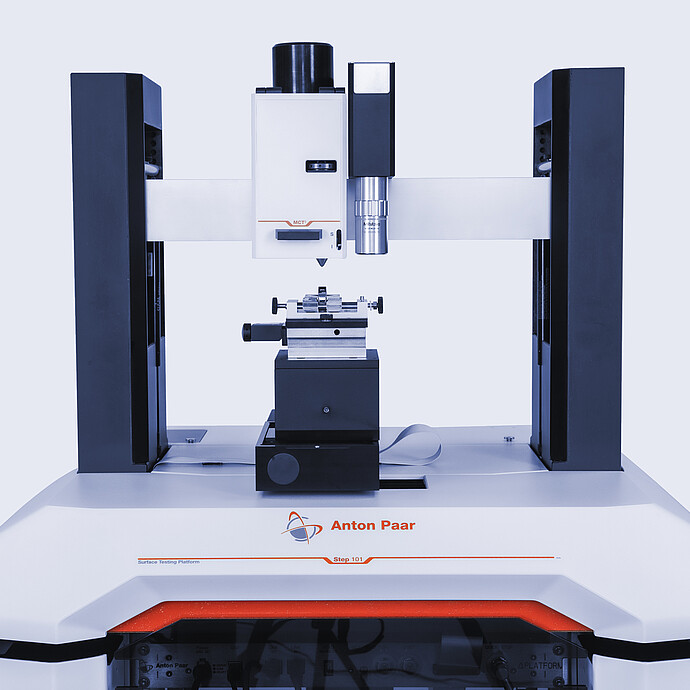

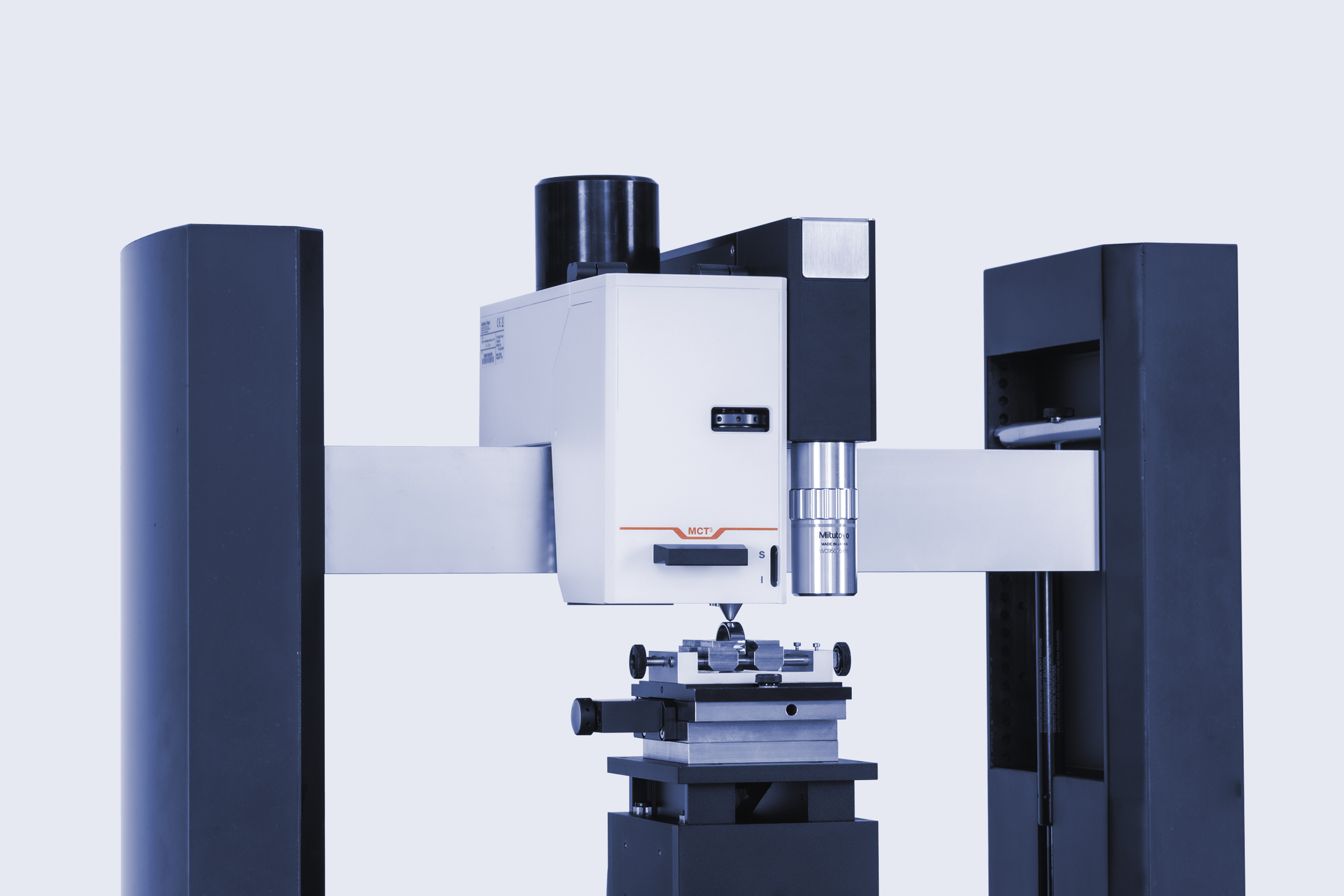

Micro Combi Tester:

MCT³

- 4-in-1 setup for instrumented indentation, conventional hardness, scratch & basic tribology testing

- Measurement of hardness, elastic modulus, coating adhesion, scratch resistance, wear, and other surface mechanical properties

- For characterization of hard coatings, thermal/plasma spray coatings, cementitious materials, metals, and polymers

The Micro Combi Tester (MCT³) is a universal measurement head for full mechanical characterization of coatings and bulk samples.

The unique wide load range of this instrument allows the determination of adhesion, scratch resistance, hardness, elastic modulus, friction, and wear for a wide range of samples. It is applicable to organic and inorganic, as well as soft and hard, coatings (between 1 µm and 20 µm), and also bulk materials.

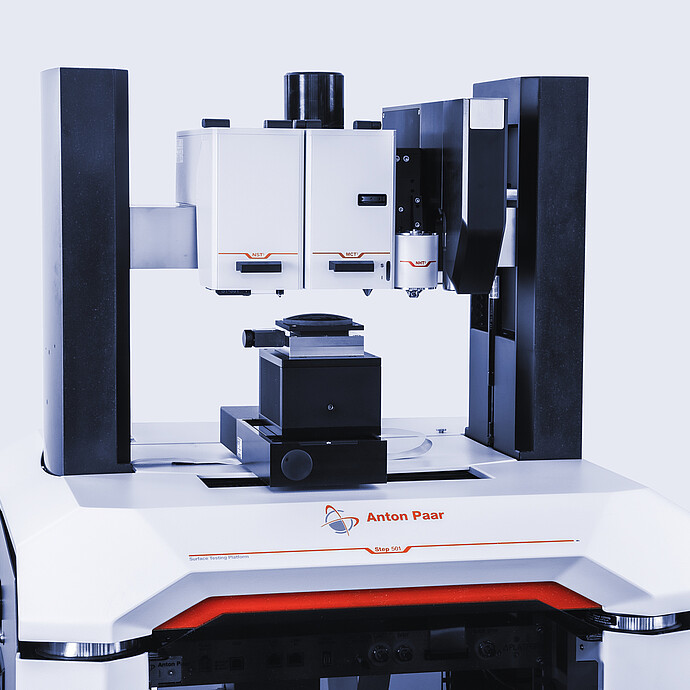

Expand the characterization load range by combining this instrument with other instrumented indentation testing or scratch testing heads, or even an atomic force microscope, all on a unified Step surface testing platform.

Key features

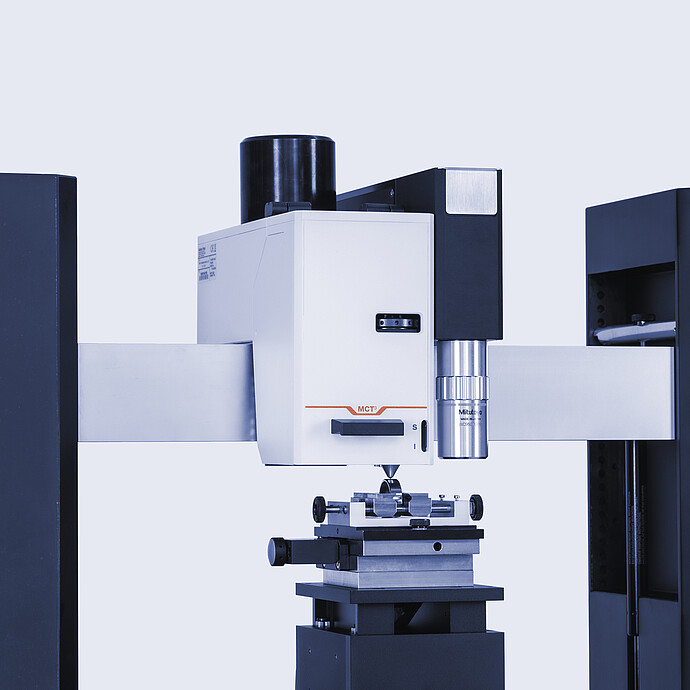

Four-in-one mechanical characterization

The unique mechanical design of the Micro Combi Tester MCT³ incorporates four different mechanical characterization measurement methods into only one measurement head without compromising on measurement quality. With one and the same head you can perform measurements of coating adhesion and scratch resistance (scratch testing), hardness and elastic modulus (instrumented indentation testing), Vickers hardness (conventional hardness testing) and friction and wear (multi-pass tribological testing).

Fully automated mechanical characterization tester

Like all scratch testers from Anton Paar, MCT³ automatically detects critical loads. Using the signal of friction force, penetration depth, or acoustic emission, an algorithm analyzes these signals and automatically determines the critical loads without subjecting them to any operator influence. The software package enables Vickers hardness tests, where the imprint is detected and measured automatically. Hardness and elastic modulus can be determined at various positions in a single measurement with the instrumented indentation technique.

The ideal load range for a wide range of applications

MCT³ performs scratch and instrumented indentation (IIT) tests from small depths (a few nm for surface detection) to great depths (maximum 1 mm). Its wide range of applied and measured force (from 10 mN to 30 N) matches almost all sample characteristics. This load and depth range is ideal for the mechanical characterization of hard coatings (PVD, CVD from 1 µm to 20 µm), thermal/plasma spray coatings, cementitious materials, metals, and polymers. If your standards require conventional hardness testing for bulk materials, MCT³ provides Vickers hardness testing within the same force range.

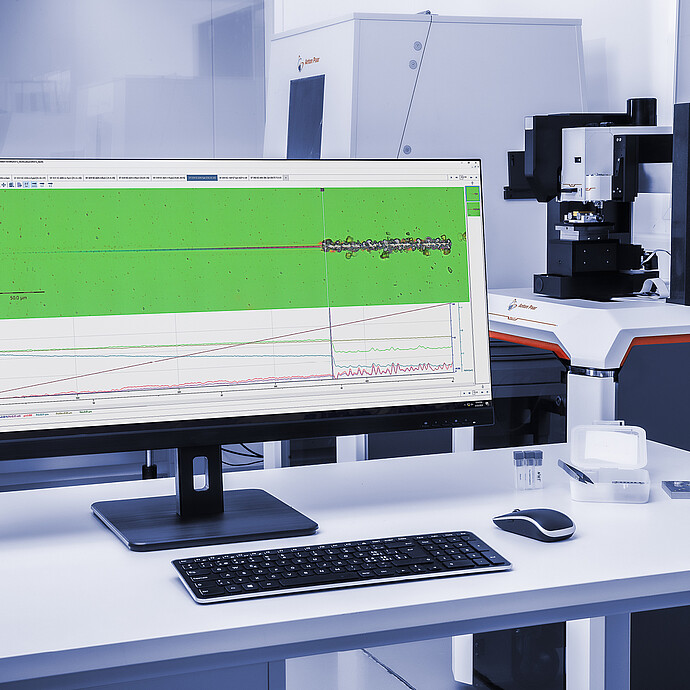

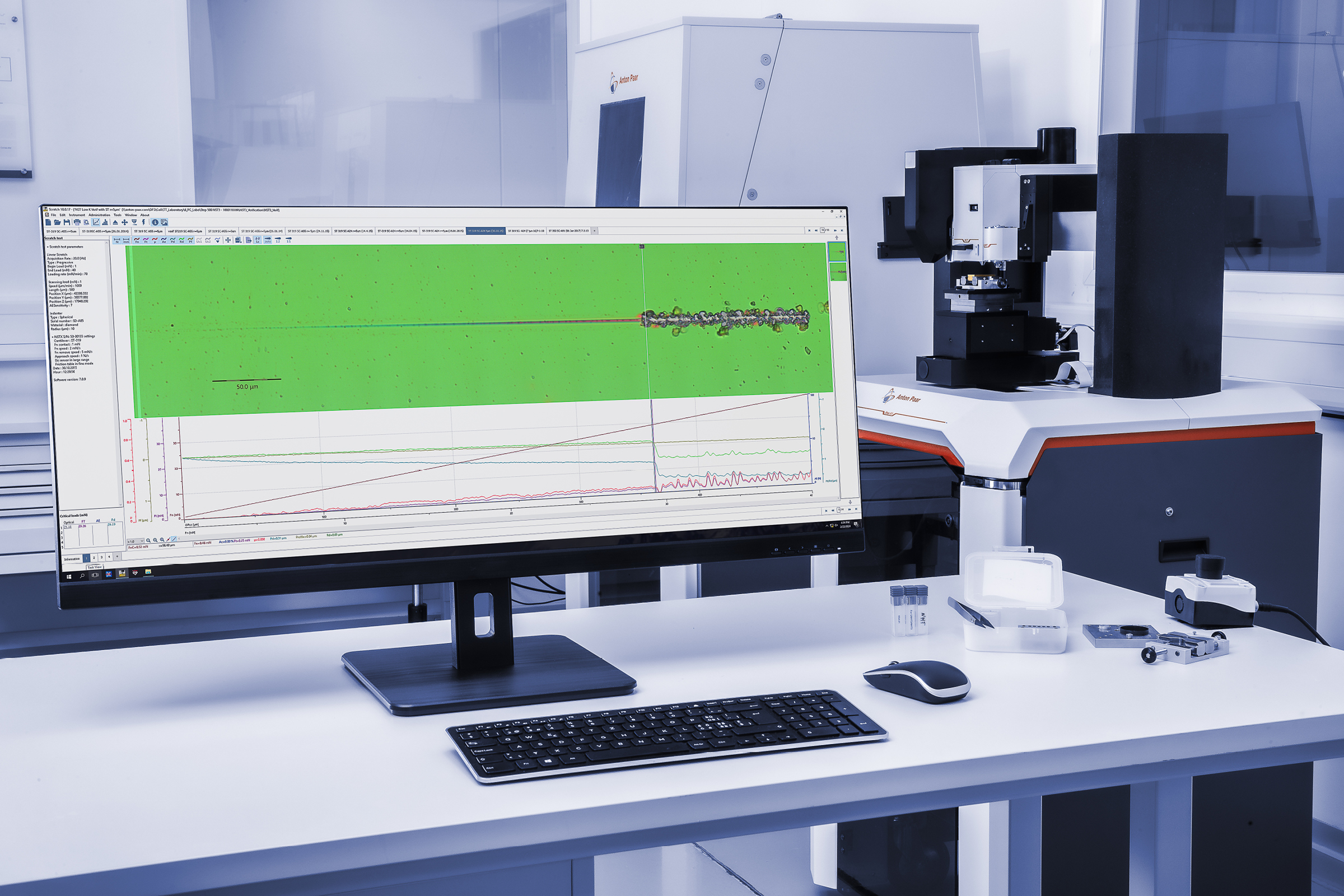

Patented Synchronized Panorama Mode

This unique feature automatically synchronizes the recording of all sensor signals with the whole scratch image in perfect focus. The critical loads can be easily identified by observing the synchronized optical and signal recordings. Anton Paar is the holder of U.S. patent 8261600 and European patent EP 2065695.

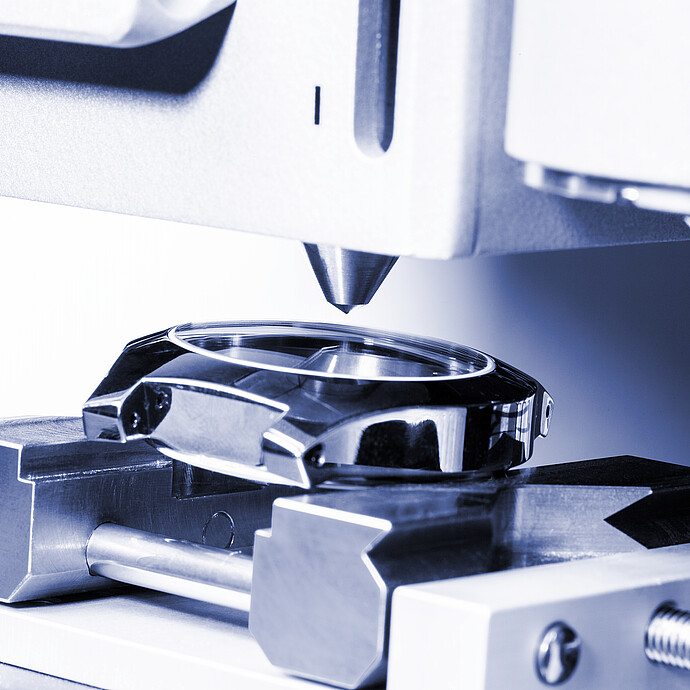

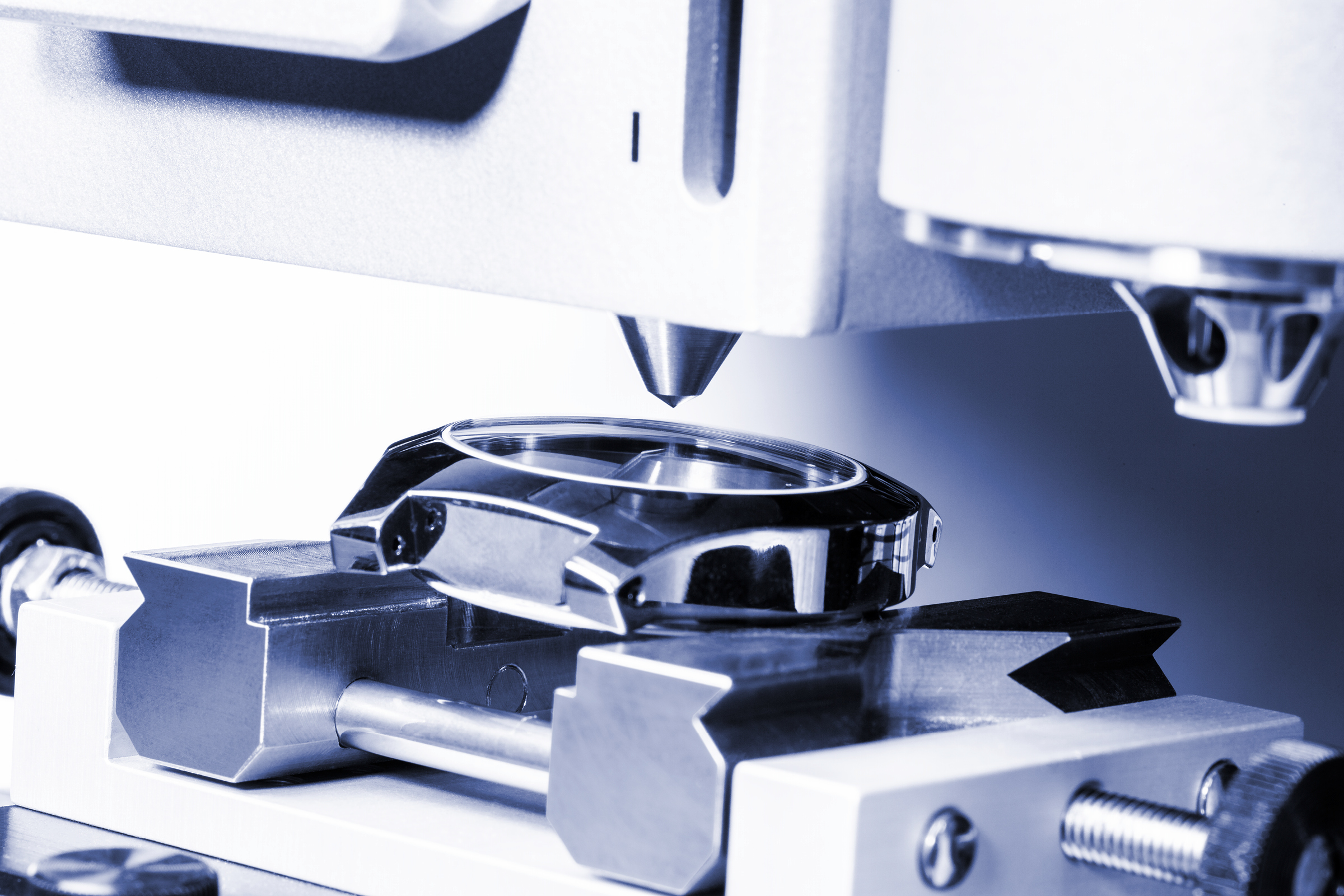

Perfect results even for curved and uneven surfaces

Due to its unique force sensor control, the MCT³ scratch system detects every surface deviation and the active force feedback corrects these deviations.

Regardless of the shape of the sample, MCT³ is capable of performing perfectly reliable measurements on uneven and curved surfaces (e.g. lenses) by following the shape with total control of the desired load.

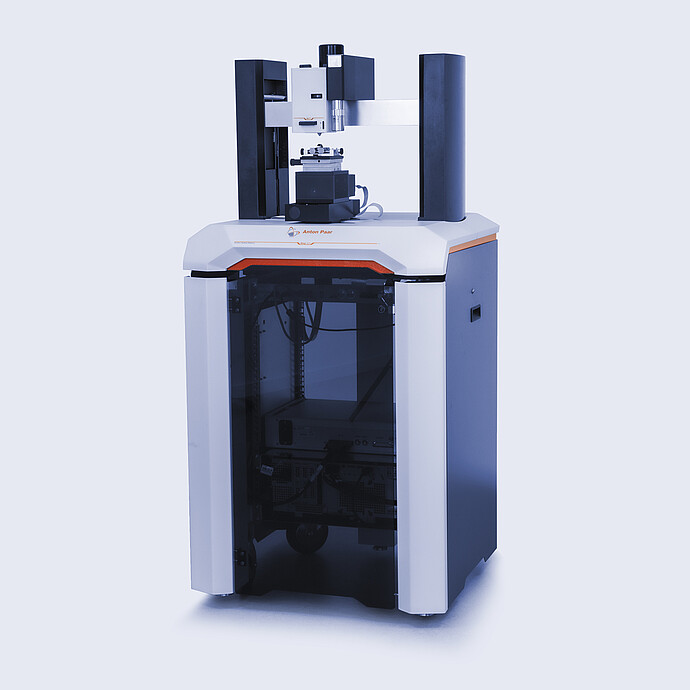

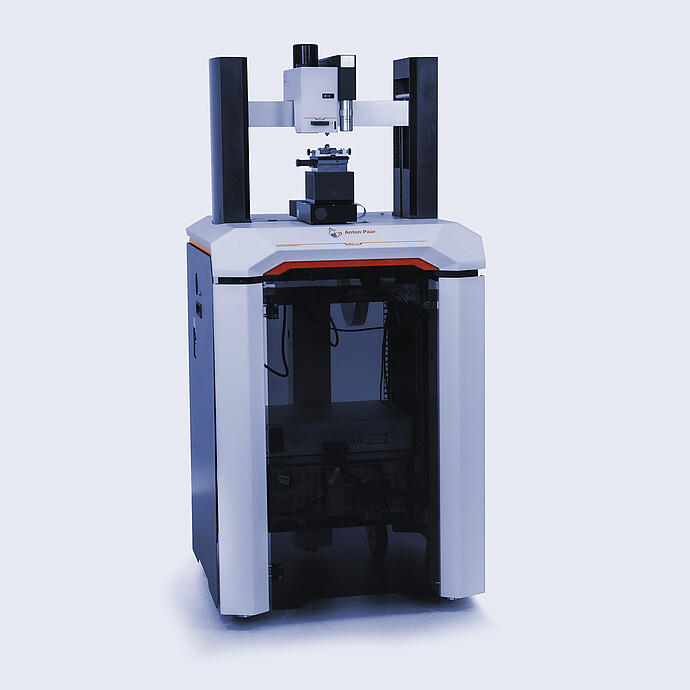

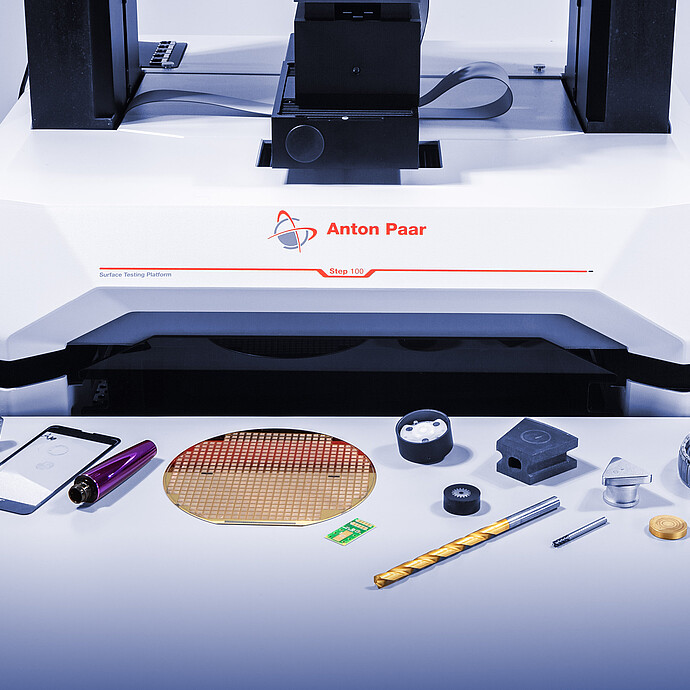

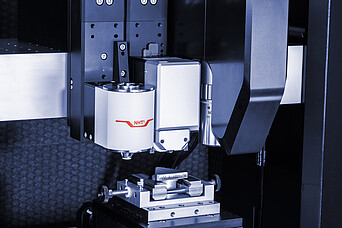

Maximum Micro Combi Tester versatility with Step platform

Maximize the versatility of the MCT³ Micro Combi Tester with the Step platform. Complement the MCT³ head with another indentation or scratch tester to fully cover the nano/micro/macro range, or add the AFM to obtain surface topography and complete mechanical surface characterization with a single platform.

Specifications

| Maximum load [N] | 30 |

| Load resolution [μN] | 6 |

| Load noise floor [rms] [μN] | 100 |

| Loading rate [N/min] | up to 300 |

| Depth range [μm] | 1000 |

| Depth resolution [nm] | 0.03 |

| Depth noise floor [rms] [nm] | 1.5 |

| Data acquisition rate [kHz] | 192 |

| Scratch speed [mm/min] | 0.1 to 600 |

| Options | |

| Peltier heating up to 120 °C | ✓ |

| Heating stage up to 200 °C | ✓ |

| Cooling down to -120 °C | ✓ |

| Liquid testing | ✓ |

Standards

ASTM

ISO

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Adhesion and hardness of galvanic layers by scratch test and nanoindentation Application Reports

-

Adhesion of coatings in Li-ion battery electrodes by scratch test Application Reports

-

Applications of indentation and scratch in automotive industry Application Reports

-

Applications of indentation in polymer industry Application Reports

-

Applications of nanoindentation in biology and medicine Application Reports

-

Applications of scratch testing in polymer industry Application Reports

-

Automatic Vickers hardness test by scratch tester Application Reports

-

Biofouling – when Adhesion is a Double-edged Sword Application Reports

-

Biomedical applications 2: Adhesion and scratch resistance by scratch testing Application Reports

-

Characterization of electrodes in Lithium-ion batteries by nanoindentation Application Reports

-

Characterization of polymers and polymeric paints by MCT³ Application Reports

-

Characterization of the scratch resistance of ceramic tiles: Part I Application Reports

-

Comparison of nanoindentation with conventional hardness Application Reports

-

Compression of microparticles by cylindrical flat punch using a nanoindenter Application Reports

-

Contribution of nanoindentation and tribology to investigation of welds Application Reports

-

E-Book - A Practical Guide for Great Building Materials Application Reports

-

E-Book - Field Guide to Battery Materials Characterization – Revised and Updated Application Reports

Similar products

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

Accessory for Step Platforms:

Atomic Force Microscope (AFM)

- Versatile AFM solution for various scientific and industrial applications

- Imaging and analysis capabilities offering nanoscale surface information

- Non-destructive interaction with samples

Accessory for Scratch Testers:

Friction Module

- Material’s frictional behavior assessment

- Complementary tool in the assessment of adhesion failures

- Combines scratch and tribology testing

Accessory for Step Platforms:

Heating module

- Excellent thermal stability with testing temperatures up to 450 °C

- Correlation of surface mechanical properties with temperature

- Installation directly on the Step platform