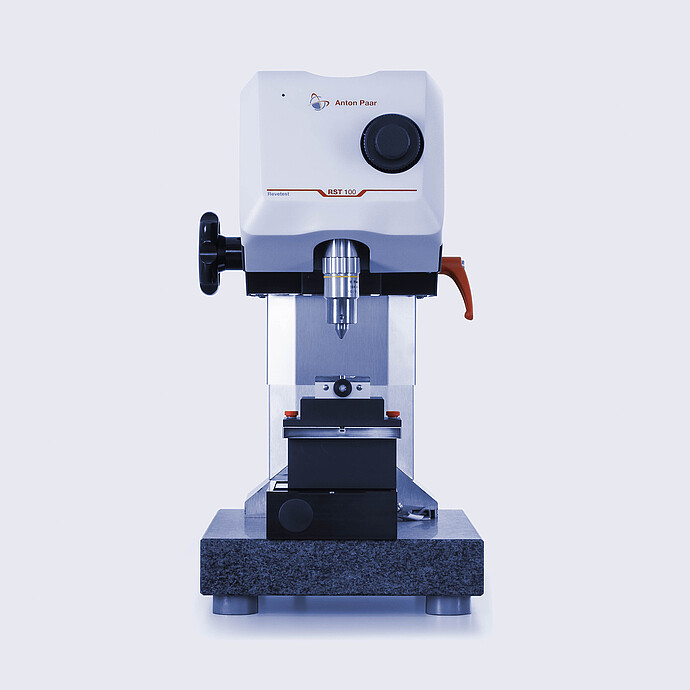

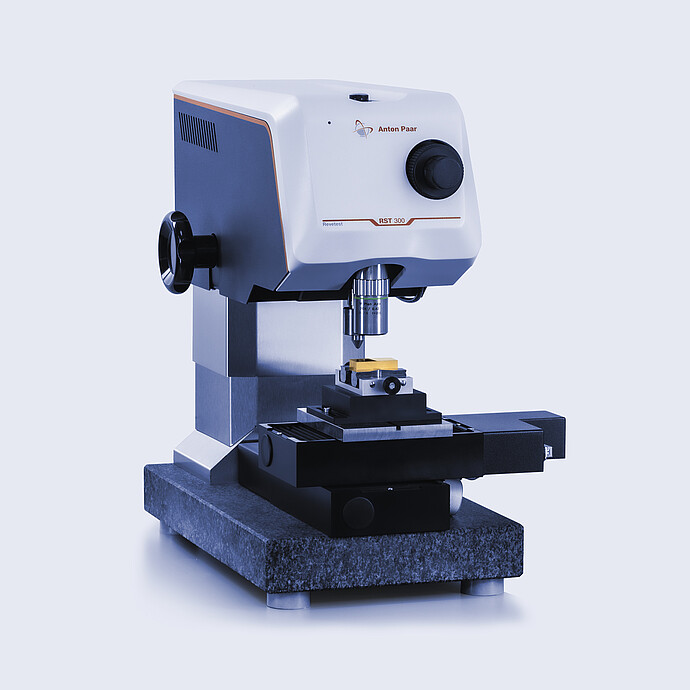

Revetest Scratch Tester:

RST

- Entry-level benchtop Revetest scratch tester

- Coating adhesion, scratch resistance, conventional Vickers hardness

- Full panorama image synchronized with friction force, and acoustic emission

- Automatic Vickers hardness tests

- Simplified scratch software

The Revetest® scratch tester series is the industrial standard, widely used for characterizing hard-coated materials with a typical coating thickness exceeding 1 μm. The RST series includes dependable instruments for the characterization of coating/substrate adhesion, surface scratch resistance, and conventional Vickers hardness. The software enables scratch tests in a wide variety of testing modes, as well as conventional Vickers hardness tests with automatic detection of the imprint. Anton Paar is the world leader in scratch testing with more than 1500 Revetest® Scratch Tester instruments sold.

Key features

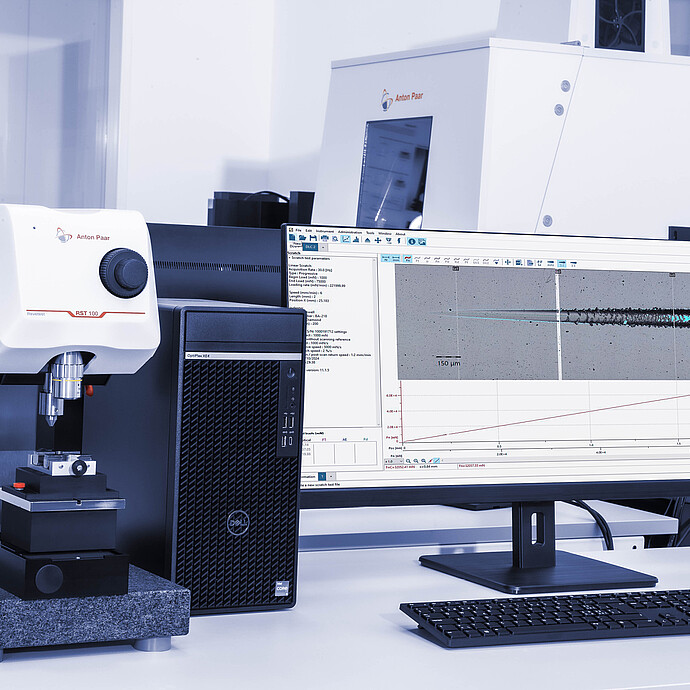

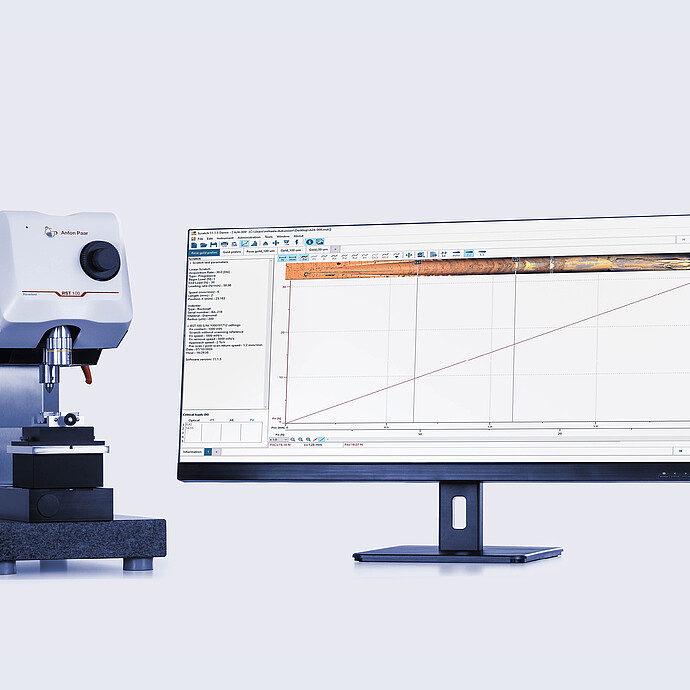

Patented synchronized panorama mode

This unique feature is exclusive to Anton Paar scratch testers. It automatically synchronizes the recording of all sensor signals with the whole scratch image in perfect focus. This way, the measurement curve can be analyzed parallel to the scratch picture on one page. Anton Paar holds the patents US 12/324, 237, and EP 2065695 for the synchronized panorama mode.

Measurements on curved and uneven surfaces

Due to its unique force sensor control, the Revetest® scratch tester system detects every surface deviation and the active force feedback corrects it. By following the shape of the sample with total control of the desired load, RST instruments also perform reliable measurements on uneven and curved surfaces.

Unique conventional Vickers hardness capabilities

This unique feature automatically detects and measures the area of the imprint of a conventional Vickers test and eliminates user influence on the Vickers hardness test results. The RST series and other Anton Paar scratch testers are the only instruments on the market with such advanced capabilities in conventional Vickers hardness testing.

Compliant with ASTM C1624, ISO 20502 and ISO EN 1071

Anton Paar works closely with standardization organizations such as ISO, ASTM, DIN, and others, in order to support our customers to meet the high requirements they have for their own products. This is especially important in quality control, where such standards are essential. By certifying our Revetest Scratch Testers accordingly, we can guarantee high-quality products and services in terms of safety, dependability, and sustainability.

High scratch measurement flexibility

Tips of different diameters and angles are available. Indenter holders are also available for applications where the use of small diameter spherical tips, Berkovich or Vickers tips, and those measuring 6 mm diameter, is required. One and the same indenter holder can be used for different kinds of tips, and one dedicated ball holder can be used for different ball materials.

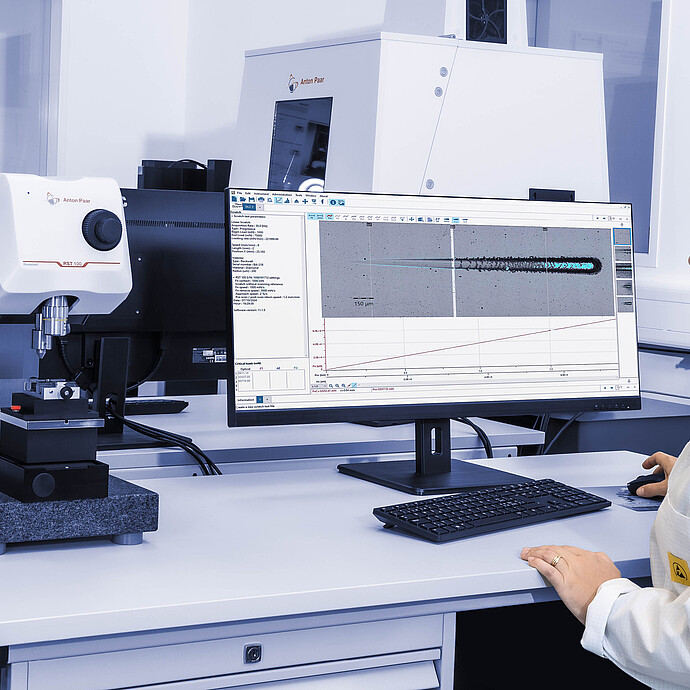

Automatic detection of critical loads

Critical load data is used to quantify the adhesive properties of different film-substrate combinations by using different sensors (acoustic emission, penetration depth, friction force) and video microscope observations. With the new software, all critical loads can be detected automatically. The user only needs to set up threshold values and start the automatic analysis of the critical loads (Lc). The Revetest Scratch Tester series are the only scratch testers on the market with automatic detection of critical loads.

Specifications

| Normal load | Fine range | Large range |

| Max. load [N] | 100 | 200 |

| Resolution [mN] | 0.1 | 0.2 |

| Noise floor [rms] [μN]* | 1000 | |

| Penetration depth (only RST 300) | Fine range | Large range |

| Max. depth [μm] | 100 | 1000 |

| Depth resolution [nm] | 0.05 | 0.5 |

| Noise floor [rms] [nm]* | 2.5 | |

| Friction load | Fine range | Large range |

| Max. friction [N] | 100 | 200 |

| Friction resolution [mN] | 0.1 | 0.2 |

| Acoustic emission sensor |

| |

| Scratching speed |

| |

| Scratch tables |

| |

*Noise floor value specified under ideal laboratory conditions and using an anti-vibration table.

Standards

ISO

ASTM

DIN EN

Standards

ISO

ASTM

DIN EN

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Adhesion and hardness of galvanic layers by scratch test and nanoindentation Application Reports

-

Adhesion of hard coatings by RST 100 scratch tester Application Reports

-

Applications of scratch testing in polymer industry Application Reports

-

Automatic Vickers hardness test by scratch tester Application Reports

-

Biomedical applications 2: Adhesion and scratch resistance by scratch testing Application Reports

-

E-Book - A Practical Guide for Great Building Materials Application Reports

-

Scratch resistance of self-healing paints on wood Application Reports

-

Application folder | Face Your Surface Brochures

Similar products

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

Accessory for Scratch Testers:

Friction Module

RST 100 | 300

- Material’s frictional behavior assessment

- Complementary tool in the assessment of adhesion failures

- Combines scratch and tribology testing

Vickers diamond NHT

RST 100 | 300

KNOOP DIAMOND

RST 100 | 300

SPHEROCONICAL DIAMOND R = 20 µm / 120° FOR MXT / RST ROCKWELL

RST 100 | 300

SPHEROCONICAL DIAMOND R = 50 µm / 120° FOR MCT / RST ROCKWELL

RST 100 | 300

SPHEROCONICAL DIAMOND R = 100 µm / 120° FOR MCT / RST ROCKWELL

RST 100 | 300

SPHEROCONICAL DIAMOND R = 200 µm / 120° FOR MXT / RST ROCKWELL

RST 100 | 300

SPHEROCONICAL DIAMOND R = 10 um / 90°

RST 100 | 300

STEEL 100 CR6 BALLS D= 6 mm, 20 PCS

RST 100 | 300

STEEL 100 CR6 BALLS D= 10mm, 5 PCES

RST 100 | 300

STEEL 440C BALLS D= 6 mm, 20 PCS

RST 100 | 300

STEEL AISI 420 BALL D = 6 mm, 20 PCS

RST 100 | 300