Stand-Alone Extruder KE 19

Brabender:

Stand-Alone Extruder KE 30

Brabender:

TwinLab-C 20/40

Brabender:

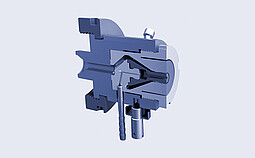

Conical Twin Screw Extruder CTSE

Brabender:

Extruder / Extrusiograph 19/25 and 19/32

Brabender:

Extruder/Extrusiograph 30/25 and 30/32

Brabender:

Extruder 19/10 DW

Brabender:

Measuring Extruder and Grooved Extruder 19/20

Brabender:

Single-Screw Extruder 19/25

Brabender:

Twin Screw Compounder TSC 42/6

Brabender:

Auto-Grader

Top flexibility: Compact devices or modular drive units

Maximum flexibility: Choose between compact devices or modular drive units between varied-scale single and twin-screw extruders – and scale up whenever you want.

Broad range of applications, application-specific configuration

These extruders go way beyond standard-solution portfolios to include different screws for different applications, modular screw elements for twin-screw extruders, and different die geometries. The application lab supports testing of the suitability of an extruder configuration for a particular application. We offer you tailor-made components, all the way up to complete solutions for specific requirements.

Feeders, tools, downstream equipment – all from a single supplier

We offer all the extrusion accessories you need: a variety of gravimetric and volumetric feeders, including forced feeders for free-flowing substances, extruder tools (die heads and screws), and solutions for conveying, cooling, pelletizing, taking off, and winding up extrudates.

Continuous live recording of process parameters

Live process monitoring delivers complete insight into the entire extrusion process. Determine correlations between process variables and final properties of the extrudate. Obtain more information and process knowledge by applying rheological die heads and down-stream equipment for melt characterization.

Extrusion at lab scale, saving resources

Low material and energy input, elimination of the need to use production machines for trials, easy cleaning, quick changeover times, and space saving. Optimize your resources.

Webinars

We offer you a great and constantly growing choice of live webinars and recordings on products, applications, and scientific topics.

View webinars