Reliable Steel Analysis for Safer, Stronger Structures

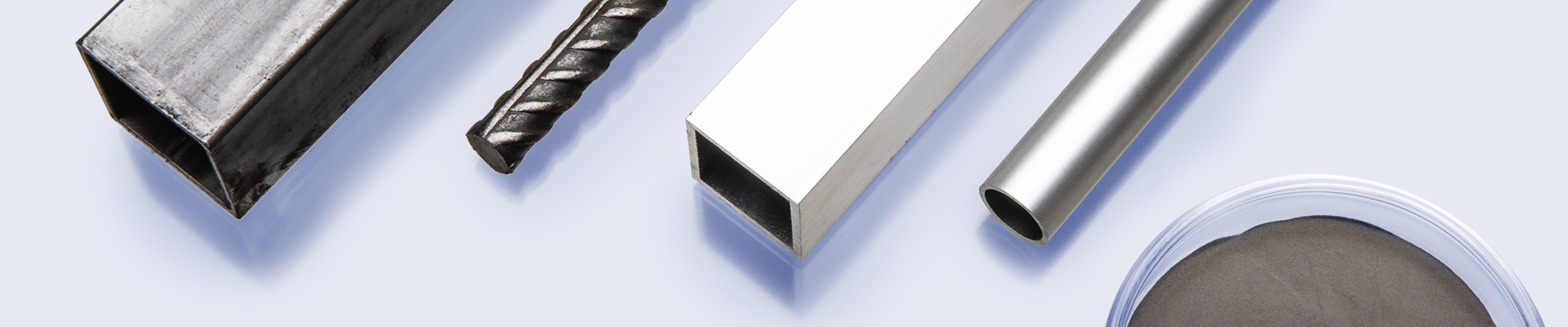

Steel is essential to modern construction and infrastructure – and so is knowing exactly how it will perform. Corrosion resistance, hardness, and compositional integrity are key to ensuring structural components remain safe, durable, and compliant over time. From bridges and tunnels to reinforcing bars or anchor wires, precise steel analysis helps meet quality standards and optimize performance.

Explore practical approaches to analyzing steel properties using proven methods and technologies from industry and research. For a deeper dive into application examples and measurement data, download the free e-book – a comprehensive guide to material analysis in the building sector.

Why Steel Analysis Matters

Steel plays a key role in the safety and longevity of buildings, bridges, pipelines, and industrial systems. Beyond its strength, however, the long-term performance of steel relies on a range of other factors – such as corrosion resistance, mechanical stability, and precise alloy composition. Surface defects, contamination, or incorrect alloying, can cause steel to corrode prematurely, lose structural integrity, or fail under load, all of which lead to serious consequences for safety and cost.

Advanced steel analysis techniques – such as those below – are essential to mitigating these risks.

Nanoindentation, for example, is used to reveal hardness gradients within steel components, which are especially important in fatigue-sensitive structures like bridge anchor wires.

Zeta potential measurements assess the effectiveness of surface coatings, which helps distinguish materials that offer superior corrosion resistance in aggressive environments.

Microwave digestion, in combination with elemental analysis, accurately quantifies key alloying elements such as chromium, nickel, molybdenum, and vanadium.

And porosity and density analysis identify voids or inclusions that compromise material performance, thereby supporting quality control.

Precise, data-driven steel analysis enables engineers and quality professionals to detect issues early, ensure compliance with standards such as ASTM, ISO, and EN, and make confident decisions that improve both product reliability and lifecycle performance.

The Must-Read Anton Paar E-Book on Building Materials

Learn how to improve the performance and durability of building materials with Anton Paar’s free e‑book, Building Better: A Practical Guide for Great Building Materials. The guide explores key topics such as hardness, corrosion resistance, and surface analysis for metals, and offers expert guidance on concrete and composite testing. It’s ideal for engineers, researchers, and quality professionals aiming to meet modern standards with confidence.

Learn how to improve the performance and durability of building materials with Anton Paar’s free e‑book, Building Better: A Practical Guide for Great Building Materials. The guide explores key topics such as hardness, corrosion resistance, and surface analysis for metals, and offers expert guidance on concrete and composite testing. It’s ideal for engineers, researchers, and quality professionals aiming to meet modern standards with confidence.

Comprehensive Steel Analysis: From Corrosion to Composition

Each property of steel – from its elemental composition to its surface behavior – plays a role in ensuring structural reliability, compliance, and longevity. That’s why Anton Paar offers steel analysis solutions that assess corrosion resistance, mechanical gradients, porosity, and coatings – ensuring safety, performance, and longevity in even the most demanding applications.

Elemental Analysis via Microwave Digestion

The accurate determination of alloying constituents in steels and nickel-based alloys is both technically and commercially significant – but also analytically demanding.

As part of broader steel analysis, Anton Paar’s microwave digestion systems – when paired with ICP-OES – enable accurate determination of elements. Multiwave 5001 delivers reliable digestion even for hard-to-digest metals, reaching temperatures up to 300 °C with advanced SmartVent technology. Proven recovery rates (91 % to 103 %) also confirm its suitability for certified reference materials and high-performance metal samples.

Measuring Coating Performance Against Corrosion

Corrosion can significantly shorten the lifespan of steel, especially in aggressive environments like seawater. Anton Paar’s SurPASS 3 analyzer uses zeta potential measurements to evaluate surface charge and conductivity – helping to improve the effectiveness of protective coatings.

Tests on stainless steel surfaces using the SurPASS 3 revealed that uncoated samples had the highest surface conductance. Coatings like DLC, SICAN, and SICON significantly reduced conductivity, with SICON, in particular, showing strong insulating properties – ideal for long-term corrosion protection.

Insights like these support more effective steel analysis in corrosion-focused applications, which in turn helps manufacturers design coatings that both last longer and perform better.

Test Coating Adhesion on Galvanized Steel

Anton Paar’s NST³, MCT³, and RST platforms are ideal tools for galvanized and coated steel.

By assess coating adhesion, thin film durability, and scratch resistance through instrumented indentation and progressive load testing, they assist manufacturers to ensure protective layers stay intact and perform as intended, even under demanding environmental and mechanical conditions.

Hardness Gradients in Steel Wires

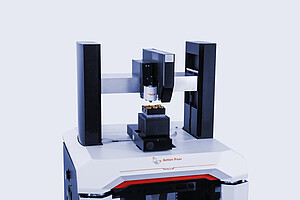

Anton Paar’s Step Platform with NHT³ Measuring Head uses high-resolution nanoindentation to map variations in hardness and elastic modulus. This is critical in applications such as bridge anchors, where steel must maintain mechanical strength across its entire cross-section.

Testing with the Step Platform with NHT³ Measuring Head revealed a consistent increase in stiffness from the core to the surface of steel wires – a key indicator of how the material handles stress and fatigue. By identifying these gradients, engineers can optimize designs, prevent premature failure, and meet the mechanical demands of critical infrastructure.

Advanced Testing to Prevent Steel Failures Before They Start

Anton Paar delivers fast, reliable steel analysis of material properties at every stage – from material development to quality assurance. These insights are critical for improving product reliability, meeting international standards, and preventing failures in environments such as construction, infrastructure, and energy.

By enabling accurate measurement of properties like hardness, zeta potential, elastic modulus, and plastic deformation, Anton Paar instruments reduce the need for trial-and-error in steel development – helping to optimize processing parameters early, reduce costs, and ensure faster compliance.

The Step Platform with NHT³ Measuring Head, for example, offers critical insights into how steel behaves under stress using high-resolution nanoindentation to map hardness and elastic modulus. In demanding applications like bridge anchors, this level of detail can reveal structural gradients that directly influence fatigue life.

The SurPASS 3 analyzer, which uses zeta potential to assess surface charge and conductivity, has verified the insulating performance of advanced coatings such as SICON in harsh environments like seawater.

The Multiwave 5001 microwave digestion system enables complete decomposition of challenging steel samples for accurate alloy verification. When paired with ICP-OES, it delivers dependable trace element recovery – supporting both quality control and the development of high-performance alloys.

Trusted by manufacturers and researchers alike, Anton Paar solutions offer proven performance across applications such as the testing of stainless steel, coated components, and advanced structural materials – supporting better decision-making throughout the material lifecycle.

Gain deeper insights into optimizing steel for performance and safety