Multiparameter Measurement System:

Edible Oil Measurement Systems

- Fast characterization via specific gravity and refractive index

- Minimal sample volume required – less than 10 mL

- Automatic bubble detection with FillingCheck™ for proper filling

- Seamless data handling via AP Connect

The Edible Oil Measurement Systems offer an optimal solution for assessing and defining the qualities of edible oils. With density/specific gravity, refractive index, and – when configured with SVM – viscosity as measuring parameters, the system ensures swift, precise, and reproducible measurements. Operating costs are minimized thanks to minimal sample and solvent usage, along with low energy consumption. Control is also streamlined with a user-friendly touchscreen interface that eliminates the need for an external PC for sample management or data storage.

Included products

Key features

Measure all essential parameters in a single measurement cycle

Combining the capabilities of a density meter, refractometer, and viscometer, the Edible Oil Measurement Systems provide a comprehensive assessment of an oil’s quality and properties. This includes mass per unit volume to aid in purity determination, the oil's composition and authenticity, and its consistency, which is essential for both culinary and industrial applications. Together, the combination of these modules ensures rigorous quality control and regulatory compliance in edible oil production.

High sample throughput with fast sample filling and cleaning

Measure multiple samples effortlessly using semi- or fully automatic sample changers, and streamline your workflow with fully automatic sample processing – featuring automatic sample identification via barcode reader integration. Cleaning and maintenance have never been easier: Automatic cleaning and drying of measuring cells guarantees dependable analysis by preventing carry-over and contamination. An automatic post-analysis air check ensures efficiency and maintains optimal performance.

Usability and compliance made easy

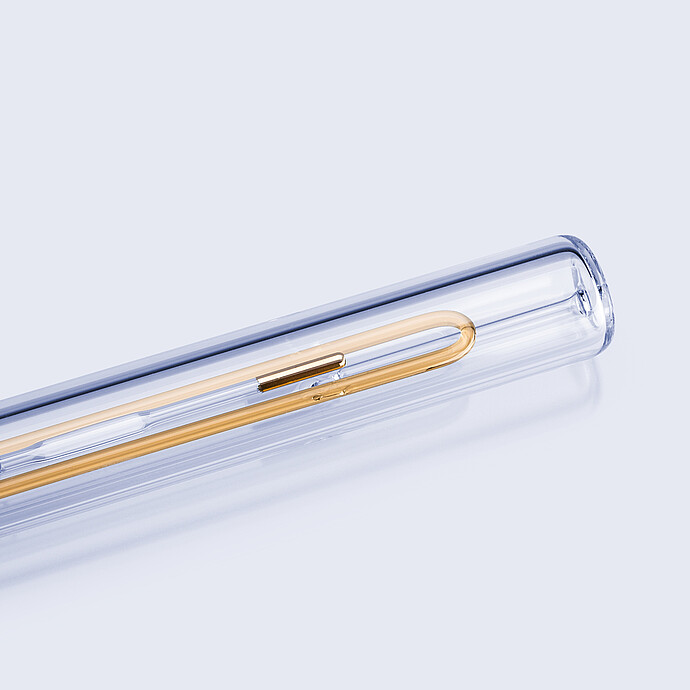

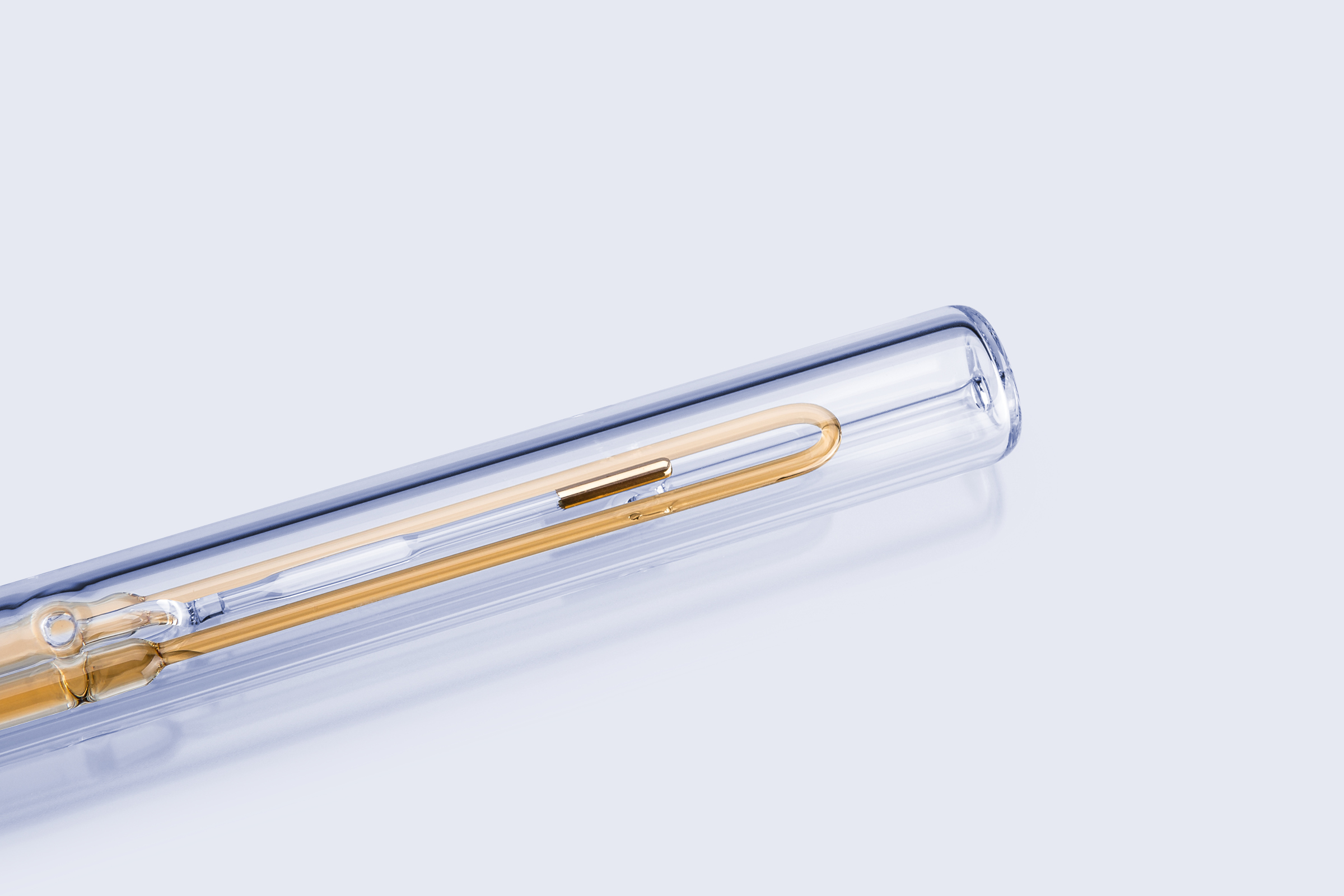

Designed according to a customer-centric and intuitive user concept, Anton Paar instruments require minimal specialized training, maximizing usability and efficiency. The DMA density meters employ the oscillating U-tube principle, approved by various national food legislation offices, and features such as FillingCheck™ (SVM and DMA) and U-View™ (DMA) ensure complete traceability of the sample filling and measurement process.

Tailored custom quantities for specialized products

Tailoring specific gravity, refractive index, and viscosity measurement requirements for unique blends is made simple with easy quantity customization for specialized products. Automatic limit checks and efficient data storage ensure consistent quality, while measurement data transfer via AP Connect supports streamlined, traceable processes.

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty