Accessory for Step Platforms:

Heating module

- Excellent thermal stability with testing temperatures up to 450 °C

- Correlation of surface mechanical properties with temperature

- Installation directly on the Step platform

Our heating stages enable simulation of real conditions and correlate the test temperature with surface mechanical properties.

Key features

Choose the ideal module for your application

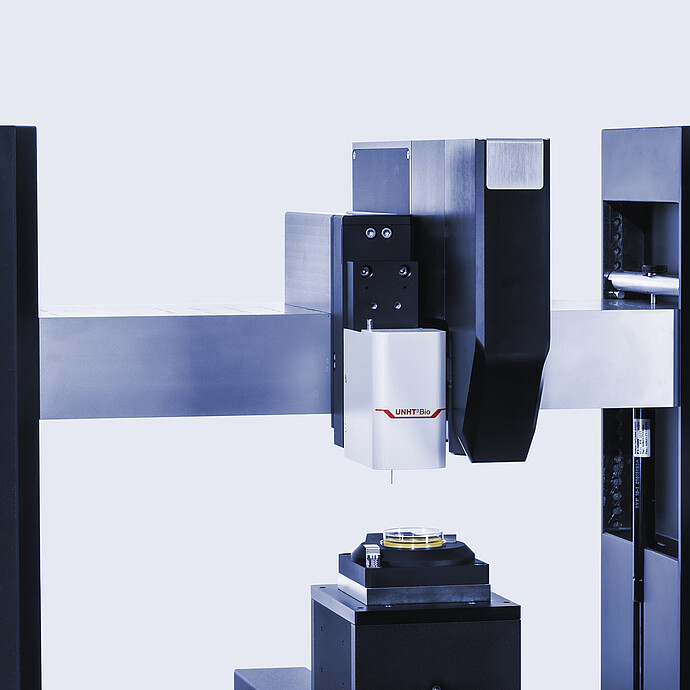

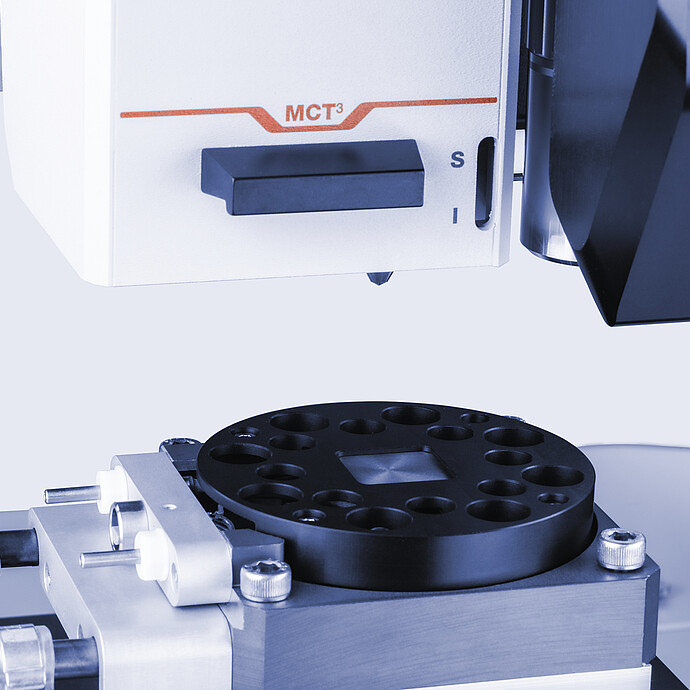

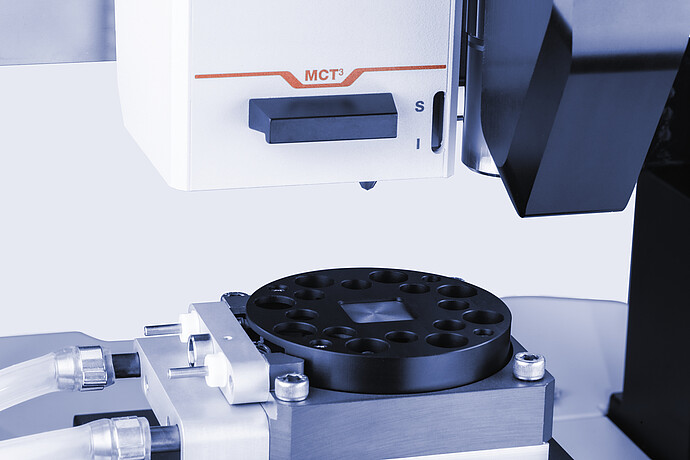

Choose from three heating modules depending on your application. The 200 °C heating module is compatible with MCT³ and UNHT³ for testing the glass transition temperature (Tg) of various bulk polymer samples or thin polymer layers. The 450 °C heating module, compatible with MCT³ and UNHT³ HTV, is the best choice for testing metals and alloys at elevated temperatures. The Petri dish heater for UNHT³ BIO, with test temperatures up to 50 °C, can mimic real biological conditions e.g. for tests at body temperature (37 °C).

Test in dry or liquid conditions

Perform tests at elevated temperatures in both dry and liquid conditions with precise temperature feedback using an integrated thermocouple – and control with the software.

Save time with the automatic temperature test procedure

Correlate surface mechanical property evolution with test temperatures. Perform automated measurements using our temperature scan mode, employing a stepwise temperature increase approach. Define mechanical test parameters and temperature steps, and run the automatic procedure.

Technical specifications

| Technical data | 200C heating module | 450C heating module | Petri dish heater |

| Temperature range | +23 °C to +200 °C | +23 °C to +450 °C | +23 °C to +50 °C |

| Test conditions | Dry | Dry | Dry/liquid |

| Temperature measurement resolution | 0.1 °C | 0.1 °C | 0.1 °C |

| Heating element dimension | 25 x 50 mm | Ø 25 mm | Ø 20 mm |

| Sample dimension | 25 x 40 mm | Ø 25 mm disk | Ø 35 mm Petri dish |

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty