Accessory for MCR:

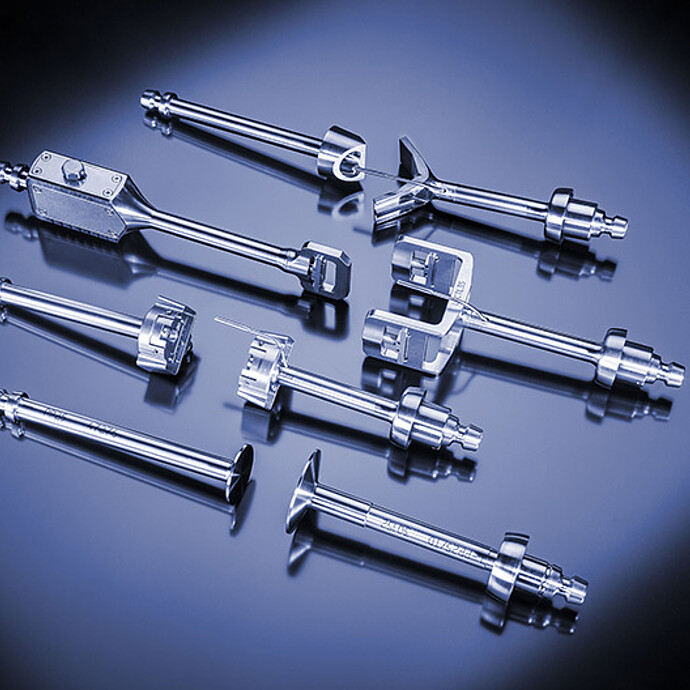

DMA Measuring Systems

- For dynamic mechanical analysis (DMA) in bending, tension, torsion, and compression

- Solid rectangular fixtures, three-point bending geometries, cantilevers, compression systems

- Compatible with MCR 702e MultiDrive

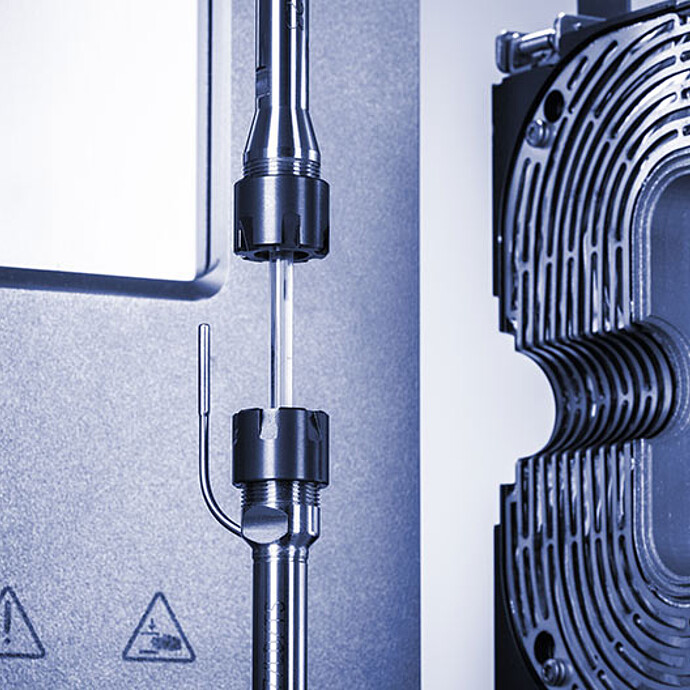

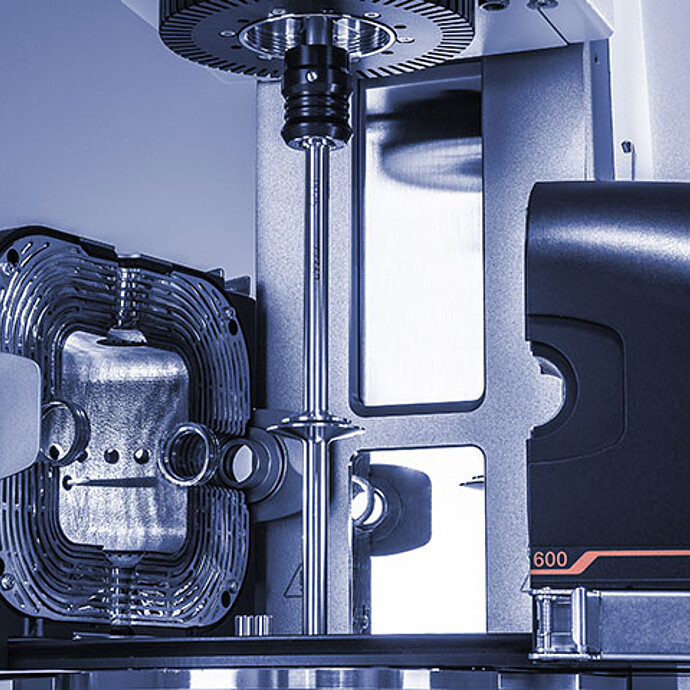

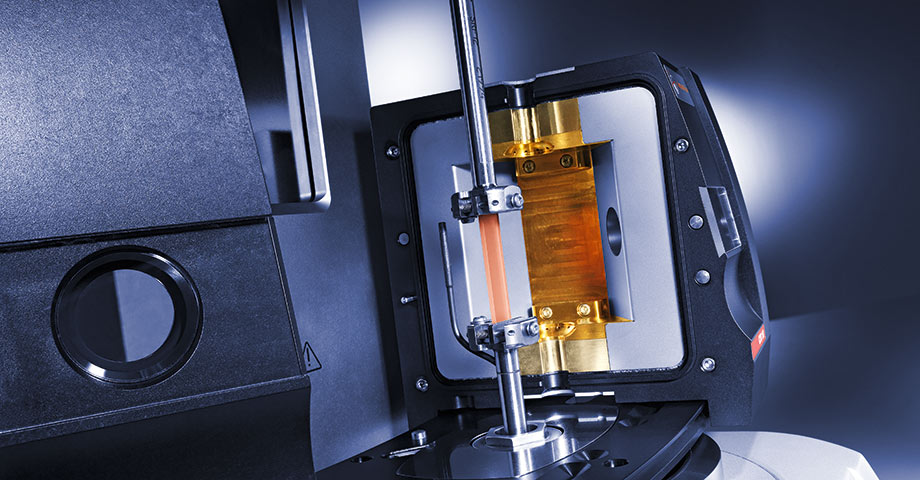

For dynamic mechanical analysis (DMA), MCR uses measuring systems with temperature sensors to ensure the highest measurement reproducibility. The QuickConnect coupling allows one-handed connection without the use of a screwing mechanism. And the Toolmaster™ functionality enables automatic tool configuration without any manual settings in the software. In combination with a touch-control feature to position the fixtures with the touch of a finger, DMA measuring systems guarantee convenient sample handling.

Key features

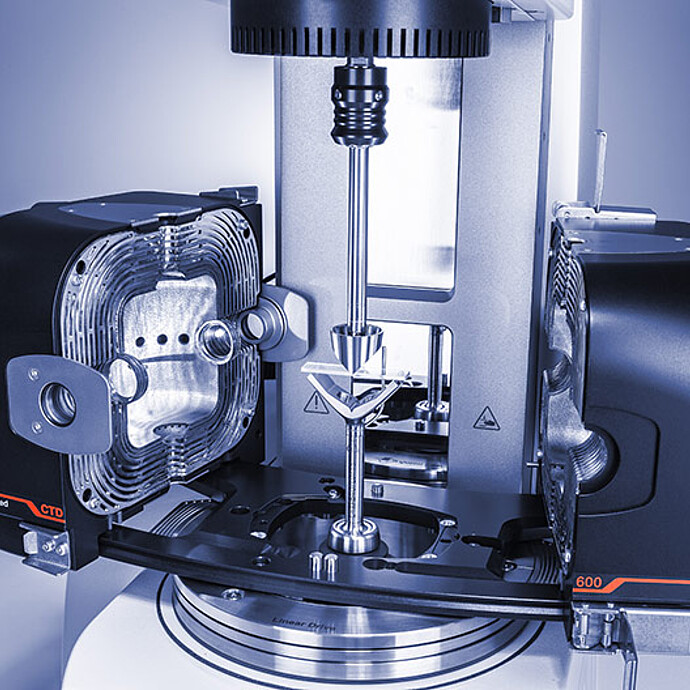

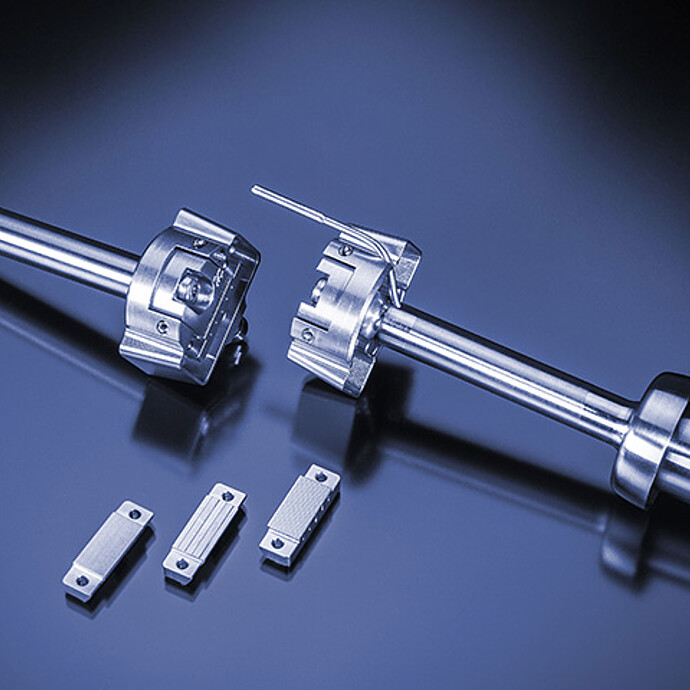

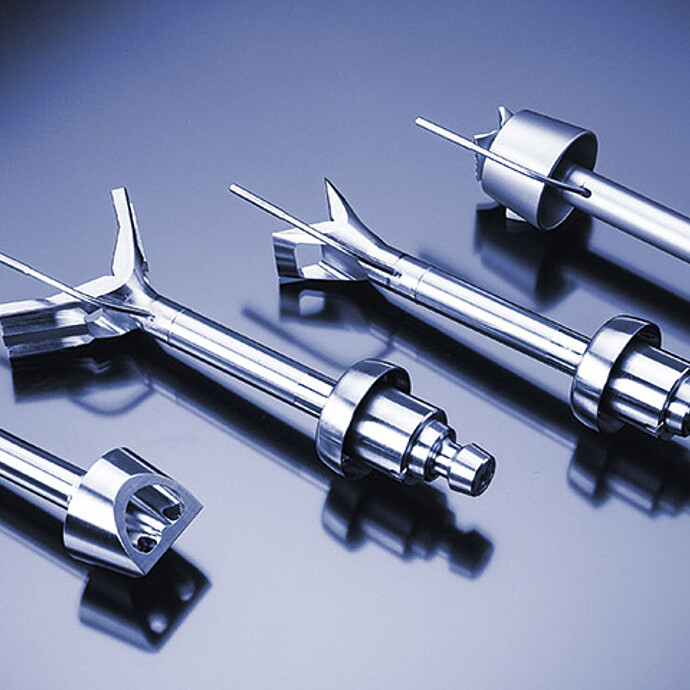

Solid rectangular or circular fixtures for one EC drive in action (SRF and SCF)

Perform DMA in torsion with only the upper EC drive of the MCR rheometer in use. These fixtures feature a specially designed sample clamping system to ensure that samples of different thicknesses can be measured precisely while being exactly aligned within the axis of the measuring system. In combination with a convection temperature device, this setup guarantees reliable characterization of viscoelastic properties of films, and rectangular or circular bars as function of amplitude, frequency, temperature or time.

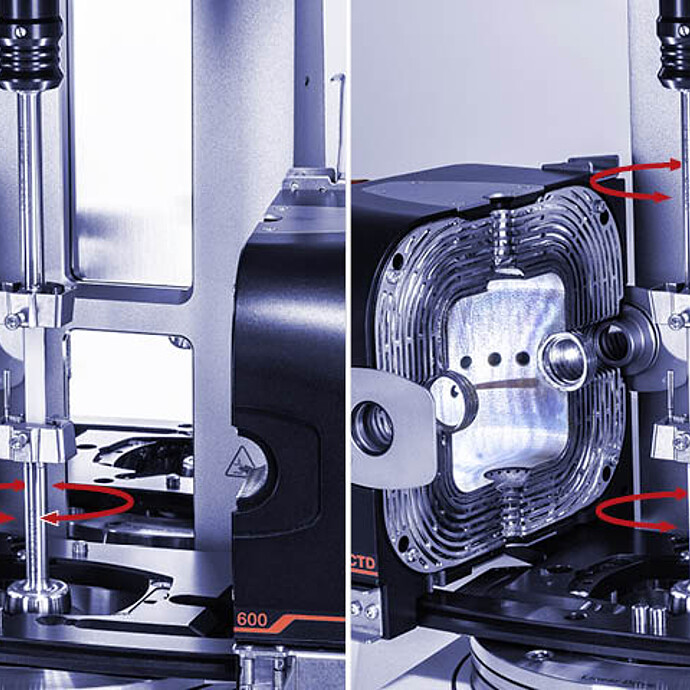

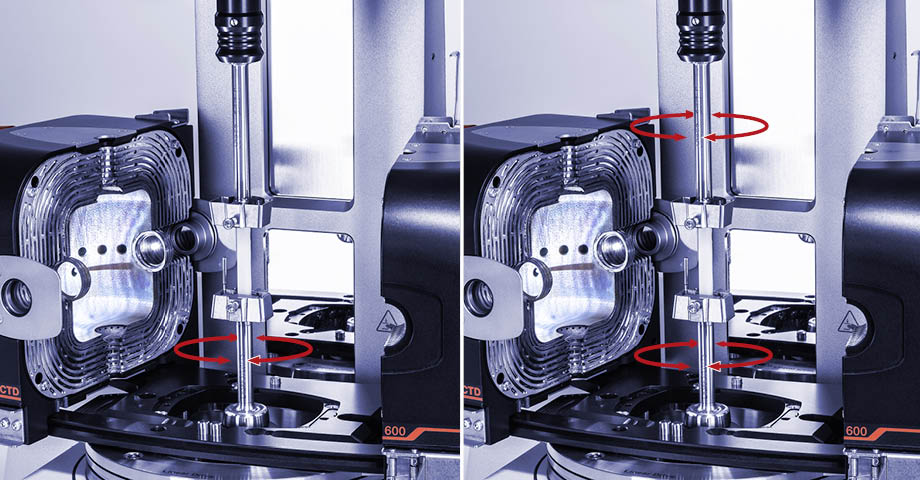

Solid rectangular or circular fixtures for two EC drives in action (SRF/TD and SCF/TD)

With the systems for MCR 702e MultiDrive, DMA measurements in torsion are possible by using both EC drives. Therefore, measurements in a separate motor transducer mode and in counter-oscillation mode can be performed additionally to all other modes, with the device using only one EC drive. As both options – measurements on solid bars with one EC drive or two EC drives – are available with MCR 702e MultiDrive, the best possible measurement setup for each sample can be chosen.

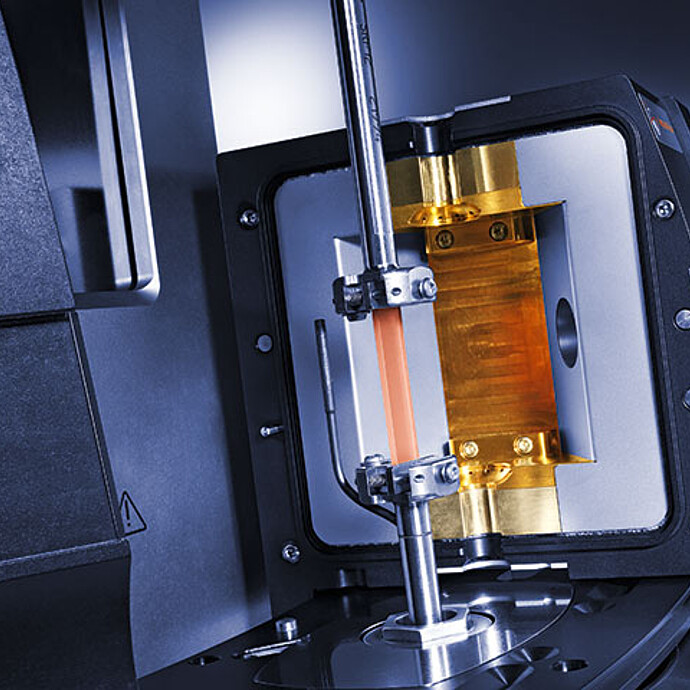

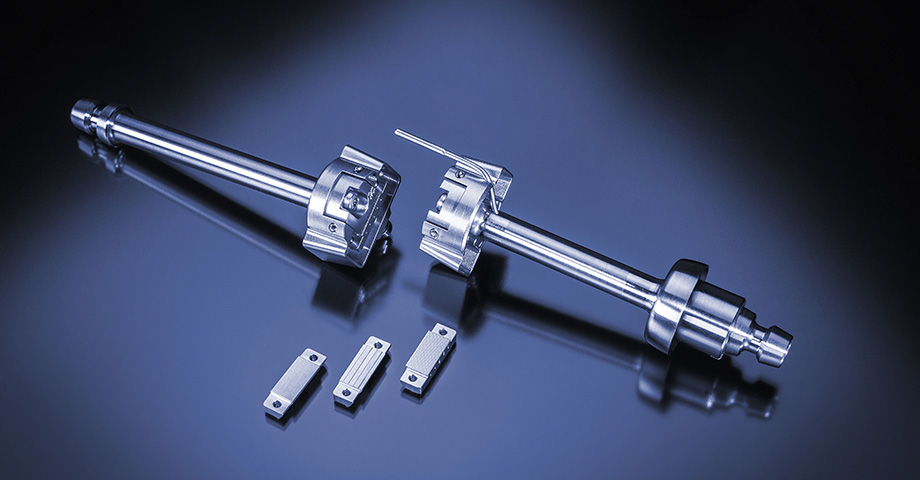

Solid rectangular fixture for a linear drive or an EC drive in action (SRF/LD)

This special measuring system ensures measurements while the linear drive or the rotational drive of an MCR 702e MultiDrive is in action. With this setup, dynamic mechanical analysis (DMA) in tension and torsion can be performed. This can be used, for example, to determine the complex Young’s modulus |E*| as well as the complex shear modulus |G*| and even the Poisson’s ratio of films, fibers, and thin solids. Furthermore, it is also suitable for measuring the thermal expansion of solid bars.

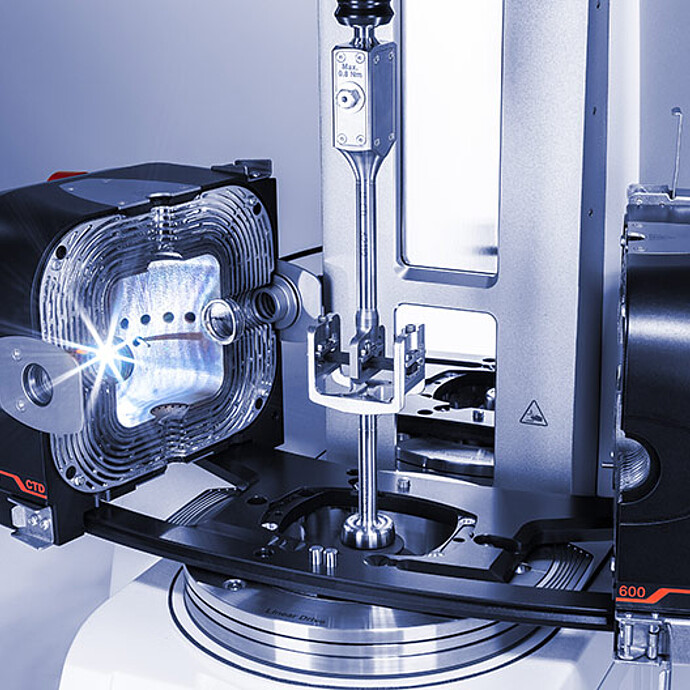

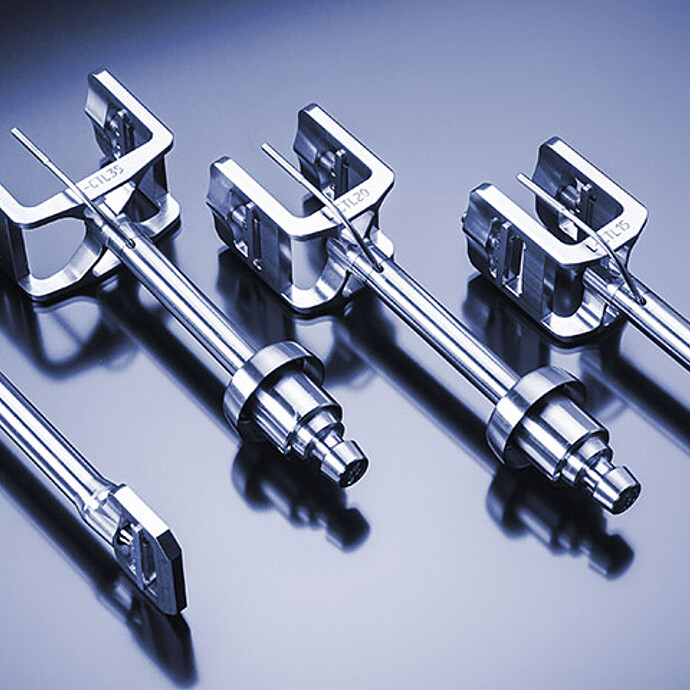

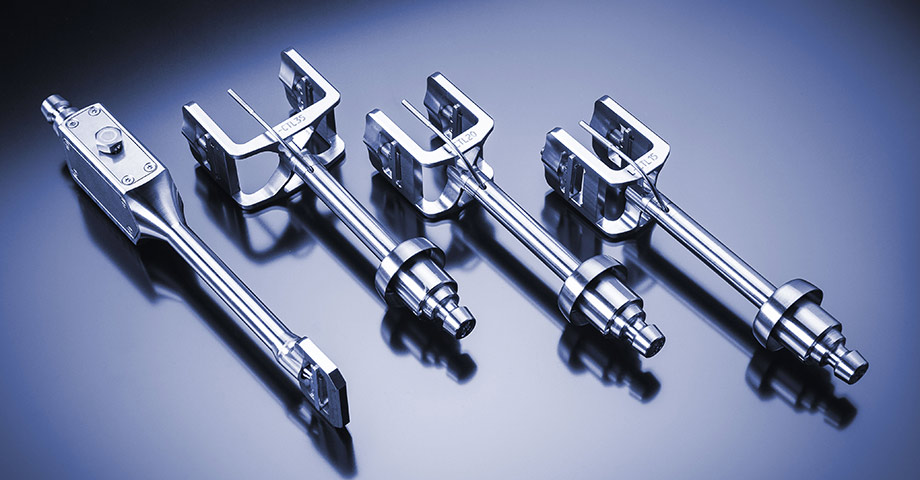

Three-point-bending geometries for a linear drive in action (TPB/LD)

These measuring systems are suitable for dynamic mechanical analysis (DMA) in bending mode, using the linear drive of an MCR 702e MultiDrive . To perform a three-point-bending test, the sample is positioned on both ends of a movable sample support, while a static bending tool is placed at the midpoint of the sample. Because no additional clamping of the sample is necessary, measuring errors due to restraints are minimized. This makes the measuring systems suitable for an accurate characterization of stiff materials, such as composites and thermoplastics below their Tg, thermosets, as well as metals and ceramics.

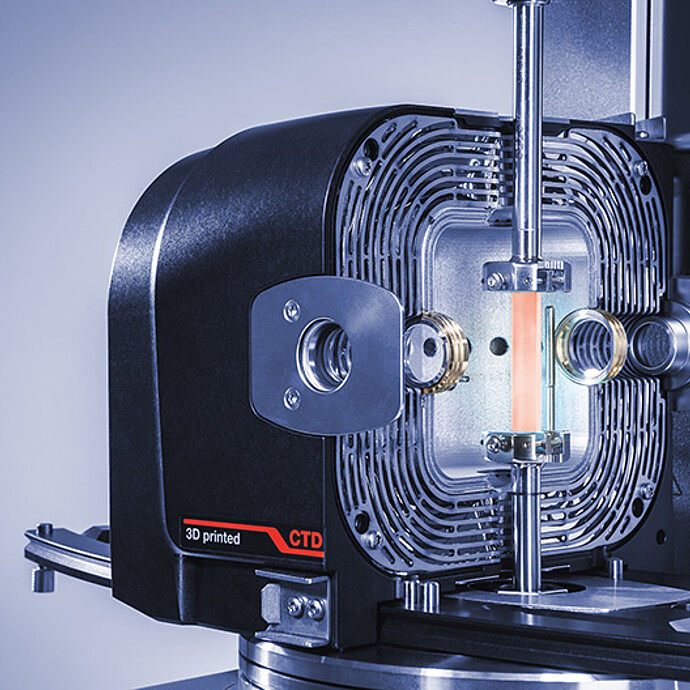

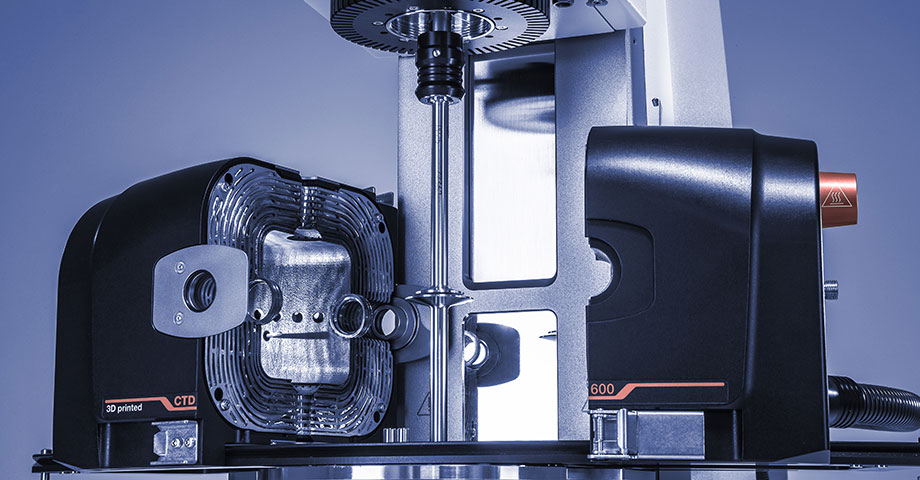

Cantilevers for a linear drive in action (CTL/LD)

Cantilevers are used for dynamic mechanical analysis (DMA) in bending mode with the linear drive of the MCR 702e MultiDrive . In case of dual cantilevers, the sample is attached between two fixtures on both ends and on a central fixture at the midpoint of the sample. In a single cantilever, the sample is mounted between the central fixture and only one fixture at the end. The measuring systems are not only suitable for materials with low stiffness, but also for materials showing dramatic changes in dynamic mechanical properties which could otherwise feature strong bowing under load.

Compression systems for a linear drive in action (PP/TD)

For DMA in compression, plate-plate measuring systems can be combined with the linear drive of an MCR 702e MultiDrive . The lower part of the measuring system contains an integrated temperature sensor directly below the sample. Thus, the sample temperature can be measured directly, which leads to advanced temperature control and reduced heating times. The measuring systems are suitable for DMA of foams, elastomers, food systems, and gels, and can also be used for rheological characterization with the rotational drive of the measuring device in action.

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Damage Characterization of Composites by DMA in Three-Point-Bending Mode Application Reports

-

Dynamic Mechanical Characterization of EVOH Films Under Influence of Water Application Reports

-

Indirect Method to Measure the Poisson’s Ratio Application Reports

-

Measurements of Composites in Three-Point-Bending Mode Application Reports

-

Instruments - MCRxx2 Evolution series Brochures