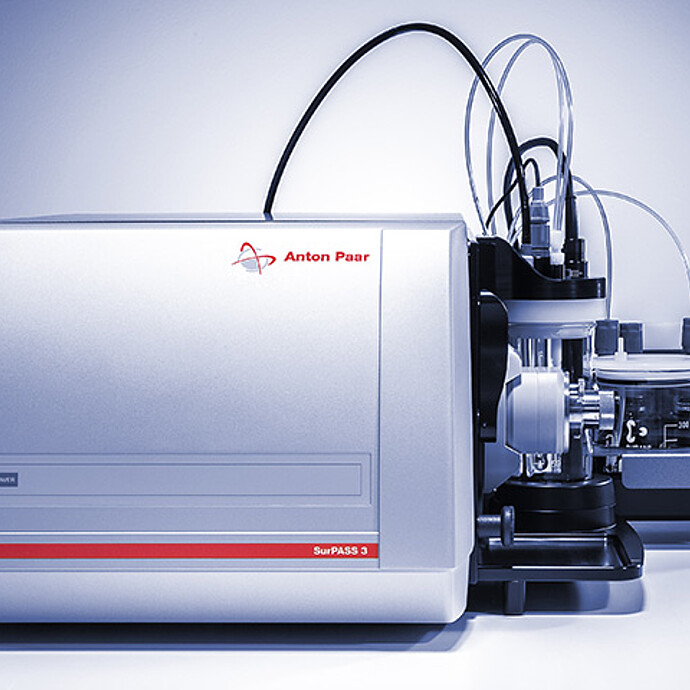

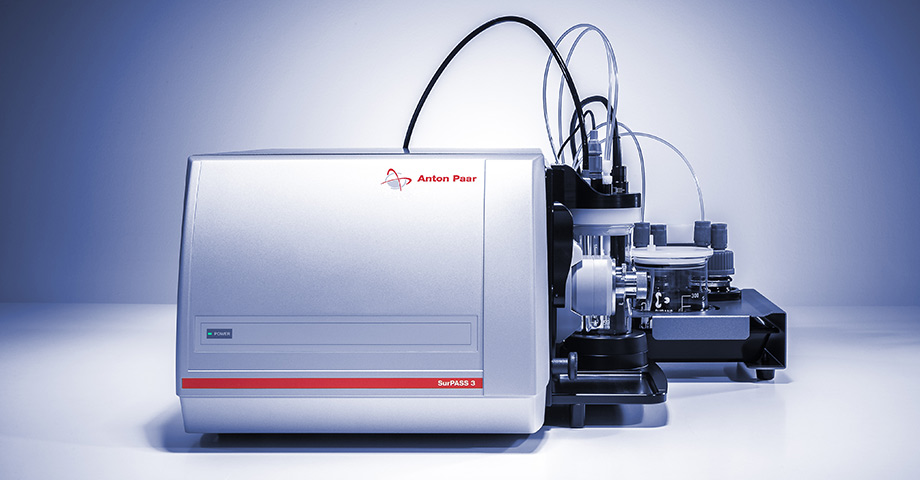

Electrokinetic Analyzer for Solid Surface Analysis:

SurPASS 3

- High-end electrokinetic analyzer for solid surface analysis

- Fully automated zeta potential analysis on macroscopic solids

- Automated detection of the isoelectric point

- Time-dependent recording of liquid-on-solid adsorption kinetics

The SurPASS 3 series features fully automated zeta potential analysis of macroscopic solids under real-life conditions. As electrokinetic analyzers, they employ the classic streaming potential and streaming current method for a direct analysis of the surface zeta potential. The zeta potential is related to the surface charge at a solid/liquid interface and is a key parameter for understanding surface properties and developing new specialized materials.

Key features

Solid surface charge analysis made easy

The SurPASS 3 series allows for direct analysis of the zeta potential at the solid/liquid interface by means of streaming potential and streaming current measurement. This gives access to the full range of zeta potential of technical materials down to a few millivolts at unprecedented reliability and reproducibility. Gain instant access to information on surface charge without the need for sophisticated evaluation or expert knowledge.

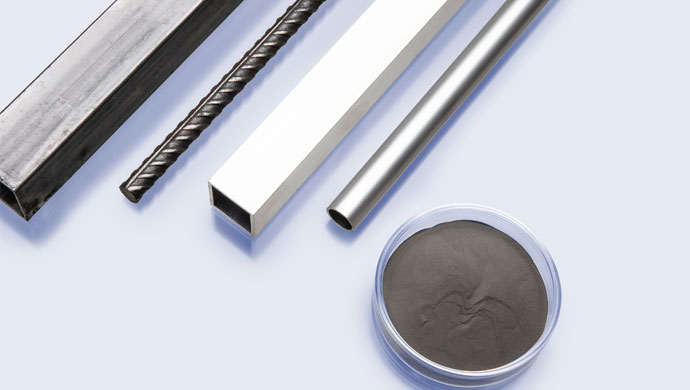

Measuring solutions from tiny particles to large wafers

The wide range of SurPASS 3 measuring cells covers it all: Elaborate measuring cells accommodate samples of any geometry ranging from powders and fibers to planar solids. Sample-specific measuring cells for contact lenses, hollow fiber membranes, flexible tubings, syringes, and vials open up surface charge analysis on samples with complex geometries. The “plug in and start” functionality allows for a quick exchange of measuring cells. The software automatically recognizes the measuring cells and displays the zeta potential.

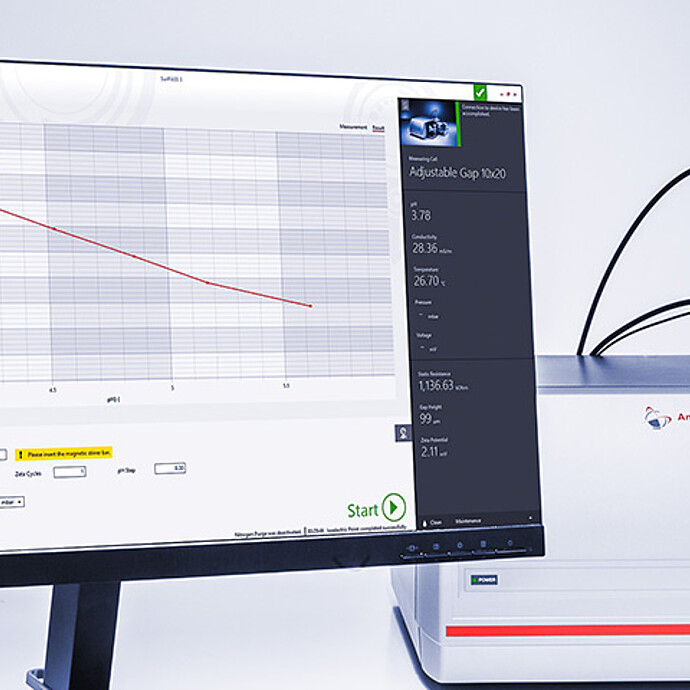

Fully automated measurements in less than two minutes

The intuitive SurPASS 3 software guides you through the measurement and displays all key parameters in real-time. The SurPASS 3 series provides zeta potential results in less than two minutes for maximized sample throughput. SurPASS 3 allows you to study pH dependences of zeta potential fully automatically and reveals the isoelectric point for a deep understanding of your sample’s chemistry. Liquid-on-solid surface adsorption kinetics can also be followed in real-time on model surfaces and on your actual sample.

Modular setup tailored to your needs

The SurPASS 3 series is just as versatile as your applications. Dedicated solutions are available for membrane applications, biomaterials, cosmetics, detergents, and semiconductors. Whether you are working on porous materials, such as membranes, or non-porous films and plates, particles >25 µm, granular material, fibers, or materials which swell strongly or are conductive: there are no restrictions. The modular setup of the instrument and measuring cells allows you to easily extend your zeta potential analysis to cover tomorrow’s needs.

Specifications

| SurPASS 3 | SurPASS 3 Eco | |

| Measuring range | ||

| Streaming potential | ±2000 mV ± (0.2 % + 4 μV) | |

| Streaming current | ±2 mA ± (0.2 % + 1 pA) | |

| Cell resistance | 5 Ω to 20 MΩ ± (2 % + 0.5 Ω) | |

| Pressure measurement | 3500 mbar ± (0.2 % + 0.5 mbar) External pressure supply (compressed N₂) is required for differential pressure > 1200 mbar | 1200 mbar ± (0.2 % + 0.5 mbar) |

| pH value | pH 2 to pH 12 | |

| Conductivity | 0.1 mS/m to 1000 mS/m | |

| Temperature | 20 °C to 40 °C Temperature control option is available | |

| Sample size requirements | ||

| Porous films, foils, or plates | Rectangular-shaped: 20 mm x 10 mm (max. thickness: 2 mm ) Disk-shaped: 14 mm or 15 mm in diameter (max. thickness: 2 mm) | |

| Non-porous films, foils, or plates | Rectangular-shaped: 20 mm x 10 mm (max. thickness: 2 mm) or min. 35 mm x 15 mm (max. thickness: 40 mm) Disk-shaped: 14 mm or 15 mm in diameter (max. thickness: 2 mm) or min. 17 mm in diameter (max. thickness: 40 mm) | |

| Particles | Particle size: min. 25 μm | |

| Fibers | Min. 100 mg | |

| Fabrics | Min. 30 mm x 30 mm | |

| Hollow fiber membranes | Length: min. 170 mm | |

| Ceramic membranes | Flat sheet: 14 mm in diameter Single channel: outer diameter 10 mm or 13 mm Multichannel: outer diameter 25 mm or 30 mm | |

| Cylindrical cores | Height: max. 4 inch Diameter: 1 inch | |

| Flexible tubing | Length: min. 100 mm Outer diameter: 0.7 mm to 6 mm | |

| Pre-filled syringes | Syringe barrel “1.0 mL long” (ISO 11040-4) | |

| Vials | 2R/4R vials (ISO format), outer diameter 16 mm | |

| Technical requirements | ||

| Mains supply | AC 115 to 230 V, 50 to 60 Hz, 200 VA | |

| Dimensions | 600 mm x 432 mm x 245 mm (D x W x H) Footprint: 612 mm x 536 mm (D x W) Clearance: 360 mm | |

| Weight | 26 kg | 24 kg |

| Software requirements |

| |

Standards

ISO

Standards

ISO

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

All Eyes on This: Streaming Potential Analysis of Contact Lenses Application Reports

-

Assessing the Zeta Potential at High Salinity Application Reports

-

Beyond surface charge to wettability: The extra gear of the zeta potential Application Reports

-

Biofouling – when Adhesion is a Double-edged Sword Application Reports

-

Black and green: catalyst and membranes for fuel cells Application Reports

-

Dynamic Streaming Potential: Basics and Applications Application Reports

-

Dynamic streaming potential analysis Episode 1: Application in textile care Application Reports

-

Dynamic streaming potential analysis Episode 2: Application to medical devices Application Reports

-

E-Book - A Practical Guide for Great Building Materials Application Reports

-

E-Book - Polymer Processing Application Reports

-

Evaluation methods for the zeta potential of solid surfaces Application Reports

-

Evidence of membrane fouling monitored by AFM and zeta potential Application Reports

-

From Pottery to Membranes: Characterization of Ceramic Powders and Surfaces Application Reports

-

Functionalized Foils in Food Packaging: A Surface Analysis Application Reports

-

How does Carbon Dioxide Affect the Surface Zeta Potential? Application Reports

SurPASS 3 Publications

Asymmetric layer-by-layer polyelectrolyte nanofiltration membranes with tunable retention

Scheepers D, Chatillon B, Nijmeijer K, Borneman Z. Asymmetric layer-by-layer polyelectrolyte nanofiltration membranes with tunable retention. Journal of Polymer Science. 2021; 59: 1293. https://doi.org/10.1002/pol.20210166

Influence of protein adsorption on aggregation in prefilled syringes

Yoneda S, Maruno T, Mori A, Hioki A, Nishiumi H, Okada R, Murakami M, Zekun W, Fukuhara A, Itagaki N, Harauchi Y, Adachi S, Okuyama, K, Sawaguchi T, Torisu T, Uchiyama S. Influence of protein adsorption on aggregation in prefilled syringes. Pharamceutical Biotechnology. 2021; 110: P3568. https://doi.org/10.1016/j.xphs.2021.07.007

Surface zeta potential of ALD-grown metal-oxide films

Xia Z, Rozyyev V, Mane AU, Elam JW, Darling SB. Surface zeta potential of ALD-grown metal-oxide films. Langmuir. 2021; 37: 11618. https://doi.org/10.1021/acs.langmuir.1c02028

Tailoring the chemical functionalization of a transparent polyethylene foil for its application in an OLED-based DNA biosensor

Dansico E, Maroh B, Feldbacher S, Mühlbacher I, Schlögl S, Melpignano P. Tailoring the chemical functionalization of a transparent polyethylene foil for its application in an OLED-based DNA biosensor. Applied Surface Science. 2021; 552: 149408. https://doi.org/10.1016/j.apsusc.2021.149408

Applicability of electro-osmotic flow for the analysis of the surface zeta potential

Plohl O, Fras Zemljic L, Potrc S, Luxbacher T. Applicability of electro-osmotic flow for the analysis of the surface zeta potential. RSC Advances. 2020; 10: 6777. https://doi.org/10.1039/C9RA10414C

Physicochemical characterization of packaging foils coated by chitosan and polyphenols colloidal formulations

Zemljič LF, Plohl O, Vesel A, Luxbacher T, Potrč S. Physicochemical characterization of packaging foils coated by chitosan and polyphenols colloidal formulations. International Journal of Molecular Sciences. 2020; 21(2):495. https://doi.org/10.3390/ijms21020495

Chitosan/glycosaminoglycan scaffolds for skin reparation

Sandri G, Rossi S, Bonferoni MC, Miele D, Faccendini A, Del Favero E, Di Cola E, Cornaglia AI, Boselli C, Luxbacher T, Malavasi L, Cantu L, Ferrari F. Chitosan/glycosaminoglycan scaffolds for skin reparation. Carbohydrate Polymers. 2019; 220: 219. https://doi.org/10.1016/j.carbpol.2019.05.069

MS2 bacteriophage inactivation using a N-doped TiO2-coated photocatalytic membrane reactor: Influence of water-quality parameters

Horovitz I, Avisar D, Luster E, Lozzi L, Luxbacher T, Mamane H. MS2 bacteriophage inactivation using a N-doped TiO2-coated photocatalytic membrane reactor: Influence of water-quality parameters. Chemical Engineering Journal. 2018; 354: 995. https://doi.org/10.1016/j.cej.2018.08.083

New collagen-coated calcium phosphate synthetic bone filler (Synergoss®): A comparative surface analysis

Iviglia G, Morra M, Cassinelli C, Torre E, Rodriguez Y Baena R. New collagen-coated calcium phosphate synthetic bone filler (Synergoss®): A comparative surface analysis. International Journal of Applied Ceramic Technology. 2018; 15: 910. https://doi.org/10.1111/ijac.12854

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

Measuring Cell for Core Samples

SurPASS 3 Standard | Eco

- Non-destructive zeta potential analysis of core samples for EOR studies

- Analyzes both axial and radial surfaces of core samples

- Tangential measurement mode to study fluid-rock surface interactions

- Efficient method without crushing core samples, enabling zeta potential gradients