Laboratory Alcohol Meter:

Alcolyzer

- Comply with AOAC, BCOJ, and OIV norms, and transfer data seamlessly

- Analyze 12 sample types with 0 % to 65 % v/v ethanol using one device

- Save time with precise results in just two minutes without distillation

- Experience 0.03% v/v alcohol repeatability, with patented NIR technology

- Unlock 35 additional parameters, such as extract, via density input

Ensure fast, accurate, direct, and compliant alcohol determination for 12 product classes. Access 35+ industry specific parameters, via manual density input, for samples such as beer, wine, sake, and spirits – without distillation. The Alcolyzer is a laboratory alcohol meter that delivers unmatched repeatability with industry-proven, patented technology. Its intuitive operation and seamless data transfer eliminate paperwork in your laboratory. Identify details about your production process, safeguard product specifications, and uncover hidden potential for optimization while reducing product loss to zero, guaranteeing the desired taste, and securing label declaration. Designed for efficiency, flexibility, and reliability, the Alcolyzer is backed by local service around the world.

Key features

Ensure regulatory compliance without distillation

The Alcolyzer 5001 and Alcolyzer 7001 ensure full compliance with AOAC, BCOJ, and OIV standards, meeting the highest industry requirements. This advanced laboratory alcohol meter integrates seamlessly into Anton Paar’s AP Connect lab execution system, or into LIMS systems. It is a key asset for a compliant, paperless lab, eliminating lost data and transcription errors, while ensuring efficient and traceable workflows.

Analyze your portfolio with a single laboratory alcohol meter

The Alcolyzer 5001 and Alcolyzer 7001 precisely determine alcohol content across a wide range of beverages – including beer, wine, spirits, RTDs, kombucha, sake, and more – without the need for product-specific calibration or reference analysis. But these digital alcohol meters also cover non-alcoholic beers and other non-alcoholic products such as wines, and spirits upon request, ensuring fast, accurate results for both traditional and low-alcohol products. With seamless operation and industry compliance, these devices guarantee efficiency, reliability, and optimal quality control for every sample.

Enhance efficiency with our direct, fast, and precise digital alcohol meters

The Alcolyzer 5001 and Alcolyzer 7001 boost efficiency with fast, precise alcohol analysis – delivering reliable results in just two minutes, without distillation. With market-leading repeatability of down to 0.01% v/v, they ensure consistent accuracy and robust performance over the long term. Designed for efficiency and durability, these devices streamline workflows, reduce downtime, and make quality control effortless.

Unlock additional parameters via density input

The Alcolyzer 5001 and Alcolyzer 7001 go beyond alcohol analysis by allowing manual input of density parameters, enabling the calculation of key values like original extract in beer, or calories in wine. This added flexibility enhances quality control, providing comprehensive insights into your beverages without additional measurements. Designed for efficiency and precision, these laboratory alcohol meters streamline analysis and support informed decision-making.

Upgrade your device for additional throughput and parameters

The laboratory alcohol meter Alcolyzer 7001 offers enhanced flexibility with upgrade options to meet evolving needs. Add color measurement at 430 nm for deeper quality insights or integrate a single or multi-sample changer to analyze up to 24 samples in one go. These upgrades streamline workflows, increase efficiency, and provide comprehensive beverage analysis with minimal effort.

Tailored for your QC

The new Alcolyzer 5001 and Alcolyzer 7001 are specifically designed for quality control – offering fast, direct, and reliable alcohol analysis. Because they handle multiple sample types with a single device, they reduce investment costs significantly, with only a small footprint. Minimal cleaning and maintenance ensure efficient, low-effort operation in daily lab routines.

Specifications

| Alcolyzer 5001 | Alcolyzer 7001 | |

| Alcohol | ||

| Measuring range | ||

| - Beer products | 0 to 12 % v/v | |

| - Wine products | 0 to 20 %v/v | |

| - Sake products | 0 to 20 %v/v | |

| - Whiskey products | 35 to 65 %v/v | |

| - Cognac products | 0 to 65% v/v | |

| - Vinegar products | - | on request |

| Typical deviation to distillation (all products) | < 0.1%v/v | |

| Repeatability s.d. | 0.03 %v/v | 0.01 %v/v |

| Color (optional) | ||

| Measuring range | - | 0 to 120 EBC (0 - 60.96 ASBC) |

| Repeatability s.d. | - | 0.1 EBC (0.05 ASBC) |

| Temperature | ||

| Displayed temperature 1) | 15 °C or 20 °C (59 °F or 68 °F) | |

| Repeatability s.d. | 0.01 °C (0.018 °F) | |

| Sample temperature | 18 to 25 °C (64.4 °F to 77 °F) | |

| Typical measuring time | 1 to 3.5 min | |

| Sample volume | 20 mL (syringe filling) vs. 40 mL (sampler filling) | |

| Typical samples | ||

| - Beer products 2) | Beer, non-alcoholic beer, beer mixed drinks, RTDs, molasses, wash, kombucha, hard seltzer, 0.0% beers on request | |

| - Wine products 2) | Sake, cider, wine, fortified wine, non-alcoholic wines on request | |

| - Sake products 2) | Sake, cider, wine, fortified wine, non-alcoholic wines on request | |

| - Whiskey products 2) | Whiskey, tequila, spirits with < 5 g/L extract | |

| - Cognac products 2) | Cognac, rum, spirits with 5 - 20 g/L extract, non-alcoholic spirits on request | |

| Vinegar on request 4) | ||

| Instrument data and operating conditions | ||

| Data memory | Measurement data: up to 10,000 Check results: up to 300 Adjustment results: up to 300 Products: up to 40 Custom quantities: up to 50 Images: up to 50 | |

| Display | 10.1" TFT WXGA (1280x800 px); PCAP touchscreen | |

| Controls | Touchscreen, optional keyboard, mouse, and barcode reader | |

| Interfaces | 4 x USB 2.0 (type A)3), 1 x USB OTG (Micro-A), 1 x RS-232, 1 x Ethernet (100 Mbit), 1 x CAN Bus | |

| RS-232C printer settings | Baud rate: 9600; Parity: none; Stop bit: 1; Data bits: 8 | |

| Environmental conditions (EN 61010) | Indoor use only | |

| Ambient temperature | +18 °C to +32 °C (+59 °F to 89.6 °F) | |

| Air humidity | Non-condensing 20 °C: < 90 % relative humidity 25 °C: < 60 % relative humidity 30 °C: < 45 % relative humidity | |

| Altitude | Max. 3000 m (9800 ft) | |

| Maximum operating pressure | Ambient pressure | |

| Pollution degree | 2 | |

| Overvoltage category | II | |

| Voltage | 100 to 240 V~, 50/60 Hz, fluctuation ±10 % | |

| Power consumption | 90 VA | |

| Power inlet | According to IEC/EN 60320-1/C14, protection class I | |

| Fuses | Ceramic tube fuses 5x20 mm; IEC60127-2; AC 250 V; T 5 AH | |

| Dimensions (L x W x H) | 526 mm x 347 mm x 230 mm (20.7 in x 13.7 in x 9 in) | |

| Weight | 17.6 kg | |

1) The sample is actually measured at 25 °C (77 °F) to minimize condensation problems. Results are calculated according to the set temperature mode (15 °C or 20 °C).

2) Please raise an application request for customized settings.

3) USB memory devices have to be formatted with FAT32 or exFAT file system.

4) Please send a request to receive more information or a quote for an Alcolyzer 7001 Vinegar.

Standards

Mebak

EBC

BCOJ

ASBC

OIV

Standards

Mebak

EBC

BCOJ

ASBC

OIV

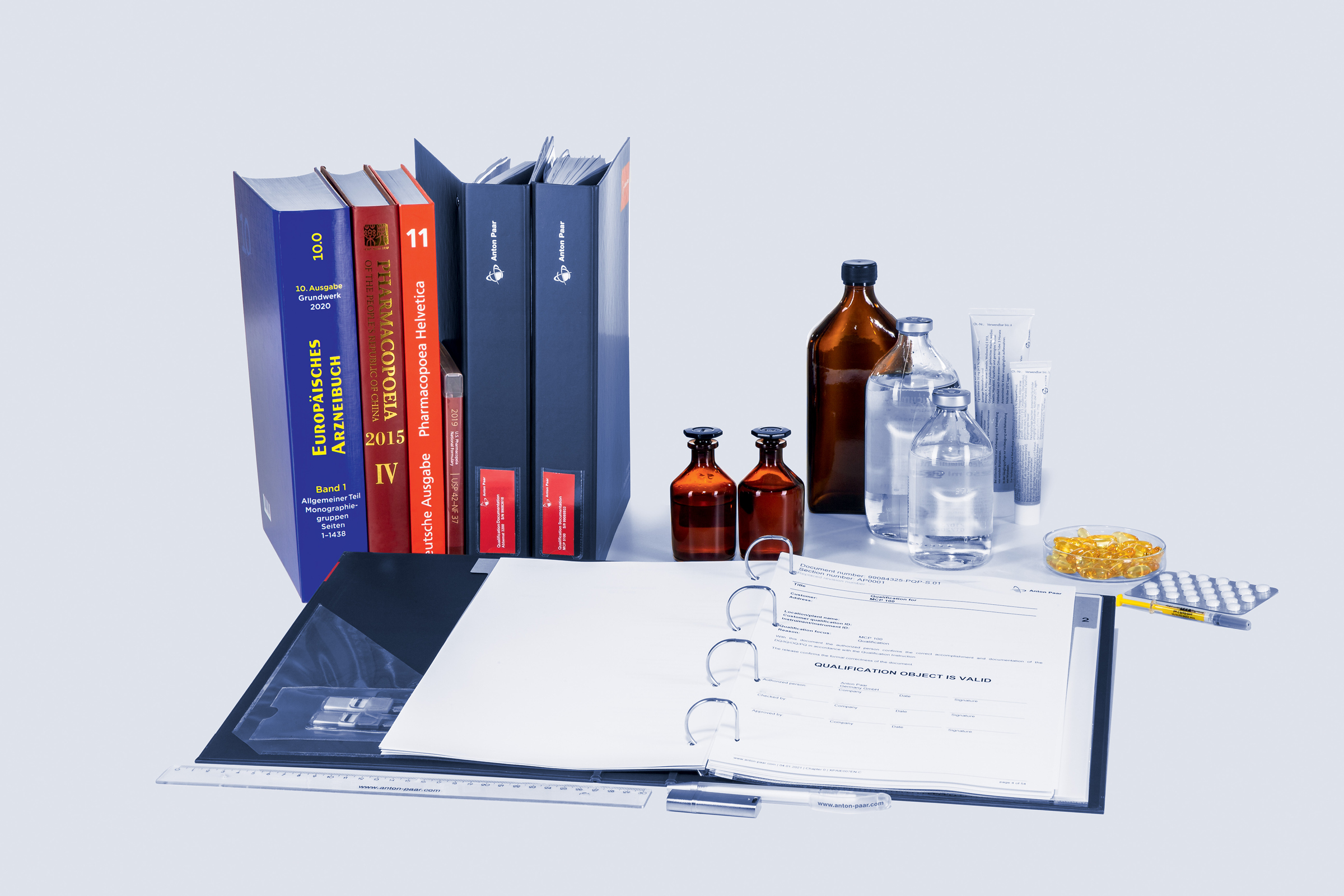

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Brochure | Beer analysis overview Brochures

-

Brochure | Spirits analysis overview Brochures

-

Brochure | Wine analysis overview Brochures

Similar products

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

Lab Execution System:

AP Connect Standard one-time license

Alcolyzer 5001

- One-time fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Standard subscription license

Alcolyzer 5001

- Annual fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Start

Alcolyzer 5001

- Kickstart your paperless lab

- Featuring key benefits of the Standard edition

- Restricted to one instrument, single user access, one export rule

PRINTER EPSON TM-U220

Alcolyzer 5001 | 7001

Sample Changer:

Xsample 520

Alcolyzer 7001

- The multi-sample changer that provides first-class filling at a snap

- Handles up to 96 samples in one magazine

- Ideal for beer, wine, soft drinks, syrups, and other aqueous samples which can be replaced without intermediate cleaning

- Multiple fillings from the same vial if required

Sample Changer:

Xsample 320

Alcolyzer 7001

- The single sample changer for easy operation

- Multiple fillings from the same vial if required

- Highly resistant wetted parts for handling of aggressive samples

- Quick replacement of the sample without intermediate cleaning