Rheometer-Raman Setup:

MCR Evolution & Cora 5001

- Uncover the molecular origins of viscoelastic behavior

- Gain deeper understanding of material properties

- Obtain scientific proof for observed rheological effects

- Reduce development cycles via a more targeted approach

- Efficient root cause analysis and corrective actions in case of deviations

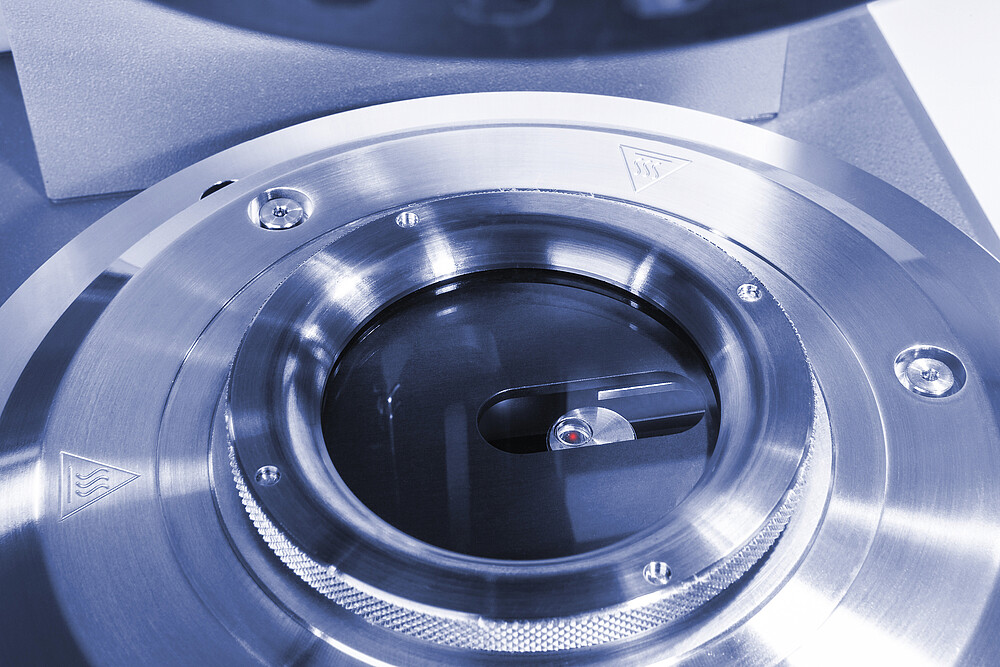

The Rheo-Raman setup – an MCR rheometer integrated with a Cora 5001 Raman spectrometer – combines two powerful measurement principles: the mechanical insights of rheology and the molecular specificity of Raman spectroscopy. By linking rheological behavior with structural parameters from Raman spectra, academic researchers can uncover the molecular origins of viscoelastic properties – replacing hypotheses with proof and enabling publication of papers in high-impact journals. In industry, the Rheo-Raman system supports efficiency gains by reducing trial-and-error cycles, identifying deviations, pinpointing their root causes, and enabling precise corrective actions.

Key features

Reduce your time-to-market with fewer development cycles

In polymer and resin product development, desired properties are often achieved via experience combined with time-consuming iterative trial and error processes. By adding chemical insights to physical measurements through the Rheo-Raman approach, development teams gain a clear picture of what drives material performance. This enables more targeted optimization, reduces the number of development cycles, saves costs, and shortens time-to-market.

Boost your research results for the next higher-grade publication

In academic research, rheological measurements alone often lead to observational results without a clear molecular explanation. By combining rheological results with chemical and molecular insights, researchers gain scientific proof – not just hypotheses.

This deeper understanding supports publication in higher-grade journals, increases visibility at top conferences, and strengthens applications for research funding – fueling a continuous cycle of scientific advancement.

Key application areas are: material science, polymer science, resins, glues and adhesives, including photo polymerization, for which simultaneous UV exposure and Raman offer strong advantages.

Optimize your polymer production processes

Developing new polymer production processes, including the right parameters, often involves repeated iterations that consume time and capacity. The valuable information acquired through a combination of physical measurements and chemical insights using the Rheo-Raman setup makes defining process windows more focused and efficient. This approach helps minimize trial and error, accelerates process refinement, reduces costs, and brings products to market faster.

Benefit from the Rheo-Raman system – or use the instruments separately

Due to cumbersome integration and alignment procedures that require specialized skills, similar systems on the market can only be used in combination. In contrast, the Rheo-Raman setup with MCR Evolution and Cora 5001 can be assembled or disassembled by users in just a minute. A visit from a service technician is not required. You can use the rheometer and Raman analyzer separately or combine them, depending on your measurement needs. This means you’re getting three solutions in one – from one and the same supplier. We guarantee that both the individual and combined solutions will work seamlessly together.

More effective QC with root cause analysis down to molecular origins

In industrial QC of polymer products such as polymer melts, adhesives, and resins, resolving deviations is often a slow, trial-and-error process based on observations and user experience. Offline testing adds further delays and unnecessary costs, while quality issues remain unresolved.

By combining rheology with Raman spectroscopy, users gain real-time, in situ chemical insights directly in the rheometer. This enables immediate identification of chemical/molecular root causes and allows for fast, targeted corrective action – reducing costs, avoiding liability risks, and keeping processes on track.

Specifications

Modular Compact Rheometer: MCR 102e/302e/502e

| Technical Data | Unit | MCR 102e | MCR 302e | MCR 502e Power |

| Bearing design | - | Air, fine-pored carbon | ||

| Motor design | - | Electronically Commutated (EC) - Permanent Magnet Synchronous Motor | ||

| Displacement transducer design | - | High-resolution optical encoder | ||

| Normal force measurement design (US Pat. 6167752, 1996) | - | 360 ° capacitive sensor, non-contacting, fully integrated in bearing | ||

| Active thermal management of bearing and normal force sensor | - | No | Yes | Yes |

| Working modes | - | Combined Motor Transducer (CMT) | ||

| Minimum torque (rotation) | nNm | 5 | 1 | 100 |

| Minimum torque (oscillation) | nNm | 5 [1] | 0.5 | 50 |

| Maximum torque | mNm | 200 | 230 | 300 |

| Minimum angular deflection (set value) | µrad | 0.5 | 0.05 | 0.05 |

| Maximum angular deflection (set value) | µrad | ∞ | ∞ | ∞ |

| Minimum angular velocity [2] | rad/s | 0 | 0 | 0 |

| Maximum angular velocity Maximum speed | rad/s 1/min | 314 3000 | 314 3000 | 220 2100 |

| Minimum angular frequency [3] | rad/s | 10 -7 | 10 -7 | 10 -7 |

| Maximum angular frequency [4] Maximum frequency | rad/s Hz | 628 100 | 628 100 | 628 100 |

| Normal force range | N | -50 to 50 | -50 to 50 | -70 to 70 |

| With Exposed Support Plate (WESP / Space) [5] | - | No | Optional | No |

| Without Support Plate (WSP) | - | No | Optional | No |

| Dimensions (W x H x D) | mm | 444 x 678 x 586 | 444 x 733 x 586 | 444 x 753 x 586 |

| Weight | kg | 42 | 46 | 47 |

| Additional Device Features | ||||

| Device display with remote control of software (decoupled from measuring sensor for mechanical and electromagnetic interference prevention) | - | Yes | Yes | Yes |

| Direct strain/stress controller | - | Yes | Yes | Yes |

| TruRate™ / TruStrain™ (sample adaptive controller) | - | Optional | Yes | Yes |

| Raw data (LAOS, waveform) | - | Optional | Yes | Yes |

| Normal force profiles (set and read) | - | Yes | Yes | Yes |

| Velocity profiles, tack, squeeze | - | Optional | Yes | Yes |

| Automatic gap control/setting (AGC/AGS) | - | Yes | Yes | Yes |

| Electronic trim lock for measuring geometry | - | Yes | Yes | Yes |

| Fully automatic temperature calibration | - | Yes | Yes | Yes |

| TruGap™ (permanent control of the real measuring gap) (US Pat. 6499336, 2000) | - | Optional | Optional | Optional |

| T-Ready™ [6] (detection of sample temperature equilibrium time) (US Pat. 8904852, 2011) | - | Yes | Yes | Yes |

| Toolmaster™ (measuring geometries and accessories, storing of zero-gap) (US Pat. 7275419, 2004) | - | Yes | Yes | Yes |

| QuickConnect Coupling for measuring geometries (one-hand operation, screwless) | - | Yes | Yes | Yes |

| Trimming mirror (360° blind sample spot prevention) | - | Yes | Yes | Yes |

| Three-point support of device (three robust feet for tool-free one hand alignment) | - | Yes | Yes | Yes |

| Three-point support for mounting of measuring cells (wobble prevention, no misalignment after changing of cells) | - | Yes | Yes | Yes |

| Maximum temperature range | °C | -160 to +1000 | -160 to +1000 | -160 to +1000 |

| Maximum pressure range | bar | up to 1000 | up to 1000 | up to 1000 |

| Ready for DMA in torsion and tension | - | Yes | Yes | Yes |

| Ready for tribology | - | Yes | Yes | Yes |

| Ready for powder flow and shear rheology | - | Yes | Yes | Yes |

[1] 2 nNm with activated TruStrain™ option

[2] In controlled shear stress (CSS) mode. In controlled shear rate (CSR) mode depending on measuring point duration and sampling rate.

[3] Theoretical value (duration per cycle = 2 years)

[4] Higher frequencies are possible using multi-wave functionality (942 rad/s (150 Hz) or even higher, depending on measuring system and sample)

[5] Enlarged working space underneath the support plate (flange) [6] Depending on used temperature device

Dual-Wavelength In-Situ Raman Spectrometer: Cora 5001 Fiber

| Single-wavelength | Dual-wavelength | |||||

| Optical specifications | ||||||

| Excitation wavelength | 532 nm | 785 nm | 1064 nm | 532 nm and 785 nm | 532 nm and 1064 nm | 785 nm and 1064 nm |

| Spectral range | 200 cm-1 to 3500 cm-1 | 100 cm-1 to 2300 cm-1 | 100 cm-1 to 2300 cm-1 | 200 cm-1 to 3500 cm-1 for 532 nm 100 cm-1 to 2300 cm-1 for 785 nm and 1064 nm | ||

| Resolution (according to ASTM E2529) | 9 cm-1 to 12 cm-1 | 6 cm-1 to 9 cm-1 | 12 cm-1 to 17 cm-1 | 9 cm-1 to 12 cm-1 for 532 nm 6 cm-1 to 9 cm-1 for 785 nm 12 cm-1 to 17 cm-1 for 1064 nm | ||

| Laser power | 50 mW** | 0 mW to 450 mW*, adjustable | 0 mW to 450 mW*, adjustable | 50 mW** for 532 nm 0 mW to 450 mW* for 785 nm and 1064 nm | ||

| Spectrograph | f/2; Transmission volume phase grating (VPG) | |||||

| Integration time | 0.005 s to 600 s | 0.005 s to 600 s | 0.001 s to 20 s | 0.005 s to 600 s for 532 nm and 785 nm 0.001 s to 20 s for 1064 nm | ||

| Wavelength calibration | Automatic via software | |||||

| Detector array | 2048 px CCD | 2048 px CCD | 256 px InGaAs | 2048 px CCD for 532 nm and 785 nm 256 px InGaAs for 1064 nm | ||

| Laser class | 3B for Fiber model | |||||

| Physical specifications | ||||||

| Dimensions (D x W x H) | 355 mm x 384 mm x 168 mm (14.0 in x 15.1 in x 6.6 in) | |||||

| Weight | 9.8 kg | |||||

| Operating range | 10 °C to 35 °C (non-condensing) | |||||

| Fiber probe dimensions | Cable length: 1.50 m | |||||

| Battery (optional) | Lithium-ion | |||||

| Battery run time | >1.5 h | |||||

| Power supply input | Line power supply input: 115/230 V AC, 50/60 Hz Car power adapter input: 9 V to 32 V DC | |||||

| Power consumption | In-line power supply input: max. 100 W DC input: typical 30 W (60 W when optional battery is charged) | |||||

| Additional specifications | ||||||

| Display | 10-inch touch screen | |||||

| Data ports | 4 x USB 2.0, 1 x Ethernet, 1 x CAN out and 1 x USB to PC | |||||

| Data export formats | .csv, .txt, .png, .spc,. aps, .pdf | |||||

| Internal storage | 8 GB | |||||

| Wireless connectivity | Wi-Fi stick (optional) | |||||

| Spectral libraries | Factory library, user-built, third-party options | |||||

| Security | User roles with customizable permissions, user password logins | |||||

*at sample

**at laser source

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

E-Book - Field Guide to Food and Feed Testing Application Reports

-

Rheo-Raman | Combining Rheology and Raman Spectroscopy Shear Rate Effects Application Reports

-

Success Story: University of Shiga Customer Success Stories

Similar products

Modular Compact Rheometer:

MCR 102e/302e/502e

Accessory for MCR:

Particle Imaging Velocimetry

Accessory for MCR:

Polarized Light Imaging

Accessory for MCR:

Rheo-Microscope

Accessory for MCR:

Rheo-SALS

Accessory for MCR:

Rheo-SANS/SAXS

Optical Accessory for MCR:

UV Light Curing System

Temperature Control for MCR:

Electrical Temperature Devices (ETD)

Temperature Control for MCR:

Peltier Systems

Optical accessory for MCR:

Rheometer-Infrared Spectrometer Adapter