When strength, safety, and reliability define success, precision material analysis becomes non-negotiable. From protective armor to advanced fuels, our technologies empower innovation by delivering data-driven confidence for industries that operate under extreme conditions.

+100

Years of Innovation

110

Countries Served

+1,000

Applications

Critical applications in aerospace, space, and defense

Anton Paar provides high-reliability solutions for complex applications in the aerospace, space, and defense sectors – ranging from advanced material qualification to regulated substance analysis and propulsion system validation.

- Advanced material testing

Evaluate the fatigue, fracture, and thermal behavior of lightweight alloys and composites. Ensure long-term performance in structures exposed to mechanical stress, pressure cycles, and high temperatures. - Energetic materials analysis

Analyze particle size, porosity, and thermal stability in high-energy materials. Optimize formulation performance and ensure repeatability for safety and consistency in manufacturing environments. - Fuels and lubricants qualification

Characterize aviation fuels, hydraulic fluids, and gear lubricants for flow, volatility, and thermal behavior – meeting specifications for use in extreme operational environments. - Substance identification

Raman and FTIR spectroscopy allow rapid identification of unknown or hazardous substances in secure industrial or research settings and in the field.

Applications

Armory and protective materials

Composites and fibers

Lightweight, tough, and essential for modern armor systems, carbon fiber, aramids, UHMWPE, and fiberglass composites are evaluated for structural integrity and thermal resistance. By linking nanoscale structure to ballistic performance, we enable faster innovation cycles in protective gear and vehicles.

Metals and alloys

High-performance steels, copper alloys, and advanced alloys are tested for dynamic mechanical behavior, tribology, and temperature stability. This ensures materials perform reliably under extreme pressure, impact, and heat conditions.

Polymers and coatings

Polymers such as PMMA, PTFE, and HDPE – as well as advanced coatings like DLC – are analyzed for hardness, wear resistance, and durability under variable temperature environments. This knowledge feeds directly into creating coatings that resist abrasion, reduce friction, and extend service life.

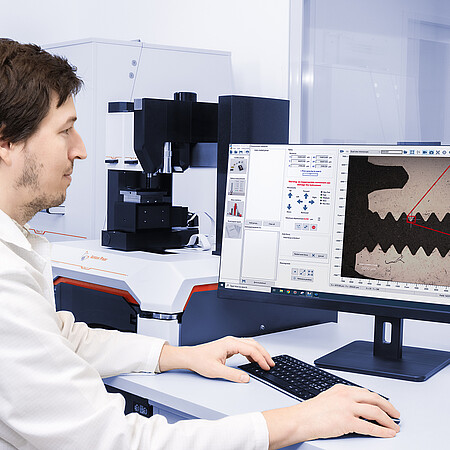

In protective systems engineering, material failure is often not visible until it's too late. Whether you're developing lightweight composite armor or structural metal reinforcements, the key to performance is understanding mechanical behavior under load, over time, and across temperature ranges.

Anton Paar’s high-reliability solutions support the measurement of viscoelastic properties, microstructural stiffness, surface hardness, and wear resistance. Instruments such as thermal analyzers, rheometers, nanoindenters, and tribometers help engineers determine how materials respond to cyclic stress, shear forces, and thermal fluctuations. These values are essential inputs for simulation, failure analysis, and final product validation.

For coatings and polymers used in ballistic and structural components, understanding adhesion, abrasion resistance, and thermal degradation is crucial. Our testing platforms provide actionable data that supports material selection, quality control, and supplier qualification in line with ISO, ASTM, and defense-specific standards.

Featured Products

Anton Paar solutions for armory and protective materials

MCR

MCR 703

SAXSpoint 500

SAXSpoint 700

MCR 703 MultiDrive

Multiwave

Multiwave

Hit 300

UNHT³

NHT³

MCT³

RST

Lyza

Cora 5001 Direct

Cora 5001 Fiber

Julia DSC

Energy systems

Hydrogen storage

Materials such as metal hydrides, MOFs, and carbons are assessed for porosity, uptake, and desorption kinetics. This enables efficient, compact, and safe hydrogen storage systems, a critical step in advancing both airborne and naval applications.

Fuel cells

Catalysts and membranes undergo surface area, density, and structural evaluation to improve efficiency and longevity. Our solutions help ensure stable power delivery in demanding environments, where energy security is a strategic advantage.

Battery materials

Gas pycnometry and surface characterization techniques validate volumetric storage, density, and material stability. These insights make it possible to optimize both traditional and emerging chemistries, accelerating deployment in UAVs and field systems.

Energy systems in aerospace and defense operate under demanding constraints: tight form factors, extreme thermal environments, and long service life without maintenance. Anton Paar’s high-reliability solutions enable engineers to validate the physical and functional performance of materials used in hydrogen storage, batteries, and fuel cells.

Gas sorption analyzers and surface area measurement instruments provide accurate insights into pore structure and adsorption behavior – essential for optimizing hydrogen storage materials like metal-organic frameworks or hydrides. These metrics are critical for balancing energy density with operational safety.

In the development of fuel cells and battery systems, thermal analyzers, particle sizing instruments, and density measurement tools help quantify degradation patterns, conductivity variations, and material stability. These capabilities support both fundamental research and industrial-scale quality control, enabling developers to meet standards for airborne, orbital, and field-deployed platforms.

High-reliability solutions in this domain ensure that energy systems meet operational specifications while minimizing failure risks over long service intervals.

Featured Products

Anton Paar solutions for energy systems

MCR

MCR 703

SAXSpoint 500

SAXSpoint 700

Nova

Autosorb

Ultrapyc

MCR 703 MultiDrive

Julia DSC

Litesizer DIF

Litesizer DIA

Explosives and chemical agents

Performance optimization

Particle size distribution, morphology, porosity, and density measurements fine-tune burn rates and flow stability for explosives like TNT, RDX, and PETN. Such data improves consistency and predictability in energetic formulations.

Safety and detection

In-process concentration monitoring ensures production remains within safe thresholds. Handheld Raman spectroscopy provides rapid, accurate identification of chemical agents and explosives – an essential tool for field operations and laboratory analysis.

Quality control

Determining true density, porosity, and thermal stability ensures energetic materials meet rigorous standards. Our technologies contribute to safer handling, transport, and storage, reducing the risks inherent in dealing with high-energy substances.

The formulation and handling of energetic materials – such as propellants and explosives – require more than safety precautions. Consistency and compliance depend on precise control of physical and chemical characteristics, verified through reliable, traceable testing.

Anton Paar’s solutions include particle characterization systems, gas adsorption analyzers, and density measurement tools that allow scientists to quantify parameters such as particle morphology, porosity, surface area, and packing density. These measurements directly affect ignition behavior, burn rate, and stability, particularly in constrained geometries or aging systems.

For compliance and quality control in regulated environments, spectroscopic methods such as Raman and infrared are used to identify substances quickly and non-destructively. These instruments are widely adopted in defense-adjacent labs, material verification workflows, and audit programs where documentation and repeatability are critical.

High-reliability solutions in this area support not just performance optimization but also risk reduction in high-energy, compliance-sensitive applications.

Featured Products

Anton Paar solutions for explosives and chemical agents

Nova

Autosorb

L-Dens

L-Sonic

L-Com 5500

DMA

Cora 5001 Direct

Cora 5001 Fiber

Litesizer DIF

Litesizer DIA

Julia DSC

Cora 100

Petroleum products and lubricants

Fuels

Jet and maritime fuels are tested for viscosity, cold-flow properties, and density. This guarantees reliable performance in extreme climates and operating conditions. Onboard fuel checks allow quick, accurate assessments in the field.

Lubricants

Hydraulic fluids, gear oils, and bearing lubricants undergo tribological and flash point testing to confirm long-term stability and safe operation under high mechanical stress.

Crude oils and refined products

Distillation, trace element analysis, and digital density checks validate the quality of crude oil and refined derivatives. This protects engines, turbines, and transmission systems from premature wear and costly downtime.

Fuels and lubricants used in aerospace and defense must perform across a wide range of operating conditions – from sub-zero climates to high-altitude heat loads, and from low-viscosity start-up to high-shear endurance. Ensuring their stability and conformity to specifications requires a deep understanding of their rheological, thermal, and chemical behavior.

Anton Paar offers high-reliability solutions that measure key parameters like viscosity, density, flash point, oxidative stability, and tribological behavior. These instruments support both R&D and routine QC workflows, whether the goal is to optimize a new jet fuel blend or validate the long-term reliability of a lubricant in a turbomachinery application.

Test results from our platforms conform to international standards (e.g., ASTM, ISO) and are used to verify compliance. With consistent, accurate data, decision-makers can qualify new suppliers, refine formulations, or troubleshoot system failures with confidence.

Ultimately, high-reliability solutions ensure that fuels and lubricants perform as intended – reducing unplanned maintenance and extending service intervals.

Featured Products

Anton Paar solutions for petroleum products and lubricants

SVM

SVM

DMA

DMA 35 Ex Petrol

Diana

PMA

TRB³

THT

Multiwave

Multiwave

Lyza

MCR

MCR 703

Julia DSC

MCR Tribometers

Certified to meet aerospace and defense standards

Anton Paar instruments are built to align with global regulatory and quality frameworks including MIL-PRF, MIL-DTL, ISO 17025, and more. All solutions support traceable workflows and validation-ready documentation for regulatory audits and certification programs.

Choose our high-reliability testing solutions for aerospace, space, and defense

Across aerospace, space, and defense programs, decisions rely on verified material properties. Anton Paar’s high-reliability solutions are built around traceable measurements, validated methods, and documented uncertainty budgets – so your teams can qualify materials, verify processes, and pass audits with confidence. Our application specialists work with R&D, QA, and procurement to align measurement strategies with MIL-PRF, MIL-DTL, ISO 17025, and comparable requirements – from feasibility through to method transfer.

We combine core disciplines – rheology and DMA, tribology, nano- and micro-mechanical testing, spectroscopy, thermal analysis, gas sorption, X-ray scattering, density, viscosity, and particle characterization – into workflows that answer engineering questions, and don’t just generate numbers.

If you need to reduce variability, shorten time-to-qualification, or standardize testing across sites, our high-reliability solutions framework provides a clear path: requirements review, method mapping to standards, sample studies with reportable KPIs, and a validation plan with calibration and documentation packages.

Talk to our specialists to scope your use case and receive a tailored measurement plan.

Connect with our specialists to discuss your specific analytical requirements and find the right solution for your needs.