Multiparameter Measurement System:

Sake Measurement System

- Single analyzing system for fermentation checks and finished sake

- 10x quicker: No distillation required for alcohol analysis

- Simultaneous measurement of alcohol and sake meter value

- Automatic checks and calibrations via built-in SOP

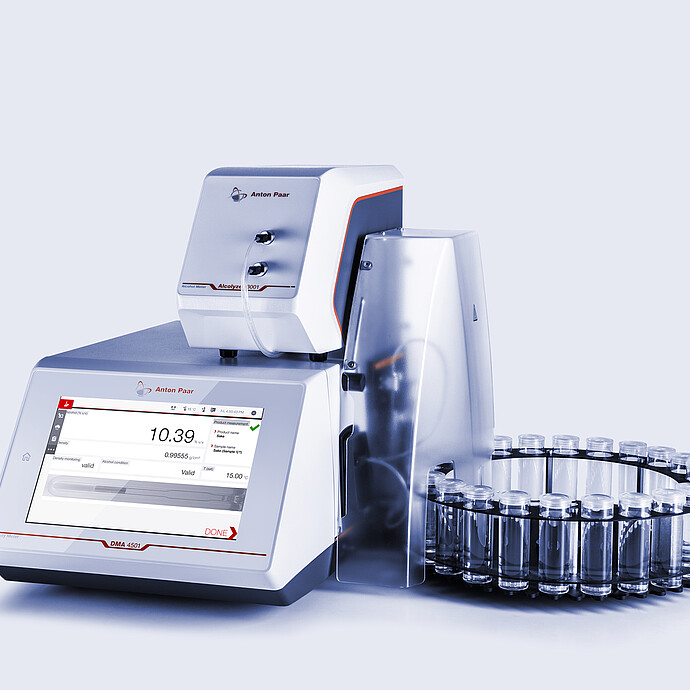

- DMA 4501, Xsample 520, Alcolyzer 3001 Sake

Designed to streamline both fermentation monitoring and final product analysis, the Sake Measurement System combines the efficiency of the DMA 4501 density meter, the precision of the Xsample 520 sample changer, and the accuracy of the Alcolyzer 3001 Sake for unparalleled measurement capabilities. Offering immediate results without distillation, it enables simultaneous measurement of alcohol content and sake meter value. Equipped with automatic checks and calibrations via built-in Standard Operating Procedures (SOP), this system ensures reliable and consistent results, optimizing the sake production process and enhancing product quality while workloads decrease significantly.

Key features

Comprehensive sake analysis with single system

This all-in-one measurement system is specifically designed for both fermentation monitoring and final product testing in sake production. It integrates a sample changer, a precision density meter, and a near-infrared (NIR) spectrometer. The system provides a streamlined and efficient method to specifically quantify the ethanol content, ensuring consistency and quality in the brewing process. This powerful combination of tools offers sake producers a robust solution for maintaining optimal fermentation conditions and verifying the final alcohol content in their products.

Streamline your measurements with AP Connect software

Use AP Connect software with the Sake Measurement System. Firstly, it will facilitate seamless integration and management of data across devices, ensuring that all measurement information is centralized and easily accessible. Secondly, it will enhance operational efficiency by automating data transfer, which minimizes manual input errors and saves time. Lastly, it will provide robust data security features, ensuring that sensitive measurement data is protected against unauthorized access.

Advanced sake measurement

The Sake Measurement System is specifically designed for the sake industry. This system facilitates simultaneous assessments of both alcohol content and sake meter value: essential metrics for quality control in sake production. The density meter accurately gauges the density of the sake, which is crucial for determining the sake meter value, while the spectrometer is finely tuned to precisely quantify ethanol content. By integrating these technologies, the system streamlines the analytical process, allowing for real-time monitoring and optimization of production parameters, ensuring consistent and high-quality sake products.

Automate your processes, enhance efficiency

The Sake Measurement System, with automatic checks and calibrations via built-in Standard Operating Procedures (SOP), offers significant advantages for customers. First, it ensures consistent accuracy and reliability of results by standardizing processes, reducing human error, and maintaining instrument precision. Second, it streamlines workflows and saves time as the system autonomously performs necessary adjustments without requiring manual intervention. Lastly, this automation enhances overall efficiency and reduces operational costs by minimizing downtime and the need for frequent manual recalibrations.

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty