Heterogeneous Integration and System-in-Package (SiP): In heterogeneous integration, two or more active or passive electronic components with differing functionalities or material properties are combined in a single SiP. The devices are arranged in multidimensional layouts – such as 2.5D interposer-based assemblies or fully 3D stacks – that depend on multilayer structures manufactured from dissimilar materials.

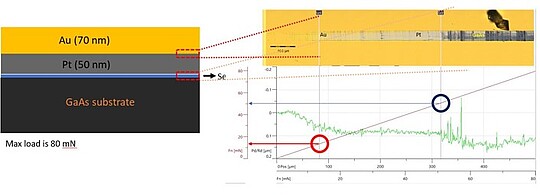

Critical load and adhesion strength

An Anton Paar scratch tester was used to evaluate the adhesion of heterogeneously integrated packaging coatings in a high-frequency chip. The chip stack consists of gold (Au)/platinum (Pt)/gallium arsenide (GaAs). The figure below shows that the critical load between the 70 nm gold layer and the 50 nm platinum layer is about 14 mN (solid red arrow), whereas the critical load between the 50 nm platinum layer and the GaAs substrate is roughly 50 mN (solid dark-blue arrow).

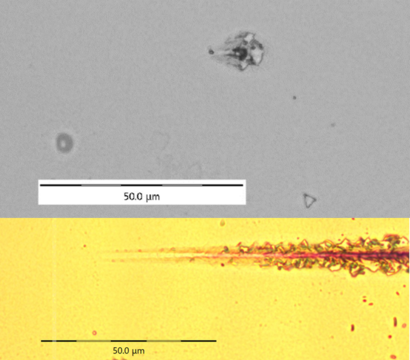

Analysis of scratch distance and heterogeneous fracture modes

Compared with competing scratch testers, the Anton Paar NST3 delivers one decisive advantage: it is the only instrument that effortlessly generates scratches long enough to clearly reveal interlayer failure mechanisms – all using the standard test procedure. What additional insight does a longer scratch provide?

The figure on the gray background shows the scratch length typically achieved with other devices; the yellow background displays the same sample after a scratch that is ten times longer, produced with the Anton Paar NST3. This extended track reveals flaking, cracking, and other coating-failure modes that would otherwise go undetected.

Because the NST3 produces scratches of sufficient length, users can derive the critical load directly from optical images – a key parameter when evaluating heterogeneous layer systems.

Advantages of Anton Paar scratch testers

The Nano Scratch Tester (NST3) is engineered to evaluate the scratch resistance and adhesion of films and coatings thinner than 1,000 nm. Key features include: patent-protected technology (US8261600) delivering comprehensive, synchronous panoramic imaging for real-time analysis; a fast-responding, low-load actuator that applies precisely the specified force; elastic recovery studies that determine true penetration depth and enable viscoelastic characterization through multiple post-scan modes after scratch formation; and the Step platform for even greater versatility.