The analysis of fuels calls for robust and accurate measurement solutions. Anton Paar’s instruments provide process and laboratory measurements to identify incoming raw material, monitor production processes, or undertake fuel quality testing of final products such as diesel, ethanol, jet fuel, fuel oil, automotive gasoline, kerosene, biofuels, synthetic fuels, bunker oils, and other fuels. Parameters such as density, viscosity, distillation behavior, flash and fire point, rheological behavior, and oxidation stability can be determined by Anton Paar devices according to governmental and environmental regulations such as ASTM, EN, and ISO.

Fuel analysis at refineries

Determining the cloud and pour point of incoming crude oil

Incoming crude oil needs to flow well at all times, even at low temperatures. Cloud and pour point of crude oil can be assessed using Anton Paar rheometers and viscometers. The results tell about the crude’s flow behavior and how the concentration of pour point depressants affects the flow. Even slight changes in the concentration of these additives have a significant influence on the flow so the analysis from a rheometer can be used to find the ideal concentration of depressants to keep crude oil moving.

Certifying petroleum products and novel biofuels according to relevant standards

So that your intermediate and final products fulfill the specifications at defined process steps, Anton Paar devices are available to help you:

- Save time when determining the viscosity values of your products. Our SVM viscometer covers the whole viscosity range so you can measure everything from jet fuel to diesel with one instrument and save huge amounts of solvent and sample (only min. 1.5 mL required).

- Obtain official certification for all your products via density measurement on small sample volumes at the highest accuracy and the appropriate measuring temperature for any type of sample.

- Measure the flash point safely on a device with almost-zero maintenance requirements.

- Characterize the oxidation stability with maximum efficiency and analyze the distillation of different ASTM D86 distillation groups.

- Determine cold flow properties (cold filter plugging, pour, cloud, and freezing point) of fuels with CFPP testers and kinematic viscometers.

- Measure the refractive index to meet quality control requirements (e.g. for fuel system icing inhibitors in aviation fuels or diesel exhaust fluids such as AdBlue).

Browse standards to find the best solution

Relevant products:

SVM

DMA 4200 M

DMA

PMA 500

RapidOxy

Callisto 100

Abbemat

DMA

Diana

Automating measurements and data transfer to increase your productivity

Automating measurements is the quickest way to become more efficient and sustainable in your laboratory. By automating the filling and cleaning steps you remove the risk of handling errors, reduce the required volume of cleaning agent, and greatly improve the repeatability of your analysis. Reusing your consumables greatly benefits the environment and your budget. Anton Paar’s viscometers and density meters, for example, can be automated for continuous measurement of up to 71 samples, including fuel samples that require heating before measurement.

To increase productivity further, Anton Paar’s lab execution software communicates with your LIMS and automates your data flow (collecting, storing, representing, and transferring the measurement results), contributing to the paperless lab.

Relevant products:

Precisely measuring the mass of final products to ensure profitable trading

Knowing exactly how much fuel or LPG you are selling increases your profits without effort. The more precisely you know the density, and therefore the mass, the more beneficial your deal: By using a density meter with 5-digit accuracy, you will know the mass per barrel of your final product accurate to 1.59 g. A digit less in density accuracy already costs you a digit of knowledge on your mass per barrel.

- For the highest precision, take a device with 5-digit accuracy.

- If you are looking for quicker and very uncomplicated density measurement for internal purposes, a 4-digit device gives you solid results at an attractive price.

- For density checks from tanks and other containers on-site, we offer a portable and intrinsically safe density meter for use outdoors.

Optimizing sample preparation (digestion) for elemental analysis (ICP)

Before analysis with ICP units, e.g. to measure the exact concentration of elements like Ni, V, Si, Na, or Al in petroleum samples, a good sample preparation is key but can often keep you waiting. Microwave-assisted digestion considerably reduces the time needed to prepare your petroleum samples for ICP analysis. Anton Paar’s digestion devices provide:

- Huge time-savings compared to conventional preparation methods

- Built-in safety features to protect your staff and facility

- Menu-guided operation so personnel need only basic training

- The option to digest many different samples in one run

Complete digestion of samples is essential when investigating corrosion problems, deactivation of catalysts, or abrasion within the combustion engine and when monitoring elemental impurities.

Characterizing new fuels, blends, and solvents for greener mobility

When new formulations of solvents and fuels need to be characterized, the modular concept of Anton Paar’s portfolio of measuring instruments allows the simultaneous determination of various physical properties at the same time and under the same conditions. Only small sample volumes of a few mL are required to determine parameters such as density, sound velocity, viscosity, pH, flash point, distillation, oxidation stability, cold flow properties, and more. Measuring modules can be combined to make a system that is operated via only one user interface and, thanks to state-of-the-art Peltier technology, measurement at different temperatures is highly convenient.

Using density values as the most reliable basis for account settlement when trading

When it comes to trading of fuel, it's equally important to properly classify the sample for sales and purchase. Precise determination with fast and accurate density measurement contributes to increasing profits and to setting a reliable basis for account settlement. In the industry, compliance with density measurements according to ASTM D4052, D5002, and ISO 12185 is ensured. With the option to upgrade the density meter with automatic sample changers, providing fully automatic filling and cleaning, the efficiency of analysis is maximized.

Relevant products:

Measuring the density and viscosity of highly viscous samples

Filling your density meter or viscometer properly can be challenging when it comes to heavy samples as they require heating. Anton Paar offers heated sample changers which minimize the operator’s contact with hot substances and contribute to your lab’s safety and productivity. Even if tempering is not necessary to be compliant, heating samples makes filling quicker and easier and increases your throughput per day.

- Heated sample changer for single samples

- Headed sample changer with 36-position magazine

Obtaining the correct distillation cuts during crude oil distillation

When separating the crude oil into its constituent parts based on the different temperatures at which they evaporate and condense during refining, 1 °C can make a substantial financial difference. To make sure you take the right distillation cuts from a distillation tower, you need to know the boiling range of the product very well. You can gain this knowledge by simulating the distillation in the lab. Anton Paar’s distillation analyzer:

- Gets you the results fast – so you lose the minimum time finding the optimal cut point temperatures.

- Delivers the exact temperature at a resolution of 0.1 °C

- Provides a volume resolution of only 0.01 mL

- Guarantees maximum safety and optimized output of your crude oil

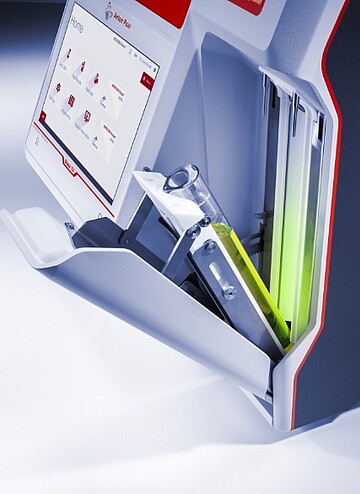

Speeding up atmospheric distillation measurement according to ASTM D86

The strict requirements for atmospheric distillation of fuels according to ASTM D86 mean that a distillation of e.g. gasoline takes 27 to 38 minutes. To help you complete more test runs in one day, Anton Paar’s distillation analyzer needs hardly any time for conditioning between samples. It also:

- Automates manual handling steps

- Gives a step-by-step guide on the screen ideal for untrained users

- Only allows a measurement to start if all steps required for compliance were completed successfully

Relevant products:

Checking the composition of incoming additives used for cracking and other manufacturing steps to ensure safe operation

When it comes to identifying raw materials on delivery, e.g. the additives used for cracking and in other manufacturing steps, mistakes can lead to uncontrolled reactions, causing risk to personnel and damage to your plant. With Anton Paar’s compact Raman spectrometers you can verify the identity of incoming goods within seconds. They need no sample preparation, chemicals, or consumables. Quick checks on incoming goods with Raman analyzers save you time and costs compared to other methods of raw material identification.

Relevant products:

Digitization and harmonization of laboratory instrument data

AP Connect is your digital hub for automated data transfer from your instruments to a central database.

With AP Connect, you can:

- Easily transfer data from your instruments to a central database, regardless of the manufacturer.

- Export measurement results to a specified location or access them directly with a standardized API.

- Drive digitalization forward and meet your requirements for streamlined data handling.

- Use AP Connect in many different applications and industries.

- Meet current regulations and requirements in the regulated environment with the Pharma Edition.

The benefits of using AP Connect:

- Increased efficiency: AP Connect automates the data transfer process, freeing up your time so you can focus on other tasks.

- Improved accuracy: AP Connect ensures that data is transferred accurately and securely, reducing the risk of errors.

- Enhanced compliance: AP Connect helps you meet regulatory requirements for data management.

- Improved decision-making: AP Connect provides you with easy access to data, so you can make informed decisions about your experiments.

If you are looking for a digital hub to help you automate data transfer, improve efficiency, and meet regulatory requirements, then AP Connect is the solution for you.

Relevant products:

Fuel testing during distribution

Checking for biodegradation and contamination during fuel storage

Having water in your fuel during storage can lead to costly and disastrous situations. To avoid this, the required dewatering process can be controlled conveniently with robust process measurement sensors. Based on the values delivered continuously by the sensor, the operator can control the valve to achieve an exact separation. This guarantees:

- Rapid reaction to variations in composition and quality

- Minimum product loss

- Reduced waste treatment costs

- Minimized risk of pollution due to human error

Depending on your plant setup, Anton Paar offers a sensor to meet your needs.

Unloading fuels without losses or mix-ups

Preventing mix-ups when unloading will keep your costs and waste low. By measuring the density online during the whole loading process, the operator can check that the correct product is being filled into the correct tank. If the measured density is outside the specified range for the expected product, the pump can be switched off immediately before contamination occurs. Anton Paar’s density sensors are:

- Robust and maintenance-free

- Ready to measure on delivery

- Designed for use in hazardous areas

Minimizing mass balance error at tank farms and fulfilling regulations

Anton Paar devices help you keep tight financial control of custody transfer points and therefore minimize the mass balance error of your tank farm. Combing our online density sensor with a volume flow meter delivers the most accurate mass determination results. You know exactly how much of each product is incoming and outgoing and reap the best financial benefit.

Minimizing product loss and waste when using multiproduct pipelines

To achieve the best product cut in multiproduct lines you need a sensor that detects the product within one second. Anton Paar’s online sensor tells you immediately as soon as the product is outside the defined range so you can close the valve. This sensor will minimize product loss and waste and save you money.

On-site density measurements in hazardous areas (Ex-zone 1)

Working in hazardous areas (Ex-zone 1) you need intrinsically safe instrumentation, e.g. when measuring the density of your petroleum product at the terminal to check whether you will fill the right fuel to your storage tank. Anton Paar’s portable DMA 35 Ex petrol measures specific gravity quickly and directly on-site. Thanks to its ATEX approval it is safe to use directly at the terminal before pumping. The density meter is ASTM D7777 compliant, guarantees user safety, and carries out all relevant unit conversions automatically. It directly takes a small sample volume of only 2 mL from the storage container via its built-in pump.

Relevant products:

Simulating the behavior of final products to understand their stability in storage

Before and after transportation, Anton Paar devices can help you assess the storage behavior of your finished products so you can predict how they behave under certain ambient conditions.

- Discover at which temperatures the product starts to evaporate and forms vapors to ensure the correct classification and storage conditions.

- Check the oxidation stability to avoid problems later such as rust, corrosion, and filter blocking in an engine system.

Relevant products:

Defining the hazard class for transportation and handling

To evaluate the flammability and assign a hazard classification before transportation you need to know the flash point. Anton Paar’s flash point testers implement referee methods used internationally for releasing petroleum products and are also used for the flash point determination of solvents or solvent mixtures. Choose your method:

- Pensky-Martens

- Cleveland

- Tag

- Abel

Relevant products:

Checking the authenticity of fuels to avoid adulteration

When buying fuels from suppliers you want to make sure that you receive the right product and not an adulterated fuel mixed with cheap components as this would lower the quality of the fuel and damage the engines and the relationship with your end customers. With Anton Paar’s compact Raman spectrometers you can quickly verify the quality of incoming goods within seconds directly at the warehouse. The portable instruments are used without any sample preparation, chemicals, or consumables, thereby reducing waste and providing a quick and low-cost approach to raw material identification.

Relevant products:

Fuel analysis for consumers

On-board measurements to check the quality of maritime fuels

To protect the engines of your ships from low-quality fuels you can use an Anton Paar density meter to check the fuel in just a few seconds before fueling. If the quality is low, you still have time to refuse it. The DMA density meters are built to withstand work on board, the vibrations of the ship do not affect the measurement. For extra flexibility, our handheld density meter is the ultimate outdoor option.

To quickly check whether the fuel has aged in storage, our small-footprint oxidation stability tester gives you the answer up to 20 times faster than other oxidation stability testers and requires no chemicals or sample preparation work.

Relevant products:

Calculating the correct CO2 emission tax based on measurement of jet fuel mass

By upgrading your existing flow meters with Anton Paar’s process density sensors, the mass of a fuelled product in an airplane can be accurately determined with only little integration effort. This lays the foundation for accurately calculating the CO2 emission tax.

Gum content measurements in fuels to avoid engine damage

As a manufacturer of fuels or a testing laboratory, you want to make sure that there is no residue in your product that could harm car and aircraft engines. Anton Paar’s gum content tester delivers this analysis in a few minutes after only a short setup time. It provides safety features to protect operators from hot parts and hot steam.

Relevant products:

Fuel analysis at testing laboratories

Higher productivity and efficient data flow in the lab

In contract laboratories and testing labs, minimizing the time and cost per sample can be achieved by:

- Increasing sample throughput by automating the filling and cleaning process, e.g. by adding a sample changer or heated sample changer to your density meters and viscometers

- Reducing solvent consumption by automating filling, even for single samples

- Employing lab execution software for seamless data flow to your LIMS and ultimate traceability for protocols in the paperless lab

Relevant products:

Automating sample preparation for more efficient lab processes

Freeing up your lab personnel from repetitive work will increase your sample throughput and reduce the potential for human error. Anton Paar’s automated solution covers sample identification, vial capping, sub-sampling, mixing, and dosing. The system also works at night and on weekends, preparing your samples for downstream analytics in the fastest way possible.

Our engineering team analyzes your workflow and custom-tailors the right setup, including:

- Bi-directional communication with your LIMS

- The combination of work steps you need

Large-scale automation for many different methods and the highest throughput

As the ultimate answer to the need for high sample throughput and minimized human interaction, Anton Paar’s automation platform takes care of sample preparation and analytics customized to your requirements, e.g.:

- 5 viscometers plus 5 density meters

- Combinations with an Anton Paar rheometer and robotic arm

- Third-party devices, including heating ovens, analyzers with flow cells, balances, and more

The platform runs multiparameter analysis while your lab personnel work on other tasks. Our engineering team customizes the setup to suit your routines.

Relevant products:

Digitization and harmonization of laboratory instrument data

AP Connect is your digital hub for automated data transfer from your instruments to a central database.

With AP Connect, you can:

- Easily transfer data from your instruments to a central database, regardless of the manufacturer.

- Export measurement results to a specified location or access them directly with a standardized API.

- Drive digitalization forward and meet your requirements for streamlined data handling.

- Use AP Connect in many different applications and industries.

- Meet current regulations and requirements in the regulated environment with the Pharma Edition.

The benefits of using AP Connect:

- Increased efficiency: AP Connect automates the data transfer process, freeing up your time so you can focus on other tasks.

- Improved accuracy: AP Connect ensures that data is transferred accurately and securely, reducing the risk of errors.

- Enhanced compliance: AP Connect helps you meet regulatory requirements for data management.

- Improved decision-making: AP Connect provides you with easy access to data, so you can make informed decisions about your experiments.

If you are looking for a digital hub to help you automate data transfer, improve efficiency, and meet regulatory requirements, then AP Connect is the solution for you.

Relevant products: