Accessory for Used-Oil Analysis:

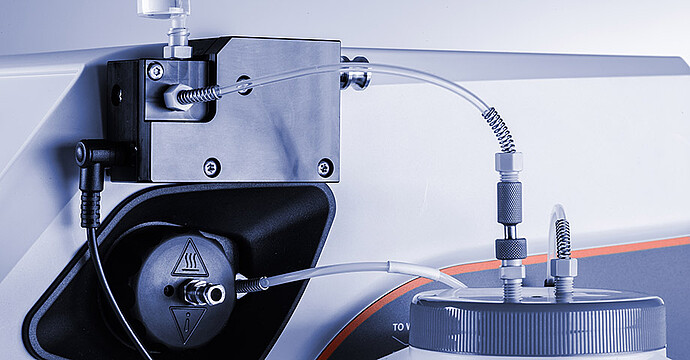

Magnetic Particle Trap (MPT)

- Compatible with SVM 1001

- Easy and efficient removal of ferromagnetic particles, making it ideal for used-oil analysis

- Automatic heating for the best performance

- Maintenance-free

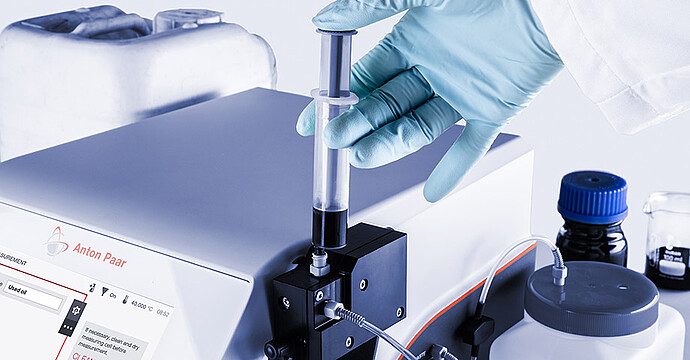

An accessory for our SVMs, the magnetic particle trap (MPT) combined with an SVM Smart Viscometer offers accurate used-oil analysis thanks to efficient removal of ferromagnetic particles before the sample reaches the SVM measuring cells. No additional lab equipment is required as the trap is directly mounted on the instrument and enables direct filling into the instrument.

With it, combine the familiar benefits of SVM viscometers with the requirements of in-service-oil / used-oil testing and oil-condition monitoring (OCM) in industries like transportation, mining, and power generation. What’s more, when purchased with an SVM, the MPT comes already installed and is upgradeable anytime, anywhere.

Key features

Analyze used oil more efficiently

- Electrical heating decreases the sample’s viscosity to optimize filtration efficiency

- Smart design saves sample, solvent, and lab space

Save lab space due to its compact size

- Mounted directly on the instrument

- No additional lab equipment required

Easy to clean and ready to use

- Simplified cleaning with a newly developed latching mechanism

- When ordered together with an SVM, the MPT comes already installed, ready for use

Technical specifications

| Magnetic Particle Trap | |

|---|---|

| Maximum operating pressure | 5 bar (72 psi) relative |

| Wetted materials (sample channel) | brass |

| Input power magnetic particle trap | 15 V DC / 2.4 A |

| Maximum temperature in normal use | 80 °C (176 °F) |

| Thermal malfunction circuit breaker (PTC) at 115 °C (239 °F) for heating circuit | |

| External Power Supply | |

|---|---|

| Input voltage range /current / frequency | 100 to 240 V AC / 1.0 A / 50 to 60 Hz |

| Output voltage / current / DC output power | 15 V DC / 2.4 A / 36 W |

| Environmental conditions (EN 61010) | Indoor use only |

| Ambient operating temperature | 0 °C to 40 °C (32 °F to 104 °F) |

| Storage temperature | -20 °C to 85 °C (-4 °F to 185 °F) |

| Short circuit protection | Permanent |

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Compatible instruments

Similar products

The magnetic particle trap for SVM™ X001 Viscometer allows for determining the viscosity index or kinematic viscosity of in-service lubricants without blocking the viscosity measuring cell.

Consumables

Consumables

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

CABLE TIE HEAT-RESISTANT 100 pcs

Magnetic Particle Trap (MPT) SVM 1001 | SVM x001

HOSE 8x12 PERBUNAN

Magnetic Particle Trap (MPT) SVM 1001 | SVM x001

ADAPTER LUER LOCK 1/4""-28 UNF PEEK

Magnetic Particle Trap (MPT) SVM 1001

CAN INTERFACE CABLE 0.6m

Magnetic Particle Trap (MPT) SVM x001

HOSE 155x3x2 FEP 2x1/4"-28 UNF

Magnetic Particle Trap (MPT) SVM 1001 | SVM x001

WASH BOTTLE PE 500 ml LUER CONE

Magnetic Particle Trap (MPT) SVM 1001 | SVM x001

PROTECTION CAP, BLACK (SQUARE USB INTERFACE)

Magnetic Particle Trap (MPT) SVM x001

HOSE 300x3x2 FEP 2x1/4"-28 UNF "AA"

Magnetic Particle Trap (MPT) SVM x001

O-RING 3x1 KALREZ 6375 SPECTRUM

Magnetic Particle Trap (MPT) SVM x001