| Measuring range | |

| Temperature control and measurement | 20 °C |

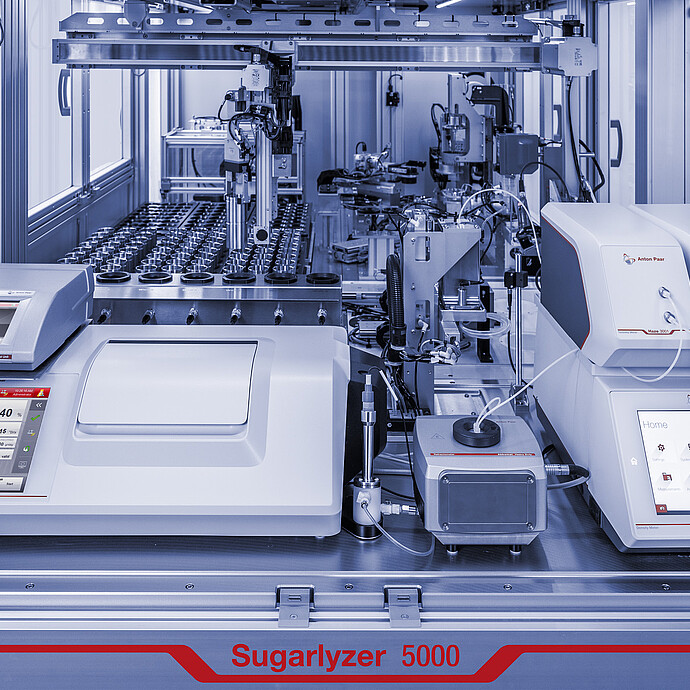

| Sugar content (°Z) at 589 nm | ± 259 °Z (± 89.9 °OR) |

| Dry substance (°Brix) | 1.26 - 1.72 nD |

| Turbidity [1] | 0 EBC to 100 EBC / 0 NTU to 400 NTU |

| Color [1] | 0 EBC to 120 EBC |

| Density | 0 g/cm³ to 3 g/cm³ |

| pH value | pH 0 to pH 14 |

| Repeatability s.d. |

| Temperature control and measurement | ± 0.1 °C |

| Sugar content (°Z) at 589 nm | ± 0.003 °OR; ± 0.01 °Z" |

| Dry substance (°Brix) | ± 0.000001 nD |

| Turbidity [1] | 0.02 EBC / 0.08 NTU |

| Color [1] | 0.1 EBC |

| Density | 0.000005 g/cm³ |

| pH value | 0.02 (in the range pH 3 to pH 7) |

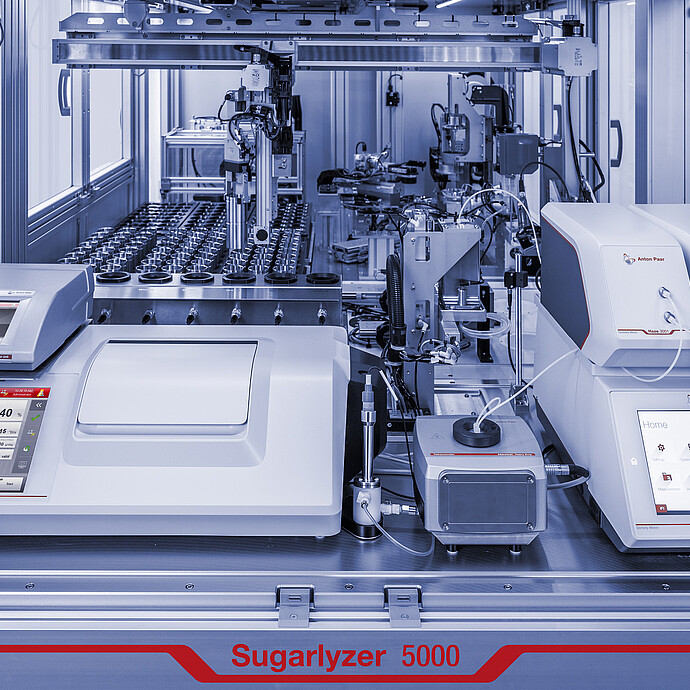

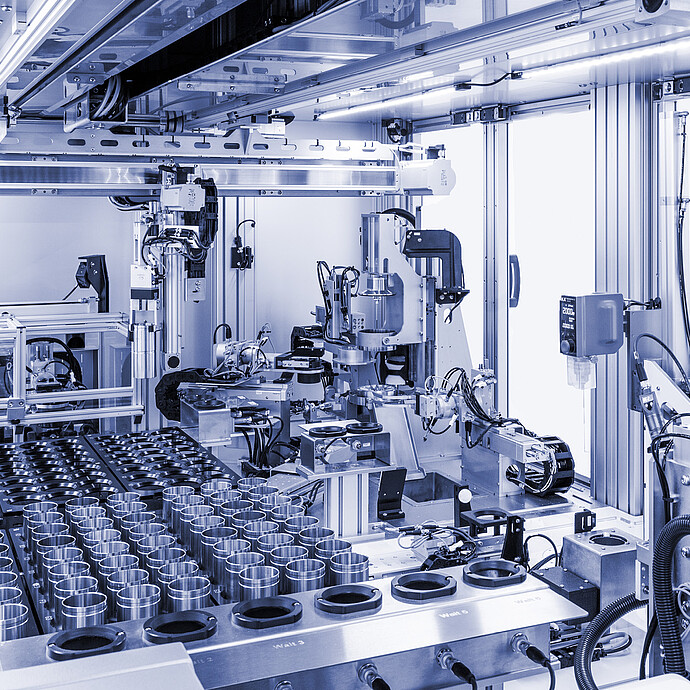

| Sample loading capacity | 72 sample cups |

| Typical cycle time per sample | approx. 5 min. |

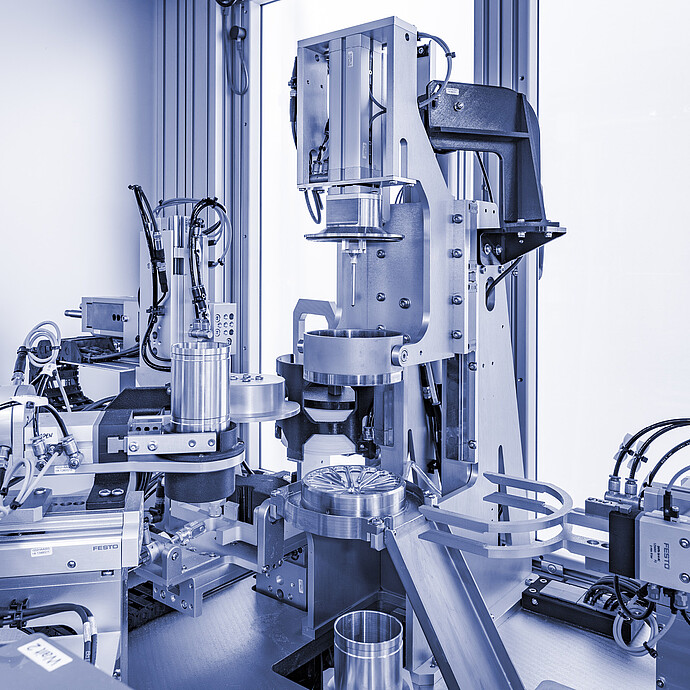

| Sample preparation |

| Dosing accuracy (DI water and clearifying agent) | 0.04 ml or 1 % |

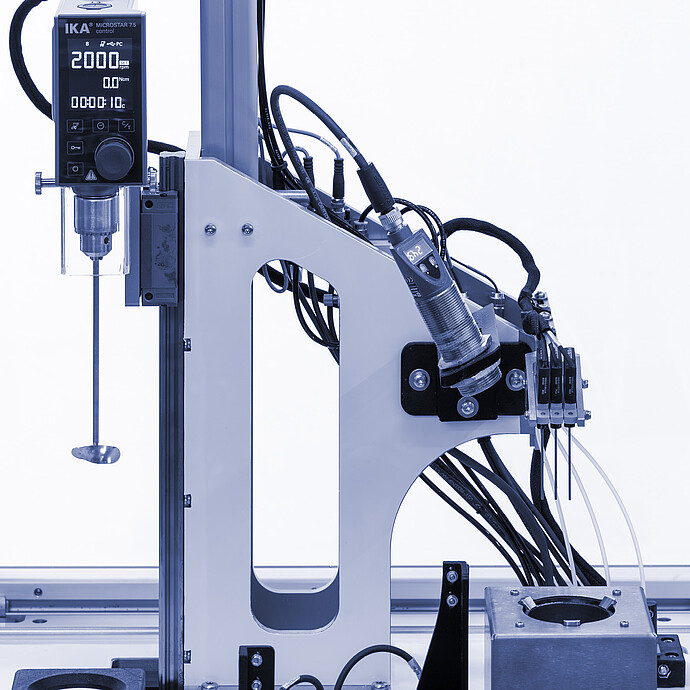

| Mixing speed | 0 rpm to 2,000 rpm |

| Sample pre-tempering station | 65 °C |

| Sample volume required | 90 ml to 150 ml / cup |

| Environmental conditions |

| Ambient temperature | 22 °C (min. 20 °C, max. 25 °C) |

| Relative humidity (not condensing) | at 15 °C to 30 °C: 0 % - 70 %, (non-condensing) |

| Tested sample types [2] |

| Sample types | raw juice, thin juice, thick juice, syrup, molasses, sugar |

| Further details |

| Pressurized air | ISO 8573-1:2010 [7:4:4], Particle: Class 6, Water: Class 4, Oil: Class 3, Pressure 6 - 10 bar, Pipe diameter Ø 12 mm |

| DI water hot | 4 bar to 6 bar abs., chlorine-free (55 °C to 60 °C) 10 L/min |

| DI water cold | 2 bar to 4 bar abs., chlorine-free (Room temperature; approx. 20 °C ± 1 %) 1 L/min |

| Communication interface | Export of results via CSV-files or bidirectional connection to a LIMS system |

| Power supply | 1 x 230 V 50 Hz to 60 Hz 16 A |

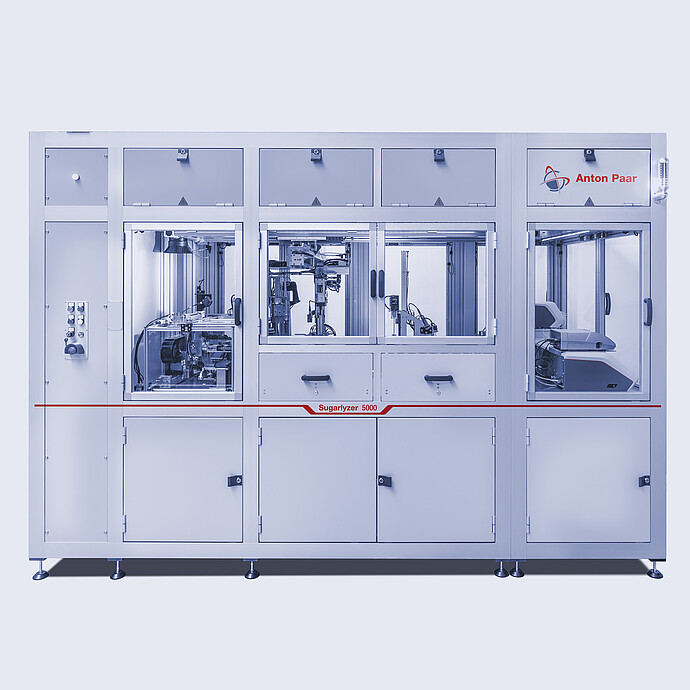

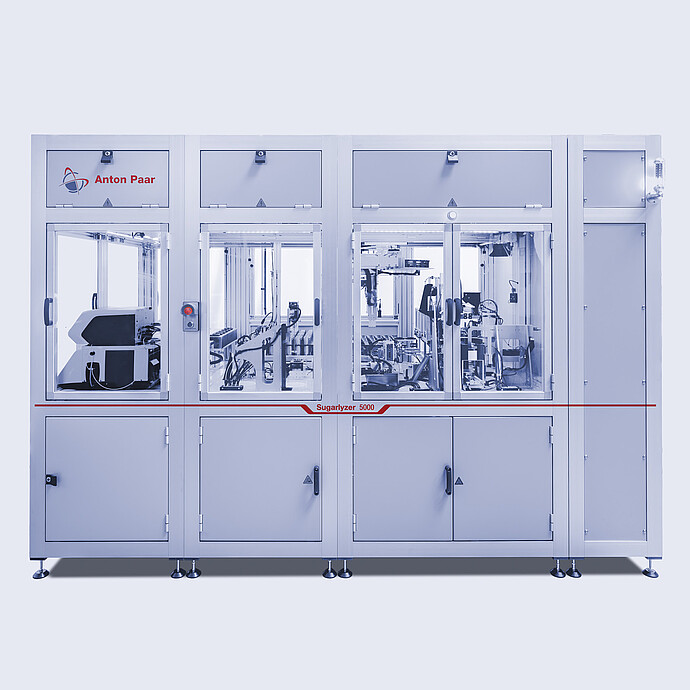

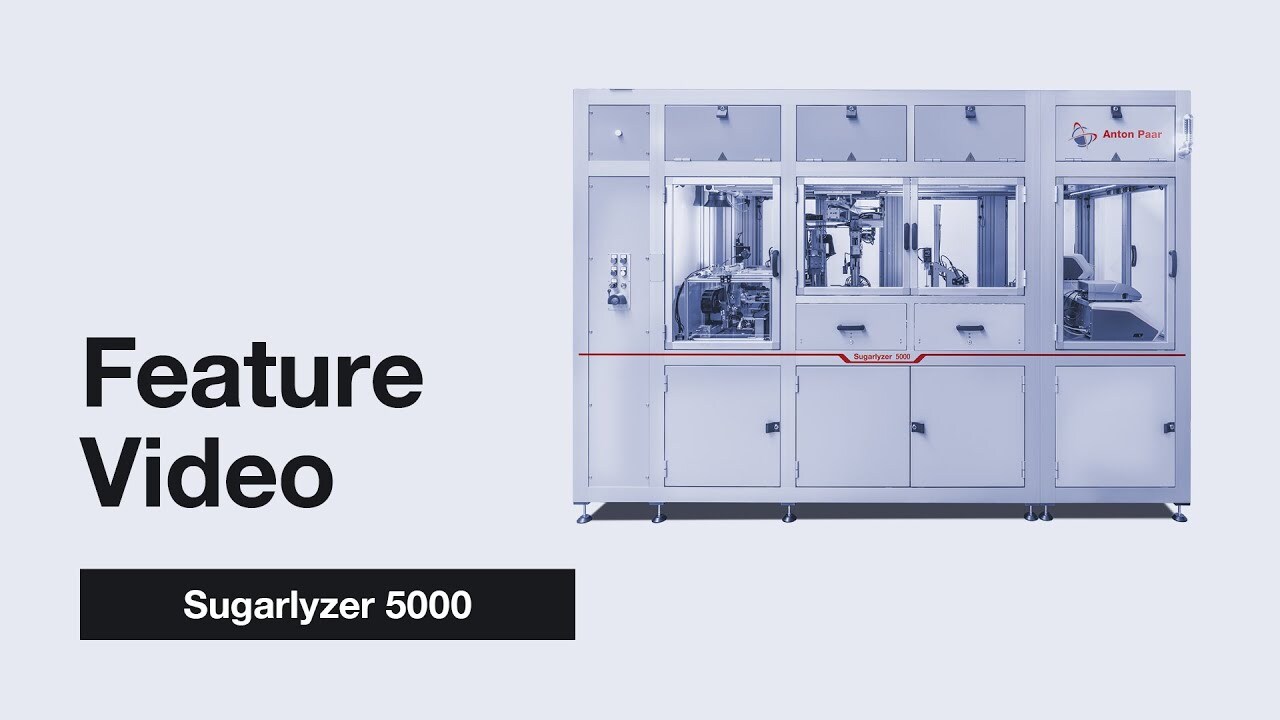

| Dimensions (L x W x H) (without signal lights and ventilation) | 3,300 mm x 1,600 mm x 2,300 mm |

| Distance from the nearest wall | 900 mm |

| Weight | Approx. 2,300 kg (5,071 lbs) |

| Altitude | Max. 2,000 m (max. 6,560 ft) |

| Ventilation (connection to suction line from customer) | 200 m³/h |

| Air consumption | 300 L/min; peak 800 L/min |

| Sound pressure | Weighted average sound pressure level La = 62 dB(A), short term

below 85 dB(A) |

| Display | Industrial-PC 1,920 px x 1,080 px |

| Controls | Mouse + Keyboard |