Anton Paar's measuring instruments deliver hard facts on crude oil properties, essential for optimizing drilling, yield, treatment, and transportation. By evaluating and simulating well conditions, you can optimize drilling and improve reservoir yield.

Anton Paar's wide range of crude oil analysis solutions includes density, viscosity, flash point, rheological behavior, salinity, and refractive index measurement as well as sample digestion for trace analysis. This knowledge optimizes crude oil treatment and ensures hassle-free transportation to the refinery.

Use crude oil analysis for exploration and production

Choosing the right extraction strategy based on actual reservoir conditions

Simulating the behavior of the live crude oil in the laboratory gives you all the information you need to decide which agents to use for extraction. With a digital density measurement, you can replace your current estimates about the reliability of a reservoir’s productivity with hard facts.

Choose this digital density meter for density measurement in the lab at temperatures between -10 °C and 200 °C and elevated pressures up to 500 bar, compliant with ASTM D5002.

Choose this density measuring cell for density measurement between -10 °C and 200 °C and at even higher pressures up to 1400 bar.

Relevant products:

Determining the bubble point to increase the extraction potential of the well

In crude oil production knowledge of the bubble point helps you increase the overall extraction potential of the well. With a digital density meter you can determine the bubble point in the lab more quickly and more reliably compared to manual methods.

Choose this digital density meter for determining the bubble point in the lab at temperatures between -10 °C and 200 °C and elevated pressures up to 500 bar, compliant with ASTM D5002.

Choose this density measuring cell for determining the bubble point between -10 °C and 200 °C and at even higher pressures up to 1400 bar.

Relevant products:

Ideal drilling fluid management to reduce cost of recovery

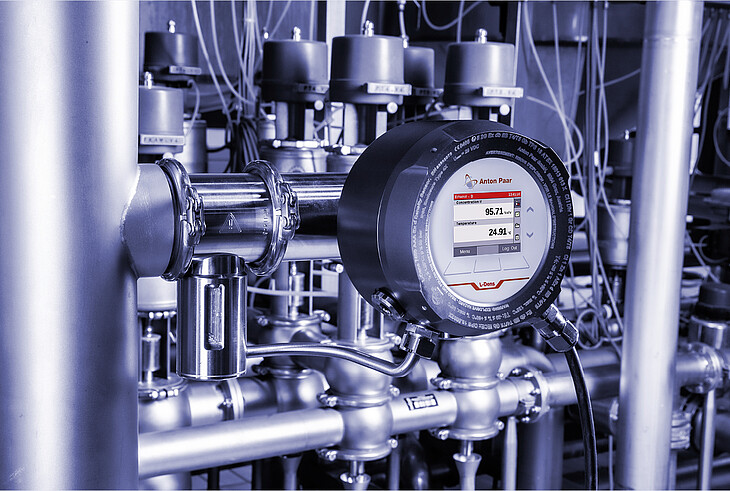

Optimizing the performance of the drilling process by fine-tuning the properties of the drilling fluid increases the yield of crude oil reservoirs. This is achieved by measuring the density of the drilling mud with inline instrumentation which has the benefits of:

- Not requiring personnel to be on-site for sample drawing

- Real-time availability of crucial data

- Helping to avoid fracture of the formation, thereby helping to increase the yield

Relevant products:

Checking the purity of crude oil after delivery

Determine automatically the °API for crude oil classification and check the crude oil purity within 30 seconds with just one measurement.

Following recovery, after the crude oil is treated to remove sediment, water, and other contaminants, you can assess the degree of purity by means of density measurements. Depending on national regulations and company preferences, you can perform measurements across the whole temperature range from 0 °C to 100 °C to draw a complete picture of the temperature-dependent behavior of the crude oil at hand.

Relevant products:

Determine the rheological properties of crude oil under different environmental conditions

Rheological properties, especially viscosity, depend on environmental conditions like temperature and pressure (in the pipe/in the well) as well as the gas environment. The MCR in combination with a pressure cell (up to 1,000 bar) enables rheological characterization by controlling those factors.

Relevant products:

Rheological characterization of drilling fluids/drilling mud under high pressure and high temperatures

When drilling offshore, high pressure levels and low temperatures occur in the well. This combination makes it extremely difficult to design a suitable drilling fluid that provides the desired properties at field conditions. High-pressure rheology (MCR & pressure cell) enables the simulation of drilling conditions for improved drilling fluid design.

Relevant products:

Perform rheological characterization and viscosity measurement of fracturing fluids

The high-pressure cells for Anton Paar rheometers offer fast and easy characterization of samples with different temperature and pressure combinations, enabling a comprehensive investigation of rheological properties for quality control and development of new fracture fluid recipes.

Relevant products:

Simulate hydrate formation

Hydrate formation occurs at low temperatures and high pressures. Simulate hydrate formation using the MCR equipped with a pressure cell and characterize the rheological properties of the formed hydrates.

Relevant products:

Crude oil testing at refineries

Checking the purity of crude oil after delivery

Determine automatically the °API for crude oil classification and check the crude oil purity within 30 seconds with just one measurement.

Following recovery, after the crude oil is treated to remove sediment, water, and other contaminants, you can assess the degree of purity by means of density measurements. Depending on national regulations and company preferences, you can perform measurements across the whole temperature range from 0 °C to 100 °C to draw a complete picture of the temperature-dependent behavior of the crude oil at hand.

Relevant products:

Efficient draining of storage tanks

The Anton Paar L-Sonic 5100 Ex is a sound velocity meter that can quickly and accurately detect the boundary zone between salt water/crude oil or water/petroleum. This information can be used to automate the tank drainage process, ensuring that all salt water and rain water are removed before the crude oil and petroleum products are processed.

The L-Sonic 5100 Ex offers a number of benefits, including:

- Reduced costs: The L-Sonic 5100 Ex can help reduce the costs associated with tank drainage by automating the process and eliminating the need for manual labor.

- Increased efficiency: The L-Sonic 5100 Ex can help improve the efficiency of the tank drainage process by reducing the time it takes to complete the task.

- Reduced environmental impact: The L-Sonic 5100 Ex can help reduce the environmental impact of tank drainage by preventing crude oil and petroleum products from entering the waste water system.

- Improved compliance: The L-Sonic 5100 Ex can help refineries and tank farms comply with environmental regulations by ensuring that all salt water and rain water is removed from crude oil and petroleum products before they are processed.

The L-Sonic 5100 Ex is a valuable tool for refineries and tank farms that need to separate salt water and rain water from crude oil and petroleum products. It can help to reduce costs, increase efficiency, reduce environmental impact, and improve compliance.

Relevant products:

Conducting crude oil analysis to evaluate composition and classify it according to API

Determine automatically the °API for crude oil classification and checking the crude oil purity within 30 seconds with just one measurement.

Following recovery, after the crude oil is treated to remove sediment, water, and other contaminants, you can assess the degree of purity by means of density measurements. Depending on national regulations and company preferences, you can perform measurements across the whole temperature range from 0 °C to 100 °C to draw a complete picture of the temperature-dependent behavior of the crude oil at hand.

Relevant products:

Digitization and harmonization of laboratory instrument data

AP Connect is your digital hub for automated data transfer from your instruments to a central database.

With AP Connect, you can:

- Easily transfer data from your instruments to a central database, regardless of the manufacturer.

- Export measurement results to a specified location or access them directly with a standardized API.

- Drive digitalization forward and meet your requirements for streamlined data handling.

- Use AP Connect in many different applications and industries.

- Meet current regulations and requirements in the regulated environment with the Pharma Edition.

The benefits of using AP Connect:

- Increased efficiency: AP Connect automates the data transfer process, freeing up your time so you can focus on other tasks.

- Improved accuracy: AP Connect ensures that data is transferred accurately and securely, reducing the risk of errors.

- Enhanced compliance: AP Connect helps you meet regulatory requirements for data management.

- Improved decision-making: AP Connect provides you with easy access to data, so you can make informed decisions about your experiments.

If you are looking for a digital hub to help you automate data transfer, improve efficiency, and meet regulatory requirements, then AP Connect is the solution for you.

Relevant products:

Crude oil analysis for transportation and distribution

Evaluating the flow behavior to obtain good pumpability for transport

When diluting heavy and extra-heavy crude oil so it can be pumped through the pipeline without difficulty, viscosity measurements or rheological tests are perfectly suited to assess flow behavior and fine-tune the viscosity of the blend. Anton Paar offers a wide range of rheometers and viscometers for easy, fast, and accurate analysis of flow behavior. Choose from:

- A benchtop solution for full evaluation of the flow behavior (optionally equipped for high-pressure measurements)

- A compact solution for measuring the kinematic viscosity in a few minutes

- An Ex-certified inline viscometer for continuous monitoring of the viscosity in the process line

Phase detection in pipelines

The loss of valuable raw materials and the contamination of the process water can be minimized by a precise product differentiation in pipelines or tanks. React immediately to avoid spills and contamination of the refinery’s waste water system with crude oil, diesel, or any other petroleum product. The L-Sonic 5100 and L-Dens 7400 are designed to be installed on any pipeline or tank and can detect different (or unwanted) phases within seconds. Use the measurement to control safety valves or ring alarms. Shut in automatically any oilfield or refinery process within seconds to avoid contamination and damage.

Relevant products: