Polymer characterization

Whether your polymer films are used for packaging, plastic bags, photographic films, substrates for flexible solar cells, flexible displays, touch panels, or circuit boards – their composition always determines their properties. The requirements they need to fulfill are as diverse as their fields of application and a thorough investigation of their properties is necessary for modifying their formulation or simply testing their quality.

Investigation of thin films and nanofilms (thickness <1 µm)

Very thin (~1 µm and less) polymeric films, which often consist of multiple layers, are often used as electric insulation or protection against corrosion for electronic components such as printed circuit boards (PCB) or smartphone parts as well as refractive films on optical lenses. They can also be used as sensors for humidity or lithography, antibacterial coatings of stents, or even for genome sequencing.

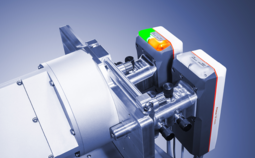

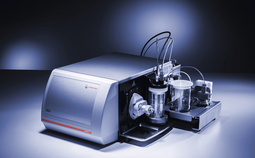

To test thin films and nanofilms you can use the nanoscratch test method for measuring the adhesion and scratch resistance of each layer of the thin film or the final material with one instrument. Insights into the surface zeta potential of thin films and related surface properties can be gained by measurement of the streaming potential or streaming current.

Besides adhesion, scratch resistance, and the surface zeta potential, also the nanostructure is of great interest. Find out the most about your material by performing:

- topography measurements

- measurements of mechanical properties

- measurements of electrical properties

Investigation of thick films (thickness >1 µm)

Protective or decorative films such as protective paints for cars, white appliances, or epoxy paints for floor lining must resist damage, which is mainly caused by scratching. In the case of metals, paints protect the base material mainly against corrosion but also against scratches.

Use the most efficient and most reliable scratch test technique to assess the films’ scratch resistance and find out about how well the coating resists damage under precisely defined conditions. Those tests also provide information about its elastic recovery.

In order to find out how a film performs under certain environmental conditions, such as temperature, humidity, or stress conditions dynamic mechanical analysis is the right choice to ensure that the final product quality meets users’ expectations.

When developing your films you want to be sure that the surface finish will be perfect. That’s why you want to characterize your polymer melts and also design the processing operations accordingly. Comprehensive rheological characterization helps you achieve all this.

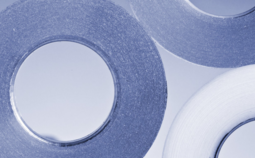

Investigation of adhesive films

As an increasing number of industrial and consumer products are adhered rather than joined, welded, soldered, screwed, or clamped, adhesive films have a bright future ahead. But adhesive films are often produced by coating a base layer with a liquid adhesive layer, which needs to be cured during the process.

Make use of the benefits of rheological characterization for determining the curing kinetics of the adhesive layer, thereby finding the ideal design of the production process.

So that the stickiness of your adhesive film is not lost below a certain temperature use dynamic mechanical analysis in order to determine the temperature range in which the film will stick to other surfaces.

Find the right polymer characterization solution

No matter if thin films and nanofilms, thick films, or adhesive films – their composition always determines their properties. It is essential to thoroughly investigate these properties so that your polymer films can fulfill the specific requirements in any field of application. A thorough investigation is also a prerequisite of formulation modifications and quality control.

| Solution | Your benefit | Instrument | |

The produced film has low surface quality (rippled surface). | Perform rheological measurements to characterize the viscoelasticity of the used raw material in order to optimize process conditions. | Consistent quality of the produced films, without surface imperfections or defects | |

The packaging film shows increased failure rates in tropical/arid/cold climates. | Analyze the mechanical performance of the film in controlled-humidity DMA tests. | The guarantee that your product reaches your customer in good condition, independent of climate conditions | |

The film ruptures during use. | Perform tensile testing to determine the strain- or stress at break. Perform dynamic mechanical analysis to investigate film brittleness (as indicated by the measured damping factor). | Improved product quality based on a better selection of materials tailored to the product requirements | |

Adhesive residues remain on the surface after peeling off the adhesive tape (incompletely cured adhesive layer). | Investigate the aging behavior of the adhesive depending on temperature and time. | Higher product quality due to optimized material formulations and processing conditions | |

The paint scratches too easily. | Perform precisely controlled scratch tests to measure the scratch resistance. | Feedback about scratch resistance of paints with new formulations | |

The polymer films and paints must recover after scratch damage. | Perform precisely defined scratch tests to measure the depth during the scratch and the depth after the recovery. | Testing different films and coatings and optimizing the formulation to achieve the best possible recovery of the paint or the film after scratch damage | |

The polymer film/paint has to resist aging. | Perform indentation measurements with a creep segment to measure the creep properties of the film/paint. Analyze the surface zeta potential at various pH values to determine the isoelectric point. | Possibility to rank different films/paints according to their creep properties and select the best ones. Possibility to correlate the zeta potential to aging propensity. | |

The produced film has insufficient optical quality, it is shallow (high variation in dispersion). | Perform refractive index measurements at different wavelengths and determine the dispersion. | Consistent quality of the produced films. Shallow polymers can be already sorted out during the development of new products. | |

The film does not exhibit the desired wetting behavior | Analyze the surface zeta potential to gain knowledge of the surface functionalities. | The option to adjust the properties to get a film with the desired wetting behavior. | |

The polymer thin film does not show antibacterial behavior | Analyze the surface zeta potential at various pH values to gain knowledge of the isoelectric point. | Detection of the proper material composition that exhibits antibacterial behavior. | |

The interaction between a polymer thin film and an aqueous solution needs to be predicted | Analyze the surface zeta potential to find out whether molecules of the liquid adsorb on the surface or whether components of the thin film get eluted. | Access to a surface-sensitive technique that allows you to analyze the real-life sample. |

You did not find your specific situation? Anton Paar still has the solution for your challenge. Just contact us for more information.

Learn more about polymer characterization from leading experts in the field

Get an insight into how an academic expert in the field of polymer characterization uses Anton Paar instruments as part of his daily work. Read this interview and find out how Anton Paar instruments are used in academic research for gaining deeper insights into polymers and developing innovative polymer products.

Silicone coating analysis with scratch testing

“We found out that the scratch behavior (adhesion, cohesion) was different going from thin to thick when compared to from thick to thin.”

Professor James Kohl, University of San Diego

Educational resources

Polymer characterization webinars

Polymer characterization application reports

Applications of indentation, scratch, tribology and coating thickness measurements in automotive industry Part II: Tribology and thickness of coatings