Plaques de contrôle en quartz avec détection automatique

- La technologie Toolmaster™ permet d'économiser du temps grâce au transfert automatique de données.

- Élimine la saisie manuelle des données, améliorant la sécurité et la précision des données

- Soyez conforme aux normes internationales

- La mesure de température sans fil garantit des résultats traçables et fiables

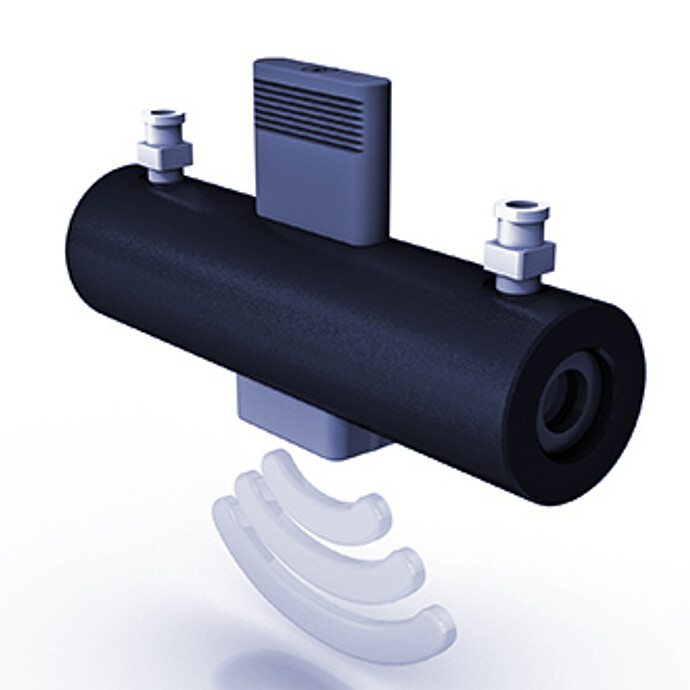

Des plaques de contrôle en quartz sont utilisées pour contrôler et ajuster l'échelle du polarimètre. Les plaques de contrôle en quartz sont fournies dans un mallette avec le certificat du fabricant et le tableau de correction de la température. Tous les quartz de contrôle satisfont aux normes internationales (ICUMSA et OIML). La précision de la rotation optique (OR) est de ± 0,002 °OR.

Toutes les plaques de quartz sont équipées de la technologie Toolmaster™ : L'instrument reconnait automatiquement le quartz de contrôle et toutes les données d'ajustement sont transférées automatiquement.

Caractéristiques principales

Gain de temps et amélioration de la sécurité des données

- Manipulation rapide

- Sécurité des données améliorée grâce à l'élimination de la saisie manuelle des données

- Résultats traçables, transférés automatiquement au polarimètre

- Mesure de la température sans fil, aucune mesure externe de la température nécessaire

Service certifié Anton Paar

- Plus de 350 experts techniques certifiés par les fabricants dans le monde

- Assistance qualifiée dans votre langue locale

- Protection de votre investissement tout au long de son cycle de vie

- 3 ans de garantie