Inline Beverage Analyzer:

Cobrix

- Density and sound velocity sensor with a p/T CO2 measurement

- Low maintenance – on average every 6 to 18 months

- Advanced diet measurement and measurement check

- Product-specific setups at the best value

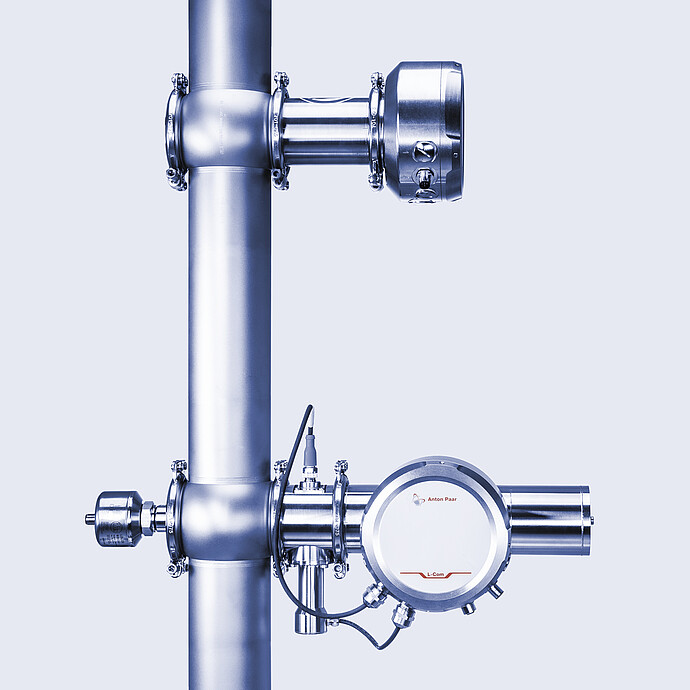

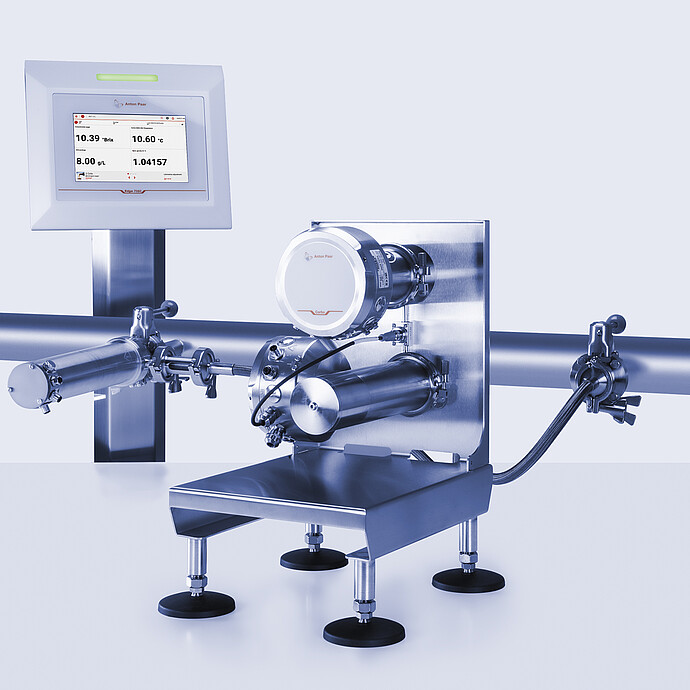

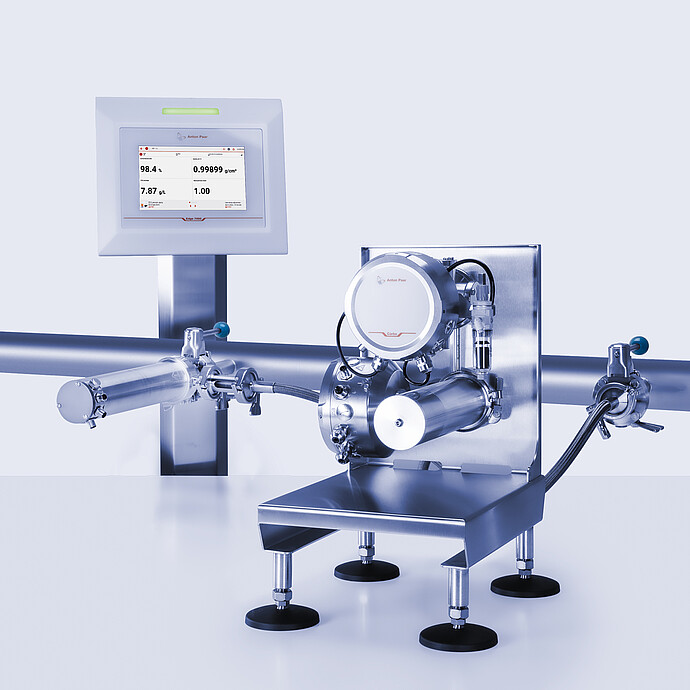

- Inline and bypass installation option

The inline beverage analyzers Cobrix 5501/5601 and Cobrix 7501/7601 models provide comprehensive real-time monitoring of critical parameters throughout the production of soft drinks. Pre-calibrated at the factory, the Cobrix models simplify the setup process, eliminating the need for time-consuming, product-specific adjustments on-site. Beyond the standard measurements of °Brix, %Diet, and CO2, these advanced instruments can also evaluate alcohol levels, sugar inversion, and, if required, conductivity, color, and oxygen content. The addition of TA measurement ensures a more robust analysis, aiding producers in achieving optimal taste and quality consistency in their beverages. The advanced diet measurement included in Cobrix 7501/7601 provides a new standard with regards to measurement stability and speed of diet beverages.

Key features

Market-leading accuracy and repeatability

With Cobrix, guarantee in-spec production while preventing unnecessary use of raw materials. This inline beverage analyzer provides the highest accuracy and repeatability for measuring %Diet, and key parameters like CO2, °Brix, sugar inversion, total acidity and alcohol concentration.

Advanced diet measurement for increased speed and stability

Elevate your sugar-free beverage production with Cobrix’s advanced diet measurement. This feature of the inline beverage analyzer Cobrix 7501 and Cobrix 7601 employs dual measurements for improved accuracy and reduced calibration needs. It is also available as an upgrade for Cobrix 5501 and Cobrix 5601. Achieve efficiency in the Quality Management Program with decreased laboratory checks and optimized processes.

Measurement Check

The measurement check acts as a ratio or "fingerprint" that compares all components to ionic ones, primarily acids. This method not only monitors product composition to minimize taste deviations, but also employs two independent measurements to validate composition. It comes out of the box with Cobrix 7501 and Cobrix 7601 and is available as an upgrade for Cobrix 5501 and 5601. When the results match the product-specific benchmarks, they confirm the accuracy of the beverage's blending, composition, and overall measurement. This identifies discrepancies such as sugar carry-over, missing critical ingredients, carry-over from cleaning processes, absence of key aroma components, or sensor malfunctions, ensuring a high level of quality control and consistency in the final product.

Configurable thresholds for tolerance and control limits

Safeguard your product quality via product- and application-specific detection of production anomalies.

A fit for your production environment

With the Cobrix inline beverage analyzer you can choose between an inline or bypass version to suit your production needs. The evaluation unit can be placed as far as 250 meters from the sensor, enabling easy access to production data. It features a standard Ethernet connection to Davis 5 software, allowing for the visualization of statistical, production data, and trends throughout the plant, and can also integrate with laboratory equipment if needed. This system offers versatile communication options, including classic analog outputs (4 mA to 20 mA), digital I/Os, and a selection of fieldbuses, ensuring seamless data integration across various platforms.

Safe for pressurized water and chemical foam cleaning

High-grade housing materials and an IP65 or higher rating for sensors and evaluation unit allow for chemical foaming and pressurized water factory cleaning.

Specifications

| Cobrix 5501/5601 | Cobrix 7501/7601 | |

| Sugar/Diet concentration | ||

| Range | 0 °Brix to 50 °Brix 0 °Brix to 15 °Brix for products with sugar inversion 0 %Diet to 150 %Diet of target | |

| Accuracy | Sugared drinks: <0.02 °Brix Diet drinks: <1 % | Sugared drinks: <0.02 °Brix Diet drinks: <0.5 % |

| Stability diet (coefficient of variation) | <1 % | <0.5 % |

| CO2 concentration | ||

| Range | 0 Volumes to 6 Volumes 0 g/L to 12 g/L | |

| Accuracy | 0.025 Vol. (0.05 g/L) | |

| FABs(alcopops) | ||

| Alcohol range | 0 %w/w to 16 %w/w (%weight/weight) 0 %v/v to 20 %v/v (%volume/volume at 20 °C) | |

| Alcohol accuracy | 0.02 %v/v | |

| Measuring temperature | 0 °C to +30 °C 0 °C to +25 °C for products with sugar inversion, diets, and FABs | |

| Advanced diet measurement | x | ✓ |

| Measurement check method | x | ✓ |

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Beverage / Soft Drinks | The impact of sugar inversion on soft drinks with sugar Application Reports

-

Beverage | Hard Seltzer | Process measurement for Hard Seltzer manufacturing Application Reports

-

Beverage | Soft Drinks | Complete Your Soft Drink Analysis Application Reports

-

Beverage | Soft Drinks | Online Process Measurement in the Soft Drink Industry Application Reports

-

Beverage | Softdrinks | Cobrix 7501/7601 - Beverage Analysis 4.0 Application Reports

-

Process Engineering Solutions | Overview Brochures

Similar products

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

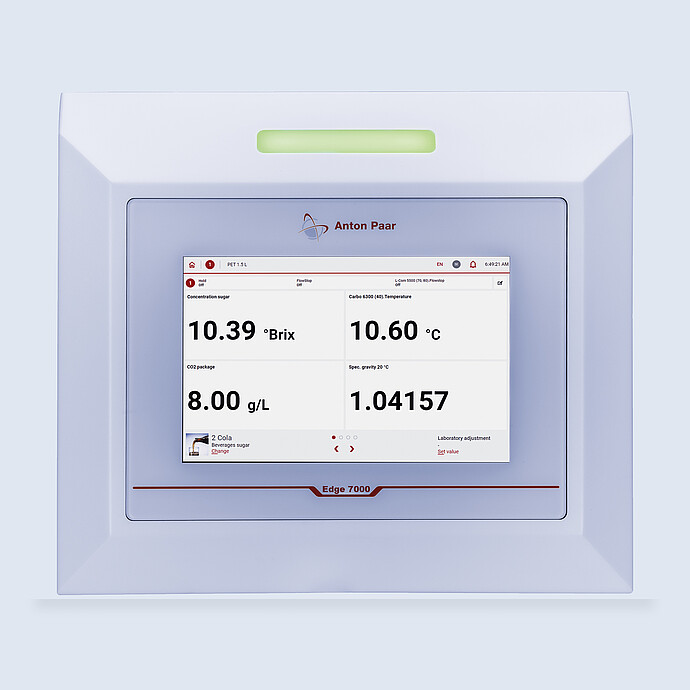

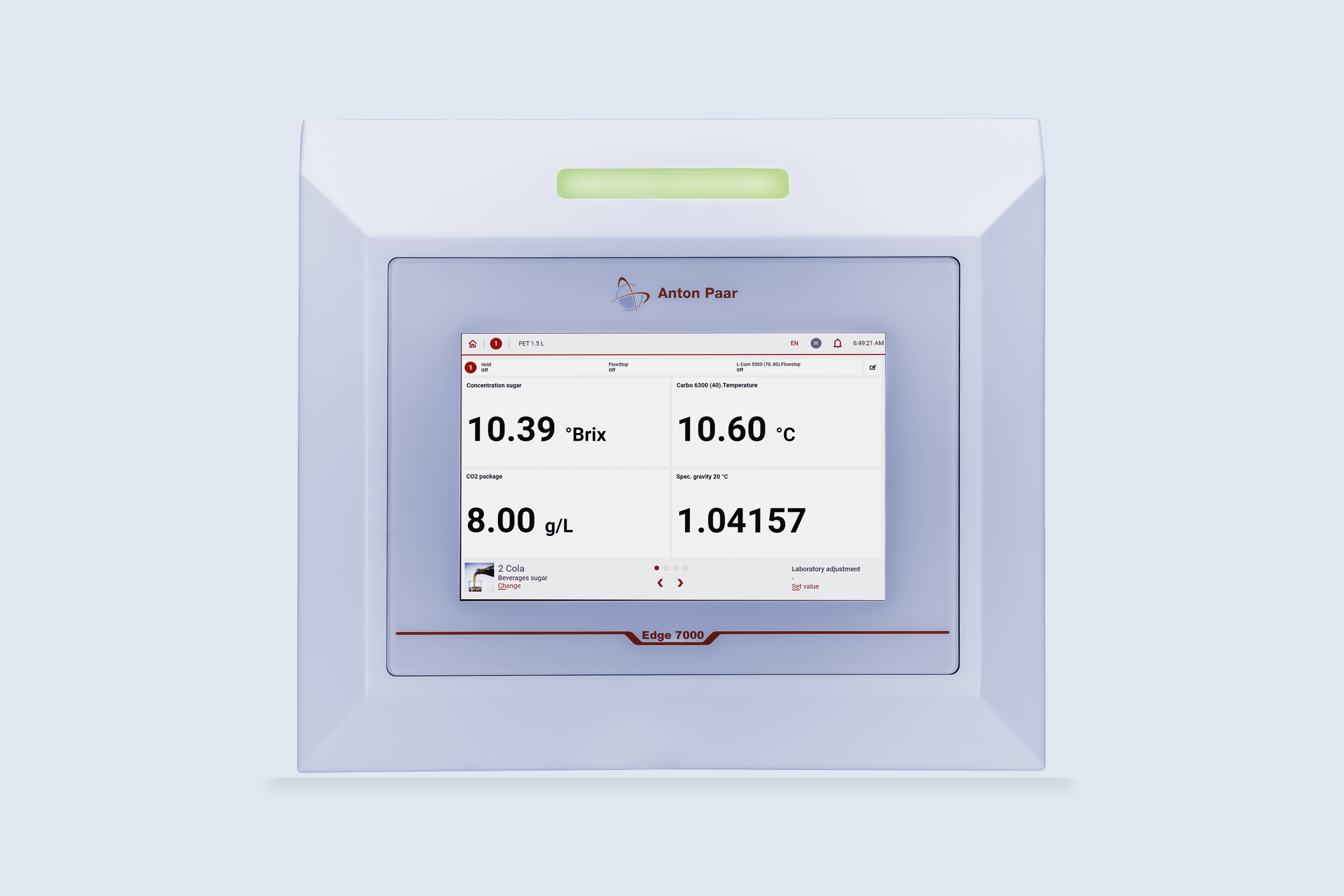

High Performance Process Controller:

Edge

Cobrix 7501 | 7601 | 5501 | 5601

Data Recording Software:

DAVIS 5

Cobrix 7501 | 7601 | 5501 | 5601

- Visualize your production data directly from your office desktop

- Improve your process capability

- Powerful reporting and complete traceability

- Alerts prevent out-of-spec production

- Calibration and adjustment at the push of a button

Color Sensor:

L-Col 6100

Cobrix 7501 | 7601 | 5501 | 5601

- Inline color measurement for all kinds of beverages

- EBC/MEBAK®/ASCB-compliant

- Tailor-made wavelength configurations

- Seamless integration with beverage analyzers

- Easy installation at your plant