|

Instrument |

Samples |

Measurement |

|

Benchtop density

meter:

DMA

Anton Paar’s Next-Level Density Meter. 4-digit density measurements

in 20 seconds (DMA 4101). Measuring modules for various applications

(DMA 4501). 0.000005 g/cm3 accuracy (DMA 5001).

Automation options with

Xsample sample changers are available.

Show product details

|

- H2SO4

- H3PO4

- HCl

- HNO3

- NaOH

- NH3 /

NH4OH

|

Density |

H2SO4 : Determination of

dilution to a defined concentration

Product labeling:

Final product quality check

Final

H2SO4 product: Efficient

quality control

Concentration

determination of acids or bases as incoming goods in the

production of cleaning agents

Concentration check of

binary and quasi-binary solutions

Weight-to-volume

conversion for sale of products by volume and for

filling volume control according to national taxation

law

Etching in the metal

industry: Incoming goods check to calculate the

right amount of every chemical

Fertilizer

industry: Quality check of incoming goods (e.g.,

monoammonium phosphate (MAP)and diammonium phosphate (DAP))

Product labeling:

Final product quality check

Production of

detergents and cleaning agents: Assurance of maximum

activity via addition of precise amount of phosphoricacid

PVC manufacturing:

Concentration determination of HCl before reaction with

acetylene (attemperatures from 140 °C to 200 °C)

Chlorides

manufacturing: HCI concentration check for incoming

goods

HCl dilution:

Determination to a defined concentration

Production of

hydrochloric acid: Concentration check after

dissolving HCl in water

Final HCl product:

Efficient quality control

Product labeling:

Final product quality check

Fertilizer

industry: Quality check of incoming goods (e.g.,

ammonium nitrate, often in combinationwith urea)

Nylon

manufacturing: Concentration check of incoming goods

(HNO3 is an important reagentin the formation of

adipic acid, which is used to manufature nylon)

Etching in the metal

industry: Incoming goods check in order to remove

contaminants and oxides frommetal surfaces

Product labeling:

Final product quality check

Final NaOH product:

Efficient quality control

Sodium hydroxide:

Concentration check before shipping

Product labeling:

Final product quality check

NaOH dilution:

Determination to a defined concentration

Binary and quasi-binary

solutions: Concentration check

Production of chemicals

such as solvents, plastics, fabrics, adhesives,

herbicides, dyes, inks, pharmaceuticals:

Concentration determination

Fertilizer

industry: Concentration check (based on

stoichiometric reactions) of substanceswhere NH3

as a fundamental compound is involved

Product

labeling: Final product quality check

|

|

Benchtop density

meter:

DMA 5001

Unmatched 6-digit accuracy, even with highly viscous and highly dense

samples. A density meter for the best performance in demanding,

high-end applications. Automation options with

Xsample sample changers are available.

Show product details

|

|

Density |

Quality check based on

concentration and purity of electronic-grade

H3PO4 for etching in the

semiconductor industry

Qualiy check based on

concentration and purity in the manufacturing of solar

panels as dopant

|

|

Compact digital density

meter:

DMA

Rugged compact digital density meter for quick density and

concentration checks near the production line, in storage

facilities, and in the lab.

Show product details

|

- HCl

- H2SO4

- H3PO4

- HNO3

- NaOH

- NH3 /

NH4OH

|

Density |

H2SO4 : Determination of

dilution to a defined concentration

Etching in the metal

industry: Incoming goods check to calculate the

right amount of every chemical

Etching in the metal

industry: Incoming goods check to calculate the

right amount of every chemical

PVC manufacturing:

Concentration determination of HCl before reaction with

acetylene (attemperatures from 140 °C to 200 °C)

Chlorides

manufacturing: HCI concentration check for incoming

goods

HCl dilution:

Determination to a defined concentration

Production of

hydrochloric acid: Concentration check after

dissolving HCl in water

Product labeling:

Final product quality check

Concentration

determination of acids or bases as incoming goods in the

production of cleaning agents

Concentration check of

binary and quasi-binary solutions

Weight-to-volume

conversion for sale of products by volume and for

filling volume control according to national taxation

law

Etching in the metal

industry: Incoming goods check to calculate the

right amount of every chemical

Fertilizer

industry: Quality check of incoming goods (e.g.,

monoammonium phosphate (MAP)and diammonium phosphate (DAP))

Product labeling:

Final product quality check

Production of

detergents and cleaning agents: Assurance of maximum

activity via addition of precise amount of phosphoricacid

Fertilizer

industry: Quality check of incoming goods (e.g.,

ammonium nitrate, often in combinationwith urea)

Nylon

manufacturing: Concentration check of incoming goods

(HNO3 is an important reagentin the formation of

adipic acid, which is used to manufature nylon)

Etching in the metal

industry: Incoming goods check in order to remove

contaminants and oxides frommetal surfaces

Product labeling:

Final product quality check

Final NaOH product:

Efficient quality control

Sodium hydroxide:

Concentration check before shipping

Acids and bases as

incoming goods in the production of cleaning agents:

Concentration determination

Binary and quasi-binary

solutions: Concentration check

Production of chemicals

such as solvents, plastics, fabrics, adhesives,

herbicides, dyes, inks, pharmaceuticals:

Concentration determination

Fertilizer

industry: Concentration check (based on

stoichiometric reactions) of substanceswhere NH3

as a fundamental compound is involved

Product

labeling: Final product quality check

|

|

DMA 4200 M is the ideal density meter for measurements of heavy

petroleum samples at high temperatures and pressures. It saves you

time, money, and solvent, and improves your quality control.

Show product details

|

|

Density |

Etching in the metal

industry: Incoming goods check to calculate the

right amount of every chemical

Semiconductor

industry: Concentration check and purity assessment

because HF is used as a strongetchant for SiO2

Product labeling:

Final product quality check

|

|

Use the portable digital density and contentration meter DMA 35 to

measure your sample directly on-site, and benefit from easy

operation.

Show product details

|

- H2SO4

- H3PO4

- HCl

- NaOH

- HNO3

- NH3 /

NH4OH

|

Density |

Sulfuric acid

concentration, lead-acid battery production:

Measurement to calculate the state of lead acid battery

charge, QCof lead acid battery during production, and before

shipment of the batteries

Unloading: Product

identification

Lead-acid battery

manufacturing: Initial dilution of incoming sulfuric

acid to different storage concentration

Lead-acid battery

manufacturing: Filling of correct acid concentration

according to type and size

H2SO4 : Determination of

dilution to a defined concentration

Etching in the metal

industry: Incoming goods check to calculate the

right amount of every chemical

Fertilizer

manufacturing: Quality control and minimal use of

raw materials plus product indentificationduring unloading

Unloading: Product

identification

Concentration

determination of acids or bases as incoming goods in the

production of cleaning agents

Concentration check of

binary and quasi-binary solutions

Weight-to-volume

conversion for sale of products by volume and for

filling volume control according to national taxation

law

Etching in the metal

industry: Incoming goods check to calculate the

right amount of every chemical

Fertilizer

industry: Quality check of incoming goods (e.g.,

monoammonium phosphate (MAP)and diammonium phosphate (DAP))

Unloading: Product

identification

Etching in the metal

industry: Incoming goods check to calculate the

right amount of every chemical

PVC manufacturing:

Concentration determination of HCl before reaction with

acetylene (attemperatures from 140 °C to 200 °C)

Chlorides

manufacturing: HCI concentration check for incoming

goods

HCl dilution:

Determination to a defined concentration

Production of

hydrochloric acid: Concentration check after

dissolving HCl in water

Fertilizer

industry: Quality check of incoming goods (e.g.,

ammonium nitrate, often in combinationwith urea)

Nylon

manufacturing: Concentration check of incoming goods

(HNO3 is an important reagentin the formation of

adipic acid, which is used to manufature nylon)

Etching in the metal

industry: Incoming goods check in order to remove

contaminants and oxides frommetal surfaces

Product labeling:

Final product quality check

NaOH as an incoming

good for a variety of chemicals and products, including

those for water treatment, aluminum production, and the

pulp and paper industry: Concentration determination

Unloading: Product

identification

Final NaOH product:

Efficient quality control

Sodium hydroxide:

Concentration check before shipping

Cleaning in the food

and beverage industry (water treatment, food processing,

cleaners for beverage bottles): Concentration

determination of sodium hydroxide

Acids and bases as

incoming goods in the production of cleaning agents:

Concentration determination

NH3 / (NH4OH

applications

Fertilizer

industry: Concentration check (based on

stoichiometric reactions) of substanceswhere NH3

as a fundamental compound is involved

Product

labeling: Final product quality check

|

|

4-digit-accuracy inline density meter, designed for hazardous

environments; comprehensive concentration formula database; easy

integration with minimal engineering efforts and costs; multiple

materials available (also in Ex versions).

Show product details

|

- Acetic acid

- Citric acid

- H2SO4

- H3BO3

- H3PO4

- HCl

- HNO3

- NaOH

- Oleum

|

Density |

Plastics

industry: Minimal use of raw materials

Food

industry: Optimal taste and conservation

Pharmaceutical

industry: Measurement of

C4H6O3 (acetoacetic acid)

in C2H4O2 acetic acid

anhydride

Food

industry: Optimal taste and conservation

Cleaning agent

manufacturing: Optimal softening and lime

dissolution

Detergent

manufacturing: Optimal softening

Lead-acid battery

manufacturing: Optimal alpha-to-beta PbO2

ratio during the formation process

Concentration at inlet

& outlet of drying tower: Measurement to

optimize SO2 drying process and prevent equipment

corrosion

H2SO4 : Determination of

dilution to a defined concentration

Lead-acid battery

manufacturing: Initial dilution of incoming sulfuric

acid to different storage concentration

Fertilizer

manufacturing: Quality control and minimal use of

raw materials, plus product indentification

Final

H2SO4 product: Efficient

quality control

Unloading: Product

identification

Metal industry:

Optimization of the pickling process

Nuclear power

plant: Creation of optimal neutron velocity

Fertilizer

manufacturing: Quality control and minimal use of

raw materials plus product indentificationduring unloading

H3PO4 dilution: Determination

to a defined concentration

Unloading: Product

identification

Metal industry:

Optimization of pickling process

Manufacturing

process: Running of HCl absorber in optimal

concentration range

Final HCl product:

Efficient quality control

HCl dilutions:

Determination to a defined concentration

Gas scrubber: Safe

cleaning of exhaust gases

Unloading: Product

identification

Metal industry:

Optimization of the pickling process

Fertilizer

manufacturing: Quality control and minimal use of

raw materials plus product indentificationduring unloading

HNO3

dilution: Determination to a defined concentration

Food and beverage

industry: Safe disinfection and cleaning with

minimal HNO3 consumption

Unloading: Product

identification

Final NaOH product:

Efficient quality control

NaOH dilution:

Determination to a defined concentration

Viscose industry:

Provision of optimal NaOH recyling process

Food and beverage

industry: Safe disinfection and cleaning with

minimal NaOH consumption

Diaphragm cell creation

of caustic soda: Incoming brine concentration

measurement, guarantee of less energyconsumption in the

subsequent evaporation step

Unloading: Product

identification

Oleum absorbers:

Control of H2SO4 concentration at the

inlet and of oleum concentrationat the outlet – for both

absorbers

Final oleum

product: Efficient quality control

Unloading: Product

identification

|

|

Outstanding accuracy of up to 5 x 10-5 g/cm³;

comprehensive concentration formula database; easy integration with

minimal engineering efforts and costs; available in Alloy C-276

(also in Ex version).

Show product details

|

|

Density |

CMP slurry:

Determination of stable density within specification limits

|

|

Continuous monitoring, 3-digit density-and-concentration accuracy,

even at low flow rates (≤80 L/h), with Anton Paar’s compact inline

density meter.

Show product details

|

|

Density |

CMP slurry:

Determination of stable density within specification limits

Lead-acid battery

manufacturing: Filling of correct acid concentration

according to type and size

Lead-acid battery

manufacturing: Optimal alpha-to-beta PbO2

ratio during the formation process

|

|

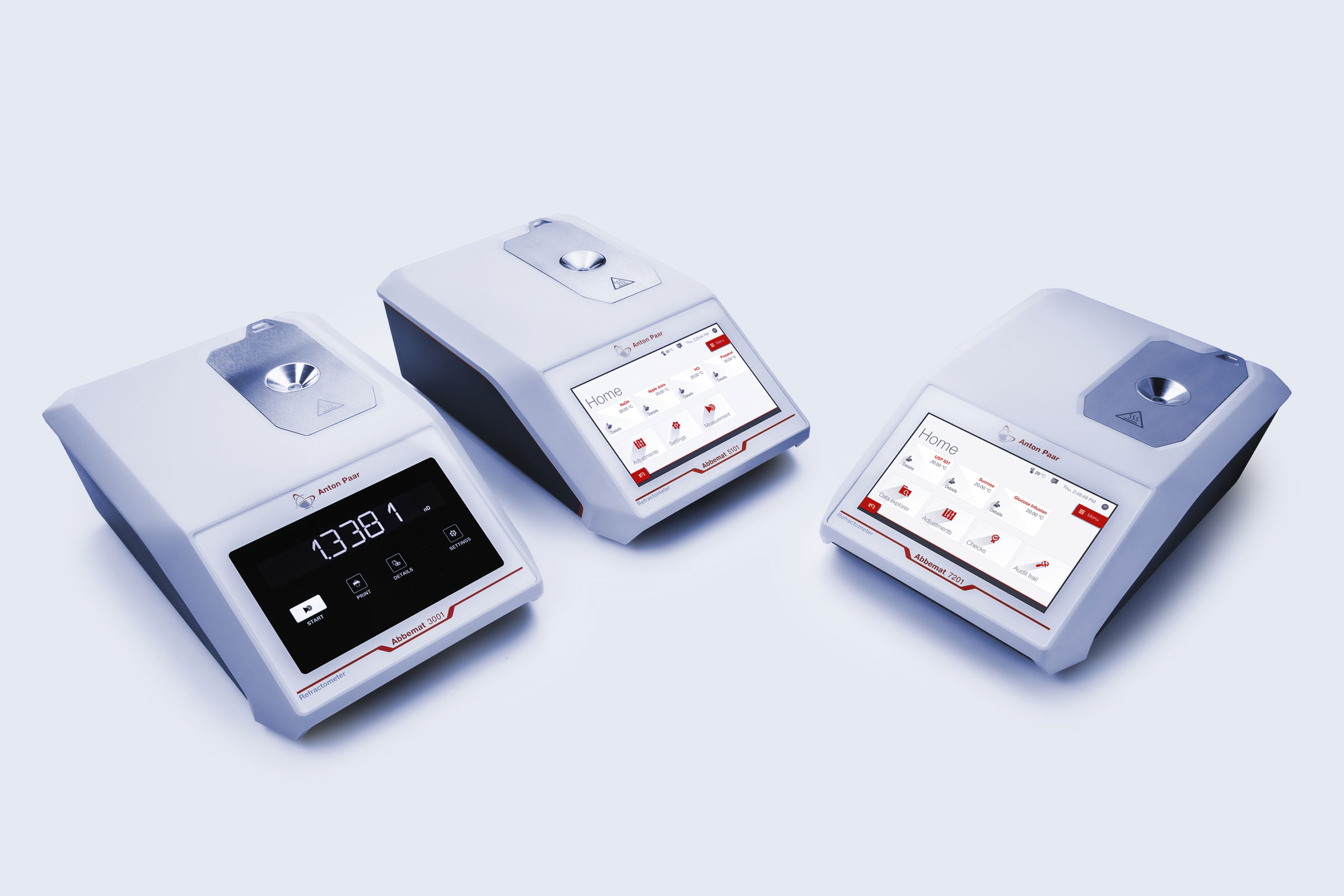

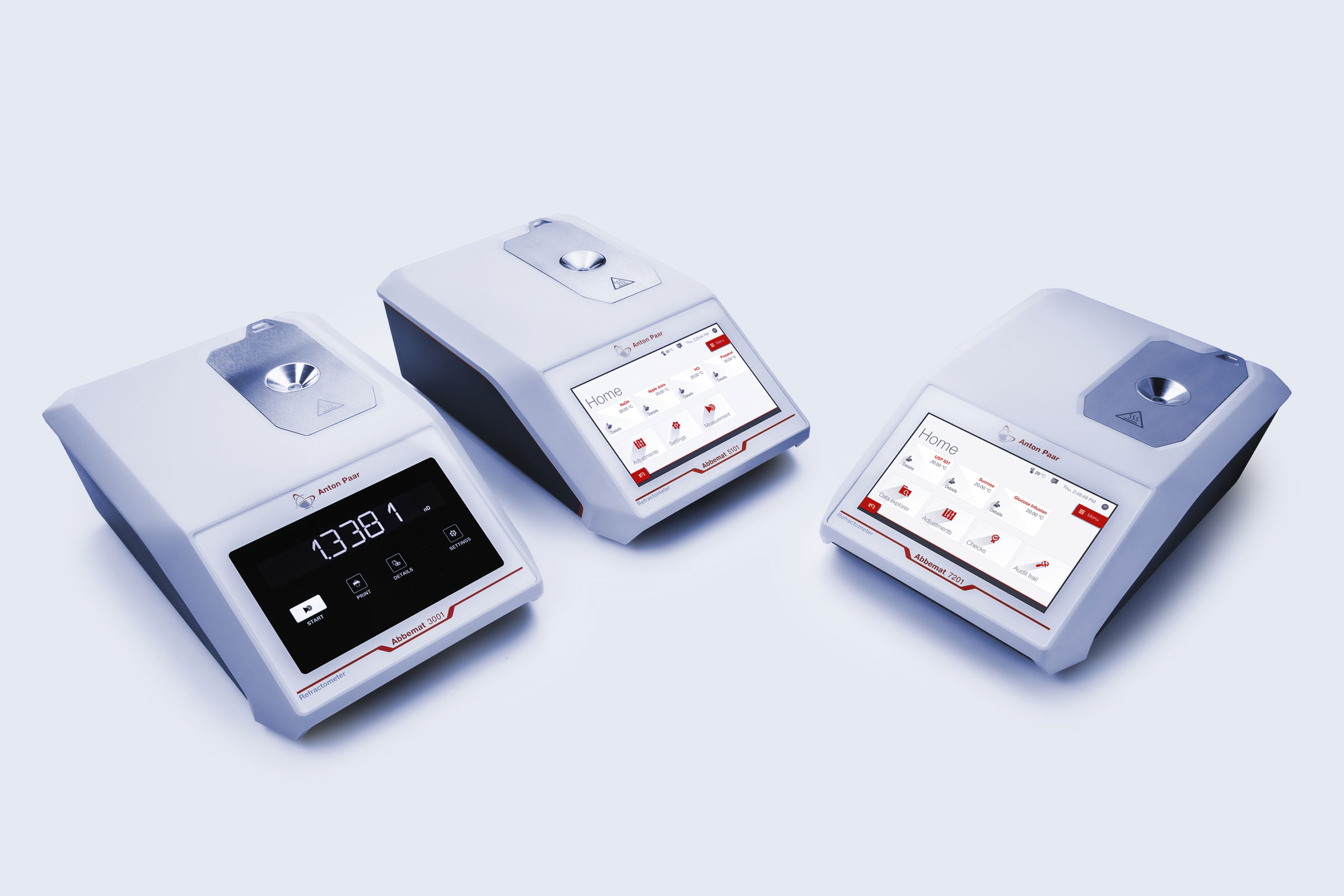

Powerful refractometer series for quick, straightforward qualitative and quantitative analysis of substances.

Show product details

|

- Acetic acid

- Citric acid

- Formic acid

- H2SO4

- H3PO4

- HCl

- HNO3

- NaOH

- NH3 /

NH4OH

|

Refractive index |

Methanol

carbonylation: Concentration check of final acetic

acid

Production of

vinyl acetate or PET: Assurance that acetic acid

meets required specifications

Food

industry: Concentration check of acetic acid (E260)

as a preservative beforeaddition to product

Food and

beverage production: Quality check via addition of

right concentration of citric acid foracidifying and

flavoring

Detergents,

soaps, pharmaceuticals, cosmetics: Maintainenance of

optimum pH via addition of the right amount of citricacid

Pharmaceutical

and cosmetics industry: Quality and concentration

check of citric acid before use as pH buffer

Conversion of sulfur

trioxide to sulfuric acid: Concentration

determination of sulfuric acid in production

Fertilizer

production: Chemical extraction of phosphate via

utilization of the right concentration of sulfuric acid

Pickling solution:

Optimization, for removal of surface impurities from metals

Production of fibers,

hydrofluoric acid, paints, and pigments: Knowledge

about the exact concentration of sulfuric acid required

Paper bleaching

process: Generation of the right amount of chlorine

dioxide by adding the correctamount of sulfuric acid

Production of

fertilizers: Assurance of right sulfuric acid

concentration to obtain the best possibleyield of phosphoric

acid during wet process

Preservation of

beverages and food (E338): Guarantee of soft drink

taste and quality via addition of the rightamount of

phosphoric acid

Production of

detergents and cleaning agents:: Assurance of

maximum activity via addition of precise amount of

phosphoricacid

Conversion of rust or

protection of metal against corrosion:: Optimal

concentration determination of phosphoric acid

Production and shipping

of nitric acid: Determination of correct dilution

Production process of

fertilizers and explosives: Purity and concentration

assessment

Production of adipic

acid (raw material for nylon): Concentration

determination

Production of

hydrochloric acid: Concentration check after

dissolving HCl in water

Transesterification

process of edible or non-edible oils: Concentration

determination for hydrochloric acid before use

Production of

dichloropropanol: Concentration measurement of

hydrochloric acid to assure the right molar ratio with

glycerol

Production of

phenylenediamine: Concentration determination of

hydrochloric acid when adding to the process

Production of

bisphenol: Concentration determination of

hydrochloric acid when adding to the process

Alkaline products or

waste water: Concentration determination of

hydrochloric acid to optimize neutralization process

Oil well acidizing:

Concentration determination of hydrochloric acid to improve

well productivity

Production of

high-fructose corn syrup: Concentration

determination for the inversion process

Quality assurance for

sauces, juices, and canned goods (pH

adjustment/acidification): Concentration

determination of hydrochloric acid

Production of

hydrochlorides and other drugs: Traceable

concentration measurement of hydrochloric acid

Sodium hydroxide:

Concentration check before shipping

Pulp and paper:

Optimum bleaching results via addition of a sodium hydroxide

solution of the necessary concentration

Production of chemicals

such as solvents, plastics, fabrics, adhesives,

herbicides, dyes, inks, pharmaceuticals:

Concentration determination

Saponification and

manufacturing of anionic surfactants for soap and

detergent: Guarantee of quality via use of exact

amount of sodium hydroxide required

Cleaning in the food

and beverage industry (water treatment, food processing,

cleaners for beverage bottles): Concentration

determination of sodium hydroxide

Household

cleaner: Addition of exact amount of ammonia for

optimum cleaning results

Food production

(E527): Quantity check of additive as an acidity

regulator or disintegrating agent

Fertilizer

production: Check for correct nitrogen amount

Ammonium

salts: Concentration determination of ammonia and

acid to guarantee smooth production

Personal care

products: Quality control when an exact amount of

ammonia needs to be added

Pharmaceutical

drug production: Purity and concentration check

|

|

Digital heavy duty

refractometer:

Abbemat 650

Refractive index measurements with robust refractometers. For high

temperatures, multiple wavelengths, and samples with high or low

refractive index.

Show product details

|

|

Refractive index |

Hydrofluoric acid

production: Concentration determination and

assurance of right dilutions to minimize the risk for

exposure of staff

|

|

Inline refractometer L-Rix 5100/5200 fulfills NAMUR NE 107, is

designed according to EHEDG, and is ready for measuring

concentration.

Show product details

|

|

Refractive index |

Food and beverage

industry: Safe disinfection and cleaning with

minimal HNO3 consumption

Food and beverage

industry: Safe disinfection and cleaning with

minimal NaOH consumption

|

|

Density and sound velocity

meter:

DSA 5000 M

DSA 5000 M is the only instrument that combines density and sound

velocity measurements in one setup with the most accurate density

results. Automation options with

Xsample sample changers are available.

Show product details

|

|

Density, sound velocity |

Final

H2SO4 product: Efficient

quality control

Etching (0 %-100 %) in

the semiconductor industry: Purity and concentration

check to avoid the reduction of water efficiency

|

|

Inline concentration measurement, interface detection, product

identification, and OCR measurements; usable in hazardous

environments.

Show product details

|

- Acetic acid

- HNO3

- NaOH

- H2SO4

- HCl

- H3PO4

- Oleum

|

Sound velocity |

Plastics

industry: Minimal use of raw materials

Final

H2SO4 product: Efficient

quality control

Unloading: Product

identification

Absorption

process: Efficiency maximization

Semiconductor

industry: Purity and concentration check for etching

Unloading: Product

identification

Unloading: Product

identification

Electrolysis cell:

Optimal brine concentration

Unloading: Product

identification

Diaphragm cell creation

of caustic soda: Incoming brine concentration

measurement, guarantee of less energyconsumption in the

subsequent evaporation step

Unloading: Product

identification

Optimal brine

concentration of electrolysis cell

Unloading: Product

identification

|

|

L-Com 5500 represents Anton Paar’s new density and sound velocity

sensor combination in one instrument for the measurement of

3-component mixtures.

Show product details

|

|

Density, sound velocity |

Plastics

industry: Minimal use of raw materials

Viscose industry:

Guarantee of constantly high fiber quality and minimal use

of NaOH

|