即饮饮料分析仪:

RTD 测量系统

- 软饮料和 RTD 分析(0% v/v 至 12% v/v 酒精,0% w/w 至 14% w/w 浸出物)

- 成品瓶或罐装产品八分钟内即可出结果

- 转化校正后的密度准确度为 0.0003 g/cm³

- 四种 RTD 模型分别用于无糖饮料、蔗糖、HFCS 42 和 HFCS 55

- 可同步分析 14 项以上样品专属参数

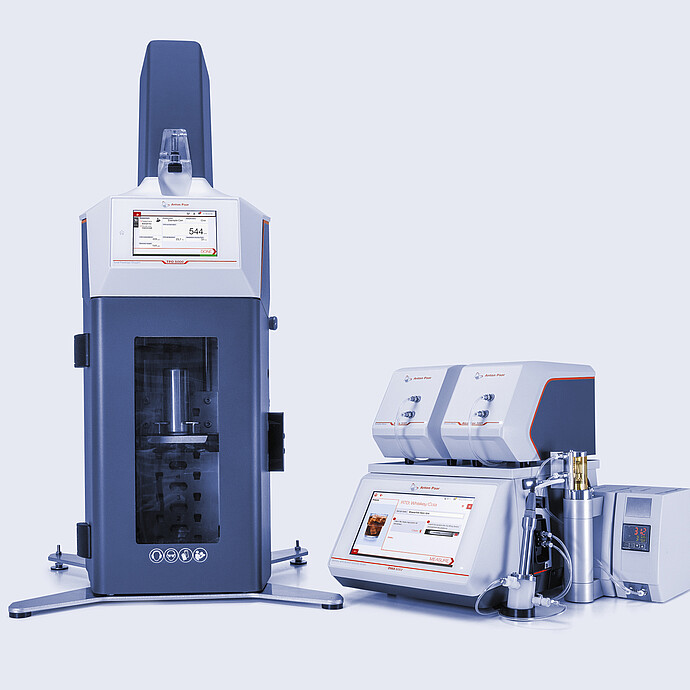

以极高的精度和速度测量即饮 (RTD) 产品,例如威士忌可乐、金汤力和其他混合饮料。该一体化解决方案集成密度、声速与近红外光谱技术,即便面对成分复杂的碳酸类样品,亦可输出高精度检测数据。RTD 测量系统支持成品包装直接进样分析,无需蒸馏前处理。经转化校正的密度测定技术,可实现稳定的过程监控,新鲜密度测量精度达 0.0003 g/cm³。系统可自动计算多项样品专属参数,内置四套化学计量学模型,分别适配人工甜味剂、蔗糖及果葡糖浆(42 或 55)甜化的 RTD。

包含的产品

关键功能

单次测量,获取全部关键参数

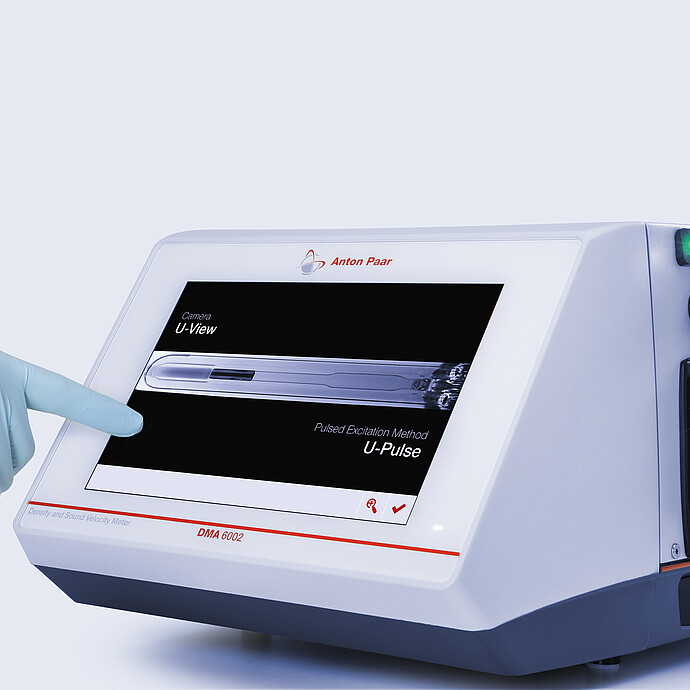

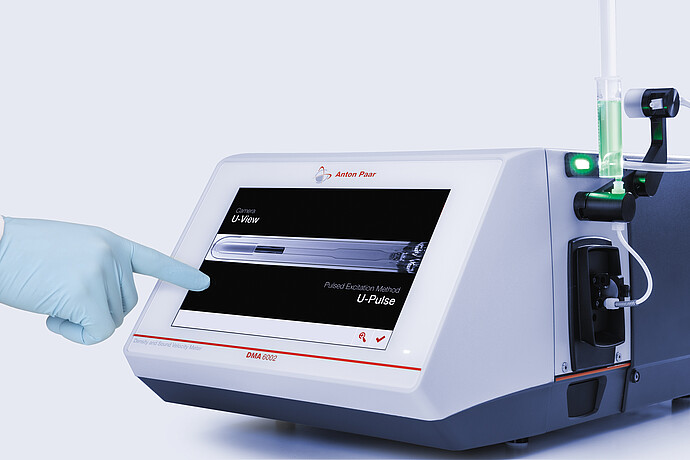

RTD 测量系统可助力您轻松监控全生产流程中 CO2、酒精、糖和甜味剂的关键平衡。系统搭载 U-View、U-Dry、U-Pulse 和 FillingCheck 等功能,可最大限度地提高可用性和可靠性,确保无缝操作和可靠结果。样品制备与进样完成后,系统可同步开展近红外光谱分析、密度与声速测定、酒精含量检测及选做项目分析,仅需一份包装样品即可获得全面检测数据。

精确定位,完全合规

RTD 测量系统可测定各类软饮料和即饮饮品的酒精含量,为产品规格核验及法规合规性验证提供数据支撑。安东帕的数字式密度计基于 U 型管振荡原理,该原理已通过税务机构与海关实验室认证。只需使用水和二元溶液进行一次简单校正,即可确保结果符合葡萄酒中酒精测定参考方法。

使用 AP Connect 保护数据存储

AP Connect 实验室执行软件旨在轻松管理您的数据存储需求。为了更深入地了解生产趋势和质量,系统可捕获全量数据点并支持快速调取,同时配备工具实现数据的高效分析与检索。该软件的直观界面简化了对批次间变化的跟踪,确保了产品质量的一致性。借助 AP Connect,饮料生产商可专注于工艺优化,无需担忧数据存储安全。

全面掌握含酒精 RTD 质量信息

本系统集成近红外光谱、密度及声速检测技术,可对含酒精 RTD 开展全面分析。除测定酒精与糖分含量外,系统还具备糖分转化校正功能,可实现生产过程数据与灌装储存后成品数据的精准比对。此举可确保不同生产厂区及全产品生命周期内,数据的透明度与可靠性均达到行业领先水平。

规格

| 推荐配置 | 配置 1 | 配置 2 |

|---|---|---|

| 参数 | °Brix | % Diet | 新鲜糖 °Brix | 转化糖 °Brix | 转化程度 | 酒精含量 | CO2 | 溶解 O2 | °Brix | % Diet | 新鲜糖 °Brix | 转化糖 °Brix | 转化程度 | 酒精含量 | CO2 | TPO |

| 测量范围 | ||

| 密度 | 0 g/cm³ 至 3 g/cm³ | |

| 声速 | 1000 m/s 至 2000 m/s | |

| 温度 | 20 ℃ | |

| CO2 浓度 | 30 ℃ (86 ℉) 下 0 vol. 至 6 vol.(0 g/L 至 12 g/L) <15 ℃ (59 ℉) 时 0 vol. 至 10 vol.(0 g/L 至 20 g/L) | 20 ℃ (95 ℉) 下 0 至 4 vol.(0 至 8 g/L) |

| O2 浓度 | DO:0 ppm 至 4 ppm1 | DO:0 ppm 至 45 ppm; HSO:0 hPa 至 1000 hPa |

| 软饮料测量 | ||

| 新鲜糖/转化糖浓度 | 0 °Brix 至 80 °Brix | |

| 转化度 | 0% 至 100% | |

| 无糖浓度 | 0% Diet 到 200% Diet;或 0 mL NaOH 至 200 mL NaOH;或 0 g/L TA 至 200 g/L TA;或 0 mg/mL H3PO4 至 600 mg/100 mL H3PO4 | |

| CO₂ 浓度 | 0.005 vol. (0.01 g/L) | |

| O2 浓度 | 2 ppb(在 <200 ppb 的范围内) | TPO:25 ppb 或 6% 测量值(以较高者为准)1 |

| 重复性标准偏差 | ||

| 密度 | 0.000001 g/cm³ | |

| 声速 | 0.1 m/s | |

| 温度 | 0.001 ℃ (0.002 ℉) | |

| 实际糖浓度 | <0.01 °Brix 2 | |

| 新鲜糖/转化糖浓度 | 0.02 °Brix 2 | |

| 转化度 | 1% | |

| 无糖浓度 | 0.5% Diet | |

| RTD 测量3 | ||

| 测量范围 | ||

| 酒精度 | 0% v/v 至 12% v/v | RTD:0% v/v 至 12% v/v;其他产品 0% v/v 至 20% v/v |

| 密度 | 0 g/cm³ 至 3 g/cm³ | |

| 浸出物(蔗糖或 HFCS 42 或 HFCS 55) | 0% w/w 至 14% w/w | |

| 重复性标准偏差 | ||

| 酒精度 | 0.01% v/v | 0.01% v/v |

| 密度 | 0.000005 g/cm³ | 0.000005 g/cm³ |

| 被测样品4 | Jack Daniels®、Coca Cola®、Jim Beam Bourbon® 可乐、Barcadi® 朗姆可乐 | |

| 预期偏差值(相对于参考方法)5 | ||

| RTD 酒精 | <0.06% v/v | |

| RTD 糖含量 | 0.03 °Brix | |

| 新鲜密度 | 0.0003 g/cm³ | |

| 其他信息 | ||

| 每次测量的最小样品用量 | 150 mL | 260 mL |

| 单个样品的常规测量时间 | 3 分钟(含进样时间) | 8 分钟(含进样时间)至 10 分钟 |

| 尺寸(长 x 宽 x 高) | 482 mm x 750 mm x 670 mm (19.0 in x 29.5 in x 26.4 in) | 515 mm x 1200 mm x 1120 mm (20.3 in x 47.3 in x 44.1 in) |

| 基本信息 | ||

| 电源 | AC 100 V 至 240 V,50/60 Hz,浮动 ±10%,190 VA | |

| 特色功能 | U-View™、FillingCheck™、ThermoBalance™、全量程黏度修正、超快速测量模式 | |

| 内存 | 最多可存储 10000 个含相机图像的测量值 | |

| 环境条件 | (EN 61010) 仅用于室内 | |

| 环境温度 | 15 ℃ 至 35 ℃(59 °F 至 95 °F) | |

| 空气湿度 | 无冷凝;20 ℃,相对湿度 <90%;25 ℃,相对湿度 <60%;30 ℃,相对湿度 <45% | |

商标:U-View (006834791)、FillingCheck (006834725)

1 环境温度和样品温度为 23 ℃ (73.4 °F),并且采用标准清洁。请注意:同批次样品重复性测定时,首测数据不计入统计。

2 高达 60 °Brix(20 ℃ 下)

3 来自 DMA 6002 软件版本 6.7.2。有关被测包装尺寸的信息,请参阅 TPO 5000 说明手册或联系您的安东帕代表。

4 各组分采用其典型的配比方案。可根据要求批准其他样品类型。

5 相关指标通过密度、声速及近红外光谱检测法测定。干扰物质的存在会影响其中一个或多个参数,从而可能导致结果偏差增大。