With our broad portfolio of analyzing instruments for tank terminals – ranging from portable devices that you can use in hazardous environments, to highly accurate lab instruments and inline equipment that provide you real-time results – you’re ready to implement your own 24/7 lab base, and perform essential tests in just a few minutes.

No matter the number and type of products traded and stored at your tank terminal, we have a combination of solutions that fits your needs. Our affordable, compliant, easy-to-use digital instrumentation eliminates operator influence from your processes, giving you the confidence and peace of mind associated with knowing that your measurements are always accurate.

- Safeguard your processes with high-quality instruments and integrated safety features

- Enhance your productivity with automated solutions and minimal operator interaction

- Maximize your throughput and eliminate product loss during transportation, due to quick measurements and fast reaction times

- Certify your products according to relevant standard specifications

- Reduce waste and environmental impact by using smaller sample volumes and fewer solvents

- Save time (up to 50 %, depending on the method) thanks to fast measurements and minimum sample preparation compared to traditional methods

Crude Oil Analysis in Tank Terminals

Choosing the right extraction strategy based on actual reservoir conditions

Simulating the behavior of the live crude oil in the laboratory gives you all the information you need to decide which agents to use for extraction. With a digital density measurement, you can replace your current estimates about the reliability of a reservoir’s productivity with hard facts.

Choose this digital density meter for density measurement in the lab at temperatures between -10 °C and 200 °C and elevated pressures up to 500 bar, compliant with ASTM D5002.

Choose this density measuring cell for density measurement between -10 °C and 200 °C and at even higher pressures up to 1400 bar.

Relevant products:

Determining the bubble point to increase the extraction potential of the well

In crude oil production knowledge of the bubble point helps you increase the overall extraction potential of the well. With a digital density meter you can determine the bubble point in the lab more quickly and more reliably compared to manual methods.

Choose this digital density meter for determining the bubble point in the lab at temperatures between -10 °C and 200 °C and elevated pressures up to 500 bar, compliant with ASTM D5002.

Choose this density measuring cell for determining the bubble point between -10 °C and 200 °C and at even higher pressures up to 1400 bar.

Relevant products:

Ideal drilling fluid management to reduce cost of recovery

Optimizing the performance of the drilling process by fine-tuning the properties of the drilling fluid increases the yield of crude oil reservoirs. This is achieved by measuring the density of the drilling mud with inline instrumentation which has the benefits of:

- Not requiring personnel to be on-site for sample drawing

- Real-time availability of crucial data

- Helping to avoid fracture of the formation, thereby helping to increase the yield

Relevant products:

Evaluating the flow behavior to obtain good pumpability for transport

When diluting heavy and extra-heavy crude oil so it can be pumped through the pipeline without difficulty, viscosity measurements or rheological tests are perfectly suited to assess flow behavior and fine-tune the viscosity of the blend. Anton Paar offers a wide range of rheometers and viscometers for easy, fast, and accurate analysis of flow behavior. Choose from:

- A benchtop solution for full evaluation of the flow behavior (optionally equipped for high-pressure measurements)

- A compact solution for measuring the kinematic viscosity in a few minutes

- An Ex-certified inline viscometer for continuous monitoring of the viscosity in the process line

Phase detection in pipelines

The loss of valuable raw materials and the contamination of the process water can be minimized by a precise product differentiation in pipelines or tanks. React immediately to avoid spills and contamination of the refinery’s waste water system with crude oil, diesel, or any other petroleum product. The L-Sonic 5100 and L-Dens 7400 are designed to be installed on any pipeline or tank and can detect different (or unwanted) phases within seconds. Use the measurement to control safety valves or ring alarms. Shut in automatically any oilfield or refinery process within seconds to avoid contamination and damage.

Relevant products:

Efficient draining of storage tanks

The Anton Paar L-Sonic 5100 Ex is a sound velocity meter that can quickly and accurately detect the boundary zone between salt water/crude oil or water/petroleum. This information can be used to automate the tank drainage process, ensuring that all salt water and rain water are removed before the crude oil and petroleum products are processed.

The L-Sonic 5100 Ex offers a number of benefits, including:

- Reduced costs: The L-Sonic 5100 Ex can help reduce the costs associated with tank drainage by automating the process and eliminating the need for manual labor.

- Increased efficiency: The L-Sonic 5100 Ex can help improve the efficiency of the tank drainage process by reducing the time it takes to complete the task.

- Reduced environmental impact: The L-Sonic 5100 Ex can help reduce the environmental impact of tank drainage by preventing crude oil and petroleum products from entering the waste water system.

- Improved compliance: The L-Sonic 5100 Ex can help refineries and tank farms comply with environmental regulations by ensuring that all salt water and rain water is removed from crude oil and petroleum products before they are processed.

The L-Sonic 5100 Ex is a valuable tool for refineries and tank farms that need to separate salt water and rain water from crude oil and petroleum products. It can help to reduce costs, increase efficiency, reduce environmental impact, and improve compliance.

Relevant products:

Monitor product quality of incoming crudes and fuels

Crude oil transported to a refinery is always a blend from many different sources (wells), even when it is from one region and one brand. The density is one of the main properties for the characterization and quality of incoming crude oil.

Relevant products:

Checking the purity of crude oil after delivery

Determine automatically the °API for crude oil classification and check the crude oil purity within 30 seconds with just one measurement.

Following recovery, after the crude oil is treated to remove sediment, water, and other contaminants, you can assess the degree of purity by means of density measurements. Depending on national regulations and company preferences, you can perform measurements across the whole temperature range from 0 °C to 100 °C to draw a complete picture of the temperature-dependent behavior of the crude oil at hand.

Relevant products:

Digitization and harmonization of laboratory instrument data

AP Connect is your digital hub for automated data transfer from your instruments to a central database.

With AP Connect, you can:

- Easily transfer data from your instruments to a central database, regardless of the manufacturer.

- Export measurement results to a specified location or access them directly with a standardized API.

- Drive digitalization forward and meet your requirements for streamlined data handling.

- Use AP Connect in many different applications and industries.

- Meet current regulations and requirements in the regulated environment with the Pharma Edition.

The benefits of using AP Connect:

- Increased efficiency: AP Connect automates the data transfer process, freeing up your time so you can focus on other tasks.

- Improved accuracy: AP Connect ensures that data is transferred accurately and securely, reducing the risk of errors.

- Enhanced compliance: AP Connect helps you meet regulatory requirements for data management.

- Improved decision-making: AP Connect provides you with easy access to data, so you can make informed decisions about your experiments.

If you are looking for a digital hub to help you automate data transfer, improve efficiency, and meet regulatory requirements, then AP Connect is the solution for you.

Relevant products:

Improve the mass balance of the tank farm

Crude oil transported to a refinery is always a blend from many different sources (wells), even when it comes from one region and one brand. Density is one of the main properties for the characterization and the quality of incoming crude. Density is also a main quality parameter of fuels, which are very often delivered via pipelines. With an inline density sensor, the L-Dens 7400, an alarm can be triggered immediately if something should be delivered incorrectly.

Fuel Analysis in Tank Terminals

Checking for biodegradation and contamination during fuel storage

Having water in your fuel during storage can lead to costly and disastrous situations. To avoid this, the required dewatering process can be controlled conveniently with robust process measurement sensors. Based on the values delivered continuously by the sensor, the operator can control the valve to achieve an exact separation. This guarantees:

- Rapid reaction to variations in composition and quality

- Minimum product loss

- Reduced waste treatment costs

- Minimized risk of pollution due to human error

Depending on your plant setup, Anton Paar offers a sensor to meet your needs.

Checking the authenticity of fuels to avoid adulteration

When buying fuels from suppliers you want to make sure that you receive the right product and not an adulterated fuel mixed with cheap components as this would lower the quality of the fuel and damage the engines and the relationship with your end customers. With Anton Paar’s compact Raman spectrometers you can quickly verify the quality of incoming goods within seconds directly at the warehouse. The portable instruments are used without any sample preparation, chemicals, or consumables, thereby reducing waste and providing a quick and low-cost approach to raw material identification.

Learn more

Defining the hazard class for transportation and handling

To evaluate the flammability and assign a hazard classification before transportation you need to know the flash point. Anton Paar’s flash point testers implement referee methods used internationally for releasing petroleum products and are also used for the flash point determination of solvents or solvent mixtures. Choose your method:

- Pensky-Martens

- Cleveland

- Tag

- Abel

Relevant products:

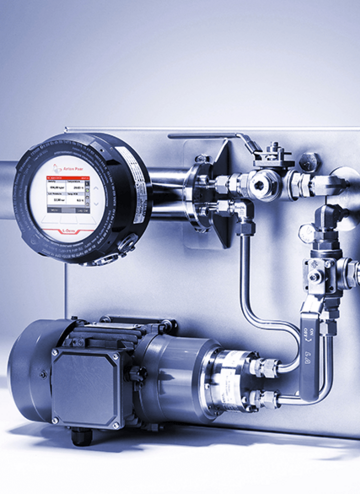

Minimizing mass balance error at tank farms and fulfilling regulations

Anton Paar devices help you keep tight financial control of custody transfer points and therefore minimize the mass balance error of your tank farm. Combing our online density sensor with a volume flow meter delivers the most accurate mass determination results. You know exactly how much of each product is incoming and outgoing and reap the best financial benefit.

Minimizing product loss and waste when using multiproduct pipelines

To achieve the best product cut in multiproduct lines you need a sensor that detects the product within one second. Anton Paar’s online sensor tells you immediately as soon as the product is outside the defined range so you can close the valve. This sensor will minimize product loss and waste and save you money.

On-site density measurements in hazardous areas (Ex-zone 1)

Working in hazardous areas (Ex-zone 1) you need intrinsically safe instrumentation, e.g. when measuring the density of your petroleum product at the terminal to check whether you will fill the right fuel to your storage tank. Anton Paar’s portable DMA 35 Ex petrol measures specific gravity quickly and directly on-site. Thanks to its ATEX approval it is safe to use directly at the terminal before pumping. The density meter is ASTM D7777 compliant, guarantees user safety, and carries out all relevant unit conversions automatically. It directly takes a small sample volume of only 2 mL from the storage container via its built-in pump.

Relevant products:

Simulating the behavior of final products to understand their stability in storage

Before and after transportation, Anton Paar devices can help you assess the storage behavior of your finished products so you can predict how they behave under certain ambient conditions.

- Discover at which temperatures the product starts to evaporate and forms vapors to ensure the correct classification and storage conditions.

- Check the oxidation stability to avoid problems later such as rust, corrosion, and filter blocking in an engine system.

Relevant products:

Unloading fuels without losses or mix-ups

Preventing mix-ups when unloading will keep your costs and waste low. By measuring the density online during the whole loading process, the operator can check that the correct product is being filled into the correct tank. If the measured density is outside the specified range for the expected product, the pump can be switched off immediately before contamination occurs. Anton Paar’s density sensors are:

- Robust and maintenance-free

- Ready to measure on delivery

- Designed for use in hazardous areas

Optimize the fueling of aircrafts

The highly accurate inline density sensor L-Dens 7400 in combination with a volume flow meter optimizes the over-fueling of an aircraft, reduces the CO2 emissions tax, and is a continuous quality control measurement.

Hazard classification of flammable liquids

Transport and storage of flammable liquids are conducted with the necessary caution according to health and safety regulations. To determine the needs for storage and transport the flash point of flammable liquids has to be determined. According to the flash point temperature determined, safety measures are applied in line with respective national or international regulations. The PMA 500 is the perfect instrument to conduct flash point testing on crude oil, bitumen, fuels, and lubricants. The 10x longer lifetime of the electric igniter and the increased cooling speed after a measurement increase productivity and save running costs and maintenance time.

Relevant products:

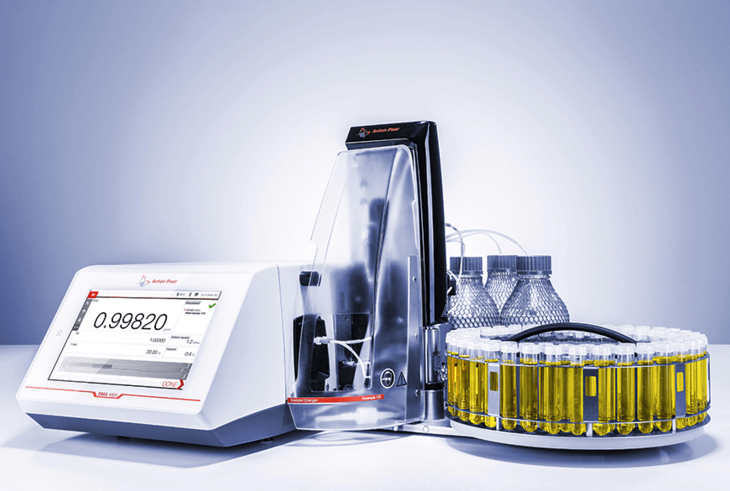

Trade fuel profitably

When it comes to trading fuel, it’s important to properly classify the sample for sales and purchase. Precise determination with fast and accurate density measurements contributes to an increase in profits and to setting a reliable basis for account settlement. Within the industry, compliance with density measurements according to ASTM D4052, D5002, and ISO 12185 is ensured. With the option to upgrade the density meter with automatic sample changers, providing fully automatic filling and cleaning, the efficiency of analysis is maximized.

Relevant products:

Digitization and harmonization of laboratory instrument data

AP Connect is your digital hub for automated data transfer from your instruments to a central database.

With AP Connect, you can:

- Easily transfer data from your instruments to a central database, regardless of the manufacturer.

- Export measurement results to a specified location or access them directly with a standardized API.

- Drive digitalization forward and meet your requirements for streamlined data handling.

- Use AP Connect in many different applications and industries.

- Meet current regulations and requirements in the regulated environment with the Pharma Edition.

The benefits of using AP Connect:

- Increased efficiency: AP Connect automates the data transfer process, freeing up your time so you can focus on other tasks.

- Improved accuracy: AP Connect ensures that data is transferred accurately and securely, reducing the risk of errors.

- Enhanced compliance: AP Connect helps you meet regulatory requirements for data management.

- Improved decision-making: AP Connect provides you with easy access to data, so you can make informed decisions about your experiments.

If you are looking for a digital hub to help you automate data transfer, improve efficiency, and meet regulatory requirements, then AP Connect is the solution for you.

Relevant products:

Product identification when unloading trains

When unloading a train in a tank farm, there is a risk of accidentally connecting the wrong wagon to the manifold. Without inline density measurement with the L-Dens 7400, different products would then be pumped into the same tank. In most cases, the mixing of different products results in out-of-spec products, and the contaminated product has to be refined again with a large financial loss.

Product detection in multiproduct pipelines

Tank terminals are supplied with a wide range of products in different ways, either via pipeline or by train and ship. Multiproduct pipelines transport different products and grades, which are pumped one after the other. Currently, the most common method to ensure the correct transfer of the products to the corresponding tanks at the tank terminal is run-time-based. Due to variations in flow speed, volumetric changes or pressure drops, even a precise calculation cannot assure an exact product cut in the way that it can be guaranteed via product detection with the inline density sensor L-Dens 7300.

Relevant products:

Lubricant Analysis in Tank Terminals

Enabling fast turnaround times at the filling line

When it comes to changing products in the filling lines, time is money. Knowing when the next batch of product is in the line and can be filled into the tank trucks is important information you need to have as soon as possible. To achieve that, Anton Paar's fast but precise SVM viscometer is the best solution. Getting your results in less than four minutes enables you to reduce the amount of lubricant that goes to waste and saves money.

Relevant products:

Unloading lubricants without losses or mix-ups

Preventing mix-ups when unloading will keep your costs and waste low. By measuring the density online during the whole loading process, the operator can check that the correct product is being filled into the correct tank. If the measured density is outside the specified range for the expected product, the pump can be switched off immediately before contamination occurs. Anton Paar’s density sensors are:

- Robust and maintenance-free

- Ready to measure on delivery

- Designed for use in hazardous areas

Minimizing mass balance error at tank farms and fulfilling regulations

Anton Paar devices help you keep tight financial control of custody transfer points and therefore minimize the mass balance error of your tank farm. Combing our online density sensor with a volume flow meter delivers the most accurate mass determination results. You know exactly how much of each product is incoming and outgoing and reap the best financial benefit.

Minimizing product loss and waste when using multiproduct pipelines

To achieve the best product cut in multiproduct lines you need a sensor that detects the product within one second. Anton Paar’s online sensor tells you immediately as soon as the product is outside the defined range so you can close the valve. This sensor will minimize product loss and waste and save you money.

Performing on-site density measurements in hazardous areas (Ex-zone 1)

When working in hazardous areas (Ex-zone 1) you need intrinsically safe instrumentation, e.g. when measuring the density of your lubricant at the terminal to check whether you will fill the right product into your storage tank. Anton Paar’s portable DMA 35 Ex petrol measures specific gravity quickly and directly on-site. Thanks to its ATEX approval it is safe to use directly at the terminal before pumping. The density meter is ASTM D7777-compliant, guarantees the highest user safety, and carries out all relevant unit conversions automatically. It directly takes a small sample volume of only 2 mL from the storage container via its built-in pump.

Relevant products:

Simulating the behavior of final products to understand their stability in storage

Before and after transportation, Anton Paar devices can help you assess the storage behavior of your finished products so you can predict how they behave under certain ambient conditions.

- Discover at which temperatures the product starts to evaporate and forms vapors to ensure the correct classification and storage conditions.

- Check the oxidation stability to avoid problems later such as rust, corrosion, and filter blocking in an engine system.

Relevant products:

Defining the hazard class for transportation and handling

To evaluate the flammability and assign a hazard classification before transportation you need to know the flash point. Anton Paar’s flash point testers implement referee methods used internationally for releasing petroleum products and are also used for the flash point determination of solvents or solvent mixtures. Choose your method:

- Pensky-Martens

- Cleveland

- Tag

- Abel

Relevant products:

On-site density measurements in hazardous areas (Ex-zone 1)

Working in hazardous areas (Ex-zone 1) you need intrinsically safe instrumentation, e.g. when measuring the density of your petroleum product at the terminal to check whether you will fill the right fuel to your storage tank. Anton Paar’s portable DMA 35 Ex petrol measures specific gravity quickly and directly on-site. Thanks to its ATEX approval it is safe to use directly at the terminal before pumping. The density meter is ASTM D7777 compliant, guarantees user safety, and carries out all relevant unit conversions automatically. It directly takes a small sample volume of only 2 mL from the storage container via its built-in pump.

Relevant products:

Digitization and harmonization of laboratory instrument data

AP Connect is your digital hub for automated data transfer from your instruments to a central database.

With AP Connect, you can:

- Easily transfer data from your instruments to a central database, regardless of the manufacturer.

- Export measurement results to a specified location or access them directly with a standardized API.

- Drive digitalization forward and meet your requirements for streamlined data handling.

- Use AP Connect in many different applications and industries.

- Meet current regulations and requirements in the regulated environment with the Pharma Edition.

The benefits of using AP Connect:

- Increased efficiency: AP Connect automates the data transfer process, freeing up your time so you can focus on other tasks.

- Improved accuracy: AP Connect ensures that data is transferred accurately and securely, reducing the risk of errors.

- Enhanced compliance: AP Connect helps you meet regulatory requirements for data management.

- Improved decision-making: AP Connect provides you with easy access to data, so you can make informed decisions about your experiments.

If you are looking for a digital hub to help you automate data transfer, improve efficiency, and meet regulatory requirements, then AP Connect is the solution for you.

Relevant products:

Enabling fast turnaround times at the filling line

When it comes to changing products in the filling lines, time is money. Knowing when the next batch of product is in the line and can be filled into the tank trucks is important information you need to have as soon as possible. Anton Paar's fast but precise SVM viscometer is the best solution. Getting your results in less than four minutes enables you to reduce the amount of lubricant that goes to waste and saves money.

Relevant products:

Bitumen and Asphalt Analysis in Tank Terminals

Fulfilling all international standards for asphalt and bitumen testing

Regulatory requirements for asphalt binder and bitumen testing have intensified significantly in recent years, especially as they relate to elasticity and flexibility. Analysis with high-performance instruments ensures that modern asphalt and bitumen products meet these requirements both in quality control and during product development. Anton Paar’s dynamic shear rheometers can analyze unmodified as well as modified asphalt binders and bitumen across a wide temperature range, for all kinds of bitumen, according to international standards methods.

Anton Paar offers a wide portfolio of measuring equipment fulfilling all current and upcoming standards for the asphalt and bitumen industry, including rotational rheometers and viscometers with a temperature range of up to 300 °C, a density meter for heavy petroleum samples, instruments to determine the consistency and brittle behavior of bitumen at low temperatures, and flash point testers for maximum safety during transportation and storage.

Product specifications

- AASHTO M320, M332

- ASTM D6373, D8239, D449, D2521, D3381, D5078, D6114

- EN 13108, EN 14023, EN 12591

Standards

- Density: D8188

- Penetration: D5, EN 1426

- Softening point: D36, EN 1427

- Fraass Breaking Point: EN 12 593

- Cleveland flash & fire point: D92, ISO 2592

- Rheology:

- AASHTO T315, T316, T350, TP101 UL, TP123, TP126

- ASTM D7175, D4402, D7405, D7552

- DIN EN13302, EN13702, EN16659

Relevant products:

Classifying bitumen based on accurate penetration testing

The patented sensor plunger with automatic surface detection enables more reliable and more accurate penetration test results in a fraction of the time required by manual methods. This ensures good repeatability at different locations due to the reduction of potential human error. The penetration value is crucial to determining the correct degree of bitumen hardness, and, in turn, the right bitumen type for the asphalt mixture.

Relevant products:

Measuring rheological properties of asphalt binders regularly and quickly

The rheometer's active Peltier elements, covering the upper and lower plate, help set the temperature in minutes, significantly reducing measurement and cleaning time. Additional functionalities, such as the Toolmaster™ feature, save even more time as the zero gap doesn’t have to be determined again before each measurement.

SmartPave 92’s air-cooled plates make the use of liquid counter-cooling devices obsolete, reducing maintenance costs and freeing up lab space.

Relevant products:

Developing asphalt and bitumen emulsions with long-term stability

Bitumen emulsions must remain stable to avoid sedimentation during storage and transportation. Specifically tailored mixtures of emulsifiers and other additives are required. You can investigate the effects of emulsifiers and additives on the stability of the bitumen emulsion by measuring the zeta potential with Anton Paar’s particle analyzer Litesizer 500, using the patented cmPALS technique. Knowing the zeta potential can help you understand and modify the coagulation of bitumen particles, giving insights into long-term stability. Absolute zeta potential values higher than +/- 30 mV indicate a stable emulsion.

Relevant products:

Determination of flash and fire point of bitumen

The flash and fire point of bitumen is an important parameter within product specifications and can be measured, e.g., according to ASTM D92 using an open cup flash and fire point tester. Furthermore, closed cup methods, such as ASTM D93, can be used to determine the flash point within a closed environment (e.g., during transport, storage, or in-use) and is recognized as an important safety parameter. Both our PMA 500 and CLA 5 are perfectly suited for flash and fire point testing on bitumen. The PMA 500 in particular comes with features, such as the 10x longer lifetime of the electric igniter or the 20 % decreased cooling time needed (compared to competitive instruments), making flash point testing more efficient than ever before.

Relevant products:

Digitization and harmonization of laboratory instrument data

AP Connect is your digital hub for automated data transfer from your instruments to a central database.

With AP Connect, you can:

- Easily transfer data from your instruments to a central database, regardless of the manufacturer.

- Export measurement results to a specified location or access them directly with a standardized API.

- Drive digitalization forward and meet your requirements for streamlined data handling.

- Use AP Connect in many different applications and industries.

- Meet current regulations and requirements in the regulated environment with the Pharma Edition.

The benefits of using AP Connect:

- Increased efficiency: AP Connect automates the data transfer process, freeing up your time so you can focus on other tasks.

- Improved accuracy: AP Connect ensures that data is transferred accurately and securely, reducing the risk of errors.

- Enhanced compliance: AP Connect helps you meet regulatory requirements for data management.

- Improved decision-making: AP Connect provides you with easy access to data, so you can make informed decisions about your experiments.

If you are looking for a digital hub to help you automate data transfer, improve efficiency, and meet regulatory requirements, then AP Connect is the solution for you.

Relevant products:

Calculating asphalt and bitumen mass for quick, flawless trading

Measuring density is a well-established method for asphalt testing and characterization, quality control, and precise account settlement, where known volumes of bitumen need to be converted to mass. This requires sample handling (preheating) as well as measurements at elevated temperatures.

The unique digital density meter DMA 4200 M with its robust Hastelloy C276 measuring cell is ASTM D8188 compliant and by far the quickest method to determine bitumen density. It is also safe at temperatures up to 200 °C. The instrument has a number of benefits over traditional methods (including hydrometers and pycnometers):

- Automatic temperature control for only 2 mL sample volume

- Convenient cleaning routines with reduced solvent consumption, producing only minimum waste

- Results in a few minutes, freeing up operator time

- Minimum manual steps per operator, reducing potential human error

Version 2:

The density measurement of bitumen is crucial for product quantification and volume-to-mass conversion. Conventional methods of analysis are labor-prone, time-consuming, and require a significant amount of sample. By switching to state-of-the-art measurement technology, provided by density analysis through the oscillating U-tube method, analysis doesn’t just get simpler – it’s also streamlined for the trade of asphalt and bitumen by the use of incorporated tables, converting the density results to the desired reference temperature. Within a matter of minutes, the relevant density values are determined, and the use of solvents for cleaning is reduced to an absolute minimum.

Relevant products: