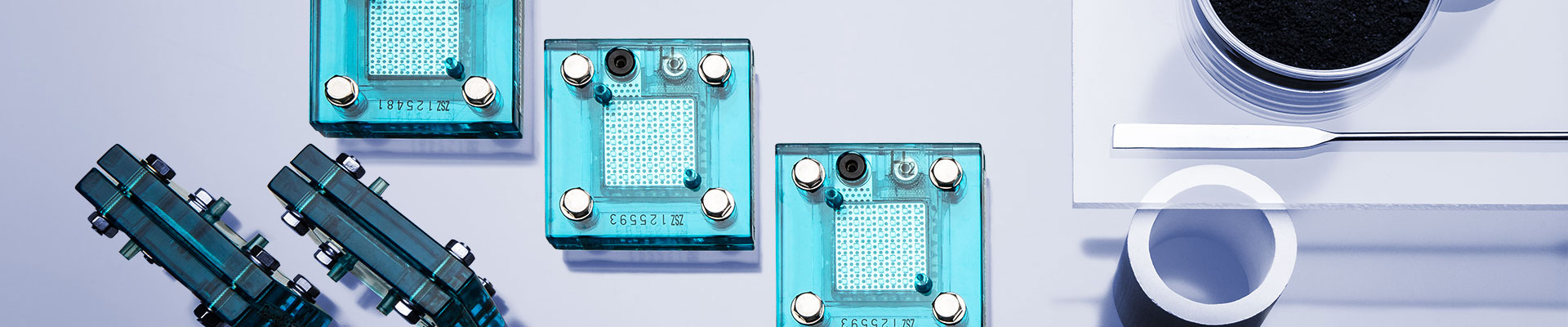

Hydrogen fuel cell research and production

To achieve optimal fuel cell performance, you need to fully characterize the physicochemical properties of the active components and engineer them to your advantage. Anton Paar solutions optimize every single fuel cell component.

Research and production

Catalysts

Ensuring optimal catalytic activity is key to fuel cell performance.

To improve catalytic activity you can evaluate and adjust the particle size of the catalyst material using a particle analyzer. To help build fuel cells that maintain their activity over time, you can assess the active metal area and dispersion using Anton Paar’s chemisorption devices. Optimizing these physicochemical properties provides a significant cost benefit as noble metals can be implemented more efficiently before cell assembly.

To determine the final concentration of these noble metals, elemental analysis has to be performed which is only possible after adequate sample preparation with microwave-assisted acid digestion.

Research into novel materials for fuel cells, in particular catalysts, is facilitated and accelerated by microwave synthesis.

Catalyst support

To improve the catalyst support you can minimize the variability between batches of carbon before impregnation/deposition. Anton Paar’s gas sorption analyzers deliver a detailed assessment of the pore size and surface area which can be used to achieve a consistent surface area and pore size of the nanoporous carbon.

Modifying the surface of carbon nanotubes can also improve catalytic performance by facilitating the proton transfer through the catalyst layer. These modifications can be performed based on evaluation of the zeta potential of the surfaces with Anton Paar’s electrokinetic analyzer.

Gas diffusion layer

The gas diffusion layer can be improved by optimizing fluid permeability and controlling flooding. To evaluate the gas permeability, water management, and ohmic behavior before cell assembly, you can perform pore size distribution measurements which can be used to optimize performance.

To ensure consistent and sufficient fluid transport before cell assembly and control flooding, use a vapor sorption analyzer to perform hydrophobicity/hydrophilicity measurements and determine the best gas diffusion layer composition.

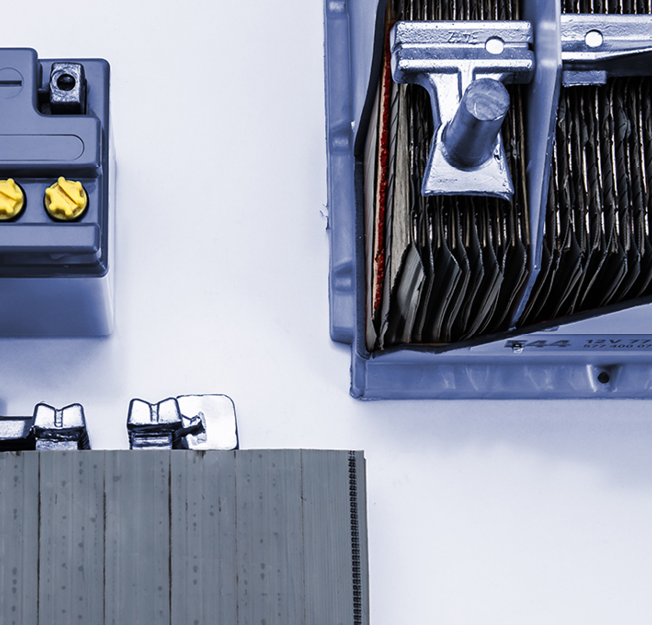

Lead-acid battery manufacturing and maintenance

Whether you are producing, maintaining, or servicing lead-acid batteries, you want to know the concentration of sulfuric acid in the battery and therefore the state of charge.

Lithium-ion battery production

Make only top-quality lithium-ion batteries, using Anton Paar solutions for characterizing active materials in battery materials research, checking raw materials, verifying the quality of electrolytes and solvents before use, and much more.

3-year warranty

- Effective January 1, 2020, all new Anton Paar instruments* include repair for 3 years.

- Customers avoid unforeseen costs and can always rely on their instrument.

- Alongside the warranty there is a wide range of additional services and maintenance options available.

* Due to the technology they use, some instruments require maintenance according to a maintenance schedule. Complying with the maintenance schedule is a prerequisite for the 3-year warranty.